Investigating the Environmental Impact of Power Steering Fluid Disposal

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Background and Objectives

Power steering fluid has been an integral component of automotive systems since the mid-20th century, facilitating easier vehicle maneuvering and control. This hydraulic fluid, typically composed of mineral oil or synthetic compounds, transmits power in the steering system, reducing the effort required to turn the steering wheel. As automotive technology has evolved, so too has the composition and application of power steering fluid, with modern formulations designed to enhance performance and longevity.

The development of power steering systems has been driven by the need for improved vehicle handling, especially in larger vehicles. Over time, the focus has shifted towards creating more efficient and environmentally friendly solutions. This evolution has led to the introduction of electric power steering systems in many modern vehicles, which do not require traditional hydraulic fluid. However, a significant number of vehicles on the road still utilize hydraulic power steering systems, necessitating ongoing attention to the environmental impact of power steering fluid disposal.

The primary objective of investigating the environmental impact of power steering fluid disposal is to address the potential hazards associated with improper handling and disposal of this automotive waste. Power steering fluid, like many petroleum-based products, can have detrimental effects on soil, water systems, and wildlife if released into the environment. The investigation aims to quantify these impacts, identify current disposal practices, and explore more sustainable alternatives.

Furthermore, this research seeks to align with broader environmental protection goals and regulatory frameworks. As global awareness of environmental issues increases, there is growing pressure on the automotive industry to adopt more sustainable practices throughout the vehicle lifecycle, including maintenance and end-of-life disposal. Understanding the environmental implications of power steering fluid disposal is crucial for developing effective mitigation strategies and informing policy decisions.

The investigation also aims to explore the potential for recycling and reprocessing power steering fluid. This aspect of the research is particularly relevant given the increasing emphasis on circular economy principles in the automotive sector. By examining the feasibility of recycling power steering fluid, the study could potentially identify new opportunities for resource conservation and waste reduction.

Ultimately, the goal is to provide a comprehensive understanding of the environmental challenges posed by power steering fluid disposal and to pave the way for more sustainable practices in the automotive industry. This research is expected to contribute valuable insights that could influence future automotive design, maintenance procedures, and waste management strategies, thereby reducing the environmental footprint of vehicle operation and maintenance.

The development of power steering systems has been driven by the need for improved vehicle handling, especially in larger vehicles. Over time, the focus has shifted towards creating more efficient and environmentally friendly solutions. This evolution has led to the introduction of electric power steering systems in many modern vehicles, which do not require traditional hydraulic fluid. However, a significant number of vehicles on the road still utilize hydraulic power steering systems, necessitating ongoing attention to the environmental impact of power steering fluid disposal.

The primary objective of investigating the environmental impact of power steering fluid disposal is to address the potential hazards associated with improper handling and disposal of this automotive waste. Power steering fluid, like many petroleum-based products, can have detrimental effects on soil, water systems, and wildlife if released into the environment. The investigation aims to quantify these impacts, identify current disposal practices, and explore more sustainable alternatives.

Furthermore, this research seeks to align with broader environmental protection goals and regulatory frameworks. As global awareness of environmental issues increases, there is growing pressure on the automotive industry to adopt more sustainable practices throughout the vehicle lifecycle, including maintenance and end-of-life disposal. Understanding the environmental implications of power steering fluid disposal is crucial for developing effective mitigation strategies and informing policy decisions.

The investigation also aims to explore the potential for recycling and reprocessing power steering fluid. This aspect of the research is particularly relevant given the increasing emphasis on circular economy principles in the automotive sector. By examining the feasibility of recycling power steering fluid, the study could potentially identify new opportunities for resource conservation and waste reduction.

Ultimately, the goal is to provide a comprehensive understanding of the environmental challenges posed by power steering fluid disposal and to pave the way for more sustainable practices in the automotive industry. This research is expected to contribute valuable insights that could influence future automotive design, maintenance procedures, and waste management strategies, thereby reducing the environmental footprint of vehicle operation and maintenance.

Market Analysis of Power Steering Fluid Usage

The power steering fluid market has experienced steady growth in recent years, driven by the increasing global automotive production and the rising demand for vehicles with power steering systems. The market size for power steering fluid is estimated to be in the range of several billion dollars annually, with a compound annual growth rate (CAGR) of around 3-4% over the past five years.

