Changes in Power Steering Fluid Properties Due to Extended Heat Exposure

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Heat Exposure Background

Power steering fluid is a crucial component in modern vehicle steering systems, facilitating smooth and effortless steering control. The fluid's primary function is to transmit hydraulic power from the steering pump to the steering gear, enabling drivers to maneuver their vehicles with minimal effort. However, the performance and longevity of power steering fluid can be significantly affected by prolonged exposure to high temperatures.

The issue of changes in power steering fluid properties due to extended heat exposure has become increasingly relevant in recent years. As automotive designs have evolved to accommodate more powerful engines and compact engine compartments, the operating temperatures within these spaces have risen considerably. This trend has led to power steering fluid being subjected to higher thermal stress for extended periods.

Heat exposure can cause several detrimental effects on power steering fluid. One of the primary concerns is the breakdown of the fluid's molecular structure, which can lead to a reduction in its viscosity. As the fluid becomes thinner, its ability to maintain proper hydraulic pressure diminishes, potentially resulting in reduced steering responsiveness and increased wear on steering system components.

Furthermore, extended heat exposure can accelerate the oxidation process of the power steering fluid. Oxidation leads to the formation of sludge and varnish-like deposits within the steering system. These deposits can accumulate on critical components, such as valves and seals, impeding their proper function and potentially causing system failures.

Another significant impact of prolonged heat exposure is the degradation of the fluid's additives. Power steering fluid contains various additives designed to enhance its performance, including anti-wear agents, anti-foaming compounds, and corrosion inhibitors. As these additives break down due to heat, the fluid's ability to protect and lubricate the steering system components is compromised, potentially leading to increased wear and corrosion.

The automotive industry has long recognized the importance of maintaining proper power steering fluid properties under various operating conditions. However, the increasing thermal demands placed on these fluids have necessitated ongoing research and development efforts to improve their heat resistance and overall performance. This has led to the introduction of synthetic and semi-synthetic power steering fluids designed to withstand higher temperatures and maintain their properties for longer periods.

Understanding the changes in power steering fluid properties due to extended heat exposure is crucial for vehicle manufacturers, maintenance professionals, and drivers alike. It informs the development of more robust steering systems, guides maintenance schedules, and highlights the importance of regular fluid checks and replacements to ensure optimal vehicle performance and safety.

The issue of changes in power steering fluid properties due to extended heat exposure has become increasingly relevant in recent years. As automotive designs have evolved to accommodate more powerful engines and compact engine compartments, the operating temperatures within these spaces have risen considerably. This trend has led to power steering fluid being subjected to higher thermal stress for extended periods.

Heat exposure can cause several detrimental effects on power steering fluid. One of the primary concerns is the breakdown of the fluid's molecular structure, which can lead to a reduction in its viscosity. As the fluid becomes thinner, its ability to maintain proper hydraulic pressure diminishes, potentially resulting in reduced steering responsiveness and increased wear on steering system components.

Furthermore, extended heat exposure can accelerate the oxidation process of the power steering fluid. Oxidation leads to the formation of sludge and varnish-like deposits within the steering system. These deposits can accumulate on critical components, such as valves and seals, impeding their proper function and potentially causing system failures.

Another significant impact of prolonged heat exposure is the degradation of the fluid's additives. Power steering fluid contains various additives designed to enhance its performance, including anti-wear agents, anti-foaming compounds, and corrosion inhibitors. As these additives break down due to heat, the fluid's ability to protect and lubricate the steering system components is compromised, potentially leading to increased wear and corrosion.

The automotive industry has long recognized the importance of maintaining proper power steering fluid properties under various operating conditions. However, the increasing thermal demands placed on these fluids have necessitated ongoing research and development efforts to improve their heat resistance and overall performance. This has led to the introduction of synthetic and semi-synthetic power steering fluids designed to withstand higher temperatures and maintain their properties for longer periods.

Understanding the changes in power steering fluid properties due to extended heat exposure is crucial for vehicle manufacturers, maintenance professionals, and drivers alike. It informs the development of more robust steering systems, guides maintenance schedules, and highlights the importance of regular fluid checks and replacements to ensure optimal vehicle performance and safety.

Market Analysis for Heat-Resistant Fluids

The market for heat-resistant fluids, particularly in the context of power steering systems, has been experiencing significant growth due to the increasing demand for more durable and efficient automotive components. As vehicles become more advanced and operate under higher temperatures, the need for fluids that can withstand extended heat exposure has become paramount.

