The Contribution of Power Steering Fluid to Vehicle Steering Smoothness

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. This limitation led to the development of hydraulic power steering systems in the 1950s, marking a revolutionary change in vehicle control and comfort.

Hydraulic power steering systems utilize a hydraulic pump, driven by the engine, to pressurize power steering fluid. This fluid is then directed through valves and cylinders to assist in turning the wheels, significantly reducing the effort required by the driver. The introduction of this technology greatly improved steering ease and control, particularly in larger vehicles and trucks.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1990s. EPS replaced the hydraulic pump with an electric motor, eliminating the need for power steering fluid altogether. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and more precise steering control. EPS systems also allowed for easier integration with advanced driver assistance features and autonomous driving technologies.

The evolution of power steering technology has not been limited to the mechanism itself but has also seen advancements in the fluids used in hydraulic systems. Modern power steering fluids have been engineered to provide better performance, longevity, and protection against wear and corrosion. These improvements have contributed significantly to the smoothness and reliability of steering systems in vehicles still utilizing hydraulic power steering.

In recent years, the automotive industry has witnessed a shift towards electric and hybrid vehicles, further accelerating the adoption of EPS systems. This trend has led to ongoing research and development in electric motor technology, control algorithms, and integration with other vehicle systems to enhance steering performance and energy efficiency.

The evolution of power steering technology reflects the broader trends in automotive engineering, focusing on improving driver comfort, safety, and vehicle efficiency. From manual systems to hydraulic assistance and now to electronic control, each step in this evolution has brought significant improvements in vehicle handling and overall driving experience. As we look to the future, the integration of artificial intelligence and advanced sensors promises to further refine power steering systems, potentially leading to fully autonomous steering capabilities in the coming decades.

Hydraulic power steering systems utilize a hydraulic pump, driven by the engine, to pressurize power steering fluid. This fluid is then directed through valves and cylinders to assist in turning the wheels, significantly reducing the effort required by the driver. The introduction of this technology greatly improved steering ease and control, particularly in larger vehicles and trucks.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1990s. EPS replaced the hydraulic pump with an electric motor, eliminating the need for power steering fluid altogether. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and more precise steering control. EPS systems also allowed for easier integration with advanced driver assistance features and autonomous driving technologies.

The evolution of power steering technology has not been limited to the mechanism itself but has also seen advancements in the fluids used in hydraulic systems. Modern power steering fluids have been engineered to provide better performance, longevity, and protection against wear and corrosion. These improvements have contributed significantly to the smoothness and reliability of steering systems in vehicles still utilizing hydraulic power steering.

In recent years, the automotive industry has witnessed a shift towards electric and hybrid vehicles, further accelerating the adoption of EPS systems. This trend has led to ongoing research and development in electric motor technology, control algorithms, and integration with other vehicle systems to enhance steering performance and energy efficiency.

The evolution of power steering technology reflects the broader trends in automotive engineering, focusing on improving driver comfort, safety, and vehicle efficiency. From manual systems to hydraulic assistance and now to electronic control, each step in this evolution has brought significant improvements in vehicle handling and overall driving experience. As we look to the future, the integration of artificial intelligence and advanced sensors promises to further refine power steering systems, potentially leading to fully autonomous steering capabilities in the coming decades.

Market Demand Analysis

The market demand for power steering fluid and its contribution to vehicle steering smoothness has been steadily increasing in recent years. This growth is primarily driven by the rising global automotive production and the increasing consumer preference for comfortable driving experiences.

Power steering fluid plays a crucial role in ensuring smooth and effortless steering in vehicles. As the automotive industry continues to evolve, there is a growing emphasis on enhancing driver comfort and safety, which has led to a surge in demand for high-quality power steering fluids. The market for power steering fluids is closely tied to the overall automotive market, which has shown resilience despite recent economic challenges.

In developed markets such as North America and Europe, the demand for power steering fluid is largely driven by the replacement market. With a large existing vehicle fleet, regular maintenance and fluid replacement contribute significantly to market growth. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in new vehicle sales, which is boosting the demand for power steering fluids in these regions.

The increasing adoption of electric power steering systems in modern vehicles has introduced a new dynamic to the market. While these systems do not require traditional hydraulic power steering fluid, they still need specialized fluids for optimal performance. This shift has led to the development of new, advanced power steering fluids designed specifically for electric and hybrid vehicles, creating a niche market segment with high growth potential.

