Assessing the Reliability of Power Steering Fluids in High-Mileage Conditions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Evolution and Objectives

Power steering fluid has undergone significant evolution since its introduction in the 1950s. Initially, automatic transmission fluid (ATF) was commonly used for power steering systems due to its availability and similar properties. However, as automotive technology advanced, specialized power steering fluids were developed to meet the specific demands of modern steering systems.

The evolution of power steering fluid has been driven by several factors, including the need for improved performance, increased durability, and enhanced compatibility with various materials used in steering components. Early power steering fluids were primarily mineral oil-based, but synthetic formulations have become increasingly prevalent due to their superior thermal stability and oxidation resistance.

One of the key objectives in power steering fluid development has been to improve its reliability under high-mileage conditions. As vehicles are being driven for longer periods and greater distances, the fluid must maintain its performance characteristics over extended periods. This includes maintaining proper viscosity, resisting breakdown under high temperatures, and preventing the formation of sludge or deposits that can impair steering system function.

Another important goal has been to enhance the fluid's ability to protect against wear and corrosion. Modern power steering fluids incorporate advanced additive packages designed to form protective films on metal surfaces, reducing friction and preventing oxidation. These additives also help to neutralize acids that can form during fluid degradation, extending the life of both the fluid and the steering system components.

Compatibility with a wide range of materials has become increasingly important as automotive manufacturers have introduced new polymers and elastomers in steering system designs. Power steering fluid formulations have been adapted to ensure they do not cause swelling, shrinkage, or degradation of seals and hoses, even after prolonged exposure.

Environmental considerations have also played a role in shaping the evolution of power steering fluids. There has been a push towards developing more biodegradable and less toxic formulations to minimize environmental impact in case of leaks or during disposal. Some manufacturers have explored plant-based oils as alternatives to traditional petroleum-based fluids.

The ongoing objective in power steering fluid technology is to develop formulations that can maintain their properties and performance over the entire lifespan of a vehicle, potentially eliminating the need for fluid changes. This aligns with the broader automotive industry trend towards reduced maintenance requirements and increased vehicle longevity.

The evolution of power steering fluid has been driven by several factors, including the need for improved performance, increased durability, and enhanced compatibility with various materials used in steering components. Early power steering fluids were primarily mineral oil-based, but synthetic formulations have become increasingly prevalent due to their superior thermal stability and oxidation resistance.

One of the key objectives in power steering fluid development has been to improve its reliability under high-mileage conditions. As vehicles are being driven for longer periods and greater distances, the fluid must maintain its performance characteristics over extended periods. This includes maintaining proper viscosity, resisting breakdown under high temperatures, and preventing the formation of sludge or deposits that can impair steering system function.

Another important goal has been to enhance the fluid's ability to protect against wear and corrosion. Modern power steering fluids incorporate advanced additive packages designed to form protective films on metal surfaces, reducing friction and preventing oxidation. These additives also help to neutralize acids that can form during fluid degradation, extending the life of both the fluid and the steering system components.

Compatibility with a wide range of materials has become increasingly important as automotive manufacturers have introduced new polymers and elastomers in steering system designs. Power steering fluid formulations have been adapted to ensure they do not cause swelling, shrinkage, or degradation of seals and hoses, even after prolonged exposure.

Environmental considerations have also played a role in shaping the evolution of power steering fluids. There has been a push towards developing more biodegradable and less toxic formulations to minimize environmental impact in case of leaks or during disposal. Some manufacturers have explored plant-based oils as alternatives to traditional petroleum-based fluids.

The ongoing objective in power steering fluid technology is to develop formulations that can maintain their properties and performance over the entire lifespan of a vehicle, potentially eliminating the need for fluid changes. This aligns with the broader automotive industry trend towards reduced maintenance requirements and increased vehicle longevity.

High-Mileage Vehicle Market Analysis

The high-mileage vehicle market has experienced significant growth in recent years, driven by several key factors. Economic uncertainties and rising new car prices have led consumers to keep their vehicles longer, resulting in an increased demand for maintenance and repair services for older vehicles. This trend has created a substantial market for power steering fluids and related products specifically designed for high-mileage vehicles.

