How Power Steering Fluid Properties Influence Steering Feedback

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking.

The first major breakthrough came in the 1950s with the introduction of hydraulic power steering systems. These systems used hydraulic fluid pressure to assist in turning the wheels, significantly reducing the effort required by drivers. This innovation quickly gained popularity in the automotive industry, becoming a standard feature in many vehicles by the 1960s.

As automotive technology advanced, so did power steering systems. The 1980s and 1990s saw the development of electronic power steering (EPS) systems. Unlike hydraulic systems, EPS uses an electric motor to assist steering, eliminating the need for hydraulic fluid and pumps. This transition marked a significant shift in power steering technology, offering improved fuel efficiency and more precise control.

The early 2000s brought further refinements to EPS systems, with the integration of advanced sensors and control modules. These enhancements allowed for variable assist, providing more support at low speeds and less at high speeds, thus improving overall driving experience and safety.

In recent years, the focus has shifted towards intelligent power steering systems. These incorporate adaptive algorithms and can interface with other vehicle systems such as stability control and lane-keeping assist. This integration has paved the way for advanced driver assistance systems (ADAS) and is a crucial component in the development of autonomous vehicles.

The latest frontier in power steering evolution is the development of steer-by-wire systems. These fully electronic systems eliminate the mechanical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators. While still in the early stages of adoption, steer-by-wire technology promises unprecedented levels of customization in steering feel and responsiveness.

Throughout this evolution, the properties of power steering fluid have played a crucial role in system performance and feedback. As systems became more sophisticated, so did the requirements for steering fluids. Modern fluids must maintain consistent viscosity across a wide temperature range, resist foaming and oxidation, and provide excellent lubrication and heat dissipation. These properties directly influence the steering feedback, affecting the driver's perception of road conditions and vehicle control.

The first major breakthrough came in the 1950s with the introduction of hydraulic power steering systems. These systems used hydraulic fluid pressure to assist in turning the wheels, significantly reducing the effort required by drivers. This innovation quickly gained popularity in the automotive industry, becoming a standard feature in many vehicles by the 1960s.

As automotive technology advanced, so did power steering systems. The 1980s and 1990s saw the development of electronic power steering (EPS) systems. Unlike hydraulic systems, EPS uses an electric motor to assist steering, eliminating the need for hydraulic fluid and pumps. This transition marked a significant shift in power steering technology, offering improved fuel efficiency and more precise control.

The early 2000s brought further refinements to EPS systems, with the integration of advanced sensors and control modules. These enhancements allowed for variable assist, providing more support at low speeds and less at high speeds, thus improving overall driving experience and safety.

In recent years, the focus has shifted towards intelligent power steering systems. These incorporate adaptive algorithms and can interface with other vehicle systems such as stability control and lane-keeping assist. This integration has paved the way for advanced driver assistance systems (ADAS) and is a crucial component in the development of autonomous vehicles.

The latest frontier in power steering evolution is the development of steer-by-wire systems. These fully electronic systems eliminate the mechanical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators. While still in the early stages of adoption, steer-by-wire technology promises unprecedented levels of customization in steering feel and responsiveness.

Throughout this evolution, the properties of power steering fluid have played a crucial role in system performance and feedback. As systems became more sophisticated, so did the requirements for steering fluids. Modern fluids must maintain consistent viscosity across a wide temperature range, resist foaming and oxidation, and provide excellent lubrication and heat dissipation. These properties directly influence the steering feedback, affecting the driver's perception of road conditions and vehicle control.

Market Demand Analysis

The market demand for power steering fluid with enhanced properties to improve steering feedback has been steadily growing in recent years. This trend is driven by several factors, including the increasing consumer expectations for better driving experiences, the rise of electric and autonomous vehicles, and the ongoing pursuit of improved vehicle safety and performance.

In the automotive industry, there is a growing emphasis on driver engagement and vehicle responsiveness. As vehicles become more technologically advanced, manufacturers are seeking ways to maintain or enhance the connection between the driver and the road. Power steering fluid plays a crucial role in this aspect, as its properties directly influence the steering feel and feedback. Consequently, there is a rising demand for advanced power steering fluids that can provide more precise and responsive steering control.

The electric vehicle (EV) market has been experiencing rapid growth, with global EV sales reaching 10.5 million units in 2022. This shift towards electrification has created new challenges and opportunities for power steering systems. Electric power steering (EPS) systems, which are prevalent in EVs, require specialized fluids that can maintain their properties under different operating conditions and contribute to overall energy efficiency. As a result, there is an increasing demand for power steering fluids specifically designed for EV applications.