Consumer awareness regarding the importance of regular vehicle maintenance has also contributed to market growth. As drivers become more informed about the role of power steering fluid in maintaining steering smoothness and preventing wear and tear, they are more likely to invest in regular fluid changes and high-quality products.

The commercial vehicle segment presents another significant market opportunity. With the growth of e-commerce and logistics industries, there is an increased demand for commercial vehicles, which typically require more frequent power steering fluid replacements due to higher usage and wear.

Environmental concerns and regulatory pressures are shaping the market as well. There is a growing demand for eco-friendly, biodegradable power steering fluids that offer the same level of performance while reducing environmental impact. This trend is expected to drive innovation in fluid formulations and create new market opportunities for manufacturers who can meet these evolving requirements.

Overall, the market for power steering fluid is expected to continue its growth trajectory, driven by factors such as increasing vehicle production, growing awareness of maintenance needs, and technological advancements in both vehicle systems and fluid formulations. The industry's ability to adapt to changing vehicle technologies and environmental regulations will be crucial in sustaining this growth and meeting evolving market demands.

Power steering fluid plays a crucial role in ensuring smooth and effortless steering in vehicles. As the automotive industry continues to evolve, there is a growing emphasis on enhancing driver comfort and safety, which has led to a surge in demand for high-quality power steering fluids. The market for power steering fluids is closely tied to the overall automotive market, which has shown resilience despite recent economic challenges.

In developed markets such as North America and Europe, the demand for power steering fluid is largely driven by the replacement market. With a large existing vehicle fleet, regular maintenance and fluid replacement contribute significantly to market growth. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in new vehicle sales, which is boosting the demand for power steering fluids in these regions.

The increasing adoption of electric power steering systems in modern vehicles has introduced a new dynamic to the market. While these systems do not require traditional hydraulic power steering fluid, they still need specialized fluids for optimal performance. This shift has led to the development of new, advanced power steering fluids designed specifically for electric and hybrid vehicles, creating a niche market segment with high growth potential.

Consumer awareness regarding the importance of regular vehicle maintenance has also contributed to market growth. As drivers become more informed about the role of power steering fluid in maintaining steering smoothness and preventing wear and tear, they are more likely to invest in regular fluid changes and high-quality products.

The commercial vehicle segment presents another significant market opportunity. With the growth of e-commerce and logistics industries, there is an increased demand for commercial vehicles, which typically require more frequent power steering fluid replacements due to higher usage and wear.

Environmental concerns and regulatory pressures are shaping the market as well. There is a growing demand for eco-friendly, biodegradable power steering fluids that offer the same level of performance while reducing environmental impact. This trend is expected to drive innovation in fluid formulations and create new market opportunities for manufacturers who can meet these evolving requirements.

Overall, the market for power steering fluid is expected to continue its growth trajectory, driven by factors such as increasing vehicle production, growing awareness of maintenance needs, and technological advancements in both vehicle systems and fluid formulations. The industry's ability to adapt to changing vehicle technologies and environmental regulations will be crucial in sustaining this growth and meeting evolving market demands.

Current Challenges

Power steering fluid plays a crucial role in ensuring smooth vehicle steering, yet several challenges persist in optimizing its contribution to steering performance. One of the primary issues is fluid degradation over time, which can lead to reduced steering efficiency and increased wear on system components. As vehicles age, the power steering fluid can break down due to heat, contamination, and oxidation, resulting in decreased lubricating properties and potential system damage.

Another significant challenge is the sensitivity of power steering systems to fluid viscosity changes. Temperature fluctuations can dramatically affect fluid viscosity, leading to inconsistent steering feel across different operating conditions. This variability can be particularly problematic in extreme climates, where rapid temperature changes may occur during a single journey.

Fluid leakage remains a persistent issue in many power steering systems. Even minor leaks can lead to reduced fluid levels, compromising steering performance and potentially causing system failure. Identifying and addressing these leaks can be challenging, often requiring specialized diagnostic equipment and expertise.

The integration of power steering fluid with modern electronic power steering systems presents new complexities. As hybrid systems become more prevalent, ensuring compatibility between traditional hydraulic fluids and electronic components becomes increasingly important. Balancing the benefits of hydraulic assistance with the precision of electronic control requires careful fluid formulation and system design.

Environmental concerns also pose challenges for power steering fluid development. There is growing pressure to develop more eco-friendly fluids that maintain performance while reducing environmental impact. This includes creating biodegradable options and minimizing the use of harmful additives, which can be technically challenging and potentially costly.

