Power Steering Fluid Evaluation in Off-Road Vehicles

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering large vehicles or operating at low speeds. The need for easier vehicle control led to the development of hydraulic power steering systems in the 1950s.

Hydraulic power steering marked a revolutionary change in automotive engineering. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. It significantly reduced the effort required to steer, particularly in heavy vehicles and off-road applications. The technology quickly became standard in most vehicles, improving driver comfort and control.

As automotive technology advanced, so did power steering systems. The 1990s saw the introduction of electrohydraulic power steering, a hybrid system that combined hydraulic and electric components. This intermediate step paved the way for fully electric power steering (EPS) systems, which began to gain prominence in the early 2000s.

Electric power steering represented a paradigm shift in steering technology. Unlike hydraulic systems, EPS uses an electric motor to assist steering, eliminating the need for hydraulic fluid and pumps. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and the ability to integrate with advanced driver assistance systems (ADAS).

In recent years, the focus has shifted towards more sophisticated and intelligent steering systems. Adaptive steering technologies have emerged, capable of adjusting steering response based on vehicle speed and driving conditions. This has been particularly beneficial for off-road vehicles, where steering requirements can vary dramatically depending on terrain.

The latest developments in power steering technology are centered around steer-by-wire systems. These systems completely eliminate the mechanical connection between the steering wheel and the wheels, relying instead on electronic controls and actuators. While still in its early stages, steer-by-wire technology promises unprecedented levels of customization in steering feel and responsiveness.

For off-road vehicles, the evolution of power steering has been crucial. These vehicles often operate in challenging environments where precise steering control is essential. The development of robust, high-performance power steering fluids has played a vital role in ensuring reliable operation under extreme conditions. As power steering technology continues to advance, the evaluation and improvement of these fluids remain critical for maintaining optimal performance in off-road applications.

Hydraulic power steering marked a revolutionary change in automotive engineering. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. It significantly reduced the effort required to steer, particularly in heavy vehicles and off-road applications. The technology quickly became standard in most vehicles, improving driver comfort and control.

As automotive technology advanced, so did power steering systems. The 1990s saw the introduction of electrohydraulic power steering, a hybrid system that combined hydraulic and electric components. This intermediate step paved the way for fully electric power steering (EPS) systems, which began to gain prominence in the early 2000s.

Electric power steering represented a paradigm shift in steering technology. Unlike hydraulic systems, EPS uses an electric motor to assist steering, eliminating the need for hydraulic fluid and pumps. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and the ability to integrate with advanced driver assistance systems (ADAS).

In recent years, the focus has shifted towards more sophisticated and intelligent steering systems. Adaptive steering technologies have emerged, capable of adjusting steering response based on vehicle speed and driving conditions. This has been particularly beneficial for off-road vehicles, where steering requirements can vary dramatically depending on terrain.

The latest developments in power steering technology are centered around steer-by-wire systems. These systems completely eliminate the mechanical connection between the steering wheel and the wheels, relying instead on electronic controls and actuators. While still in its early stages, steer-by-wire technology promises unprecedented levels of customization in steering feel and responsiveness.

For off-road vehicles, the evolution of power steering has been crucial. These vehicles often operate in challenging environments where precise steering control is essential. The development of robust, high-performance power steering fluids has played a vital role in ensuring reliable operation under extreme conditions. As power steering technology continues to advance, the evaluation and improvement of these fluids remain critical for maintaining optimal performance in off-road applications.

Off-Road Market Analysis

The off-road vehicle market has experienced significant growth in recent years, driven by increasing demand for recreational activities, adventure tourism, and specialized industrial applications. This market segment encompasses a wide range of vehicles, including all-terrain vehicles (ATVs), utility task vehicles (UTVs), and modified 4x4 trucks and SUVs. The global off-road vehicle market was valued at approximately $14 billion in 2020 and is projected to reach $19 billion by 2025, with a compound annual growth rate (CAGR) of 6.3%.

North America dominates the off-road vehicle market, accounting for over 40% of the global share. This is primarily due to the popularity of outdoor recreational activities and the presence of vast off-road terrains in countries like the United States and Canada. Europe and Asia-Pacific follow as the second and third largest markets, respectively, with emerging economies in these regions showing rapid growth potential.

The demand for power steering systems in off-road vehicles has been steadily increasing, as manufacturers focus on enhancing vehicle maneuverability and reducing driver fatigue. Power steering fluid plays a crucial role in these systems, particularly in challenging off-road conditions where vehicles are subjected to extreme temperatures, dust, and vibrations. The global power steering fluid market for off-road vehicles is estimated to grow at a CAGR of 4.5% from 2021 to 2026.