The global power steering fluid market is projected to expand at a steady rate, driven by the growing automotive industry and the rising preference for vehicles with power steering systems. Developing economies, particularly in Asia-Pacific and Latin America, are expected to be key growth drivers as vehicle ownership rates increase in these regions.

Heat-resistant fluids are gaining traction not only in the automotive sector but also in industrial applications where high-temperature environments are common. This diversification of applications is contributing to the overall market growth and creating new opportunities for manufacturers.

The market is characterized by a shift towards synthetic and semi-synthetic fluids, which offer superior heat resistance compared to conventional mineral-based fluids. These advanced formulations can maintain their properties under prolonged heat exposure, reducing the frequency of fluid changes and improving overall system performance.

Environmental concerns and stringent regulations are also shaping the market landscape. There is a growing demand for eco-friendly, biodegradable fluids that can meet performance requirements while minimizing environmental impact. This trend is driving innovation in fluid formulations and creating a niche market for green alternatives.

Key players in the heat-resistant fluid market are focusing on research and development to improve fluid properties, particularly in terms of thermal stability and oxidation resistance. Collaborations between fluid manufacturers and automotive OEMs are becoming more common, as companies seek to develop tailored solutions for specific vehicle models and operating conditions.

The aftermarket segment for heat-resistant power steering fluids is also showing promise, as vehicle owners become more aware of the importance of using high-quality fluids to extend the life of their power steering systems. This segment is expected to grow as the average age of vehicles on the road increases, leading to higher demand for maintenance and replacement fluids.

The global power steering fluid market is projected to expand at a steady rate, driven by the growing automotive industry and the rising preference for vehicles with power steering systems. Developing economies, particularly in Asia-Pacific and Latin America, are expected to be key growth drivers as vehicle ownership rates increase in these regions.

Heat-resistant fluids are gaining traction not only in the automotive sector but also in industrial applications where high-temperature environments are common. This diversification of applications is contributing to the overall market growth and creating new opportunities for manufacturers.

The market is characterized by a shift towards synthetic and semi-synthetic fluids, which offer superior heat resistance compared to conventional mineral-based fluids. These advanced formulations can maintain their properties under prolonged heat exposure, reducing the frequency of fluid changes and improving overall system performance.

Environmental concerns and stringent regulations are also shaping the market landscape. There is a growing demand for eco-friendly, biodegradable fluids that can meet performance requirements while minimizing environmental impact. This trend is driving innovation in fluid formulations and creating a niche market for green alternatives.

Key players in the heat-resistant fluid market are focusing on research and development to improve fluid properties, particularly in terms of thermal stability and oxidation resistance. Collaborations between fluid manufacturers and automotive OEMs are becoming more common, as companies seek to develop tailored solutions for specific vehicle models and operating conditions.

The aftermarket segment for heat-resistant power steering fluids is also showing promise, as vehicle owners become more aware of the importance of using high-quality fluids to extend the life of their power steering systems. This segment is expected to grow as the average age of vehicles on the road increases, leading to higher demand for maintenance and replacement fluids.

Current Challenges in Fluid Stability

Power steering fluid stability under extended heat exposure presents significant challenges for automotive engineers and manufacturers. The primary concern is the degradation of fluid properties, which can lead to reduced performance and potential system failures.

One of the main challenges is oxidation. When exposed to high temperatures for prolonged periods, power steering fluid undergoes oxidative processes, resulting in the formation of sludge and varnish. These byproducts can clog valves, restrict fluid flow, and increase wear on system components. The oxidation process also leads to a breakdown of the fluid's molecular structure, reducing its viscosity and lubricating properties.

Thermal breakdown is another critical issue. Extended heat exposure can cause the fluid to break down chemically, leading to a loss of essential additives that provide anti-wear, anti-foam, and corrosion protection properties. This breakdown not only compromises the fluid's ability to protect the system but can also result in the formation of acidic compounds that accelerate corrosion of metal components.

Moisture contamination exacerbates the stability problems. High temperatures can cause any water present in the system to vaporize, creating steam pockets that lead to erratic steering performance. When the system cools, this moisture can condense and mix with the fluid, further accelerating oxidation and corrosion processes.

The loss of viscosity stability is a significant concern. As the fluid degrades under heat stress, its viscosity can fluctuate, potentially becoming too thin at high temperatures or too thick at lower temperatures. This variability affects the fluid's ability to provide consistent hydraulic pressure and lubrication, leading to increased pump wear and reduced steering responsiveness.

Seal compatibility is another challenge. Degraded fluid can become more aggressive towards rubber seals and hoses, causing them to swell, shrink, or harden. This can result in leaks, further contamination, and ultimately, system failure.