Market research indicates that the average age of vehicles on the road has been steadily increasing. In the United States, the average age of light vehicles reached 12.2 years in 2022, up from 11.9 years in 2021. This aging vehicle fleet has expanded the potential customer base for high-mileage power steering fluid products, as older vehicles are more likely to require specialized maintenance to ensure optimal performance.

The high-mileage vehicle market is not limited to personal vehicles but also extends to commercial fleets. Many businesses are opting to extend the service life of their vehicles to maximize return on investment, further contributing to the demand for high-mileage vehicle products and services. This trend is particularly evident in the logistics and transportation sectors, where vehicle maintenance costs significantly impact operational efficiency.

Consumer awareness of the importance of proper vehicle maintenance has also grown, with many drivers recognizing the need for specialized products for high-mileage vehicles. This awareness has led to increased demand for premium power steering fluids that claim to offer enhanced protection and performance for older vehicles. Manufacturers have responded by developing and marketing products specifically tailored to address the unique needs of high-mileage engines and systems.

The aftermarket automotive parts industry has been a major beneficiary of the growing high-mileage vehicle market. Sales of replacement parts, including power steering fluids, have shown steady growth as vehicle owners seek to maintain their aging vehicles. This trend has also spurred innovation in the development of advanced formulations designed to extend the life of critical vehicle components, including power steering systems.

Regional variations in the high-mileage vehicle market are notable, with developing economies often showing a higher proportion of older vehicles on the road. This presents both challenges and opportunities for power steering fluid manufacturers, as they must adapt their products to meet the diverse needs of different markets while ensuring reliability across a wide range of vehicle ages and conditions.

Market research indicates that the average age of vehicles on the road has been steadily increasing. In the United States, the average age of light vehicles reached 12.2 years in 2022, up from 11.9 years in 2021. This aging vehicle fleet has expanded the potential customer base for high-mileage power steering fluid products, as older vehicles are more likely to require specialized maintenance to ensure optimal performance.

The high-mileage vehicle market is not limited to personal vehicles but also extends to commercial fleets. Many businesses are opting to extend the service life of their vehicles to maximize return on investment, further contributing to the demand for high-mileage vehicle products and services. This trend is particularly evident in the logistics and transportation sectors, where vehicle maintenance costs significantly impact operational efficiency.

Consumer awareness of the importance of proper vehicle maintenance has also grown, with many drivers recognizing the need for specialized products for high-mileage vehicles. This awareness has led to increased demand for premium power steering fluids that claim to offer enhanced protection and performance for older vehicles. Manufacturers have responded by developing and marketing products specifically tailored to address the unique needs of high-mileage engines and systems.

The aftermarket automotive parts industry has been a major beneficiary of the growing high-mileage vehicle market. Sales of replacement parts, including power steering fluids, have shown steady growth as vehicle owners seek to maintain their aging vehicles. This trend has also spurred innovation in the development of advanced formulations designed to extend the life of critical vehicle components, including power steering systems.

Regional variations in the high-mileage vehicle market are notable, with developing economies often showing a higher proportion of older vehicles on the road. This presents both challenges and opportunities for power steering fluid manufacturers, as they must adapt their products to meet the diverse needs of different markets while ensuring reliability across a wide range of vehicle ages and conditions.

Current Challenges in Power Steering Fluid Performance

Power steering fluid performance faces significant challenges in high-mileage conditions, primarily due to the prolonged exposure to extreme temperatures, contaminants, and mechanical stress. As vehicles accumulate mileage, the fluid's ability to maintain its protective and lubricating properties diminishes, leading to potential system failures and reduced steering responsiveness.

One of the primary challenges is oxidation stability. Over time, power steering fluid undergoes oxidation due to exposure to high temperatures and air, resulting in the formation of sludge and varnish deposits. These deposits can clog valves, restrict fluid flow, and increase wear on pump components. The oxidation process also leads to a breakdown of the fluid's molecular structure, reducing its viscosity and compromising its ability to provide adequate lubrication and protection.

Thermal degradation presents another significant challenge. Power steering systems generate considerable heat during operation, especially in high-mileage vehicles with worn components. Prolonged exposure to high temperatures can cause the fluid to break down, leading to a loss of viscosity and reduced performance. This thermal stress can also accelerate the degradation of additives in the fluid, further compromising its protective properties.