Key factors driving the growth of power steering fluid demand in the off-road market include the rising popularity of off-road sports and recreational activities, increasing disposable income in developing countries, and technological advancements in power steering systems. Additionally, the growing trend of vehicle customization and aftermarket modifications has led to increased awareness and demand for high-performance power steering fluids among off-road enthusiasts.

The off-road vehicle market is highly competitive, with major players such as Polaris Industries, Honda Motor Company, Yamaha Motor Corporation, and BRP (Bombardier Recreational Products) dominating the industry. These companies are investing heavily in research and development to improve power steering systems and fluids, aiming to enhance vehicle performance and durability in challenging off-road conditions.

Environmental concerns and regulations are also shaping the off-road vehicle market, with a growing emphasis on developing eco-friendly power steering fluids. Manufacturers are focusing on producing biodegradable and non-toxic fluids that meet stringent environmental standards while maintaining optimal performance in off-road applications. This trend is expected to create new opportunities for innovation and market growth in the power steering fluid segment for off-road vehicles.

North America dominates the off-road vehicle market, accounting for over 40% of the global share. This is primarily due to the popularity of outdoor recreational activities and the presence of vast off-road terrains in countries like the United States and Canada. Europe and Asia-Pacific follow as the second and third largest markets, respectively, with emerging economies in these regions showing rapid growth potential.

The demand for power steering systems in off-road vehicles has been steadily increasing, as manufacturers focus on enhancing vehicle maneuverability and reducing driver fatigue. Power steering fluid plays a crucial role in these systems, particularly in challenging off-road conditions where vehicles are subjected to extreme temperatures, dust, and vibrations. The global power steering fluid market for off-road vehicles is estimated to grow at a CAGR of 4.5% from 2021 to 2026.

Key factors driving the growth of power steering fluid demand in the off-road market include the rising popularity of off-road sports and recreational activities, increasing disposable income in developing countries, and technological advancements in power steering systems. Additionally, the growing trend of vehicle customization and aftermarket modifications has led to increased awareness and demand for high-performance power steering fluids among off-road enthusiasts.

The off-road vehicle market is highly competitive, with major players such as Polaris Industries, Honda Motor Company, Yamaha Motor Corporation, and BRP (Bombardier Recreational Products) dominating the industry. These companies are investing heavily in research and development to improve power steering systems and fluids, aiming to enhance vehicle performance and durability in challenging off-road conditions.

Environmental concerns and regulations are also shaping the off-road vehicle market, with a growing emphasis on developing eco-friendly power steering fluids. Manufacturers are focusing on producing biodegradable and non-toxic fluids that meet stringent environmental standards while maintaining optimal performance in off-road applications. This trend is expected to create new opportunities for innovation and market growth in the power steering fluid segment for off-road vehicles.

Fluid Challenges

Power steering fluid in off-road vehicles faces unique challenges due to the extreme conditions these vehicles operate in. The harsh environments, including extreme temperatures, high humidity, and exposure to contaminants, significantly impact the fluid's performance and longevity. One of the primary challenges is maintaining fluid stability under high temperatures generated during intense off-road use. The fluid must resist thermal breakdown and oxidation to prevent the formation of sludge and deposits that can clog system components.

Another critical challenge is protecting against moisture contamination. Off-road vehicles are often exposed to water crossings and high-humidity environments, increasing the risk of water ingress into the power steering system. Water contamination can lead to corrosion of metal components, fluid degradation, and reduced lubrication properties. Developing fluids with excellent water separation characteristics and corrosion inhibitors is essential to address this issue.

Dust and particulate contamination pose a significant threat to power steering systems in off-road applications. Fine dust particles can act as abrasives, accelerating wear on pump components, seals, and valves. Fluid formulations must incorporate advanced filtration properties and dispersants to suspend contaminants and prevent them from settling on critical surfaces.

The wide temperature range encountered in off-road use presents another challenge for power steering fluids. The fluid must maintain proper viscosity and flow characteristics in both extremely cold and hot conditions. This requires careful balancing of base oils and viscosity modifiers to ensure consistent performance across a broad temperature spectrum.

Seal compatibility is a crucial consideration in fluid development for off-road vehicles. The fluid must be compatible with a wide range of seal materials used in power steering systems, as these seals are subjected to more stress and movement in off-road applications. Ensuring proper seal swelling and maintaining seal elasticity over time is essential to prevent leaks and maintain system integrity.

Foam control is another challenge that power steering fluids must address in off-road vehicles. The constant jarring and vibration experienced during off-road use can cause fluid aeration, leading to reduced system efficiency and potential pump cavitation. Anti-foam additives and careful formulation are necessary to minimize foam formation and ensure rapid air release.

Lastly, the extended service intervals often desired in off-road vehicles require fluids with exceptional oxidation stability and long-term performance characteristics. Developing fluids that can maintain their properties over extended periods, even under severe operating conditions, is crucial for reducing maintenance requirements and ensuring reliable operation in remote or challenging environments.