The automotive industry is also facing challenges in developing fluids that can maintain stability across a wider temperature range, as modern vehicles often operate in more extreme conditions. There is a growing need for fluids that can resist degradation at higher temperatures while still performing effectively in cold start situations.

Lastly, the environmental impact of fluid degradation is becoming increasingly important. As fluids break down, they may release volatile organic compounds (VOCs) and other harmful substances. Developing more stable fluids that require less frequent replacement is crucial for reducing environmental impact and meeting stricter emissions regulations.

One of the main challenges is oxidation. When exposed to high temperatures for prolonged periods, power steering fluid undergoes oxidative processes, resulting in the formation of sludge and varnish. These byproducts can clog valves, restrict fluid flow, and increase wear on system components. The oxidation process also leads to a breakdown of the fluid's molecular structure, reducing its viscosity and lubricating properties.

Thermal breakdown is another critical issue. Extended heat exposure can cause the fluid to break down chemically, leading to a loss of essential additives that provide anti-wear, anti-foam, and corrosion protection properties. This breakdown not only compromises the fluid's ability to protect the system but can also result in the formation of acidic compounds that accelerate corrosion of metal components.

Moisture contamination exacerbates the stability problems. High temperatures can cause any water present in the system to vaporize, creating steam pockets that lead to erratic steering performance. When the system cools, this moisture can condense and mix with the fluid, further accelerating oxidation and corrosion processes.

The loss of viscosity stability is a significant concern. As the fluid degrades under heat stress, its viscosity can fluctuate, potentially becoming too thin at high temperatures or too thick at lower temperatures. This variability affects the fluid's ability to provide consistent hydraulic pressure and lubrication, leading to increased pump wear and reduced steering responsiveness.

Seal compatibility is another challenge. Degraded fluid can become more aggressive towards rubber seals and hoses, causing them to swell, shrink, or harden. This can result in leaks, further contamination, and ultimately, system failure.

The automotive industry is also facing challenges in developing fluids that can maintain stability across a wider temperature range, as modern vehicles often operate in more extreme conditions. There is a growing need for fluids that can resist degradation at higher temperatures while still performing effectively in cold start situations.

Lastly, the environmental impact of fluid degradation is becoming increasingly important. As fluids break down, they may release volatile organic compounds (VOCs) and other harmful substances. Developing more stable fluids that require less frequent replacement is crucial for reducing environmental impact and meeting stricter emissions regulations.

Existing Heat-Resistant Formulations

01 Viscosity and temperature characteristics

Power steering fluids are designed to maintain optimal viscosity across a wide range of temperatures. This ensures smooth operation in both cold and hot conditions, providing consistent steering performance and system protection.- Viscosity and temperature characteristics: Power steering fluids are designed to maintain optimal viscosity across a wide range of temperatures. This ensures smooth operation in both cold and hot conditions, providing consistent steering performance and system protection.

- Anti-wear and lubrication properties: These fluids contain additives that reduce friction and wear between moving parts in the power steering system. This helps to extend the life of components such as pumps, valves, and seals, while ensuring smooth and efficient operation.

- Compatibility with system materials: Power steering fluids are formulated to be compatible with various materials used in steering systems, including metals, rubber seals, and hoses. This prevents degradation of components and ensures long-term system integrity.

- Foam resistance and air release: These fluids are designed to resist foaming and quickly release entrained air. This property is crucial for maintaining hydraulic efficiency and preventing cavitation, which can damage system components.

- Oxidation and thermal stability: Power steering fluids possess high oxidation and thermal stability to resist breakdown under high temperatures and pressures. This helps maintain fluid performance over time, reducing the frequency of fluid changes and protecting system components.

02 Anti-wear and lubrication properties

These fluids contain additives that reduce friction and wear between moving parts in the power steering system. This helps to extend the life of components such as pumps, valves, and seals, while ensuring smooth and efficient operation.Expand Specific Solutions03 Compatibility with system materials

Power steering fluids are formulated to be compatible with various materials used in steering systems, including metals, rubber, and plastics. This prevents degradation of seals and hoses, reducing the risk of leaks and system failure.Expand Specific Solutions04 Foam resistance and air release

These fluids are designed to resist foaming and quickly release entrained air. This property is crucial for maintaining hydraulic efficiency and preventing cavitation, which can damage system components.Expand Specific Solutions05 Oxidation and thermal stability

Power steering fluids possess high oxidation and thermal stability to withstand the high temperatures and pressures encountered in modern steering systems. This helps prevent fluid breakdown and the formation of harmful deposits, ensuring long-term system performance.Expand Specific Solutions