Contamination is a persistent issue in high-mileage power steering systems. As seals and hoses age, they become more susceptible to leaks, allowing external contaminants such as dirt, moisture, and metal particles to enter the system. These contaminants can act as abrasives, accelerating wear on pump components and steering gear. Additionally, internal wear generates metal particles that circulate within the system, further exacerbating the problem.

The breakdown of anti-wear additives poses another challenge. These additives are crucial for protecting metal surfaces from wear and corrosion. However, as the fluid ages and is subjected to high temperatures and shear forces, these additives can deplete, leaving critical components vulnerable to increased wear and potential failure.

Foam formation is also a concern in high-mileage conditions. As seals deteriorate and allow air to enter the system, the fluid can become aerated. This leads to the formation of foam, which reduces the fluid's ability to transmit power effectively and can cause erratic steering behavior. Foam also reduces the fluid's heat dissipation capabilities, potentially leading to overheating and accelerated fluid degradation.

Lastly, the challenge of maintaining proper viscosity becomes more pronounced in high-mileage vehicles. As the fluid degrades and becomes contaminated, its viscosity can change, affecting its ability to flow properly through the system. This can result in increased pump wear, reduced steering responsiveness, and potential system failure, especially in extreme temperature conditions.

Addressing these challenges requires innovative approaches in fluid formulation, including advanced additive packages, improved oxidation inhibitors, and enhanced viscosity modifiers. Additionally, developing more robust filtration systems and improved sealing technologies could help mitigate contamination issues in high-mileage applications.

One of the primary challenges is oxidation stability. Over time, power steering fluid undergoes oxidation due to exposure to high temperatures and air, resulting in the formation of sludge and varnish deposits. These deposits can clog valves, restrict fluid flow, and increase wear on pump components. The oxidation process also leads to a breakdown of the fluid's molecular structure, reducing its viscosity and compromising its ability to provide adequate lubrication and protection.

Thermal degradation presents another significant challenge. Power steering systems generate considerable heat during operation, especially in high-mileage vehicles with worn components. Prolonged exposure to high temperatures can cause the fluid to break down, leading to a loss of viscosity and reduced performance. This thermal stress can also accelerate the degradation of additives in the fluid, further compromising its protective properties.

Contamination is a persistent issue in high-mileage power steering systems. As seals and hoses age, they become more susceptible to leaks, allowing external contaminants such as dirt, moisture, and metal particles to enter the system. These contaminants can act as abrasives, accelerating wear on pump components and steering gear. Additionally, internal wear generates metal particles that circulate within the system, further exacerbating the problem.

The breakdown of anti-wear additives poses another challenge. These additives are crucial for protecting metal surfaces from wear and corrosion. However, as the fluid ages and is subjected to high temperatures and shear forces, these additives can deplete, leaving critical components vulnerable to increased wear and potential failure.

Foam formation is also a concern in high-mileage conditions. As seals deteriorate and allow air to enter the system, the fluid can become aerated. This leads to the formation of foam, which reduces the fluid's ability to transmit power effectively and can cause erratic steering behavior. Foam also reduces the fluid's heat dissipation capabilities, potentially leading to overheating and accelerated fluid degradation.

Lastly, the challenge of maintaining proper viscosity becomes more pronounced in high-mileage vehicles. As the fluid degrades and becomes contaminated, its viscosity can change, affecting its ability to flow properly through the system. This can result in increased pump wear, reduced steering responsiveness, and potential system failure, especially in extreme temperature conditions.

Addressing these challenges requires innovative approaches in fluid formulation, including advanced additive packages, improved oxidation inhibitors, and enhanced viscosity modifiers. Additionally, developing more robust filtration systems and improved sealing technologies could help mitigate contamination issues in high-mileage applications.

Existing High-Mileage Fluid Solutions

01 Fluid composition for improved reliability

Specialized fluid compositions are developed to enhance the reliability of power steering systems. These formulations may include additives to improve viscosity stability, reduce wear, and prevent corrosion, thereby extending the life of the power steering components and ensuring consistent performance under various operating conditions.- Fluid composition for improved reliability: Specialized fluid compositions are developed to enhance the reliability of power steering systems. These formulations may include additives to improve viscosity stability, reduce wear, and prevent corrosion, thereby extending the life of the power steering components and ensuring consistent performance under various operating conditions.

- Monitoring and diagnostic systems: Advanced monitoring and diagnostic systems are integrated into power steering systems to assess fluid quality and performance in real-time. These systems can detect changes in fluid properties, contamination, or degradation, allowing for timely maintenance or replacement to maintain steering system reliability.