Noise, vibration, and harshness (NVH) issues related to power steering fluid are another area of concern. Air entrapment in the fluid, known as aeration, can lead to steering system noise and reduced performance. Developing fluids and systems that minimize these NVH issues while maintaining optimal steering feel is an ongoing challenge for automotive engineers.

Lastly, the increasing longevity of vehicles has raised expectations for power steering fluid durability. Consumers expect steering systems to perform consistently over extended periods without frequent fluid changes. Meeting these expectations while dealing with the natural degradation of fluids over time presents a significant engineering challenge, requiring innovative fluid formulations and system designs to extend service intervals without compromising performance or safety.

Another significant challenge is the sensitivity of power steering systems to fluid viscosity changes. Temperature fluctuations can dramatically affect fluid viscosity, leading to inconsistent steering feel across different operating conditions. This variability can be particularly problematic in extreme climates, where rapid temperature changes may occur during a single journey.

Fluid leakage remains a persistent issue in many power steering systems. Even minor leaks can lead to reduced fluid levels, compromising steering performance and potentially causing system failure. Identifying and addressing these leaks can be challenging, often requiring specialized diagnostic equipment and expertise.

The integration of power steering fluid with modern electronic power steering systems presents new complexities. As hybrid systems become more prevalent, ensuring compatibility between traditional hydraulic fluids and electronic components becomes increasingly important. Balancing the benefits of hydraulic assistance with the precision of electronic control requires careful fluid formulation and system design.

Environmental concerns also pose challenges for power steering fluid development. There is growing pressure to develop more eco-friendly fluids that maintain performance while reducing environmental impact. This includes creating biodegradable options and minimizing the use of harmful additives, which can be technically challenging and potentially costly.

Noise, vibration, and harshness (NVH) issues related to power steering fluid are another area of concern. Air entrapment in the fluid, known as aeration, can lead to steering system noise and reduced performance. Developing fluids and systems that minimize these NVH issues while maintaining optimal steering feel is an ongoing challenge for automotive engineers.

Lastly, the increasing longevity of vehicles has raised expectations for power steering fluid durability. Consumers expect steering systems to perform consistently over extended periods without frequent fluid changes. Meeting these expectations while dealing with the natural degradation of fluids over time presents a significant engineering challenge, requiring innovative fluid formulations and system designs to extend service intervals without compromising performance or safety.

Existing Fluid Solutions

01 Fluid composition for improved steering smoothness

Specialized power steering fluid compositions can enhance steering smoothness. These formulations may include additives that reduce friction, improve viscosity stability, and prevent wear on steering system components. Such fluids can maintain their performance characteristics over a wide range of temperatures and operating conditions, resulting in smoother steering operation.- Fluid composition for improved steering smoothness: Specialized power steering fluid compositions can enhance steering smoothness. These formulations may include additives that reduce friction, improve viscosity, and maintain stability under various operating conditions. Such fluids can help minimize steering effort and provide consistent performance across different temperatures.

- Hydraulic system design for smoother steering: The design of the hydraulic system in power steering can significantly impact steering smoothness. This includes optimizing pump designs, valve configurations, and fluid flow paths to reduce pressure fluctuations and ensure consistent steering assistance. Improved hydraulic systems can minimize steering vibrations and provide a more refined driving experience.

- Electronic control systems for steering smoothness: Integration of electronic control systems in power steering can enhance smoothness. These systems can adjust steering assistance based on vehicle speed, driver input, and road conditions. Advanced algorithms and sensors can help optimize fluid pressure and flow, resulting in more precise and smoother steering response.

- Noise and vibration reduction in power steering: Techniques for reducing noise and vibration in power steering systems contribute to perceived smoothness. This can involve using specially designed components, implementing damping mechanisms, and optimizing fluid dynamics to minimize cavitation and turbulence. Reducing noise and vibration enhances the overall steering feel and driver comfort.

- Maintenance and servicing for consistent steering smoothness: Regular maintenance and proper servicing of power steering systems are crucial for maintaining steering smoothness. This includes timely fluid replacement, system flushing, and component inspection. Proper maintenance practices can prevent fluid degradation, system contamination, and component wear, ensuring consistent steering performance over time.