Key Manufacturers and Suppliers

The power steering fluid properties market is in a mature stage, with a global size estimated in the billions of dollars. The technology for power steering fluid is well-established, but ongoing research focuses on improving heat resistance and longevity. Key players like Toyota, Ford, and Nissan dominate the automotive sector, while specialized companies such as Afton Chemical and ExxonMobil lead in fluid technology. The market is characterized by incremental innovations rather than disruptive changes, with major automotive manufacturers and chemical companies collaborating to enhance fluid performance under extended heat exposure conditions. This technological maturity suggests a stable market with opportunities for refinement and optimization rather than revolutionary breakthroughs.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced power steering fluid formulation that maintains its properties under extended heat exposure. The fluid incorporates high-performance synthetic base oils and a proprietary additive package designed to resist thermal breakdown[1]. This formulation includes antioxidants that prevent fluid oxidation at high temperatures, maintaining viscosity stability over extended periods[2]. Ford's research has shown that their fluid can maintain optimal performance for up to 150,000 miles under normal driving conditions, even in high-temperature environments[3]. The company has also implemented a cooling system design that helps regulate power steering fluid temperature, further extending its lifespan[4].

Strengths: Extended fluid life reduces maintenance costs and improves long-term vehicle reliability. The fluid's stability under high temperatures enhances steering system performance in extreme conditions. Weaknesses: Potentially higher initial cost compared to conventional fluids. May require specialized handling during service and replacement.

JTEKT Corp.

Technical Solution: JTEKT has developed a novel power steering fluid that incorporates heat-stable polymers to maintain fluid properties under extended heat exposure. Their formulation uses a combination of high-viscosity index base oils and shear-stable viscosity improvers that resist breakdown at elevated temperatures[1]. JTEKT's fluid also contains advanced anti-wear additives that form a protective film on metal surfaces, reducing friction and heat generation in the power steering system[2]. The company has implemented a unique filtration system within their power steering units that continuously removes contaminants, extending fluid life and maintaining its properties[3]. JTEKT's research indicates that their fluid can maintain optimal performance for up to 120,000 miles in high-temperature operating conditions[4].

Strengths: Innovative polymer technology provides excellent thermal stability. Integrated filtration system extends fluid life and maintains performance. Weaknesses: May require more frequent filter replacements. The specialized formulation could limit compatibility with standard power steering systems.

Innovative Additives and Compounds

Low viscosity heat transfer fluids with increasing flash point and thermal conductivity

PatentWO2020132068A1

Innovation

- A heat transfer fluid with a mixed ester base stock system comprising partially esterified and fully esterified esters, which maintains or decreases viscosity while increasing flash point and thermal conductivity, allowing for enhanced heat transfer performance.