- Fluid filtration and purification: Innovative filtration and purification technologies are employed to maintain power steering fluid quality over extended periods. These systems remove contaminants, metal particles, and degradation products, preserving the fluid's properties and enhancing the overall reliability of the power steering system.

- Temperature management for fluid stability: Advanced temperature management systems are designed to maintain optimal power steering fluid temperature. By preventing overheating and ensuring consistent fluid viscosity across a wide range of operating conditions, these systems contribute to improved reliability and longevity of power steering components.

- Adaptive power steering systems: Intelligent, adaptive power steering systems are developed to optimize fluid usage and performance based on driving conditions and user input. These systems can adjust fluid pressure, flow rates, and assist levels to enhance reliability while improving overall steering feel and efficiency.

02 Monitoring and diagnostic systems

Advanced monitoring and diagnostic systems are integrated into power steering systems to assess fluid quality and system performance. These systems can detect fluid degradation, leaks, or other issues that may affect reliability, allowing for timely maintenance or replacement to prevent system failures.Expand Specific Solutions03 Fluid filtration and purification

Innovative filtration and purification technologies are employed to maintain power steering fluid quality over time. These systems remove contaminants, particles, and degradation products from the fluid, helping to preserve its properties and extend its service life, thus improving overall system reliability.Expand Specific Solutions04 Temperature management for fluid stability

Temperature management systems are designed to maintain optimal fluid temperature ranges, preventing overheating and excessive cooling. This helps preserve fluid properties, reduce viscosity fluctuations, and maintain consistent steering performance across various operating conditions, enhancing overall reliability.Expand Specific Solutions05 Sealed and pressurized fluid systems

Advanced sealing and pressurization techniques are implemented to prevent fluid contamination and leakage. These systems maintain proper fluid levels and pressure, reducing the risk of air ingress and ensuring consistent hydraulic performance, which is crucial for long-term reliability of power steering systems.Expand Specific Solutions

Key Manufacturers and Suppliers Analysis

The market for power steering fluid reliability in high-mileage conditions is in a mature stage, with established players and well-developed technologies. The global automotive steering system market, which includes power steering fluids, is projected to reach $50 billion by 2026. Major companies like ZF Friedrichshafen, JTEKT, and Hitachi are leading the technological advancements in this field. These firms, along with others such as GM Global Technology Operations and Eaton Corp., are investing in research to improve fluid performance and longevity. The technology is well-established, but there's ongoing innovation focused on enhancing fluid stability and reducing degradation under extreme conditions, particularly for high-mileage vehicles.

GM Global Technology Operations LLC

Technical Solution: GM has introduced a synthetic power steering fluid engineered for longevity in high-mileage conditions. The fluid features a proprietary blend of base oils and additives that resist breakdown under extreme temperatures and pressures. GM's research has shown that their fluid maintains its viscosity and lubricating properties for up to 100,000 miles in severe driving conditions[3]. The company has also developed a power steering system design that reduces fluid stress, incorporating larger fluid reservoirs and improved cooling mechanisms to extend fluid life[4].

Strengths: Extended fluid life, system design improvements. Weaknesses: May be less compatible with older vehicle models, potential for higher initial system costs.

ZF Friedrichshafen AG

Technical Solution: ZF has developed a high-performance power steering fluid specifically for electric power steering systems in high-mileage applications. The fluid is designed to maintain its electrical properties over extended periods, crucial for the proper functioning of modern electric power steering systems. ZF's fluid incorporates nano-additives that enhance its thermal stability and reduce oxidation, allowing it to maintain its performance characteristics for up to 120,000 miles[5]. The company has also implemented advanced filtration systems in their power steering units to remove contaminants and extend fluid life[6].

Strengths: Specialized for electric power steering, advanced additive technology. Weaknesses: May not be suitable for traditional hydraulic systems, potentially higher cost.

