The Effects of Moisture Ingress on Power Steering Fluid Systems

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Challenges

Power steering fluid systems face several significant challenges that impact their performance, reliability, and longevity. One of the most critical issues is moisture ingress, which can lead to a cascade of problems within the system. Water contamination in power steering fluid can cause corrosion of metal components, degradation of seals and hoses, and reduced lubrication properties. These effects can result in increased wear on pump components, steering gear, and other critical parts of the system.

The hygroscopic nature of power steering fluid makes it particularly susceptible to moisture absorption from the atmosphere. Even small amounts of water can significantly alter the fluid's properties, leading to decreased performance and potential system failure. As moisture content increases, the fluid's ability to protect against corrosion diminishes, potentially causing pitting and erosion of metal surfaces within the power steering system.

Another challenge related to moisture ingress is the formation of sludge and deposits. When water mixes with power steering fluid, it can create a milky appearance and lead to the formation of emulsions. These emulsions can clog small passages and valves within the system, reducing fluid flow and compromising steering responsiveness. Over time, this can result in increased steering effort, inconsistent performance, and premature wear of components.

Temperature fluctuations exacerbate the moisture-related challenges in power steering systems. During cold weather, water in the fluid can freeze, potentially causing damage to seals and components. Conversely, high temperatures can cause water to vaporize, leading to cavitation in the pump and erratic steering behavior. These temperature-induced issues highlight the importance of maintaining proper fluid composition and minimizing moisture contamination.

The presence of moisture also accelerates the oxidation of power steering fluid, leading to a breakdown of its chemical structure. This degradation can result in the formation of acids, which further contribute to corrosion and the deterioration of system components. As the fluid breaks down, its viscosity may change, affecting its ability to provide consistent hydraulic pressure and smooth steering operation.

Addressing these challenges requires a multifaceted approach, including improved sealing technologies, advanced fluid formulations, and enhanced maintenance practices. Developing power steering fluids with better hygroscopic stability and corrosion inhibitors is crucial. Additionally, implementing more effective moisture barriers and designing systems that minimize exposure to atmospheric conditions can help mitigate the risks associated with moisture ingress.

The hygroscopic nature of power steering fluid makes it particularly susceptible to moisture absorption from the atmosphere. Even small amounts of water can significantly alter the fluid's properties, leading to decreased performance and potential system failure. As moisture content increases, the fluid's ability to protect against corrosion diminishes, potentially causing pitting and erosion of metal surfaces within the power steering system.

Another challenge related to moisture ingress is the formation of sludge and deposits. When water mixes with power steering fluid, it can create a milky appearance and lead to the formation of emulsions. These emulsions can clog small passages and valves within the system, reducing fluid flow and compromising steering responsiveness. Over time, this can result in increased steering effort, inconsistent performance, and premature wear of components.

Temperature fluctuations exacerbate the moisture-related challenges in power steering systems. During cold weather, water in the fluid can freeze, potentially causing damage to seals and components. Conversely, high temperatures can cause water to vaporize, leading to cavitation in the pump and erratic steering behavior. These temperature-induced issues highlight the importance of maintaining proper fluid composition and minimizing moisture contamination.

The presence of moisture also accelerates the oxidation of power steering fluid, leading to a breakdown of its chemical structure. This degradation can result in the formation of acids, which further contribute to corrosion and the deterioration of system components. As the fluid breaks down, its viscosity may change, affecting its ability to provide consistent hydraulic pressure and smooth steering operation.

Addressing these challenges requires a multifaceted approach, including improved sealing technologies, advanced fluid formulations, and enhanced maintenance practices. Developing power steering fluids with better hygroscopic stability and corrosion inhibitors is crucial. Additionally, implementing more effective moisture barriers and designing systems that minimize exposure to atmospheric conditions can help mitigate the risks associated with moisture ingress.

Market Analysis for Moisture-Resistant Systems

The market for moisture-resistant power steering fluid systems has been experiencing significant growth in recent years, driven by increasing awareness of the detrimental effects of moisture ingress on vehicle performance and safety. The global automotive power steering market, which includes these systems, is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) of over 5% during the forecast period.

The demand for moisture-resistant systems is particularly strong in regions with high humidity levels or extreme weather conditions, such as Southeast Asia, coastal areas of North America, and parts of Europe. These areas have seen a surge in the adoption of advanced power steering fluid systems that can withstand moisture-related challenges, leading to improved vehicle longevity and reduced maintenance costs.

