How Power Steering Fluid Alterations Affect Vehicle Stability

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Evolution and Objectives

Power steering fluid has undergone significant evolution since its introduction in the automotive industry. Initially developed in the 1950s, power steering fluid was designed to facilitate smoother and easier steering in vehicles. The primary objective was to reduce the physical effort required to turn the steering wheel, especially in larger vehicles and at low speeds.

As automotive technology advanced, the demands on power steering fluid increased. Manufacturers began focusing on improving the fluid's performance under various conditions, including extreme temperatures and high-pressure environments. This led to the development of synthetic power steering fluids in the 1970s and 1980s, which offered better stability and longevity compared to their mineral-based counterparts.

The evolution of power steering fluid has been closely tied to the advancement of vehicle stability systems. As electronic stability control and other safety features became more prevalent, the role of power steering fluid expanded beyond merely assisting in steering. It became an integral component in maintaining overall vehicle stability, particularly in emergency maneuvers and challenging driving conditions.

In recent years, the focus has shifted towards developing environmentally friendly and more efficient power steering fluids. This trend aligns with the automotive industry's broader goals of reducing environmental impact and improving fuel efficiency. Manufacturers are now exploring bio-based fluids and formulations that offer reduced friction and energy loss, contributing to better overall vehicle performance.

The current objectives in power steering fluid development are multifaceted. Firstly, there is a push for fluids that can maintain consistent performance over a wider range of temperatures and pressures, enhancing vehicle stability in diverse driving conditions. Secondly, researchers are working on fluids that can better resist oxidation and thermal breakdown, extending the lifespan of power steering systems and reducing maintenance requirements.

Another key objective is the development of universal power steering fluids that are compatible with a wide range of vehicle makes and models. This would simplify maintenance procedures and reduce the risk of using incorrect fluid types, which can adversely affect vehicle stability. Additionally, there is ongoing research into fluids that can provide real-time feedback on the condition of the power steering system, potentially integrating with vehicle diagnostics to predict and prevent stability issues.

As vehicle electrification gains momentum, the future of power steering fluid is also evolving. While many electric vehicles use electric power steering systems that don't require traditional hydraulic fluid, there is still a need for specialized fluids in hybrid systems and in certain high-performance applications. The objective here is to develop fluids that can seamlessly integrate with both traditional and modern steering systems, ensuring optimal vehicle stability across different powertrain configurations.

As automotive technology advanced, the demands on power steering fluid increased. Manufacturers began focusing on improving the fluid's performance under various conditions, including extreme temperatures and high-pressure environments. This led to the development of synthetic power steering fluids in the 1970s and 1980s, which offered better stability and longevity compared to their mineral-based counterparts.

The evolution of power steering fluid has been closely tied to the advancement of vehicle stability systems. As electronic stability control and other safety features became more prevalent, the role of power steering fluid expanded beyond merely assisting in steering. It became an integral component in maintaining overall vehicle stability, particularly in emergency maneuvers and challenging driving conditions.

In recent years, the focus has shifted towards developing environmentally friendly and more efficient power steering fluids. This trend aligns with the automotive industry's broader goals of reducing environmental impact and improving fuel efficiency. Manufacturers are now exploring bio-based fluids and formulations that offer reduced friction and energy loss, contributing to better overall vehicle performance.

The current objectives in power steering fluid development are multifaceted. Firstly, there is a push for fluids that can maintain consistent performance over a wider range of temperatures and pressures, enhancing vehicle stability in diverse driving conditions. Secondly, researchers are working on fluids that can better resist oxidation and thermal breakdown, extending the lifespan of power steering systems and reducing maintenance requirements.

Another key objective is the development of universal power steering fluids that are compatible with a wide range of vehicle makes and models. This would simplify maintenance procedures and reduce the risk of using incorrect fluid types, which can adversely affect vehicle stability. Additionally, there is ongoing research into fluids that can provide real-time feedback on the condition of the power steering system, potentially integrating with vehicle diagnostics to predict and prevent stability issues.