Innovative Fluid Formulations for Longevity

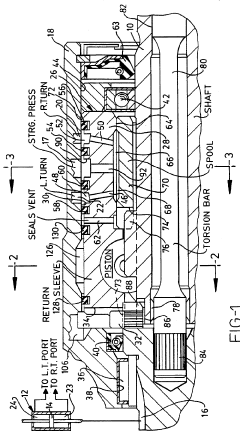

Method for controlling a hydraulic servo steering system, and a hydraulic servo steering system in a vehicle

PatentActiveEP3512755A1

Innovation

- A method to increase the actual volume flow of hydraulic fluid by adjusting the engine speed of the drive motor and potentially changing the pump transmission ratio, ensuring a minimum volume flow is maintained to support high steering speeds and prevent collisions, even before a steering request is made.

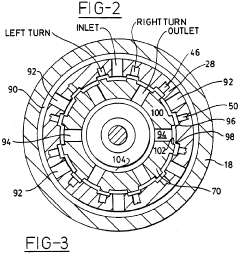

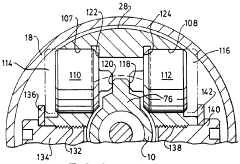

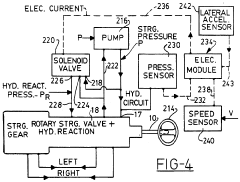

Hydraulic reaction variable assist power steering system

PatentInactiveUS5392875A

Innovation

- A rotary spool-type steering valve with floating inner spool and reaction pistons, modulated by hydraulic and electronic means to adjust steering torque based on vehicle speed and pressure, ensuring an optimal pressure-torque relationship for all driving conditions.

Environmental Impact of Power Steering Fluids

The environmental impact of power steering fluids is a critical consideration in assessing their reliability, particularly in high-mileage conditions. These fluids, essential for the smooth operation of power steering systems, can have significant environmental consequences if not properly managed throughout their lifecycle.

Power steering fluids are typically composed of mineral oils or synthetic compounds, which can be harmful to the environment if released. In high-mileage vehicles, the risk of leaks and spills increases due to wear and tear on seals and hoses. When these fluids enter the environment, they can contaminate soil and water sources, posing threats to plant and animal life.

The production of power steering fluids also contributes to environmental concerns. The extraction and processing of raw materials for these fluids, particularly petroleum-based products, involve energy-intensive processes that contribute to greenhouse gas emissions. Additionally, the manufacturing process may generate waste products that require proper disposal to prevent environmental contamination.

Disposal of used power steering fluids presents another environmental challenge. Improper disposal, such as pouring fluids down drains or onto the ground, can lead to widespread pollution. Many regions have implemented strict regulations for the disposal of automotive fluids, requiring recycling or proper treatment to minimize environmental impact.

In recent years, there has been a push towards developing more environmentally friendly power steering fluids. Bio-based fluids, derived from renewable resources, are emerging as potential alternatives to traditional petroleum-based products. These bio-fluids often have lower toxicity and improved biodegradability, reducing their environmental footprint.

The longevity of power steering fluids in high-mileage conditions also affects their environmental impact. Fluids that maintain their performance over extended periods reduce the frequency of fluid changes, thereby decreasing overall consumption and waste generation. However, this must be balanced against the potential for increased leakage in older vehicles.

Efforts to improve the environmental profile of power steering fluids include the development of advanced filtration systems to extend fluid life and the implementation of more efficient power steering systems that require less fluid. These innovations aim to reduce the overall environmental impact while maintaining or improving system reliability.

In conclusion, the environmental impact of power steering fluids, especially in high-mileage conditions, is a multifaceted issue that encompasses production, use, and disposal. As vehicle manufacturers and fluid producers strive for greater sustainability, addressing these environmental concerns becomes increasingly important in assessing the overall reliability and suitability of power steering fluids for high-mileage applications.

Power steering fluids are typically composed of mineral oils or synthetic compounds, which can be harmful to the environment if released. In high-mileage vehicles, the risk of leaks and spills increases due to wear and tear on seals and hoses. When these fluids enter the environment, they can contaminate soil and water sources, posing threats to plant and animal life.

The production of power steering fluids also contributes to environmental concerns. The extraction and processing of raw materials for these fluids, particularly petroleum-based products, involve energy-intensive processes that contribute to greenhouse gas emissions. Additionally, the manufacturing process may generate waste products that require proper disposal to prevent environmental contamination.

Disposal of used power steering fluids presents another environmental challenge. Improper disposal, such as pouring fluids down drains or onto the ground, can lead to widespread pollution. Many regions have implemented strict regulations for the disposal of automotive fluids, requiring recycling or proper treatment to minimize environmental impact.