The demand for power steering fluid is closely tied to the automotive industry's performance, particularly in the passenger vehicle segment. As more countries implement stricter safety regulations and consumer preferences shift towards vehicles with enhanced driving comfort, the adoption of power steering systems has become nearly universal in modern automobiles. This trend has directly contributed to the sustained demand for power steering fluid.

Geographically, the market for power steering fluid is segmented into North America, Europe, Asia-Pacific, and the rest of the world. Asia-Pacific, led by China and India, has emerged as the fastest-growing region due to rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe, while mature markets, continue to maintain a significant share due to their large existing vehicle fleets and robust aftermarket sectors.

The power steering fluid market is characterized by a mix of established automotive fluid manufacturers and regional players. Major companies in this space include ExxonMobil, Shell, Chevron, Total, and Valvoline, among others. These companies compete based on product quality, brand recognition, distribution networks, and pricing strategies.

In recent years, there has been a growing emphasis on environmentally friendly and long-lasting power steering fluids. This shift is driven by increasing environmental concerns and the need for extended maintenance intervals. Synthetic power steering fluids, which offer improved performance and longevity compared to conventional mineral-based fluids, have been gaining market share.

The aftermarket segment plays a crucial role in the power steering fluid market, as regular fluid changes are essential for maintaining the performance and longevity of power steering systems. The do-it-yourself (DIY) market for power steering fluid replacement has also been growing, particularly in developed economies where consumers are increasingly comfortable with basic vehicle maintenance tasks.

Looking ahead, the power steering fluid market is expected to face challenges from the growing adoption of electric power steering systems, which do not require traditional hydraulic fluids. However, the large existing fleet of vehicles with hydraulic power steering systems will continue to support demand for power steering fluid in the foreseeable future, particularly in the aftermarket segment.

The demand for power steering fluid is closely tied to the automotive industry's performance, particularly in the passenger vehicle segment. As more countries implement stricter safety regulations and consumer preferences shift towards vehicles with enhanced driving comfort, the adoption of power steering systems has become nearly universal in modern automobiles. This trend has directly contributed to the sustained demand for power steering fluid.

Geographically, the market for power steering fluid is segmented into North America, Europe, Asia-Pacific, and the rest of the world. Asia-Pacific, led by China and India, has emerged as the fastest-growing region due to rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe, while mature markets, continue to maintain a significant share due to their large existing vehicle fleets and robust aftermarket sectors.

The power steering fluid market is characterized by a mix of established automotive fluid manufacturers and regional players. Major companies in this space include ExxonMobil, Shell, Chevron, Total, and Valvoline, among others. These companies compete based on product quality, brand recognition, distribution networks, and pricing strategies.

In recent years, there has been a growing emphasis on environmentally friendly and long-lasting power steering fluids. This shift is driven by increasing environmental concerns and the need for extended maintenance intervals. Synthetic power steering fluids, which offer improved performance and longevity compared to conventional mineral-based fluids, have been gaining market share.

The aftermarket segment plays a crucial role in the power steering fluid market, as regular fluid changes are essential for maintaining the performance and longevity of power steering systems. The do-it-yourself (DIY) market for power steering fluid replacement has also been growing, particularly in developed economies where consumers are increasingly comfortable with basic vehicle maintenance tasks.

Looking ahead, the power steering fluid market is expected to face challenges from the growing adoption of electric power steering systems, which do not require traditional hydraulic fluids. However, the large existing fleet of vehicles with hydraulic power steering systems will continue to support demand for power steering fluid in the foreseeable future, particularly in the aftermarket segment.

Environmental Challenges in Fluid Disposal

The disposal of power steering fluid presents significant environmental challenges due to its chemical composition and potential for contamination. Power steering fluid typically contains a mixture of synthetic or mineral oils, additives, and other chemicals that can be harmful to ecosystems and human health if not properly managed.

One of the primary concerns is soil contamination. When power steering fluid is improperly disposed of or leaks into the ground, it can penetrate soil layers, altering soil chemistry and potentially rendering it unsuitable for plant growth. This contamination can persist for extended periods, affecting local flora and fauna, and potentially entering the food chain through bioaccumulation in plants and animals.

Water pollution is another critical issue associated with power steering fluid disposal. If the fluid enters water systems, it can form a film on the surface, reducing oxygen transfer and impacting aquatic life. The chemicals in the fluid can also dissolve in water, leading to widespread contamination of both surface and groundwater resources. This pollution can have far-reaching effects on drinking water supplies and aquatic ecosystems.