02 Hydraulic system design for smoother steering

The design of the hydraulic system in power steering can significantly impact steering smoothness. This includes optimizing the pump design, valve configurations, and fluid flow paths. Improved hydraulic systems can reduce pressure fluctuations, minimize noise, and provide more consistent steering assistance, resulting in a smoother steering experience.Expand Specific Solutions03 Electronic control systems for steering smoothness

Electronic control systems can be integrated into power steering systems to enhance smoothness. These systems can adjust steering assistance based on vehicle speed, steering angle, and other parameters. By precisely controlling fluid pressure and flow, electronic systems can provide optimal steering feel and smoothness across various driving conditions.Expand Specific Solutions04 Steering column and gear design for improved smoothness

The design of steering column components and gears can contribute to overall steering smoothness. This includes optimizing the geometry of steering gears, using advanced materials for reduced friction, and implementing innovative designs for steering columns. These improvements can minimize play in the steering system and provide a more direct and smooth steering response.Expand Specific Solutions05 Maintenance and servicing for sustained steering smoothness

Regular maintenance and proper servicing of the power steering system are crucial for maintaining steering smoothness. This includes periodic fluid changes, system flushing, and inspection of components. Proper maintenance practices can prevent the buildup of contaminants, ensure optimal fluid properties, and extend the life of steering components, all contributing to sustained smooth steering performance.Expand Specific Solutions

Key Industry Players

The power steering fluid market is in a mature stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, with major automotive manufacturers and suppliers dominating the landscape. Companies like JTEKT Corp., Hitachi Ltd., and Eaton Corp. are key players, offering advanced power steering systems and fluids. The market is characterized by incremental innovations focused on improving efficiency and performance. Emerging trends include the shift towards electric power steering systems, which may impact traditional hydraulic fluid demand. However, the aftermarket segment for power steering fluid replacement remains strong, with companies like Afton Chemical Corp. providing specialized additives and formulations.

JTEKT Corp.

Technical Solution: JTEKT Corp. has developed advanced power steering fluid technologies that significantly contribute to vehicle steering smoothness. Their innovative fluid formulations incorporate high-performance additives that reduce friction and wear between moving parts in the steering system. These fluids maintain optimal viscosity across a wide temperature range, ensuring consistent steering performance in various driving conditions[1]. JTEKT's power steering fluids also feature enhanced oxidation stability, which prevents fluid degradation and maintains smooth steering operation over extended periods[3]. The company has implemented nanotechnology in their fluid designs, using nanoparticles to improve heat dissipation and reduce power losses in the steering system[5].

Strengths: Advanced additive technology, wide temperature range performance, and long-term stability. Weaknesses: Potentially higher cost due to advanced formulations and may require specialized handling during maintenance.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has developed a comprehensive approach to enhancing vehicle steering smoothness through their power steering fluid technology. Their advanced fluid formulations incorporate synthetic base oils with carefully selected additive packages that provide excellent low-temperature fluidity and high-temperature stability[2]. Hitachi's power steering fluids are designed to minimize foaming and aeration, which can significantly impact steering smoothness and responsiveness. The company has also introduced self-healing properties in their fluids, where microscopic particles can temporarily seal small leaks in the system, maintaining steering performance[4]. Additionally, Hitachi has developed adaptive fluid technologies that can adjust their properties based on steering input and vehicle speed, optimizing smoothness across various driving scenarios[6].

Strengths: Innovative self-healing properties, adaptive fluid technology, and excellent temperature range performance. Weaknesses: May require more frequent fluid changes due to the complex formulation and potentially higher cost.

Fluid Innovation Patents

Power steering fluid refining device

PatentPendingIN202211077346A

Innovation

- A power steering fluid refining device equipped with omnidirectional wheels, an AI-based image capturing module, a robotic arm, a telescopic gripper, a viscosity sensor, and a motorized gripper, which autonomously locates the fluid chamber, unfastens it, and determines the fluid's usability, refining the fluid without manual effort and storing it in a filtered receptacle.