In the passenger vehicle segment, luxury and high-performance car manufacturers have been at the forefront of implementing moisture-resistant power steering fluid systems. This trend is gradually trickling down to mid-range and economy vehicles as consumers become more aware of the long-term benefits of these systems. The commercial vehicle sector, including heavy-duty trucks and buses, has also shown increased interest in moisture-resistant solutions due to the critical nature of their operations and the high cost of downtime.

The aftermarket for moisture-resistant power steering fluid systems has seen substantial growth as well. Vehicle owners are increasingly opting for upgrades or replacements that offer better protection against moisture ingress, especially in older vehicles that may be more susceptible to such issues. This has created new opportunities for automotive component manufacturers and service providers specializing in power steering system maintenance and upgrades.

Key market players in this sector include established automotive parts manufacturers, as well as specialized fluid system companies. These firms are investing heavily in research and development to create more effective moisture-resistant technologies, such as advanced sealing materials, improved fluid formulations, and innovative system designs that minimize the risk of moisture ingress.

The market analysis also reveals a growing trend towards the integration of moisture-resistant features with other advanced technologies in power steering systems, such as electric power steering (EPS) and steer-by-wire systems. This convergence is expected to drive further innovation and market growth in the coming years, as vehicle manufacturers seek to offer more reliable, efficient, and technologically advanced steering solutions to their customers.

The demand for moisture-resistant systems is particularly strong in regions with high humidity levels or extreme weather conditions, such as Southeast Asia, coastal areas of North America, and parts of Europe. These areas have seen a surge in the adoption of advanced power steering fluid systems that can withstand moisture-related challenges, leading to improved vehicle longevity and reduced maintenance costs.

In the passenger vehicle segment, luxury and high-performance car manufacturers have been at the forefront of implementing moisture-resistant power steering fluid systems. This trend is gradually trickling down to mid-range and economy vehicles as consumers become more aware of the long-term benefits of these systems. The commercial vehicle sector, including heavy-duty trucks and buses, has also shown increased interest in moisture-resistant solutions due to the critical nature of their operations and the high cost of downtime.

The aftermarket for moisture-resistant power steering fluid systems has seen substantial growth as well. Vehicle owners are increasingly opting for upgrades or replacements that offer better protection against moisture ingress, especially in older vehicles that may be more susceptible to such issues. This has created new opportunities for automotive component manufacturers and service providers specializing in power steering system maintenance and upgrades.

Key market players in this sector include established automotive parts manufacturers, as well as specialized fluid system companies. These firms are investing heavily in research and development to create more effective moisture-resistant technologies, such as advanced sealing materials, improved fluid formulations, and innovative system designs that minimize the risk of moisture ingress.

The market analysis also reveals a growing trend towards the integration of moisture-resistant features with other advanced technologies in power steering systems, such as electric power steering (EPS) and steer-by-wire systems. This convergence is expected to drive further innovation and market growth in the coming years, as vehicle manufacturers seek to offer more reliable, efficient, and technologically advanced steering solutions to their customers.

Current Moisture Ingress Issues

Moisture ingress in power steering fluid systems remains a persistent challenge in the automotive industry, affecting both vehicle performance and safety. The primary issue stems from the hygroscopic nature of power steering fluids, which tend to absorb moisture from the surrounding environment. This absorption occurs through various pathways, including microscopic gaps in seals, breather caps, and even through the reservoir itself.

One of the most significant current issues is the degradation of power steering fluid properties due to moisture contamination. As water content increases, the fluid's viscosity changes, leading to inconsistent steering performance and increased wear on system components. This degradation can result in reduced responsiveness of the steering system, particularly noticeable during low-speed maneuvers or parking.

Corrosion is another critical concern arising from moisture ingress. Water in the system can cause oxidation of metal components, including pumps, valves, and steering racks. This corrosion not only compromises the integrity of these parts but also introduces abrasive particles into the fluid, further exacerbating wear and potentially leading to system failure.

The automotive industry is also grappling with the challenge of accurately detecting and measuring moisture content in power steering systems. Current methods often rely on periodic fluid checks or maintenance schedules, which may not adequately address the dynamic nature of moisture ingress. This gap in real-time monitoring capabilities can lead to undetected moisture accumulation, potentially compromising vehicle safety and performance.