The improper disposal of power steering fluid can also contribute to air pollution. When incinerated or exposed to high temperatures, certain components of the fluid may release toxic fumes and particulate matter into the atmosphere. These emissions can contribute to smog formation and pose respiratory health risks to nearby populations.

Furthermore, the production and disposal of power steering fluid contribute to the depletion of non-renewable resources. Many power steering fluids are petroleum-based, and their manufacture and disposal cycle perpetuates reliance on fossil fuels, contributing to broader environmental concerns such as climate change and resource scarcity.

The challenge of proper disposal is compounded by the lack of widespread, accessible recycling facilities for automotive fluids. Many consumers and even some automotive service centers may not have convenient access to appropriate disposal methods, increasing the risk of improper disposal through general waste streams or illegal dumping.

Addressing these environmental challenges requires a multi-faceted approach. This includes developing more environmentally friendly power steering fluid formulations, improving recycling infrastructure and accessibility, enhancing public education on proper disposal methods, and implementing stricter regulations and enforcement mechanisms to prevent environmental contamination from improper disposal practices.

One of the primary concerns is soil contamination. When power steering fluid is improperly disposed of or leaks into the ground, it can penetrate soil layers, altering soil chemistry and potentially rendering it unsuitable for plant growth. This contamination can persist for extended periods, affecting local flora and fauna, and potentially entering the food chain through bioaccumulation in plants and animals.

Water pollution is another critical issue associated with power steering fluid disposal. If the fluid enters water systems, it can form a film on the surface, reducing oxygen transfer and impacting aquatic life. The chemicals in the fluid can also dissolve in water, leading to widespread contamination of both surface and groundwater resources. This pollution can have far-reaching effects on drinking water supplies and aquatic ecosystems.

The improper disposal of power steering fluid can also contribute to air pollution. When incinerated or exposed to high temperatures, certain components of the fluid may release toxic fumes and particulate matter into the atmosphere. These emissions can contribute to smog formation and pose respiratory health risks to nearby populations.

Furthermore, the production and disposal of power steering fluid contribute to the depletion of non-renewable resources. Many power steering fluids are petroleum-based, and their manufacture and disposal cycle perpetuates reliance on fossil fuels, contributing to broader environmental concerns such as climate change and resource scarcity.

The challenge of proper disposal is compounded by the lack of widespread, accessible recycling facilities for automotive fluids. Many consumers and even some automotive service centers may not have convenient access to appropriate disposal methods, increasing the risk of improper disposal through general waste streams or illegal dumping.

Addressing these environmental challenges requires a multi-faceted approach. This includes developing more environmentally friendly power steering fluid formulations, improving recycling infrastructure and accessibility, enhancing public education on proper disposal methods, and implementing stricter regulations and enforcement mechanisms to prevent environmental contamination from improper disposal practices.

Current Disposal Methods and Practices

01 Biodegradable power steering fluids

Development of environmentally friendly power steering fluids that are biodegradable and less harmful to ecosystems. These fluids are designed to break down naturally in the environment, reducing long-term pollution and ecological impact in case of leaks or spills.- Biodegradable power steering fluids: Development of environmentally friendly power steering fluids that are biodegradable and less harmful to ecosystems. These fluids are designed to break down naturally in the environment, reducing long-term pollution and ecological impact in case of leaks or spills.

- Recycling and disposal methods: Implementation of efficient recycling and disposal methods for used power steering fluids to minimize environmental contamination. This includes the development of specialized collection systems, treatment processes, and repurposing techniques to reduce waste and promote circular economy principles.

- Leak prevention and detection systems: Innovation in leak prevention and detection systems for power steering fluid reservoirs and lines. These technologies aim to minimize fluid loss and environmental contamination by quickly identifying and addressing leaks, thereby reducing the overall environmental impact of power steering systems.

- Alternative power steering technologies: Development of alternative power steering technologies that reduce or eliminate the need for traditional hydraulic fluids. This includes electric power steering systems and other innovative approaches that aim to improve energy efficiency and reduce environmental impact associated with fluid-based systems.

- Improved fluid formulations: Research and development of improved power steering fluid formulations with enhanced performance characteristics and reduced environmental impact. These formulations may include additives that extend fluid life, improve efficiency, and reduce the frequency of fluid changes, thereby minimizing waste and environmental exposure.