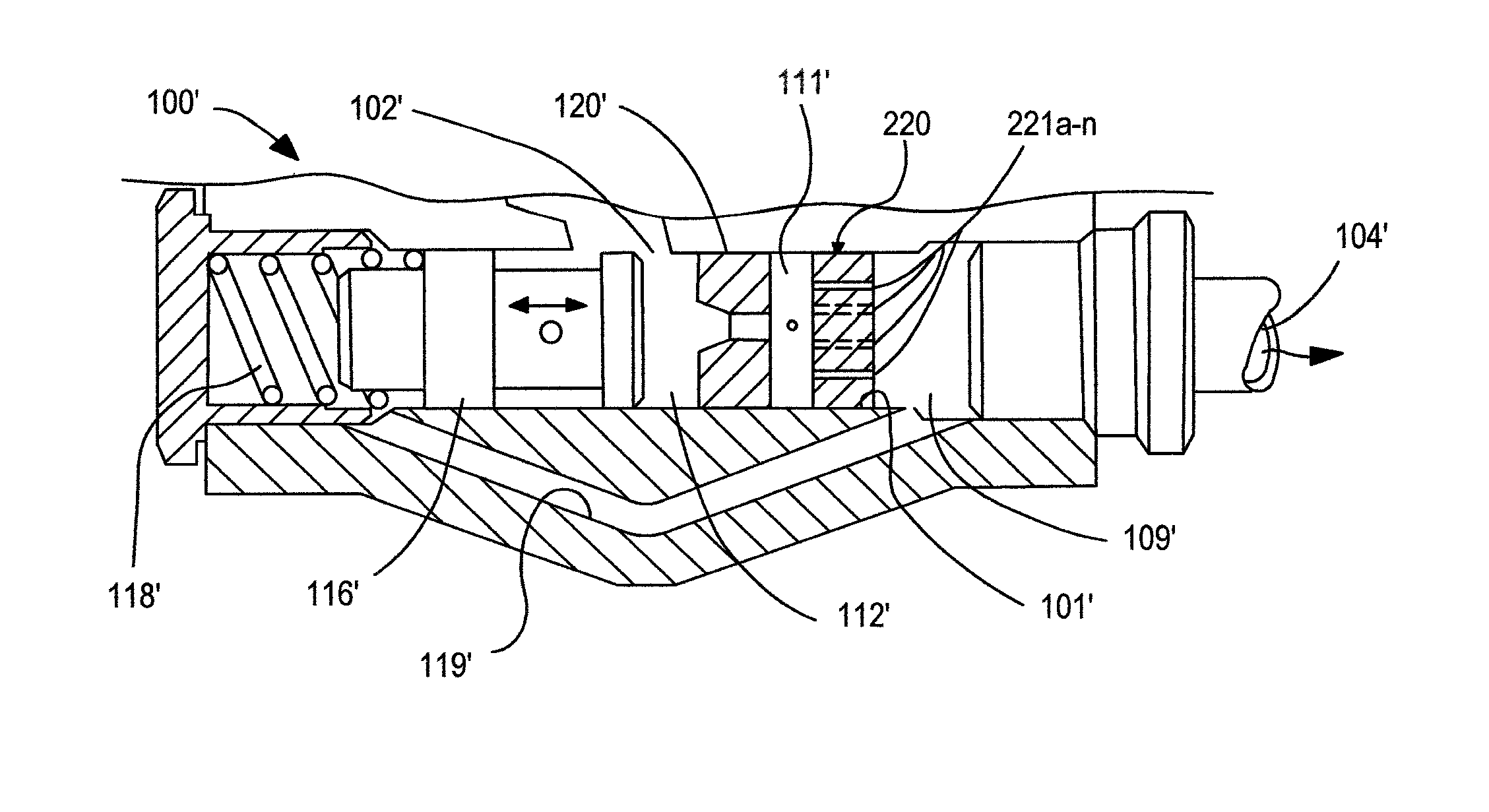

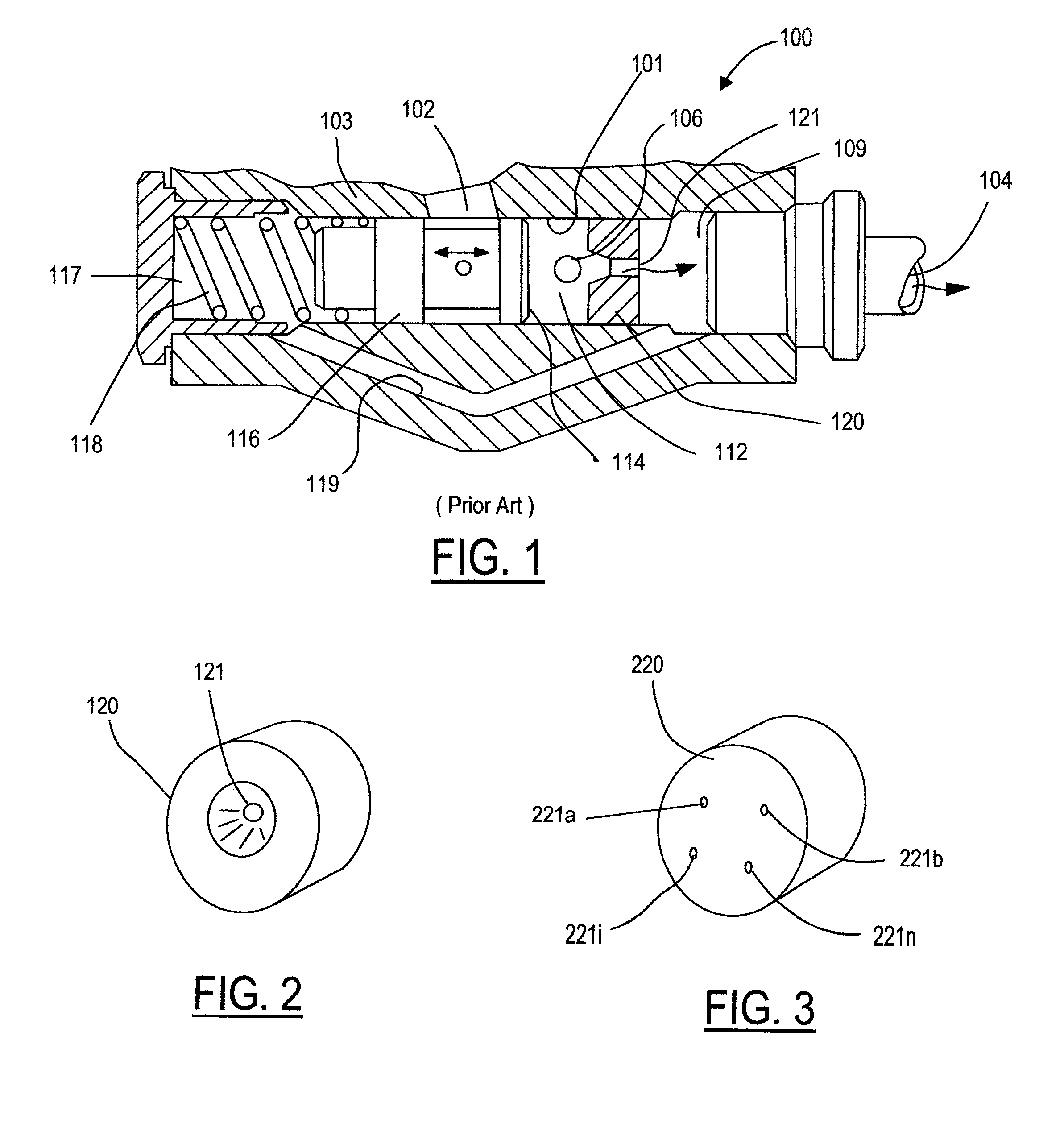

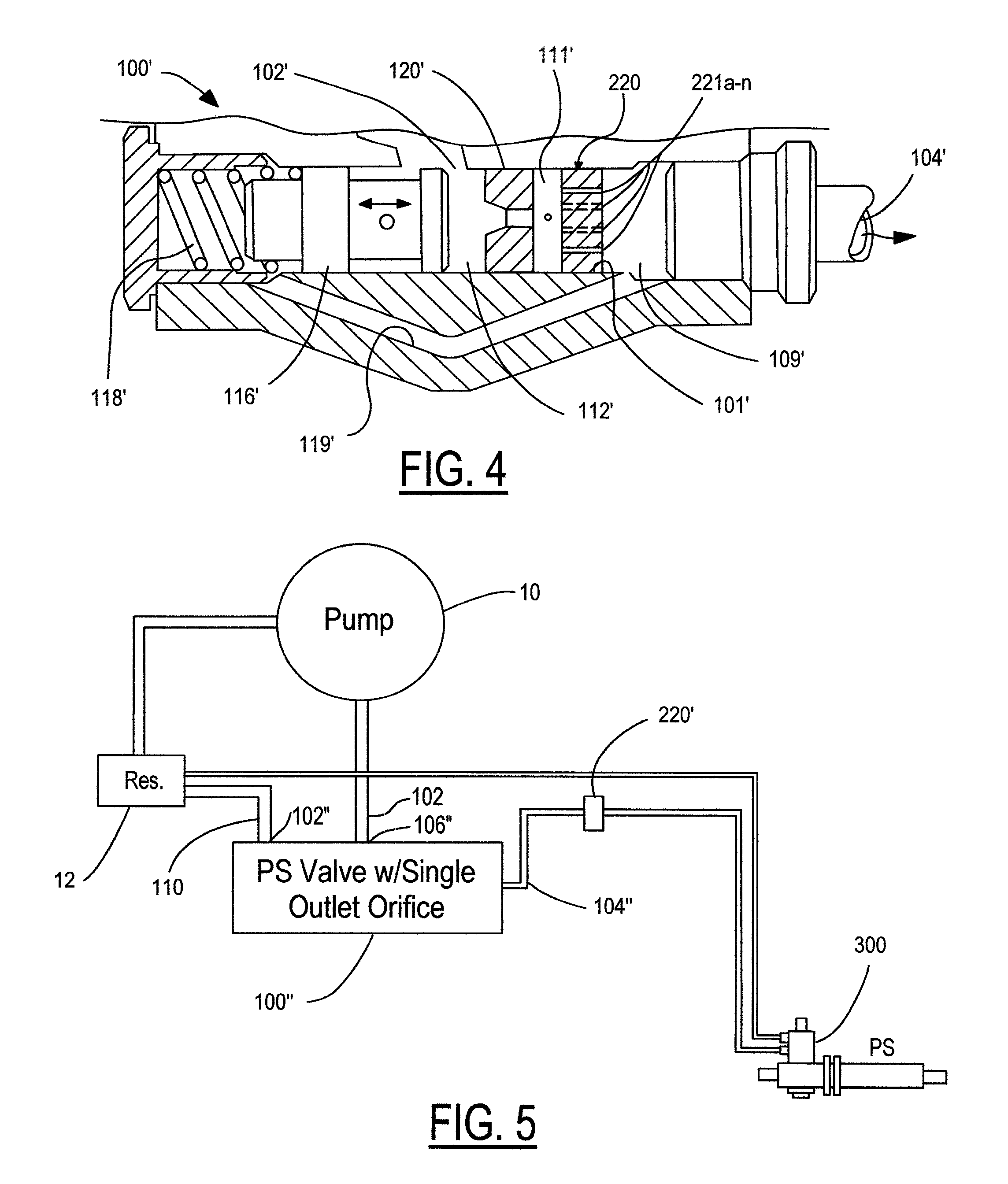

Power steering pump flow control

PatentInactiveUS7993111B2

Innovation

- A multiple passage orifice element is added downstream of a single passage outlet orifice element in a hydraulic flow control valve, providing increased resistance to high viscosity fluid flow through a greater wetted surface area, which prevents pulsation and noise by increasing shear forces and backpressure during cold starts, while maintaining normal operation at higher temperatures.

Environmental Impact Assessment

The environmental impact of changes in power steering fluid properties due to extended heat exposure is a critical consideration in the automotive industry. As power steering systems are exposed to high temperatures over prolonged periods, the fluid's properties can degrade, potentially leading to various environmental concerns.

One of the primary environmental issues associated with degraded power steering fluid is the increased likelihood of leaks. As the fluid's viscosity and lubricating properties change due to heat exposure, seals and gaskets may become less effective, resulting in fluid seepage. This can lead to soil and water contamination, particularly in areas where vehicles are frequently parked or serviced.

The chemical composition of power steering fluid also undergoes changes when subjected to extended heat exposure. These alterations may result in the formation of harmful compounds that can be released into the environment through evaporation or leaks. Some of these compounds may contribute to air pollution or pose risks to local ecosystems if they enter water sources.