Environmental factors play a significant role in exacerbating moisture ingress issues. Vehicles operating in high-humidity climates or those frequently exposed to water (such as during car washes or in rainy conditions) are particularly susceptible. The industry is struggling to develop universal solutions that can effectively mitigate moisture ingress across diverse operating environments.

Lastly, the longevity of power steering systems is directly impacted by moisture ingress. Premature component failures, increased maintenance frequency, and reduced overall system lifespan are common consequences. This not only affects consumer satisfaction but also raises concerns about the environmental impact of more frequent part replacements and fluid changes.

Addressing these current moisture ingress issues requires a multifaceted approach, combining improved material science for better sealing, advanced fluid formulations with enhanced moisture resistance, and innovative monitoring technologies. The industry's focus is shifting towards developing holistic solutions that can effectively combat moisture ingress while maintaining the performance and reliability of power steering systems across various vehicle types and operating conditions.

One of the most significant current issues is the degradation of power steering fluid properties due to moisture contamination. As water content increases, the fluid's viscosity changes, leading to inconsistent steering performance and increased wear on system components. This degradation can result in reduced responsiveness of the steering system, particularly noticeable during low-speed maneuvers or parking.

Corrosion is another critical concern arising from moisture ingress. Water in the system can cause oxidation of metal components, including pumps, valves, and steering racks. This corrosion not only compromises the integrity of these parts but also introduces abrasive particles into the fluid, further exacerbating wear and potentially leading to system failure.

The automotive industry is also grappling with the challenge of accurately detecting and measuring moisture content in power steering systems. Current methods often rely on periodic fluid checks or maintenance schedules, which may not adequately address the dynamic nature of moisture ingress. This gap in real-time monitoring capabilities can lead to undetected moisture accumulation, potentially compromising vehicle safety and performance.

Environmental factors play a significant role in exacerbating moisture ingress issues. Vehicles operating in high-humidity climates or those frequently exposed to water (such as during car washes or in rainy conditions) are particularly susceptible. The industry is struggling to develop universal solutions that can effectively mitigate moisture ingress across diverse operating environments.

Lastly, the longevity of power steering systems is directly impacted by moisture ingress. Premature component failures, increased maintenance frequency, and reduced overall system lifespan are common consequences. This not only affects consumer satisfaction but also raises concerns about the environmental impact of more frequent part replacements and fluid changes.

Addressing these current moisture ingress issues requires a multifaceted approach, combining improved material science for better sealing, advanced fluid formulations with enhanced moisture resistance, and innovative monitoring technologies. The industry's focus is shifting towards developing holistic solutions that can effectively combat moisture ingress while maintaining the performance and reliability of power steering systems across various vehicle types and operating conditions.

Existing Moisture Prevention Solutions

01 Moisture prevention in power steering systems

Various methods are employed to prevent moisture ingress in power steering fluid systems. These include using specialized seals, designing components to minimize exposure to moisture, and implementing drainage systems to remove any accumulated water. Such measures help maintain the integrity and performance of the power steering system.- Moisture prevention in power steering systems: Various methods are employed to prevent moisture ingress in power steering fluid systems. These include using specialized seals, designing components to minimize exposure to moisture, and implementing drainage systems to remove any accumulated water. Such measures help maintain the integrity and performance of the power steering system.

- Fluid composition for moisture resistance: Specialized power steering fluid compositions are developed to resist moisture absorption and mitigate the effects of any water that does enter the system. These fluids may contain additives that repel water or prevent corrosion, ensuring the longevity and efficiency of the power steering system even in humid environments.

- Moisture detection and monitoring systems: Advanced sensors and monitoring systems are integrated into power steering systems to detect the presence of moisture. These systems can alert drivers or maintenance personnel to potential issues before they cause significant damage, allowing for timely intervention and maintenance.

- Venting and pressure regulation: Power steering systems incorporate venting mechanisms and pressure regulation devices to manage internal pressure and prevent moisture ingress. These components help equalize pressure differences that could draw in moisture and ensure proper system operation under various environmental conditions.

- Maintenance and servicing procedures: Specific maintenance and servicing procedures are developed to address moisture-related issues in power steering systems. These may include regular fluid checks and replacements, system flushing, and the use of specialized tools and techniques to remove moisture and prevent its reentry during servicing.