The autonomous vehicle sector is another key driver of market demand for advanced power steering fluids. While fully autonomous vehicles may not require traditional steering feedback, semi-autonomous systems still rely on precise steering control for safety and performance. The global market for autonomous vehicles is projected to grow significantly in the coming years, creating a new segment for specialized power steering fluids that can meet the unique requirements of these advanced systems.

Safety considerations are also fueling the demand for improved power steering fluids. Enhanced steering feedback can contribute to better vehicle control and accident prevention. As automotive safety standards become more stringent worldwide, there is a growing need for power steering fluids that can maintain consistent performance under various driving conditions and over extended periods.

The aftermarket segment for power steering fluids is also experiencing growth. Vehicle owners are becoming more aware of the importance of regular maintenance and the impact of high-quality fluids on vehicle performance. This has led to an increased demand for premium power steering fluids that offer superior protection and performance benefits.

In conclusion, the market demand for power steering fluids with properties that enhance steering feedback is driven by a combination of factors, including consumer preferences, technological advancements in the automotive industry, and safety considerations. As vehicles continue to evolve, the demand for specialized power steering fluids is expected to grow, presenting opportunities for innovation and market expansion in this sector.

In the automotive industry, there is a growing emphasis on driver engagement and vehicle responsiveness. As vehicles become more technologically advanced, manufacturers are seeking ways to maintain or enhance the connection between the driver and the road. Power steering fluid plays a crucial role in this aspect, as its properties directly influence the steering feel and feedback. Consequently, there is a rising demand for advanced power steering fluids that can provide more precise and responsive steering control.

The electric vehicle (EV) market has been experiencing rapid growth, with global EV sales reaching 10.5 million units in 2022. This shift towards electrification has created new challenges and opportunities for power steering systems. Electric power steering (EPS) systems, which are prevalent in EVs, require specialized fluids that can maintain their properties under different operating conditions and contribute to overall energy efficiency. As a result, there is an increasing demand for power steering fluids specifically designed for EV applications.

The autonomous vehicle sector is another key driver of market demand for advanced power steering fluids. While fully autonomous vehicles may not require traditional steering feedback, semi-autonomous systems still rely on precise steering control for safety and performance. The global market for autonomous vehicles is projected to grow significantly in the coming years, creating a new segment for specialized power steering fluids that can meet the unique requirements of these advanced systems.

Safety considerations are also fueling the demand for improved power steering fluids. Enhanced steering feedback can contribute to better vehicle control and accident prevention. As automotive safety standards become more stringent worldwide, there is a growing need for power steering fluids that can maintain consistent performance under various driving conditions and over extended periods.

The aftermarket segment for power steering fluids is also experiencing growth. Vehicle owners are becoming more aware of the importance of regular maintenance and the impact of high-quality fluids on vehicle performance. This has led to an increased demand for premium power steering fluids that offer superior protection and performance benefits.

In conclusion, the market demand for power steering fluids with properties that enhance steering feedback is driven by a combination of factors, including consumer preferences, technological advancements in the automotive industry, and safety considerations. As vehicles continue to evolve, the demand for specialized power steering fluids is expected to grow, presenting opportunities for innovation and market expansion in this sector.

Fluid Properties Challenges

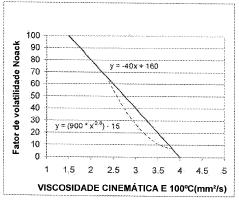

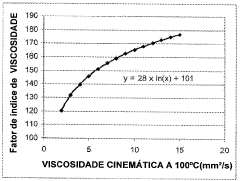

Power steering fluid plays a crucial role in the performance and feel of a vehicle's steering system. However, several challenges arise when considering the properties of these fluids and their impact on steering feedback. One of the primary issues is the fluid's viscosity and its variation with temperature. As temperatures fluctuate, the fluid's viscosity changes, potentially leading to inconsistent steering feel across different operating conditions.

Another significant challenge is the fluid's compressibility. While hydraulic fluids are generally considered incompressible, they do exhibit some level of compressibility under high pressures. This characteristic can affect the responsiveness and precision of the steering system, particularly in high-performance or heavy-duty applications where steering loads are substantial.

The fluid's ability to maintain its properties over time presents another hurdle. Oxidation and thermal breakdown can degrade the fluid's performance, altering its viscosity and lubricating properties. This degradation can lead to increased wear on steering components and a gradual change in steering feel over the vehicle's lifetime.