As vehicle electrification gains momentum, the future of power steering fluid is also evolving. While many electric vehicles use electric power steering systems that don't require traditional hydraulic fluid, there is still a need for specialized fluids in hybrid systems and in certain high-performance applications. The objective here is to develop fluids that can seamlessly integrate with both traditional and modern steering systems, ensuring optimal vehicle stability across different powertrain configurations.

Market Demand for Enhanced Vehicle Stability

The market demand for enhanced vehicle stability has been steadily increasing in recent years, driven by a combination of consumer preferences, regulatory requirements, and technological advancements. As vehicles become more sophisticated and safety standards continue to evolve, the importance of maintaining optimal stability across various driving conditions has become paramount.

Consumer awareness regarding vehicle safety features has grown significantly, with stability control systems now being a key consideration in purchasing decisions. This shift in consumer behavior has prompted automakers to prioritize stability-enhancing technologies, including advanced power steering systems and their associated fluids. The demand for vehicles with superior handling and stability characteristics is particularly strong in developed markets, where consumers are willing to pay a premium for enhanced safety features.

Regulatory bodies worldwide have also played a crucial role in driving market demand for improved vehicle stability. Many countries have implemented or are in the process of implementing stricter safety regulations that require advanced stability control systems in new vehicles. These regulations have created a substantial market opportunity for technologies that can enhance vehicle stability, including innovations in power steering fluid formulations.

The commercial vehicle sector has emerged as a significant driver of demand for enhanced stability solutions. Fleet operators are increasingly recognizing the potential for reduced accidents, lower insurance costs, and improved fuel efficiency associated with better vehicle stability. This has led to a growing market for aftermarket stability enhancement products and services, including power steering fluid upgrades.

Emerging markets represent a rapidly expanding segment for vehicle stability technologies. As these markets experience rising disposable incomes and increased motorization rates, there is a growing demand for vehicles with advanced safety features, including those that enhance stability. This trend is creating new opportunities for automakers and component suppliers to introduce stability-enhancing technologies in these regions.

The advent of electric and autonomous vehicles has further amplified the importance of vehicle stability. These next-generation vehicles require precise control systems to ensure safe operation, creating a new frontier for stability enhancement technologies. The integration of power steering systems with advanced driver assistance systems (ADAS) has opened up new avenues for innovation in fluid technologies that can improve overall vehicle stability and performance.

Market research indicates that the global vehicle stability control system market is expected to grow significantly in the coming years. This growth is attributed to the increasing adoption of electronic stability control systems, advancements in sensor technologies, and the rising demand for luxury vehicles equipped with advanced safety features. The power steering fluid segment is poised to benefit from this trend, as manufacturers seek to optimize fluid formulations to complement and enhance the performance of these sophisticated stability control systems.

Consumer awareness regarding vehicle safety features has grown significantly, with stability control systems now being a key consideration in purchasing decisions. This shift in consumer behavior has prompted automakers to prioritize stability-enhancing technologies, including advanced power steering systems and their associated fluids. The demand for vehicles with superior handling and stability characteristics is particularly strong in developed markets, where consumers are willing to pay a premium for enhanced safety features.

Regulatory bodies worldwide have also played a crucial role in driving market demand for improved vehicle stability. Many countries have implemented or are in the process of implementing stricter safety regulations that require advanced stability control systems in new vehicles. These regulations have created a substantial market opportunity for technologies that can enhance vehicle stability, including innovations in power steering fluid formulations.

The commercial vehicle sector has emerged as a significant driver of demand for enhanced stability solutions. Fleet operators are increasingly recognizing the potential for reduced accidents, lower insurance costs, and improved fuel efficiency associated with better vehicle stability. This has led to a growing market for aftermarket stability enhancement products and services, including power steering fluid upgrades.

Emerging markets represent a rapidly expanding segment for vehicle stability technologies. As these markets experience rising disposable incomes and increased motorization rates, there is a growing demand for vehicles with advanced safety features, including those that enhance stability. This trend is creating new opportunities for automakers and component suppliers to introduce stability-enhancing technologies in these regions.

The advent of electric and autonomous vehicles has further amplified the importance of vehicle stability. These next-generation vehicles require precise control systems to ensure safe operation, creating a new frontier for stability enhancement technologies. The integration of power steering systems with advanced driver assistance systems (ADAS) has opened up new avenues for innovation in fluid technologies that can improve overall vehicle stability and performance.