02 Fluid composition for moisture resistance

Specialized power steering fluid compositions are developed to resist moisture absorption and mitigate the effects of any water that does enter the system. These fluids may contain additives that repel water or prevent corrosion, ensuring the longevity and efficiency of the power steering system even in humid environments.Expand Specific Solutions03 Moisture detection and monitoring systems

Advanced sensors and monitoring systems are integrated into power steering systems to detect the presence of moisture. These systems can alert drivers or maintenance personnel to potential issues before they cause significant damage, allowing for timely intervention and maintenance.Expand Specific Solutions04 Reservoir design for moisture control

Power steering fluid reservoirs are designed with features to minimize moisture ingress and accumulation. This may include specialized venting systems, moisture-absorbing materials, or geometries that promote separation of water from the fluid. Such designs help maintain the purity of the power steering fluid over time.Expand Specific Solutions05 Maintenance and servicing for moisture management

Regular maintenance procedures are developed to address moisture-related issues in power steering systems. These may include periodic fluid changes, system flushing, and inspection of seals and components. Proper servicing helps prevent moisture-related problems and extends the life of the power steering system.Expand Specific Solutions

Key Players in Automotive Fluid Systems

The power steering fluid systems market is in a mature stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, but ongoing innovations focus on improving efficiency and addressing environmental concerns. Key players like ThyssenKrupp Presta AG, Mitsubishi Electric Corp., and Robert Bosch GmbH are at the forefront of technological advancements. These companies are investing in research to develop moisture-resistant systems and improve overall performance. The competitive landscape is characterized by a mix of established automotive suppliers and specialized steering system manufacturers, with increasing emphasis on electronic and hydraulic power steering technologies to mitigate moisture-related issues.

Showa Corp.

Technical Solution: Showa has developed innovative approaches to combat moisture ingress in power steering fluid systems. Their technology includes the use of hygroscopic materials in strategic locations within the system to absorb moisture before it can reach critical components[13]. Showa has also implemented a unique fluid circulation pattern that helps isolate any moisture that does enter the system, preventing it from spreading to sensitive areas[14]. The company's power steering fluids are formulated with water-repelling additives that create a protective barrier on internal surfaces[15].

Strengths: Innovative moisture absorption and isolation techniques. Weaknesses: May require more frequent maintenance to replace or regenerate hygroscopic materials.

Robert Bosch Automotive Steering GmbH

Technical Solution: Bosch Automotive Steering has developed specialized solutions for moisture protection in power steering fluid systems. Their technology includes advanced fluid filtration systems that can remove moisture particles as small as 3 microns[10]. The company has also implemented a thermal management system that helps prevent condensation within the fluid system by maintaining optimal operating temperatures[11]. Bosch Automotive Steering's power steering pumps are designed with specialized seals and gaskets that provide multi-layer protection against moisture ingress[12].

Strengths: Advanced filtration technology and thermal management systems. Weaknesses: May require more complex maintenance procedures due to sophisticated systems.

Innovations in Fluid System Sealing

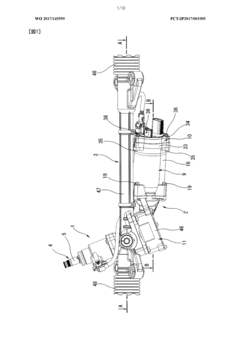

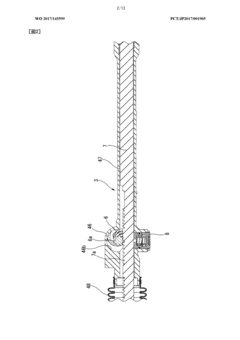

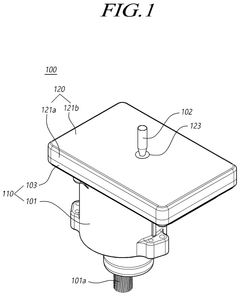

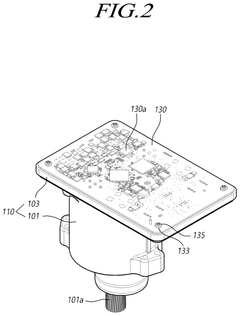

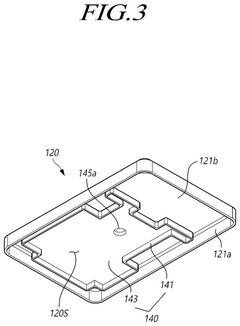

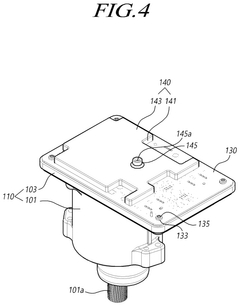

Power steering device

PatentWO2017145599A1

Innovation

- The power steering device incorporates a moisture detection sensor with electrodes extending into the motor ECU housing section, connected to the control circuit, to detect moisture intrusion early and alert the driver, with the sensor and control circuit housed internally to prevent moisture from reaching the control unit.