Another critical challenge is protecting against moisture contamination. Off-road vehicles are often exposed to water crossings and high-humidity environments, increasing the risk of water ingress into the power steering system. Water contamination can lead to corrosion of metal components, fluid degradation, and reduced lubrication properties. Developing fluids with excellent water separation characteristics and corrosion inhibitors is essential to address this issue.

Dust and particulate contamination pose a significant threat to power steering systems in off-road applications. Fine dust particles can act as abrasives, accelerating wear on pump components, seals, and valves. Fluid formulations must incorporate advanced filtration properties and dispersants to suspend contaminants and prevent them from settling on critical surfaces.

The wide temperature range encountered in off-road use presents another challenge for power steering fluids. The fluid must maintain proper viscosity and flow characteristics in both extremely cold and hot conditions. This requires careful balancing of base oils and viscosity modifiers to ensure consistent performance across a broad temperature spectrum.

Seal compatibility is a crucial consideration in fluid development for off-road vehicles. The fluid must be compatible with a wide range of seal materials used in power steering systems, as these seals are subjected to more stress and movement in off-road applications. Ensuring proper seal swelling and maintaining seal elasticity over time is essential to prevent leaks and maintain system integrity.

Foam control is another challenge that power steering fluids must address in off-road vehicles. The constant jarring and vibration experienced during off-road use can cause fluid aeration, leading to reduced system efficiency and potential pump cavitation. Anti-foam additives and careful formulation are necessary to minimize foam formation and ensure rapid air release.

Lastly, the extended service intervals often desired in off-road vehicles require fluids with exceptional oxidation stability and long-term performance characteristics. Developing fluids that can maintain their properties over extended periods, even under severe operating conditions, is crucial for reducing maintenance requirements and ensuring reliable operation in remote or challenging environments.

Current Fluid Solutions

01 Power steering fluid composition

Power steering fluids are specially formulated to provide optimal performance in power steering systems. These fluids typically contain a base oil, additives for improved lubrication, anti-wear properties, and corrosion protection. The composition may also include viscosity modifiers to ensure proper flow characteristics across a range of temperatures.- Power steering fluid composition: Power steering fluids are specially formulated to provide optimal performance in power steering systems. These fluids typically contain a base oil, additives for wear protection, anti-foaming agents, and viscosity modifiers to ensure proper function across a range of temperatures and operating conditions.

- Power steering fluid reservoirs and systems: Power steering systems incorporate reservoirs to store and supply fluid to the steering mechanism. These reservoirs are designed to maintain proper fluid levels, prevent contamination, and often include features for easy filling and monitoring of fluid levels.

- Power steering pumps and fluid circulation: Power steering pumps are crucial components that circulate fluid through the system, providing the necessary pressure for power assistance. The design of these pumps affects fluid flow, pressure regulation, and overall system efficiency.

- Power steering fluid maintenance and replacement: Regular maintenance of power steering fluid is essential for system longevity. This includes periodic checks, top-ups, and complete fluid replacements. Some systems incorporate features to facilitate easier maintenance and fluid exchange.

- Power steering fluid in electric and hybrid systems: As vehicle technology evolves, power steering systems in electric and hybrid vehicles may use specialized fluids or alternative systems. These adaptations aim to improve energy efficiency while maintaining steering performance.

02 Power steering fluid reservoirs and systems

Power steering systems incorporate reservoirs to store and supply fluid to the steering mechanism. These reservoirs are designed to maintain proper fluid levels, prevent contamination, and allow for easy fluid checks and refills. The design of the reservoir and associated components can impact the overall performance and efficiency of the power steering system.Expand Specific Solutions03 Power steering pumps and fluid circulation

Power steering pumps are crucial components that circulate fluid through the system, providing the necessary hydraulic pressure for power assistance. The design and efficiency of these pumps can significantly affect the performance of the power steering system. Innovations in pump technology focus on improving energy efficiency, reducing noise, and enhancing overall system reliability.Expand Specific Solutions04 Power steering fluid maintenance and replacement

Regular maintenance of power steering fluid is essential for optimal system performance and longevity. This includes periodic checks of fluid levels, quality, and replacement intervals. Proper maintenance procedures and tools have been developed to facilitate easy fluid changes and system flushing, helping to prevent issues related to contamination or fluid degradation.Expand Specific Solutions05 Power steering fluid in electric and hybrid systems

As automotive technology advances, power steering systems in electric and hybrid vehicles are evolving. These systems may use specialized fluids or alternative technologies that reduce or eliminate the need for traditional hydraulic power steering fluids. Innovations in this area focus on improving energy efficiency, reducing environmental impact, and integrating with advanced vehicle control systems.Expand Specific Solutions

Key Industry Players

The power steering fluid evaluation market for off-road vehicles is in a growth phase, driven by increasing demand for advanced off-road vehicles and the need for improved performance in challenging terrains. The market size is expanding, with key players like Polaris Inc., Honda Motor Co., Ltd., and Yamaha Motor Co., Ltd. leading innovation in this sector. Technological advancements are focused on developing fluids that can withstand extreme temperatures and harsh operating conditions. Companies such as Afton Chemical Corp. and Parker-Hannifin Corp. are contributing to the market's maturity by offering specialized additives and hydraulic components. The competitive landscape is diverse, with both automotive giants and specialized fluid manufacturers vying for market share.