Aeration and cavitation are additional concerns in power steering systems. Entrained air or vapor bubbles can form within the fluid, especially under high-speed or high-load conditions. These phenomena can cause erratic steering behavior and reduce the system's overall efficiency, impacting the driver's perception of steering feedback.

The compatibility of power steering fluid with various materials used in the steering system poses another challenge. Seals, hoses, and other components must withstand prolonged exposure to the fluid without degradation. Incompatibility can lead to leaks, component failure, and contamination of the fluid itself, all of which can adversely affect steering performance and feedback.

Fluid foaming is yet another property-related issue that can impact steering feedback. Excessive foaming can lead to a spongy feel in the steering wheel and reduced system efficiency. Balancing the fluid's anti-foaming properties with its other required characteristics presents a complex engineering challenge.

Lastly, the environmental impact and sustainability of power steering fluids are becoming increasingly important considerations. Developing fluids that maintain optimal steering feedback while meeting stringent environmental regulations and sustainability goals adds another layer of complexity to fluid property management.

Another significant challenge is the fluid's compressibility. While hydraulic fluids are generally considered incompressible, they do exhibit some level of compressibility under high pressures. This characteristic can affect the responsiveness and precision of the steering system, particularly in high-performance or heavy-duty applications where steering loads are substantial.

The fluid's ability to maintain its properties over time presents another hurdle. Oxidation and thermal breakdown can degrade the fluid's performance, altering its viscosity and lubricating properties. This degradation can lead to increased wear on steering components and a gradual change in steering feel over the vehicle's lifetime.

Aeration and cavitation are additional concerns in power steering systems. Entrained air or vapor bubbles can form within the fluid, especially under high-speed or high-load conditions. These phenomena can cause erratic steering behavior and reduce the system's overall efficiency, impacting the driver's perception of steering feedback.

The compatibility of power steering fluid with various materials used in the steering system poses another challenge. Seals, hoses, and other components must withstand prolonged exposure to the fluid without degradation. Incompatibility can lead to leaks, component failure, and contamination of the fluid itself, all of which can adversely affect steering performance and feedback.

Fluid foaming is yet another property-related issue that can impact steering feedback. Excessive foaming can lead to a spongy feel in the steering wheel and reduced system efficiency. Balancing the fluid's anti-foaming properties with its other required characteristics presents a complex engineering challenge.

Lastly, the environmental impact and sustainability of power steering fluids are becoming increasingly important considerations. Developing fluids that maintain optimal steering feedback while meeting stringent environmental regulations and sustainability goals adds another layer of complexity to fluid property management.

Current Fluid Solutions

01 Fluid composition for power steering systems

Specialized fluid compositions are developed for power steering systems to enhance steering feedback and overall performance. These fluids are designed to maintain proper viscosity, reduce friction, and improve the responsiveness of the steering system. They may include additives to prevent wear, reduce noise, and maintain system integrity under various operating conditions.- Fluid composition for power steering systems: Specialized fluid compositions are developed for power steering systems to enhance steering feedback and overall performance. These fluids often include additives to improve lubrication, reduce wear, and maintain viscosity under various operating conditions. The composition of the fluid plays a crucial role in transmitting steering forces and providing smooth operation.

- Hydraulic control systems for power steering: Advanced hydraulic control systems are designed to optimize power steering performance and feedback. These systems may include pressure regulators, flow control valves, and sensors to adjust fluid pressure and flow based on driving conditions. The precise control of hydraulic fluid contributes to improved steering feel and responsiveness.

- Electric power steering with fluid feedback: Electric power steering systems incorporating fluid-based feedback mechanisms are developed to provide a more natural steering feel. These hybrid systems combine the efficiency of electric motors with the tactile feedback of hydraulic systems, using fluid pressure sensors and control algorithms to simulate traditional hydraulic steering characteristics.

- Steering column design for improved feedback: Innovative steering column designs are created to enhance the transmission of road feel and steering feedback to the driver. These designs may incorporate specialized bearings, dampers, or fluid-filled chambers to filter unwanted vibrations while preserving important tactile information from the road surface.

- Adaptive steering systems with fluid-based feedback: Advanced adaptive steering systems are developed to adjust steering feedback based on driving conditions and driver preferences. These systems may use a combination of fluid pressure modulation, electronic controls, and mechanical components to provide variable steering assistance and feedback, enhancing both comfort and control.