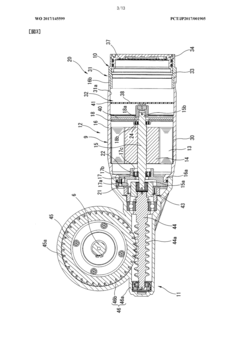

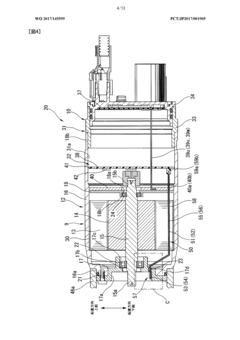

Vehicle steering device

PatentPendingUS20240351632A1

Innovation

- A vehicle steering device design featuring a power pack housing with a motor and substrate housing, where a sealing member is injected through a communication hole to fill the empty space above the printed circuit board and solidify, preventing moisture entry and ensuring the electronic control unit's reliability.

Environmental Impact of Fluid Leakage

The environmental impact of fluid leakage from power steering systems is a significant concern that extends beyond the immediate operational issues. When moisture ingress compromises the integrity of power steering fluid systems, it can lead to fluid leakage, which poses substantial environmental risks. These leaks can contaminate soil and water sources, potentially harming ecosystems and wildlife.

Power steering fluid typically contains a mixture of synthetic and mineral oils, along with various additives. When these fluids leak into the environment, they can persist for extended periods, resisting natural degradation processes. The contamination can alter soil chemistry, affecting plant growth and microbial communities essential for healthy ecosystems. In aquatic environments, even small amounts of leaked fluid can form a film on the water surface, disrupting oxygen exchange and harming aquatic life.

The potential for groundwater contamination is particularly concerning. As power steering fluid seeps into the ground, it can migrate through soil layers and eventually reach underground water reservoirs. This contamination can render water sources unsafe for human consumption and agricultural use, necessitating costly remediation efforts.

Wildlife is also at risk from fluid leakage. Animals may ingest contaminated soil or water, leading to various health issues. Birds and small mammals can become coated in the fluid, compromising their ability to regulate body temperature and potentially leading to hypothermia or other health complications.

From an atmospheric perspective, the volatile organic compounds (VOCs) present in power steering fluids can contribute to air pollution when exposed to the environment. These compounds can participate in photochemical reactions, potentially contributing to smog formation and exacerbating air quality issues in urban areas.

The cumulative effect of widespread fluid leakage from numerous vehicles can significantly impact local ecosystems and contribute to broader environmental degradation. This underscores the importance of proper maintenance, early detection of moisture ingress, and prompt repair of power steering systems to prevent leaks. Additionally, it highlights the need for environmentally friendly fluid formulations and improved containment systems in vehicle design to mitigate the potential environmental impact of leaks when they do occur.

Power steering fluid typically contains a mixture of synthetic and mineral oils, along with various additives. When these fluids leak into the environment, they can persist for extended periods, resisting natural degradation processes. The contamination can alter soil chemistry, affecting plant growth and microbial communities essential for healthy ecosystems. In aquatic environments, even small amounts of leaked fluid can form a film on the water surface, disrupting oxygen exchange and harming aquatic life.

The potential for groundwater contamination is particularly concerning. As power steering fluid seeps into the ground, it can migrate through soil layers and eventually reach underground water reservoirs. This contamination can render water sources unsafe for human consumption and agricultural use, necessitating costly remediation efforts.

Wildlife is also at risk from fluid leakage. Animals may ingest contaminated soil or water, leading to various health issues. Birds and small mammals can become coated in the fluid, compromising their ability to regulate body temperature and potentially leading to hypothermia or other health complications.