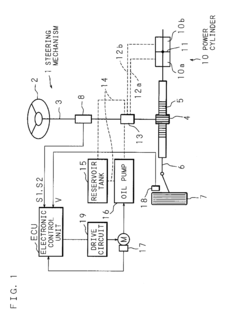

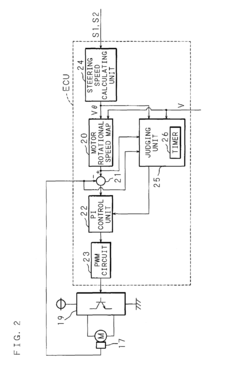

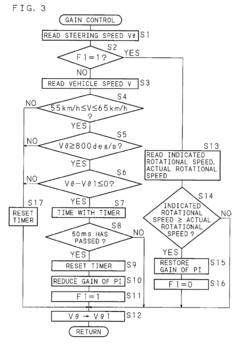

Power steering apparatus

PatentInactiveEP1602556A2

Innovation

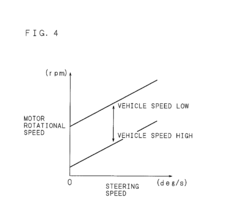

- A power steering apparatus that includes an oil pump, an electric motor, vehicle speed and steering speed detectors, and a feedback control system with gain reduction mechanisms to adjust the motor's rotational speed based on detected changes, ensuring smooth steering assistance without obstruction.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and use of power steering fluid in vehicles. As governments worldwide increasingly focus on reducing environmental impact, the automotive industry faces stringent regulations that directly affect the composition and disposal of power steering fluids.

One of the primary concerns addressed by environmental regulations is the toxicity of power steering fluids. Traditional fluids often contained harmful chemicals that posed risks to both human health and the environment. In response, regulations have been implemented to limit or ban the use of certain toxic substances in power steering fluids. This has led to the development of more environmentally friendly alternatives, such as biodegradable fluids and synthetic formulations with reduced toxicity.

The disposal of used power steering fluid is another area heavily influenced by environmental regulations. Many countries have established strict guidelines for the proper handling and recycling of automotive fluids, including power steering fluid. These regulations aim to prevent contamination of soil and water sources, which can occur when fluids are improperly disposed of. As a result, automotive manufacturers and service centers have had to implement comprehensive recycling programs and disposal protocols.

Regulations have also driven innovation in power steering system design, encouraging the development of electric power steering systems that eliminate the need for hydraulic fluid altogether. This shift towards electric systems is partly motivated by the desire to reduce the environmental impact associated with fluid-based systems, including potential leaks and disposal issues.

The impact of environmental regulations extends to the manufacturing process of power steering fluids as well. Manufacturers are required to adhere to strict emissions standards and waste management practices during production. This has led to the adoption of cleaner manufacturing technologies and more efficient production processes, further reducing the environmental footprint of power steering fluid production.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This may lead to further innovations in power steering fluid formulations, with a focus on renewable resources and enhanced biodegradability. Additionally, there may be increased pressure to transition away from fluid-based systems entirely, favoring electric or other alternative technologies that offer improved environmental performance.

The automotive industry must remain vigilant and adaptable to these evolving regulations, as compliance is not only a legal requirement but also increasingly important for consumer acceptance and brand reputation. As such, the development of environmentally friendly power steering solutions that maintain or improve steering smoothness will continue to be a key focus for automotive engineers and researchers in the coming years.

One of the primary concerns addressed by environmental regulations is the toxicity of power steering fluids. Traditional fluids often contained harmful chemicals that posed risks to both human health and the environment. In response, regulations have been implemented to limit or ban the use of certain toxic substances in power steering fluids. This has led to the development of more environmentally friendly alternatives, such as biodegradable fluids and synthetic formulations with reduced toxicity.

The disposal of used power steering fluid is another area heavily influenced by environmental regulations. Many countries have established strict guidelines for the proper handling and recycling of automotive fluids, including power steering fluid. These regulations aim to prevent contamination of soil and water sources, which can occur when fluids are improperly disposed of. As a result, automotive manufacturers and service centers have had to implement comprehensive recycling programs and disposal protocols.

Regulations have also driven innovation in power steering system design, encouraging the development of electric power steering systems that eliminate the need for hydraulic fluid altogether. This shift towards electric systems is partly motivated by the desire to reduce the environmental impact associated with fluid-based systems, including potential leaks and disposal issues.

The impact of environmental regulations extends to the manufacturing process of power steering fluids as well. Manufacturers are required to adhere to strict emissions standards and waste management practices during production. This has led to the adoption of cleaner manufacturing technologies and more efficient production processes, further reducing the environmental footprint of power steering fluid production.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This may lead to further innovations in power steering fluid formulations, with a focus on renewable resources and enhanced biodegradability. Additionally, there may be increased pressure to transition away from fluid-based systems entirely, favoring electric or other alternative technologies that offer improved environmental performance.