02 Hydraulic control systems for power steering

Advanced hydraulic control systems are implemented in power steering to optimize steering feedback. These systems may include pressure-sensitive valves, flow control mechanisms, and hydraulic circuits designed to modulate fluid pressure and flow based on steering input and vehicle conditions. This results in improved steering feel and responsiveness across different driving scenarios.Expand Specific Solutions03 Electronic control units for power steering feedback

Electronic control units (ECUs) are integrated into power steering systems to enhance steering feedback. These units process data from various sensors to adjust steering assistance and feedback in real-time. They can modify the hydraulic or electric power steering characteristics based on vehicle speed, road conditions, and driver input, providing a more natural and responsive steering feel.Expand Specific Solutions04 Variable assist power steering systems

Variable assist power steering systems are designed to provide different levels of steering assistance and feedback based on driving conditions. These systems can adjust the amount of power steering fluid pressure or electric motor assistance to optimize steering feel at different speeds and during various maneuvers. This results in lighter steering at low speeds and firmer, more responsive steering at higher speeds.Expand Specific Solutions05 Steering column and rack design for improved feedback

Innovations in steering column and rack design contribute to enhanced steering feedback in power steering systems. These may include optimized geometry of steering components, improved seals and bushings, and advanced materials that reduce friction and play in the system. Such designs aim to provide a more direct and communicative connection between the steering wheel and the road, even with power assistance.Expand Specific Solutions

Key Industry Players

The power steering fluid properties market is in a mature stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, but ongoing research focuses on improving steering feedback and performance. Key players like ThyssenKrupp Presta AG, ZF Friedrichshafen AG, and JTEKT Corporation are leading innovation in this field. These companies, along with automotive giants such as BMW, Honda, and Toyota, are investing in advanced power steering technologies to enhance driver experience and vehicle safety. The competitive landscape is characterized by a mix of specialized component manufacturers and integrated automotive suppliers, with a growing emphasis on electronic power steering systems and their integration with autonomous driving technologies.

thyssenkrupp AG

Technical Solution: ThyssenKrupp has developed an advanced power steering fluid with optimized viscosity and compressibility characteristics. Their fluid maintains consistent performance across a wide temperature range, ensuring smooth steering feedback in various driving conditions. The company has implemented a proprietary additive package that enhances the fluid's anti-wear properties and reduces friction between moving parts[1]. This results in improved steering responsiveness and reduced power consumption. ThyssenKrupp's fluid also incorporates advanced seal-conditioning agents to prolong the life of steering system components[2].

Strengths: Consistent performance across temperature ranges, improved steering responsiveness, reduced power consumption. Weaknesses: Potentially higher cost due to proprietary additives, may require specific maintenance schedules.

Danfoss Power Solutions Ltd.

Technical Solution: Danfoss has engineered a high-performance power steering fluid that focuses on optimizing the balance between viscosity and compressibility. Their fluid utilizes advanced polymer technology to maintain optimal viscosity under high shear conditions, ensuring consistent steering feedback even during rapid steering maneuvers[3]. The company has also incorporated nano-scale friction modifiers that significantly reduce internal friction within the steering system, leading to enhanced steering precision and reduced energy losses[4]. Danfoss' fluid formulation includes advanced anti-foaming agents to prevent cavitation and maintain system efficiency.

Strengths: Excellent performance under high shear conditions, enhanced steering precision, reduced energy losses. Weaknesses: May be more sensitive to contamination, potentially higher cost due to advanced formulation.

Innovative Fluid Designs

POWER STEERING FLUID AND PROCESS FOR PRODUCING A POWER STEERING FLUID

PatentInactiveBRPI0813418A2

Innovation

- A power steering fluid comprising greater than 50 weight % base oil with consecutive numbers of carbon atoms and a viscosity index improver, blended to achieve a viscosity index of greater than 290 and a Brookfield Viscosity at -40°C of less than 1900 mPa.s, utilizing Fischer-Tropsch derived base oils with high cycloparaffinic functionality and a specific hydroisomerization process.