02 Recycling and disposal methods

Implementation of efficient recycling and disposal methods for used power steering fluids to minimize environmental contamination. This includes developing systems for collecting, treating, and repurposing used fluids, as well as establishing proper disposal protocols to prevent soil and water pollution.Expand Specific Solutions03 Leak prevention and containment

Design of improved sealing systems and containment mechanisms to prevent power steering fluid leaks. This involves developing advanced materials and engineering solutions to minimize the risk of fluid escape, reducing the potential for environmental contamination.Expand Specific Solutions04 Alternative power steering technologies

Development of alternative power steering technologies that reduce or eliminate the need for traditional hydraulic fluids. This includes electric power steering systems and other innovative approaches that minimize the use of potentially harmful fluids, thereby reducing environmental impact.Expand Specific Solutions05 Fluid life extension and maintenance

Implementation of techniques and additives to extend the life of power steering fluids, reducing the frequency of fluid changes and disposal. This includes developing improved filtration systems and maintenance practices to keep fluids in optimal condition for longer periods, minimizing waste and environmental impact.Expand Specific Solutions

Key Players in Automotive Fluid Industry

The environmental impact of power steering fluid disposal is an emerging concern in the automotive industry, currently in its early stages of development. The market for environmentally friendly disposal solutions is growing, driven by increasing regulatory pressure and consumer awareness. While the technology is still evolving, major players like Ford, Hitachi, and Bosch are investing in research and development to address this issue. The competitive landscape is characterized by a mix of established automotive manufacturers and specialized fluid management companies, with varying levels of technological maturity. As the industry progresses, we can expect to see more innovative solutions and collaborations aimed at minimizing the environmental footprint of power steering fluid disposal.

Eaton Corp.

Technical Solution: Eaton Corporation has developed an innovative power steering system that significantly reduces the environmental impact of fluid disposal. Their Electric Power Steering (EPS) technology eliminates the need for traditional hydraulic power steering fluid altogether, instead using electric motors to assist steering[7]. This approach completely eliminates the environmental concerns associated with power steering fluid disposal. For their hydraulic systems still in use, Eaton has developed a high-efficiency power steering pump that reduces fluid consumption and extends fluid life. They have also implemented a closed-loop recycling program for power steering fluid in their manufacturing and service operations, using advanced filtration and rejuvenation techniques to maximize fluid reuse[8].

Strengths: EPS technology eliminates fluid disposal issues, high-efficiency pumps reduce fluid consumption, and closed-loop recycling maximizes reuse. Weaknesses: Transition to EPS may be costly for some vehicle models, and the recycling program may have limited reach outside of Eaton's direct operations.

Robert Bosch Automotive Steering GmbH

Technical Solution: Bosch has developed a comprehensive approach to mitigate the environmental impact of power steering fluid disposal. Their strategy includes the development of advanced power steering systems that require less fluid and are more resistant to leaks and contamination. Bosch has also created a new generation of biodegradable power steering fluids that break down more easily in the environment[9]. For disposal, Bosch has implemented a centralized collection and treatment system across their service network. This system uses a multi-stage filtration and chemical treatment process to remove contaminants from used fluid, allowing for safe disposal or potential reuse in industrial applications. Bosch has also invested in research on electro-hydraulic steering systems that use significantly less fluid while maintaining high performance[10].

Strengths: Comprehensive approach from fluid formulation to disposal, wide-reaching service network for collection, and investment in future technologies. Weaknesses: Implementation across diverse global markets may be challenging, and the effectiveness of biodegradable fluids may vary in different environmental conditions.

Innovative Recycling Technologies

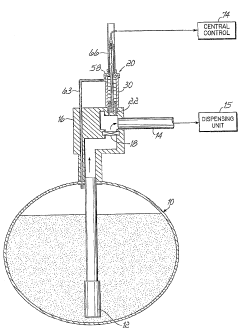

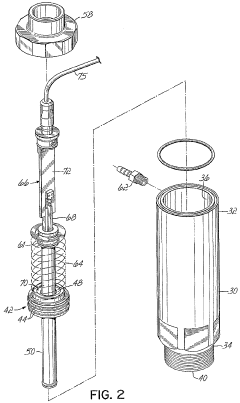

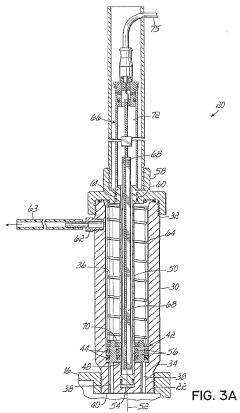

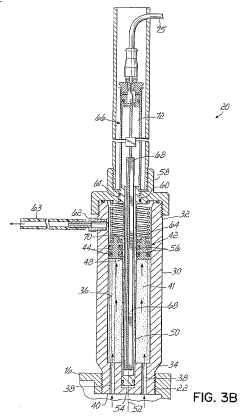

Line leak detector

PatentWO2007084909A1

Innovation

- A leak detection system using a biased piston connected to a magnetostatic waveguide with a pulsed magnetostrictive apparatus, providing thousands of positional measuring points over a short time period, allowing for precise detection of small leaks without flow rate restrictions.