Market research indicates that the global vehicle stability control system market is expected to grow significantly in the coming years. This growth is attributed to the increasing adoption of electronic stability control systems, advancements in sensor technologies, and the rising demand for luxury vehicles equipped with advanced safety features. The power steering fluid segment is poised to benefit from this trend, as manufacturers seek to optimize fluid formulations to complement and enhance the performance of these sophisticated stability control systems.

Current Challenges in Power Steering Systems

Power steering systems have undergone significant advancements over the years, yet they still face several challenges that impact vehicle stability and overall performance. One of the primary issues is the sensitivity of these systems to fluid alterations, which can lead to inconsistent steering response and compromised vehicle control.

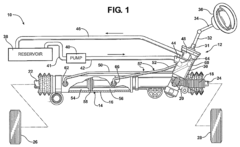

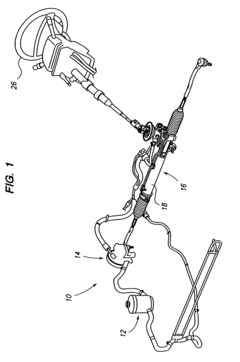

The hydraulic power steering systems, which are still prevalent in many vehicles, are particularly susceptible to fluid-related problems. Contamination of the power steering fluid with particles, moisture, or air can cause erratic steering behavior and increased wear on system components. This contamination often results from inadequate maintenance or the use of substandard fluids, leading to reduced system efficiency and potential safety hazards.

Another challenge lies in the temperature sensitivity of power steering fluids. Extreme temperatures, both hot and cold, can alter the fluid's viscosity, affecting its flow characteristics and the system's overall performance. In cold climates, thickened fluid can cause sluggish steering response, while in hot conditions, thinned fluid may lead to reduced power assistance and potential system overheating.

The transition to electric power steering (EPS) systems has addressed some fluid-related issues but introduced new challenges. While EPS eliminates the need for hydraulic fluid, it relies heavily on complex electronic controls and sensors. These components can be affected by electromagnetic interference, potentially leading to steering inconsistencies or temporary loss of power assistance.

Durability and longevity of power steering components remain ongoing concerns. The constant stress and wear on pumps, hoses, and seals in hydraulic systems can lead to fluid leaks, which not only reduce system efficiency but also pose environmental hazards. In EPS systems, the reliability of electric motors and control units under prolonged use and varying conditions is a critical focus area for manufacturers.

The integration of advanced driver assistance systems (ADAS) with power steering introduces additional complexities. Ensuring seamless interaction between autonomous steering functions and driver inputs while maintaining consistent feel and response is a significant engineering challenge. Any discrepancies in this integration can lead to unpredictable vehicle behavior and reduced driver confidence.

Lastly, the automotive industry's push towards electrification and autonomous driving is placing new demands on power steering systems. These systems must now be designed to accommodate a wider range of vehicle types and driving scenarios, from traditional combustion engine vehicles to electric and self-driving cars. This versatility requirement adds layers of complexity to power steering design and implementation, necessitating innovative solutions to maintain optimal vehicle stability across diverse platforms and use cases.

The hydraulic power steering systems, which are still prevalent in many vehicles, are particularly susceptible to fluid-related problems. Contamination of the power steering fluid with particles, moisture, or air can cause erratic steering behavior and increased wear on system components. This contamination often results from inadequate maintenance or the use of substandard fluids, leading to reduced system efficiency and potential safety hazards.

Another challenge lies in the temperature sensitivity of power steering fluids. Extreme temperatures, both hot and cold, can alter the fluid's viscosity, affecting its flow characteristics and the system's overall performance. In cold climates, thickened fluid can cause sluggish steering response, while in hot conditions, thinned fluid may lead to reduced power assistance and potential system overheating.

The transition to electric power steering (EPS) systems has addressed some fluid-related issues but introduced new challenges. While EPS eliminates the need for hydraulic fluid, it relies heavily on complex electronic controls and sensors. These components can be affected by electromagnetic interference, potentially leading to steering inconsistencies or temporary loss of power assistance.