Furthermore, the degradation of power steering fluid properties often necessitates more frequent fluid changes. This increased maintenance requirement leads to a higher volume of waste fluid that must be properly disposed of or recycled. Improper disposal of used power steering fluid can have severe consequences for the environment, including soil contamination and potential harm to aquatic life if it enters water systems.

The production of replacement power steering fluid to compensate for degraded fluid also has environmental implications. The manufacturing process consumes energy and resources, contributing to carbon emissions and potentially impacting air and water quality in the vicinity of production facilities.

Additionally, the reduced efficiency of power steering systems operating with degraded fluid can lead to increased fuel consumption in vehicles. This, in turn, results in higher emissions of greenhouse gases and other pollutants, exacerbating air quality issues and contributing to climate change.

To mitigate these environmental impacts, research and development efforts are focusing on creating more heat-resistant power steering fluids and improving system designs to reduce fluid degradation. Some manufacturers are exploring alternative power steering technologies, such as electric power steering, which eliminate the need for hydraulic fluid altogether, potentially reducing long-term environmental impacts.

In conclusion, the environmental impact of changes in power steering fluid properties due to extended heat exposure is multifaceted, affecting soil, water, and air quality. Addressing these concerns requires a comprehensive approach, including improved fluid formulations, better system designs, and the exploration of alternative technologies to minimize the environmental footprint of power steering systems in vehicles.

One of the primary environmental issues associated with degraded power steering fluid is the increased likelihood of leaks. As the fluid's viscosity and lubricating properties change due to heat exposure, seals and gaskets may become less effective, resulting in fluid seepage. This can lead to soil and water contamination, particularly in areas where vehicles are frequently parked or serviced.

The chemical composition of power steering fluid also undergoes changes when subjected to extended heat exposure. These alterations may result in the formation of harmful compounds that can be released into the environment through evaporation or leaks. Some of these compounds may contribute to air pollution or pose risks to local ecosystems if they enter water sources.

Furthermore, the degradation of power steering fluid properties often necessitates more frequent fluid changes. This increased maintenance requirement leads to a higher volume of waste fluid that must be properly disposed of or recycled. Improper disposal of used power steering fluid can have severe consequences for the environment, including soil contamination and potential harm to aquatic life if it enters water systems.

The production of replacement power steering fluid to compensate for degraded fluid also has environmental implications. The manufacturing process consumes energy and resources, contributing to carbon emissions and potentially impacting air and water quality in the vicinity of production facilities.