Power steering system for vehicles

PatentWO1991006462A1

Innovation

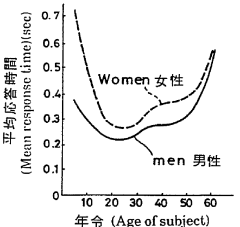

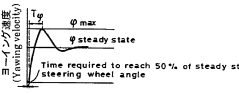

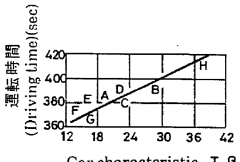

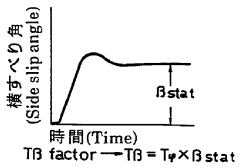

- The implementation of a pressure oil setting valve in the hydraulic piping upstream of the directional control valve, which injects compensatory pressure oil during steering wheel engagement and retraction, and a reaction force regulating valve that adjusts steering force based on vehicle speed, reduces phase lag without increasing gain, enhancing steering response and compensating for driver physiological differences.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and use of power steering fluids, influencing their properties and, consequently, steering feedback. As governments worldwide increasingly focus on environmental protection and sustainability, the automotive industry faces stringent regulations that impact the composition and performance of power steering fluids.

One of the primary environmental concerns regarding power steering fluids is their potential for toxicity and environmental contamination. Traditional mineral oil-based fluids can pose significant risks if leaked or improperly disposed of. In response, many countries have implemented regulations that mandate the use of biodegradable and less toxic alternatives. These regulations have led to the development of synthetic and bio-based power steering fluids that offer improved environmental profiles while maintaining performance characteristics.

The European Union's End-of-Life Vehicles (ELV) Directive is a prime example of environmental regulation impacting power steering fluid properties. This directive aims to reduce the environmental impact of vehicles at the end of their lifecycle by promoting recyclability and limiting the use of hazardous substances. As a result, power steering fluid manufacturers have had to reformulate their products to comply with these regulations, often leading to changes in viscosity, thermal stability, and other properties that can affect steering feedback.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal of power steering fluids, classifying them as used oil. These regulations have encouraged the development of power steering fluids with longer service life and improved stability, reducing the frequency of fluid changes and the associated environmental impact. However, these changes in fluid properties can also influence steering system performance and feedback.

The push for increased fuel efficiency and reduced emissions has indirectly affected power steering fluid properties. As automotive manufacturers strive to meet stringent fuel economy standards, there is a growing trend towards electric power steering systems. While these systems eliminate the need for traditional hydraulic power steering fluids, they introduce new challenges in terms of feedback and feel, prompting research into alternative fluids and lubricants that can enhance the performance of electric systems while meeting environmental standards.

Global efforts to reduce greenhouse gas emissions have also led to the exploration of low-viscosity power steering fluids. These fluids can contribute to improved fuel efficiency by reducing parasitic losses in the steering system. However, the change in viscosity can significantly impact steering feedback, requiring careful balancing between environmental compliance and performance characteristics.

As environmental regulations continue to evolve, the power steering fluid industry must adapt, driving innovation in fluid formulations and steering system designs. This ongoing process of regulatory compliance and technological advancement will continue to shape the relationship between power steering fluid properties and steering feedback, challenging engineers to develop solutions that meet both environmental and performance requirements.

One of the primary environmental concerns regarding power steering fluids is their potential for toxicity and environmental contamination. Traditional mineral oil-based fluids can pose significant risks if leaked or improperly disposed of. In response, many countries have implemented regulations that mandate the use of biodegradable and less toxic alternatives. These regulations have led to the development of synthetic and bio-based power steering fluids that offer improved environmental profiles while maintaining performance characteristics.

The European Union's End-of-Life Vehicles (ELV) Directive is a prime example of environmental regulation impacting power steering fluid properties. This directive aims to reduce the environmental impact of vehicles at the end of their lifecycle by promoting recyclability and limiting the use of hazardous substances. As a result, power steering fluid manufacturers have had to reformulate their products to comply with these regulations, often leading to changes in viscosity, thermal stability, and other properties that can affect steering feedback.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal of power steering fluids, classifying them as used oil. These regulations have encouraged the development of power steering fluids with longer service life and improved stability, reducing the frequency of fluid changes and the associated environmental impact. However, these changes in fluid properties can also influence steering system performance and feedback.

The push for increased fuel efficiency and reduced emissions has indirectly affected power steering fluid properties. As automotive manufacturers strive to meet stringent fuel economy standards, there is a growing trend towards electric power steering systems. While these systems eliminate the need for traditional hydraulic power steering fluids, they introduce new challenges in terms of feedback and feel, prompting research into alternative fluids and lubricants that can enhance the performance of electric systems while meeting environmental standards.

Global efforts to reduce greenhouse gas emissions have also led to the exploration of low-viscosity power steering fluids. These fluids can contribute to improved fuel efficiency by reducing parasitic losses in the steering system. However, the change in viscosity can significantly impact steering feedback, requiring careful balancing between environmental compliance and performance characteristics.