Durability and longevity of power steering components remain ongoing concerns. The constant stress and wear on pumps, hoses, and seals in hydraulic systems can lead to fluid leaks, which not only reduce system efficiency but also pose environmental hazards. In EPS systems, the reliability of electric motors and control units under prolonged use and varying conditions is a critical focus area for manufacturers.

The integration of advanced driver assistance systems (ADAS) with power steering introduces additional complexities. Ensuring seamless interaction between autonomous steering functions and driver inputs while maintaining consistent feel and response is a significant engineering challenge. Any discrepancies in this integration can lead to unpredictable vehicle behavior and reduced driver confidence.

Lastly, the automotive industry's push towards electrification and autonomous driving is placing new demands on power steering systems. These systems must now be designed to accommodate a wider range of vehicle types and driving scenarios, from traditional combustion engine vehicles to electric and self-driving cars. This versatility requirement adds layers of complexity to power steering design and implementation, necessitating innovative solutions to maintain optimal vehicle stability across diverse platforms and use cases.

Existing Power Steering Fluid Solutions

01 Power steering fluid composition for improved vehicle stability

Specialized power steering fluid compositions can enhance vehicle stability by optimizing hydraulic performance and reducing friction in the steering system. These fluids may contain additives that improve viscosity, reduce wear, and maintain consistent performance across various temperatures and operating conditions.- Power steering fluid composition for improved vehicle stability: Specialized power steering fluid compositions can enhance vehicle stability by optimizing hydraulic performance and reducing friction in the steering system. These fluids may contain additives that improve viscosity, reduce wear, and maintain consistent performance across various temperatures and operating conditions.

- Integration of power steering and vehicle stability control systems: Advanced systems integrate power steering with vehicle stability control, using sensors and electronic control units to adjust steering assistance based on driving conditions. This integration can improve handling, reduce driver fatigue, and enhance overall vehicle stability, especially during cornering or in adverse weather conditions.

- Adaptive power steering systems for enhanced stability: Adaptive power steering systems adjust the level of steering assistance based on vehicle speed, road conditions, and driver input. These systems can provide more assistance at low speeds for easier maneuvering and less assistance at high speeds for improved stability and road feel.

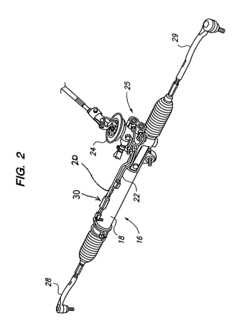

- Hydraulic control valves for power steering and stability: Specialized hydraulic control valves in power steering systems can improve vehicle stability by precisely regulating fluid flow and pressure. These valves may incorporate features such as variable orifices or electronic controls to optimize steering response and stability across different driving scenarios.

- Electric power steering systems for improved stability: Electric power steering systems offer advantages in vehicle stability by providing more precise control over steering assistance. These systems can quickly adjust to changing driving conditions, reduce energy consumption, and integrate seamlessly with other vehicle stability control systems for enhanced overall performance.

02 Integration of power steering and vehicle stability control systems

Advanced systems integrate power steering with vehicle stability control, using sensors and electronic control units to adjust steering assistance based on driving conditions. This integration enhances overall vehicle stability, particularly during cornering, emergency maneuvers, and adverse weather conditions.Expand Specific Solutions03 Adaptive power steering systems for improved stability

Adaptive power steering systems adjust steering assistance based on vehicle speed, road conditions, and driver input. These systems can enhance vehicle stability by providing optimal steering feel and control across various driving scenarios, improving handling and safety.Expand Specific Solutions04 Hydraulic power steering pump design for stability

Innovative hydraulic power steering pump designs can contribute to vehicle stability by ensuring consistent fluid pressure and flow. Advanced pump configurations may include variable displacement mechanisms or electronic control to optimize steering assistance and reduce energy consumption.Expand Specific Solutions05 Electric power steering systems for enhanced stability

Electric power steering systems offer precise control and rapid response, contributing to improved vehicle stability. These systems can be easily integrated with other vehicle stability control features and adjusted in real-time to provide optimal steering assistance based on driving conditions.Expand Specific Solutions