From an atmospheric perspective, the volatile organic compounds (VOCs) present in power steering fluids can contribute to air pollution when exposed to the environment. These compounds can participate in photochemical reactions, potentially contributing to smog formation and exacerbating air quality issues in urban areas.

The cumulative effect of widespread fluid leakage from numerous vehicles can significantly impact local ecosystems and contribute to broader environmental degradation. This underscores the importance of proper maintenance, early detection of moisture ingress, and prompt repair of power steering systems to prevent leaks. Additionally, it highlights the need for environmentally friendly fluid formulations and improved containment systems in vehicle design to mitigate the potential environmental impact of leaks when they do occur.

Safety Regulations for Steering Systems

Safety regulations for steering systems play a crucial role in ensuring the reliability and performance of power steering fluid systems, particularly in the context of moisture ingress. These regulations are designed to protect vehicle occupants and other road users by maintaining the integrity of steering components under various environmental conditions.

In many jurisdictions, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe have established stringent standards for steering system safety. These standards often include specific requirements related to the resistance of power steering fluid systems to moisture ingress and its potential effects.

One key aspect of these regulations is the requirement for manufacturers to conduct rigorous testing of power steering fluid systems under simulated moisture exposure conditions. This typically involves subjecting the system to accelerated aging tests, where it is exposed to high humidity environments for extended periods. The system must demonstrate its ability to maintain proper functionality and safety performance throughout these tests.

Additionally, safety regulations often mandate the use of moisture-resistant materials and sealing technologies in the construction of power steering fluid systems. This includes specifications for the quality and composition of seals, gaskets, and other components that come into contact with the power steering fluid. Manufacturers are required to use materials that can withstand prolonged exposure to moisture without degradation or compromise of their sealing properties.

Furthermore, regulations may specify requirements for the power steering fluid itself. This can include standards for the fluid's hygroscopic properties, its ability to maintain viscosity and lubrication characteristics in the presence of moisture, and its resistance to oxidation and breakdown when exposed to water. Manufacturers must ensure that the fluid used in their systems meets these regulatory standards to maintain compliance.

Safety regulations also often address the design of power steering fluid reservoirs and associated components. These may include requirements for proper venting to prevent moisture accumulation, as well as specifications for the placement and protection of fluid lines to minimize the risk of moisture ingress due to environmental factors or road spray.

In addition to component-specific regulations, there are often broader safety standards that indirectly impact the design and performance of power steering fluid systems. These may include requirements for overall vehicle stability, steering responsiveness, and fail-safe mechanisms in the event of system failure. Manufacturers must demonstrate that their power steering systems, including the fluid components, can meet these broader safety criteria even under adverse conditions such as moisture ingress.

In many jurisdictions, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe have established stringent standards for steering system safety. These standards often include specific requirements related to the resistance of power steering fluid systems to moisture ingress and its potential effects.

One key aspect of these regulations is the requirement for manufacturers to conduct rigorous testing of power steering fluid systems under simulated moisture exposure conditions. This typically involves subjecting the system to accelerated aging tests, where it is exposed to high humidity environments for extended periods. The system must demonstrate its ability to maintain proper functionality and safety performance throughout these tests.

Additionally, safety regulations often mandate the use of moisture-resistant materials and sealing technologies in the construction of power steering fluid systems. This includes specifications for the quality and composition of seals, gaskets, and other components that come into contact with the power steering fluid. Manufacturers are required to use materials that can withstand prolonged exposure to moisture without degradation or compromise of their sealing properties.

Furthermore, regulations may specify requirements for the power steering fluid itself. This can include standards for the fluid's hygroscopic properties, its ability to maintain viscosity and lubrication characteristics in the presence of moisture, and its resistance to oxidation and breakdown when exposed to water. Manufacturers must ensure that the fluid used in their systems meets these regulatory standards to maintain compliance.

Safety regulations also often address the design of power steering fluid reservoirs and associated components. These may include requirements for proper venting to prevent moisture accumulation, as well as specifications for the placement and protection of fluid lines to minimize the risk of moisture ingress due to environmental factors or road spray.

In addition to component-specific regulations, there are often broader safety standards that indirectly impact the design and performance of power steering fluid systems. These may include requirements for overall vehicle stability, steering responsiveness, and fail-safe mechanisms in the event of system failure. Manufacturers must demonstrate that their power steering systems, including the fluid components, can meet these broader safety criteria even under adverse conditions such as moisture ingress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!