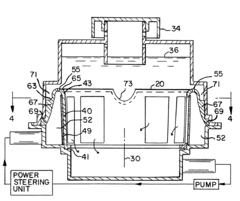

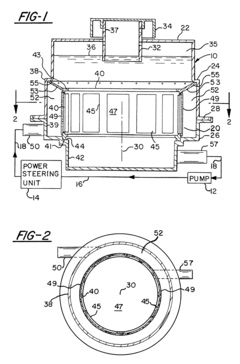

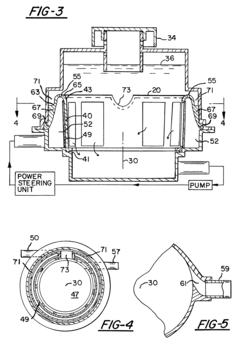

Power steering fluid reservoir

PatentInactiveUS6286545B1

Innovation

- A compact fluid reservoir with a filtration unit located in the return line, utilizing a swirling fluid motion to mix heated and cool fluid temperatures evenly, and a filtration media with 40 micron porosity to prevent cavitation and pulsations, while minimizing noise through controlled back pressure and de-aeration.

Regulatory Framework for Fluid Disposal

The regulatory framework for power steering fluid disposal is a complex and evolving landscape that varies across jurisdictions. In the United States, the Environmental Protection Agency (EPA) classifies used power steering fluid as a hazardous waste under the Resource Conservation and Recovery Act (RCRA). This classification mandates specific handling, storage, and disposal procedures to minimize environmental impact.

At the federal level, the EPA's regulations require businesses generating more than 100 kilograms of hazardous waste per month to obtain an EPA identification number and comply with strict waste management protocols. These protocols include proper labeling, secure storage, and disposal through licensed hazardous waste treatment facilities. Smaller generators may be subject to less stringent requirements but are still obligated to ensure environmentally responsible disposal.

State-level regulations often build upon federal guidelines, with some states imposing more stringent requirements. For example, California's Department of Toxic Substances Control (DTSC) has implemented additional measures for power steering fluid disposal, including mandatory recycling programs and extended producer responsibility initiatives.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including power steering fluid. Signatory countries are required to implement national legislation to control the movement and disposal of such wastes.

The European Union's Waste Framework Directive (2008/98/EC) establishes a legal framework for waste treatment in the EU, emphasizing waste prevention, reuse, and recycling. Under this directive, power steering fluid is classified as hazardous waste, subject to strict handling and disposal regulations.

Many countries have adopted extended producer responsibility (EPR) programs, which place the onus on manufacturers to manage the entire lifecycle of their products, including disposal. These programs incentivize the development of more environmentally friendly power steering systems and fluids.

Regulatory bodies are increasingly focusing on promoting circular economy principles in automotive fluid management. This approach encourages the development of closed-loop systems for power steering fluid recycling and reuse, aiming to minimize waste generation and environmental impact.

As environmental concerns grow, regulatory frameworks are likely to become more stringent, potentially leading to the phasing out of certain harmful components in power steering fluids and the promotion of alternative, more environmentally friendly technologies such as electric power steering systems.

At the federal level, the EPA's regulations require businesses generating more than 100 kilograms of hazardous waste per month to obtain an EPA identification number and comply with strict waste management protocols. These protocols include proper labeling, secure storage, and disposal through licensed hazardous waste treatment facilities. Smaller generators may be subject to less stringent requirements but are still obligated to ensure environmentally responsible disposal.

State-level regulations often build upon federal guidelines, with some states imposing more stringent requirements. For example, California's Department of Toxic Substances Control (DTSC) has implemented additional measures for power steering fluid disposal, including mandatory recycling programs and extended producer responsibility initiatives.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including power steering fluid. Signatory countries are required to implement national legislation to control the movement and disposal of such wastes.

The European Union's Waste Framework Directive (2008/98/EC) establishes a legal framework for waste treatment in the EU, emphasizing waste prevention, reuse, and recycling. Under this directive, power steering fluid is classified as hazardous waste, subject to strict handling and disposal regulations.