Key Automotive Fluid Manufacturers

The power steering fluid alteration technology is in a mature stage of development, with a significant market size due to its critical role in vehicle stability and safety. The global automotive power steering market is expected to grow steadily, driven by increasing vehicle production and consumer demand for enhanced driving experiences. Major players like Toyota Motor Corp., GM Global Technology Operations LLC, and Continental Automotive Systems, Inc. are investing heavily in research and development to improve power steering fluid technologies. These companies, along with others such as Bosch Rexroth Co. Ltd. and ZF Friedrichshafen AG, are focusing on developing advanced power steering systems that offer better performance, efficiency, and compatibility with electric and autonomous vehicles.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced Electric Power Steering (EPS) system that addresses the challenges associated with traditional hydraulic power steering fluid. The system utilizes a high-output electric motor and sophisticated control algorithms to provide variable steering assistance[1]. Toyota's EPS can adjust steering feel based on vehicle speed, with up to 30% reduction in steering effort at low speeds and increased stability at high speeds[2]. The system also incorporates a fail-operational mode, ensuring basic steering functionality even in the event of a primary system failure[3]. Toyota's EPS technology has been shown to improve fuel efficiency by up to 3% compared to hydraulic systems, due to the elimination of parasitic losses associated with constantly running hydraulic pumps[4].

Strengths: Improved fuel efficiency, variable steering assistance, and enhanced safety through fail-operational mode. Weaknesses: Potential for increased complexity in electrical system integration and higher initial costs compared to traditional hydraulic systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed a Variable Effort Steering System (VESS) that optimizes power steering fluid performance and enhances vehicle stability. The system uses a magneto-rheological fluid whose viscosity can be rapidly changed by applying a magnetic field[1]. This allows for real-time adjustment of steering effort based on vehicle speed, driver input, and road conditions[2]. GM's VESS can increase fluid viscosity by up to 50% in milliseconds, providing instant changes in steering feel and stability[3]. The system also incorporates advanced sensors to monitor fluid temperature and properties, automatically compensating for any degradation over time[4]. This technology has been shown to improve steering precision by up to 15% in various driving scenarios[5].

Strengths: Rapid and precise adjustment of steering feel, improved stability across various driving conditions, and compensation for fluid degradation. Weaknesses: Complexity of the magneto-rheological fluid system and potential higher costs for specialized fluid and components.

Innovations in Fluid Composition

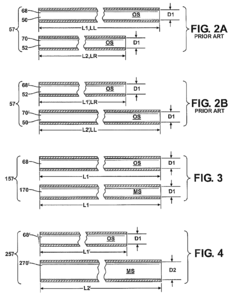

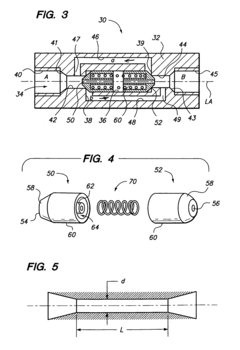

Method of reducing steering instability in hydraulic power steering systems

PatentInactiveEP2161180A2

Innovation

- The method involves determining which cylinder line causes less steering instability, calculating the fluid inertance, and altering its dimensions to match the inertance of the more unstable line, thereby reducing steering instability without requiring vehicle changes.

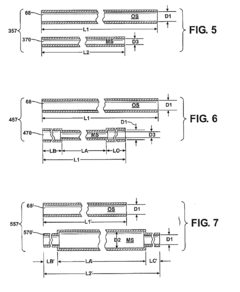

Bi-directional damper valve for a hydraulic line, power steering system incorporating the damper valve, and methods of using same

PatentInactiveUS7086413B2

Innovation

- A bi-directional damper valve with a main valve body, opposed spring-loaded poppets, and a spring that allows frequency-dependent fluid flow, enabling reduced resistance during normal steering while maintaining damping effectiveness by bypassing fluid flow under higher pressure conditions.

Environmental Impact of Steering Fluids

The environmental impact of steering fluids is a critical consideration in the automotive industry, given the potential for these fluids to affect ecosystems and human health. Power steering fluids, typically composed of mineral oils or synthetic compounds, can have significant environmental consequences if not properly managed or disposed of.