Additionally, the reduced efficiency of power steering systems operating with degraded fluid can lead to increased fuel consumption in vehicles. This, in turn, results in higher emissions of greenhouse gases and other pollutants, exacerbating air quality issues and contributing to climate change.

To mitigate these environmental impacts, research and development efforts are focusing on creating more heat-resistant power steering fluids and improving system designs to reduce fluid degradation. Some manufacturers are exploring alternative power steering technologies, such as electric power steering, which eliminate the need for hydraulic fluid altogether, potentially reducing long-term environmental impacts.

In conclusion, the environmental impact of changes in power steering fluid properties due to extended heat exposure is multifaceted, affecting soil, water, and air quality. Addressing these concerns requires a comprehensive approach, including improved fluid formulations, better system designs, and the exploration of alternative technologies to minimize the environmental footprint of power steering systems in vehicles.

Regulatory Standards for Automotive Fluids

Regulatory standards for automotive fluids play a crucial role in ensuring the safety, performance, and environmental compliance of vehicles. In the context of power steering fluid properties affected by extended heat exposure, several key regulations and standards come into play.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum performance requirements for power steering fluids, including their thermal stability and resistance to oxidation under high-temperature conditions. Manufacturers must ensure that their power steering fluids meet or exceed these standards to maintain compliance.

The International Organization for Standardization (ISO) also provides guidelines for automotive fluids, including ISO 7308, which specifies the requirements for mineral oil-based brake and clutch fluids. While not directly related to power steering fluids, these standards often influence the overall regulatory landscape for automotive fluids.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees automotive safety regulations, including those related to steering systems and fluids. NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) include requirements for steering control systems, which indirectly affect the specifications for power steering fluids.

The Environmental Protection Agency (EPA) regulates the environmental impact of automotive fluids, including their disposal and potential for contamination. Power steering fluids must comply with EPA guidelines to minimize environmental risks associated with leaks, spills, or improper disposal.

European regulations, such as those set by the European Chemicals Agency (ECHA) under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) framework, also impact the composition and use of automotive fluids. Manufacturers must ensure that power steering fluids comply with REACH requirements, particularly concerning the use of certain chemicals and their potential environmental and health impacts.

The Automotive Fluid Manufacturers Association (AFMA) provides industry guidelines and best practices for the production and use of automotive fluids, including power steering fluids. While not regulatory in nature, these guidelines often influence industry standards and regulatory developments.

As concerns about the long-term effects of heat exposure on power steering fluid properties grow, regulatory bodies may consider updating existing standards or introducing new ones. This could include more stringent requirements for thermal stability, oxidation resistance, and long-term performance under high-temperature conditions.

Manufacturers and researchers must stay abreast of these regulatory standards and anticipate potential changes to ensure that power steering fluids continue to meet safety, performance, and environmental requirements, even when subjected to extended heat exposure.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum performance requirements for power steering fluids, including their thermal stability and resistance to oxidation under high-temperature conditions. Manufacturers must ensure that their power steering fluids meet or exceed these standards to maintain compliance.

The International Organization for Standardization (ISO) also provides guidelines for automotive fluids, including ISO 7308, which specifies the requirements for mineral oil-based brake and clutch fluids. While not directly related to power steering fluids, these standards often influence the overall regulatory landscape for automotive fluids.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees automotive safety regulations, including those related to steering systems and fluids. NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) include requirements for steering control systems, which indirectly affect the specifications for power steering fluids.

The Environmental Protection Agency (EPA) regulates the environmental impact of automotive fluids, including their disposal and potential for contamination. Power steering fluids must comply with EPA guidelines to minimize environmental risks associated with leaks, spills, or improper disposal.

European regulations, such as those set by the European Chemicals Agency (ECHA) under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) framework, also impact the composition and use of automotive fluids. Manufacturers must ensure that power steering fluids comply with REACH requirements, particularly concerning the use of certain chemicals and their potential environmental and health impacts.

The Automotive Fluid Manufacturers Association (AFMA) provides industry guidelines and best practices for the production and use of automotive fluids, including power steering fluids. While not regulatory in nature, these guidelines often influence industry standards and regulatory developments.

As concerns about the long-term effects of heat exposure on power steering fluid properties grow, regulatory bodies may consider updating existing standards or introducing new ones. This could include more stringent requirements for thermal stability, oxidation resistance, and long-term performance under high-temperature conditions.

Manufacturers and researchers must stay abreast of these regulatory standards and anticipate potential changes to ensure that power steering fluids continue to meet safety, performance, and environmental requirements, even when subjected to extended heat exposure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!