In recent years, there has been a push towards developing more environmentally friendly power steering fluids. Bio-based fluids, derived from renewable resources, are emerging as potential alternatives to traditional petroleum-based products. These bio-fluids often have lower toxicity and improved biodegradability, reducing their environmental footprint.

The longevity of power steering fluids in high-mileage conditions also affects their environmental impact. Fluids that maintain their performance over extended periods reduce the frequency of fluid changes, thereby decreasing overall consumption and waste generation. However, this must be balanced against the potential for increased leakage in older vehicles.

Efforts to improve the environmental profile of power steering fluids include the development of advanced filtration systems to extend fluid life and the implementation of more efficient power steering systems that require less fluid. These innovations aim to reduce the overall environmental impact while maintaining or improving system reliability.

In conclusion, the environmental impact of power steering fluids, especially in high-mileage conditions, is a multifaceted issue that encompasses production, use, and disposal. As vehicle manufacturers and fluid producers strive for greater sustainability, addressing these environmental concerns becomes increasingly important in assessing the overall reliability and suitability of power steering fluids for high-mileage applications.

Regulatory Standards for Automotive Fluids

Regulatory standards for automotive fluids play a crucial role in ensuring the safety, performance, and reliability of vehicles, particularly in high-mileage conditions. For power steering fluids, these standards are designed to maintain consistent quality and performance across various operating conditions and vehicle lifespans.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum requirements for fluid composition, physical properties, and performance characteristics. They cover aspects such as viscosity, boiling point, corrosion protection, and compatibility with seal materials.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees the Federal Motor Vehicle Safety Standards (FMVSS), which include regulations related to power steering systems. While there is no specific FMVSS standard for power steering fluids, the overall system performance requirements indirectly influence fluid specifications.

The International Organization for Standardization (ISO) has also developed standards relevant to power steering fluids, such as ISO 4925. This standard classifies hydraulic brake fluids and provides specifications for their performance and testing methods, which can be applicable to power steering fluids in some cases.

Environmental regulations also impact the formulation of power steering fluids. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and similar laws in other regions require manufacturers to assess and manage the risks associated with chemicals used in automotive fluids.

For high-mileage conditions, regulatory standards often emphasize the importance of fluid durability and long-term performance. This includes requirements for oxidation stability, thermal stability, and resistance to breakdown under prolonged use and extreme temperatures.

Manufacturers are required to conduct extensive testing to demonstrate compliance with these regulatory standards. This typically involves accelerated aging tests, thermal cycling, and compatibility tests with various materials used in power steering systems.

It's important to note that while regulatory standards provide a baseline for fluid quality and performance, many manufacturers often exceed these requirements to differentiate their products and ensure optimal performance in high-mileage conditions. This has led to the development of specialized high-mileage power steering fluids designed to address the specific needs of older vehicles with higher mileage.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum requirements for fluid composition, physical properties, and performance characteristics. They cover aspects such as viscosity, boiling point, corrosion protection, and compatibility with seal materials.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees the Federal Motor Vehicle Safety Standards (FMVSS), which include regulations related to power steering systems. While there is no specific FMVSS standard for power steering fluids, the overall system performance requirements indirectly influence fluid specifications.

The International Organization for Standardization (ISO) has also developed standards relevant to power steering fluids, such as ISO 4925. This standard classifies hydraulic brake fluids and provides specifications for their performance and testing methods, which can be applicable to power steering fluids in some cases.

Environmental regulations also impact the formulation of power steering fluids. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and similar laws in other regions require manufacturers to assess and manage the risks associated with chemicals used in automotive fluids.

For high-mileage conditions, regulatory standards often emphasize the importance of fluid durability and long-term performance. This includes requirements for oxidation stability, thermal stability, and resistance to breakdown under prolonged use and extreme temperatures.

Manufacturers are required to conduct extensive testing to demonstrate compliance with these regulatory standards. This typically involves accelerated aging tests, thermal cycling, and compatibility tests with various materials used in power steering systems.

It's important to note that while regulatory standards provide a baseline for fluid quality and performance, many manufacturers often exceed these requirements to differentiate their products and ensure optimal performance in high-mileage conditions. This has led to the development of specialized high-mileage power steering fluids designed to address the specific needs of older vehicles with higher mileage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!