The automotive industry must remain vigilant and adaptable to these evolving regulations, as compliance is not only a legal requirement but also increasingly important for consumer acceptance and brand reputation. As such, the development of environmentally friendly power steering solutions that maintain or improve steering smoothness will continue to be a key focus for automotive engineers and researchers in the coming years.

Safety Considerations

Safety considerations are paramount when discussing the contribution of power steering fluid to vehicle steering smoothness. The proper maintenance and handling of power steering fluid directly impact the safety of drivers, passengers, and other road users. Regular checks of power steering fluid levels and quality are essential to ensure optimal steering performance and prevent potential accidents caused by steering system failures.

One critical safety aspect is the prevention of fluid leaks. Power steering fluid leaks can lead to a sudden loss of steering assistance, potentially causing the driver to lose control of the vehicle. This risk is particularly high during high-speed maneuvers or in emergency situations where quick steering responses are crucial. Regular inspections of power steering components, including hoses, seals, and the pump, can help identify and address potential leak sources before they become critical safety hazards.

The quality and type of power steering fluid used also play a significant role in safety. Using the wrong type of fluid or contaminated fluid can cause damage to the power steering system, leading to reduced steering responsiveness or complete system failure. Manufacturers specify the appropriate fluid type for each vehicle model, and adhering to these specifications is crucial for maintaining optimal steering performance and safety.

Temperature fluctuations can affect power steering fluid viscosity, potentially impacting steering smoothness and safety. In extreme cold conditions, the fluid may thicken, leading to increased steering effort and reduced responsiveness. Conversely, in high-temperature environments, the fluid may become too thin, potentially causing pump cavitation and reduced steering assistance. Using temperature-stable fluids and ensuring proper fluid levels can mitigate these risks and maintain consistent steering performance across various operating conditions.

The interaction between power steering fluid and other vehicle systems also has safety implications. For instance, if power steering fluid contaminates the brake system due to a leak or improper maintenance, it can severely compromise braking performance. Similarly, power steering fluid that leaks onto hot engine components can pose a fire hazard. Proper system isolation and regular maintenance checks are essential to prevent such cross-system contamination and associated safety risks.

Environmental and health considerations are also relevant to the safe handling of power steering fluid. Many power steering fluids contain chemicals that can be harmful if ingested or exposed to skin or eyes. Proper disposal of used fluid is crucial to prevent environmental contamination and protect wildlife and water sources. Service technicians and vehicle owners should follow appropriate safety protocols when handling power steering fluid, including using personal protective equipment and disposing of used fluid at authorized recycling facilities.

One critical safety aspect is the prevention of fluid leaks. Power steering fluid leaks can lead to a sudden loss of steering assistance, potentially causing the driver to lose control of the vehicle. This risk is particularly high during high-speed maneuvers or in emergency situations where quick steering responses are crucial. Regular inspections of power steering components, including hoses, seals, and the pump, can help identify and address potential leak sources before they become critical safety hazards.

The quality and type of power steering fluid used also play a significant role in safety. Using the wrong type of fluid or contaminated fluid can cause damage to the power steering system, leading to reduced steering responsiveness or complete system failure. Manufacturers specify the appropriate fluid type for each vehicle model, and adhering to these specifications is crucial for maintaining optimal steering performance and safety.

Temperature fluctuations can affect power steering fluid viscosity, potentially impacting steering smoothness and safety. In extreme cold conditions, the fluid may thicken, leading to increased steering effort and reduced responsiveness. Conversely, in high-temperature environments, the fluid may become too thin, potentially causing pump cavitation and reduced steering assistance. Using temperature-stable fluids and ensuring proper fluid levels can mitigate these risks and maintain consistent steering performance across various operating conditions.

The interaction between power steering fluid and other vehicle systems also has safety implications. For instance, if power steering fluid contaminates the brake system due to a leak or improper maintenance, it can severely compromise braking performance. Similarly, power steering fluid that leaks onto hot engine components can pose a fire hazard. Proper system isolation and regular maintenance checks are essential to prevent such cross-system contamination and associated safety risks.

Environmental and health considerations are also relevant to the safe handling of power steering fluid. Many power steering fluids contain chemicals that can be harmful if ingested or exposed to skin or eyes. Proper disposal of used fluid is crucial to prevent environmental contamination and protect wildlife and water sources. Service technicians and vehicle owners should follow appropriate safety protocols when handling power steering fluid, including using personal protective equipment and disposing of used fluid at authorized recycling facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!