As environmental regulations continue to evolve, the power steering fluid industry must adapt, driving innovation in fluid formulations and steering system designs. This ongoing process of regulatory compliance and technological advancement will continue to shape the relationship between power steering fluid properties and steering feedback, challenging engineers to develop solutions that meet both environmental and performance requirements.

Safety Considerations

Safety considerations are paramount when evaluating the influence of power steering fluid properties on steering feedback. The viscosity and compressibility of the fluid directly impact the responsiveness and consistency of the steering system, which in turn affects vehicle control and driver safety. Proper fluid properties ensure smooth power transmission and reduce the risk of sudden steering failures or inconsistencies that could lead to accidents.

One critical safety aspect is the fluid's ability to maintain consistent performance across a wide range of temperatures. Power steering systems can experience significant temperature fluctuations during operation, and the fluid must retain its properties to ensure reliable steering feedback. Fluids with poor temperature stability may become too thin at high temperatures, leading to reduced steering assistance, or too thick at low temperatures, causing sluggish response and increased driver effort.

The fluid's resistance to foaming is another crucial safety factor. Foaming can occur due to air entrainment or fluid degradation, resulting in spongy steering feel and reduced system efficiency. This compromises the driver's ability to accurately gauge road conditions and vehicle response, potentially leading to unsafe driving situations, especially during emergency maneuvers or high-speed cornering.

Corrosion protection provided by power steering fluid is essential for long-term system integrity. Corrosive fluids can damage internal components, leading to premature wear, leaks, or catastrophic failures. Such issues may manifest as sudden loss of power assistance or steering lock-up, posing severe safety risks, particularly at higher speeds or in challenging driving conditions.

The fluid's compatibility with system seals and hoses is also a critical safety consideration. Incompatible fluids can cause seal degradation, leading to leaks and potential system failures. Gradual fluid loss may result in inconsistent steering feedback, while sudden loss can lead to complete steering assistance failure, requiring significantly increased driver effort to control the vehicle.

Moreover, the fluid's ability to lubricate and cool system components affects long-term reliability and safety. Inadequate lubrication can accelerate wear on pumps, valves, and other moving parts, potentially leading to sudden failures. Proper heat dissipation prevents overheating, which can cause fluid breakdown and subsequent loss of steering assistance.

Lastly, the environmental impact of power steering fluid must be considered from a safety perspective. Biodegradable fluids reduce the risk of environmental contamination in case of leaks or spills, which is particularly important for vehicles operating in sensitive ecosystems or urban areas where fluid leaks could create hazardous conditions for other road users.

One critical safety aspect is the fluid's ability to maintain consistent performance across a wide range of temperatures. Power steering systems can experience significant temperature fluctuations during operation, and the fluid must retain its properties to ensure reliable steering feedback. Fluids with poor temperature stability may become too thin at high temperatures, leading to reduced steering assistance, or too thick at low temperatures, causing sluggish response and increased driver effort.

The fluid's resistance to foaming is another crucial safety factor. Foaming can occur due to air entrainment or fluid degradation, resulting in spongy steering feel and reduced system efficiency. This compromises the driver's ability to accurately gauge road conditions and vehicle response, potentially leading to unsafe driving situations, especially during emergency maneuvers or high-speed cornering.

Corrosion protection provided by power steering fluid is essential for long-term system integrity. Corrosive fluids can damage internal components, leading to premature wear, leaks, or catastrophic failures. Such issues may manifest as sudden loss of power assistance or steering lock-up, posing severe safety risks, particularly at higher speeds or in challenging driving conditions.

The fluid's compatibility with system seals and hoses is also a critical safety consideration. Incompatible fluids can cause seal degradation, leading to leaks and potential system failures. Gradual fluid loss may result in inconsistent steering feedback, while sudden loss can lead to complete steering assistance failure, requiring significantly increased driver effort to control the vehicle.

Moreover, the fluid's ability to lubricate and cool system components affects long-term reliability and safety. Inadequate lubrication can accelerate wear on pumps, valves, and other moving parts, potentially leading to sudden failures. Proper heat dissipation prevents overheating, which can cause fluid breakdown and subsequent loss of steering assistance.

Lastly, the environmental impact of power steering fluid must be considered from a safety perspective. Biodegradable fluids reduce the risk of environmental contamination in case of leaks or spills, which is particularly important for vehicles operating in sensitive ecosystems or urban areas where fluid leaks could create hazardous conditions for other road users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!