Many countries have adopted extended producer responsibility (EPR) programs, which place the onus on manufacturers to manage the entire lifecycle of their products, including disposal. These programs incentivize the development of more environmentally friendly power steering systems and fluids.

Regulatory bodies are increasingly focusing on promoting circular economy principles in automotive fluid management. This approach encourages the development of closed-loop systems for power steering fluid recycling and reuse, aiming to minimize waste generation and environmental impact.

As environmental concerns grow, regulatory frameworks are likely to become more stringent, potentially leading to the phasing out of certain harmful components in power steering fluids and the promotion of alternative, more environmentally friendly technologies such as electric power steering systems.

Life Cycle Assessment of Power Steering Fluids

Life Cycle Assessment (LCA) of power steering fluids is a comprehensive approach to evaluating the environmental impact of these fluids throughout their entire lifecycle, from production to disposal. This assessment typically encompasses several key stages: raw material extraction, manufacturing, distribution, use, and end-of-life management.

The production phase of power steering fluids involves the extraction and processing of raw materials, primarily petroleum-based or synthetic compounds. This stage often accounts for a significant portion of the fluid's environmental footprint due to energy-intensive extraction processes and potential environmental degradation associated with mining activities.

During the manufacturing stage, these raw materials are refined and combined to create the final product. This process may involve chemical reactions, blending, and quality control measures, all of which contribute to energy consumption and potential emissions. The environmental impact at this stage can vary depending on the manufacturing techniques employed and the energy sources used.

Distribution of power steering fluids to end-users involves transportation, which contributes to greenhouse gas emissions and fuel consumption. The extent of this impact depends on factors such as transportation distance, mode of transport, and packaging efficiency.

The use phase of power steering fluids is characterized by their performance in vehicles. While the direct environmental impact during use may be limited, factors such as fluid longevity, efficiency in reducing friction, and potential leakage can influence the overall environmental profile. Longer-lasting fluids may reduce the frequency of replacement, thereby decreasing the cumulative impact over a vehicle's lifetime.

The end-of-life stage, which includes disposal or recycling, is particularly crucial from an environmental perspective. Improper disposal of used power steering fluids can lead to soil and water contamination, posing risks to ecosystems and human health. Recycling processes, while beneficial in reducing waste, may also have associated environmental costs due to energy consumption and potential emissions during the recycling process.

A comprehensive LCA of power steering fluids would quantify the environmental impacts across these stages, typically focusing on metrics such as greenhouse gas emissions, energy consumption, water usage, and potential for ecosystem toxicity. This assessment provides valuable insights into the areas of greatest environmental concern and can guide efforts to improve the sustainability of power steering fluid production, use, and disposal.

The production phase of power steering fluids involves the extraction and processing of raw materials, primarily petroleum-based or synthetic compounds. This stage often accounts for a significant portion of the fluid's environmental footprint due to energy-intensive extraction processes and potential environmental degradation associated with mining activities.

During the manufacturing stage, these raw materials are refined and combined to create the final product. This process may involve chemical reactions, blending, and quality control measures, all of which contribute to energy consumption and potential emissions. The environmental impact at this stage can vary depending on the manufacturing techniques employed and the energy sources used.

Distribution of power steering fluids to end-users involves transportation, which contributes to greenhouse gas emissions and fuel consumption. The extent of this impact depends on factors such as transportation distance, mode of transport, and packaging efficiency.

The use phase of power steering fluids is characterized by their performance in vehicles. While the direct environmental impact during use may be limited, factors such as fluid longevity, efficiency in reducing friction, and potential leakage can influence the overall environmental profile. Longer-lasting fluids may reduce the frequency of replacement, thereby decreasing the cumulative impact over a vehicle's lifetime.

The end-of-life stage, which includes disposal or recycling, is particularly crucial from an environmental perspective. Improper disposal of used power steering fluids can lead to soil and water contamination, posing risks to ecosystems and human health. Recycling processes, while beneficial in reducing waste, may also have associated environmental costs due to energy consumption and potential emissions during the recycling process.

A comprehensive LCA of power steering fluids would quantify the environmental impacts across these stages, typically focusing on metrics such as greenhouse gas emissions, energy consumption, water usage, and potential for ecosystem toxicity. This assessment provides valuable insights into the areas of greatest environmental concern and can guide efforts to improve the sustainability of power steering fluid production, use, and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!