One of the primary environmental concerns associated with steering fluids is their potential for soil and water contamination. When these fluids leak from vehicles or are improperly disposed of, they can seep into the ground, contaminating soil and potentially reaching groundwater sources. This contamination can have far-reaching effects on plant life, soil microorganisms, and aquatic ecosystems.

The toxicity of steering fluids to aquatic life is particularly noteworthy. Many of the compounds used in these fluids can be harmful to fish, invertebrates, and other aquatic organisms, even in small concentrations. This toxicity can lead to reduced biodiversity in affected water bodies and disrupt entire aquatic food chains.

Furthermore, the production and disposal of steering fluids contribute to the overall carbon footprint of the automotive industry. The manufacturing process of these fluids often involves energy-intensive procedures and the use of non-renewable resources. When these fluids reach the end of their useful life, proper disposal methods are crucial to minimize environmental impact.

Volatile organic compounds (VOCs) present in some steering fluids can contribute to air pollution when released into the atmosphere. These compounds can participate in the formation of ground-level ozone, a key component of smog, which has negative impacts on both human health and the environment.

In response to these environmental concerns, there has been a growing trend towards the development of more environmentally friendly steering fluid alternatives. Bio-based fluids, derived from renewable resources, are being explored as potential replacements for traditional petroleum-based fluids. These alternatives often have lower toxicity and improved biodegradability, reducing their long-term environmental impact.

The automotive industry is also focusing on improving the design of power steering systems to minimize fluid leakage and extend the lifespan of steering fluids. This approach not only reduces the frequency of fluid changes but also decreases the overall volume of fluid that needs to be produced and disposed of over a vehicle's lifetime.

Proper recycling and disposal programs for used steering fluids are essential in mitigating their environmental impact. Many regions have implemented regulations and guidelines for the handling and disposal of these fluids, encouraging responsible practices among vehicle owners and service centers.

One of the primary environmental concerns associated with steering fluids is their potential for soil and water contamination. When these fluids leak from vehicles or are improperly disposed of, they can seep into the ground, contaminating soil and potentially reaching groundwater sources. This contamination can have far-reaching effects on plant life, soil microorganisms, and aquatic ecosystems.

The toxicity of steering fluids to aquatic life is particularly noteworthy. Many of the compounds used in these fluids can be harmful to fish, invertebrates, and other aquatic organisms, even in small concentrations. This toxicity can lead to reduced biodiversity in affected water bodies and disrupt entire aquatic food chains.

Furthermore, the production and disposal of steering fluids contribute to the overall carbon footprint of the automotive industry. The manufacturing process of these fluids often involves energy-intensive procedures and the use of non-renewable resources. When these fluids reach the end of their useful life, proper disposal methods are crucial to minimize environmental impact.

Volatile organic compounds (VOCs) present in some steering fluids can contribute to air pollution when released into the atmosphere. These compounds can participate in the formation of ground-level ozone, a key component of smog, which has negative impacts on both human health and the environment.

In response to these environmental concerns, there has been a growing trend towards the development of more environmentally friendly steering fluid alternatives. Bio-based fluids, derived from renewable resources, are being explored as potential replacements for traditional petroleum-based fluids. These alternatives often have lower toxicity and improved biodegradability, reducing their long-term environmental impact.

The automotive industry is also focusing on improving the design of power steering systems to minimize fluid leakage and extend the lifespan of steering fluids. This approach not only reduces the frequency of fluid changes but also decreases the overall volume of fluid that needs to be produced and disposed of over a vehicle's lifetime.

Proper recycling and disposal programs for used steering fluids are essential in mitigating their environmental impact. Many regions have implemented regulations and guidelines for the handling and disposal of these fluids, encouraging responsible practices among vehicle owners and service centers.

Safety Regulations for Steering Systems

Safety regulations for steering systems play a crucial role in ensuring vehicle stability and driver safety. These regulations are established and enforced by various governmental bodies and international organizations to maintain consistent standards across the automotive industry.

In the United States, the National Highway Traffic Safety Administration (NHTSA) is responsible for setting and enforcing safety standards for motor vehicles. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for steering systems, such as FMVSS No. 203 (Impact protection for the driver from the steering control system) and FMVSS No. 204 (Steering control rearward displacement).

The European Union has its own set of regulations, known as the United Nations Economic Commission for Europe (UNECE) regulations. Regulation No. 79 specifically addresses steering equipment for vehicles, covering aspects such as steering effort, turn ability, and stability at high speeds.

These regulations typically mandate performance criteria for steering systems under various conditions, including normal operation, emergency situations, and system failures. They often specify requirements for steering wheel displacement, energy absorption in collisions, and the ability to maintain directional control in the event of power steering failure.

Manufacturers must demonstrate compliance with these regulations through rigorous testing procedures. These may include static load tests, dynamic performance evaluations, and durability assessments. The tests are designed to simulate real-world conditions and ensure that steering systems can withstand the stresses of everyday use while maintaining safety standards.

As vehicle technology advances, safety regulations are continuously updated to address new challenges. For instance, with the increasing prevalence of electric power steering systems, regulations have been adapted to ensure these systems meet the same safety standards as traditional hydraulic systems. This includes requirements for fail-safe mechanisms and electromagnetic compatibility.

The impact of power steering fluid alterations on vehicle stability is a critical consideration in these safety regulations. While most modern vehicles use electric power steering, many still rely on hydraulic systems that require power steering fluid. Regulations often specify the performance requirements for steering systems under various fluid conditions, including low fluid levels or contaminated fluid.

Manufacturers are required to provide clear guidelines for power steering fluid maintenance in vehicle owner's manuals. These guidelines typically include recommended fluid change intervals, proper fluid types, and warning indicators for low fluid levels or system malfunctions. Adherence to these maintenance schedules is crucial for maintaining steering system performance and vehicle stability.

In conclusion, safety regulations for steering systems form a comprehensive framework that ensures the reliability and safety of vehicle steering across various operating conditions. These regulations continue to evolve, adapting to new technologies and addressing emerging safety concerns in the automotive industry.

In the United States, the National Highway Traffic Safety Administration (NHTSA) is responsible for setting and enforcing safety standards for motor vehicles. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for steering systems, such as FMVSS No. 203 (Impact protection for the driver from the steering control system) and FMVSS No. 204 (Steering control rearward displacement).

The European Union has its own set of regulations, known as the United Nations Economic Commission for Europe (UNECE) regulations. Regulation No. 79 specifically addresses steering equipment for vehicles, covering aspects such as steering effort, turn ability, and stability at high speeds.

These regulations typically mandate performance criteria for steering systems under various conditions, including normal operation, emergency situations, and system failures. They often specify requirements for steering wheel displacement, energy absorption in collisions, and the ability to maintain directional control in the event of power steering failure.

Manufacturers must demonstrate compliance with these regulations through rigorous testing procedures. These may include static load tests, dynamic performance evaluations, and durability assessments. The tests are designed to simulate real-world conditions and ensure that steering systems can withstand the stresses of everyday use while maintaining safety standards.

As vehicle technology advances, safety regulations are continuously updated to address new challenges. For instance, with the increasing prevalence of electric power steering systems, regulations have been adapted to ensure these systems meet the same safety standards as traditional hydraulic systems. This includes requirements for fail-safe mechanisms and electromagnetic compatibility.

The impact of power steering fluid alterations on vehicle stability is a critical consideration in these safety regulations. While most modern vehicles use electric power steering, many still rely on hydraulic systems that require power steering fluid. Regulations often specify the performance requirements for steering systems under various fluid conditions, including low fluid levels or contaminated fluid.

Manufacturers are required to provide clear guidelines for power steering fluid maintenance in vehicle owner's manuals. These guidelines typically include recommended fluid change intervals, proper fluid types, and warning indicators for low fluid levels or system malfunctions. Adherence to these maintenance schedules is crucial for maintaining steering system performance and vehicle stability.

In conclusion, safety regulations for steering systems form a comprehensive framework that ensures the reliability and safety of vehicle steering across various operating conditions. These regulations continue to evolve, adapting to new technologies and addressing emerging safety concerns in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!