Eaton Corp.

Technical Solution: Eaton Corporation has developed an advanced power steering fluid evaluation system specifically designed for off-road vehicles. Their approach involves a comprehensive testing protocol that simulates extreme off-road conditions to assess fluid performance. The system utilizes a combination of high-pressure hydraulic circuits and thermal cycling to replicate the demanding environments faced by off-road vehicles. Eaton's evaluation process includes analyzing fluid viscosity stability, shear resistance, and anti-wear properties under various temperature and load conditions[1]. They have also implemented advanced contamination testing to ensure fluid longevity in dusty and debris-filled environments typical of off-road use[2]. Additionally, Eaton has incorporated real-time fluid monitoring sensors into their evaluation system, allowing for continuous assessment of fluid degradation during simulated off-road operations[3].

Strengths: Comprehensive testing protocol, advanced contamination analysis, and real-time monitoring capabilities. Weaknesses: Potentially higher cost due to sophisticated testing equipment and longer evaluation periods required for thorough assessment.

Polaris Inc.

Technical Solution: Polaris Inc. has developed a proprietary power steering fluid evaluation system tailored for their off-road vehicle lineup. Their approach focuses on extreme temperature performance and durability testing. Polaris utilizes a custom-built environmental chamber that can simulate temperatures ranging from -40°F to 180°F, allowing them to assess fluid performance across the entire spectrum of potential operating conditions[4]. Their evaluation process includes cyclic loading tests that mimic the rapid steering inputs common in off-road racing and recreational riding. Polaris has also implemented a unique contamination resistance test, introducing measured amounts of abrasive particles to the fluid to evaluate its ability to maintain performance and protect steering components in dusty environments[5]. Furthermore, they have developed a long-term durability test that subjects the fluid to extended periods of high-temperature operation, simulating the effects of prolonged use in challenging terrains.

Strengths: Extensive temperature range testing, specialized contamination resistance evaluation, and long-term durability assessment. Weaknesses: Testing may be overly specific to Polaris vehicles, potentially limiting applicability to other manufacturers' off-road vehicles.

Innovative Formulations

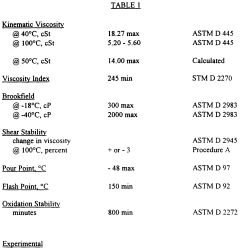

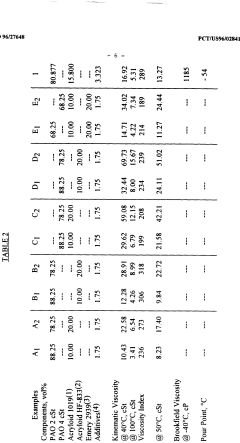

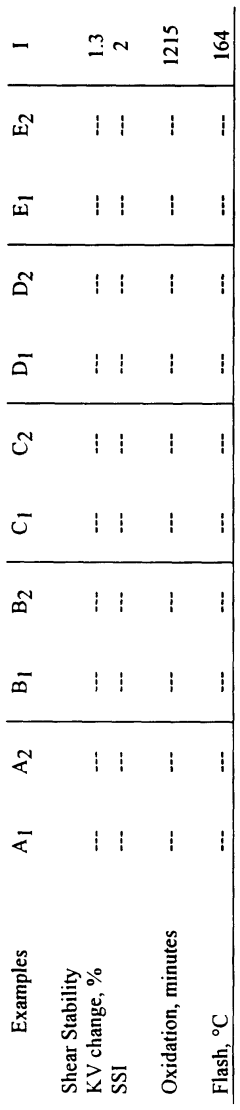

Power steering fluid with wide performance range

PatentWO1996027648A1

Innovation

- A power steering fluid comprising 75-85 vol% poly alpha olefin (PAO 2) and 14-18 vol% polymethacrylate with a weight average molecular weight of 50,000 to 300,000, along with conventional additives, is developed to achieve kinematic viscosities of 5.2-5.6 cSt @ 100°C, 14 cSt max @ 50°C, and a viscosity index of 245 minimum, while maintaining shear stability, pour point, and oxidation stability.

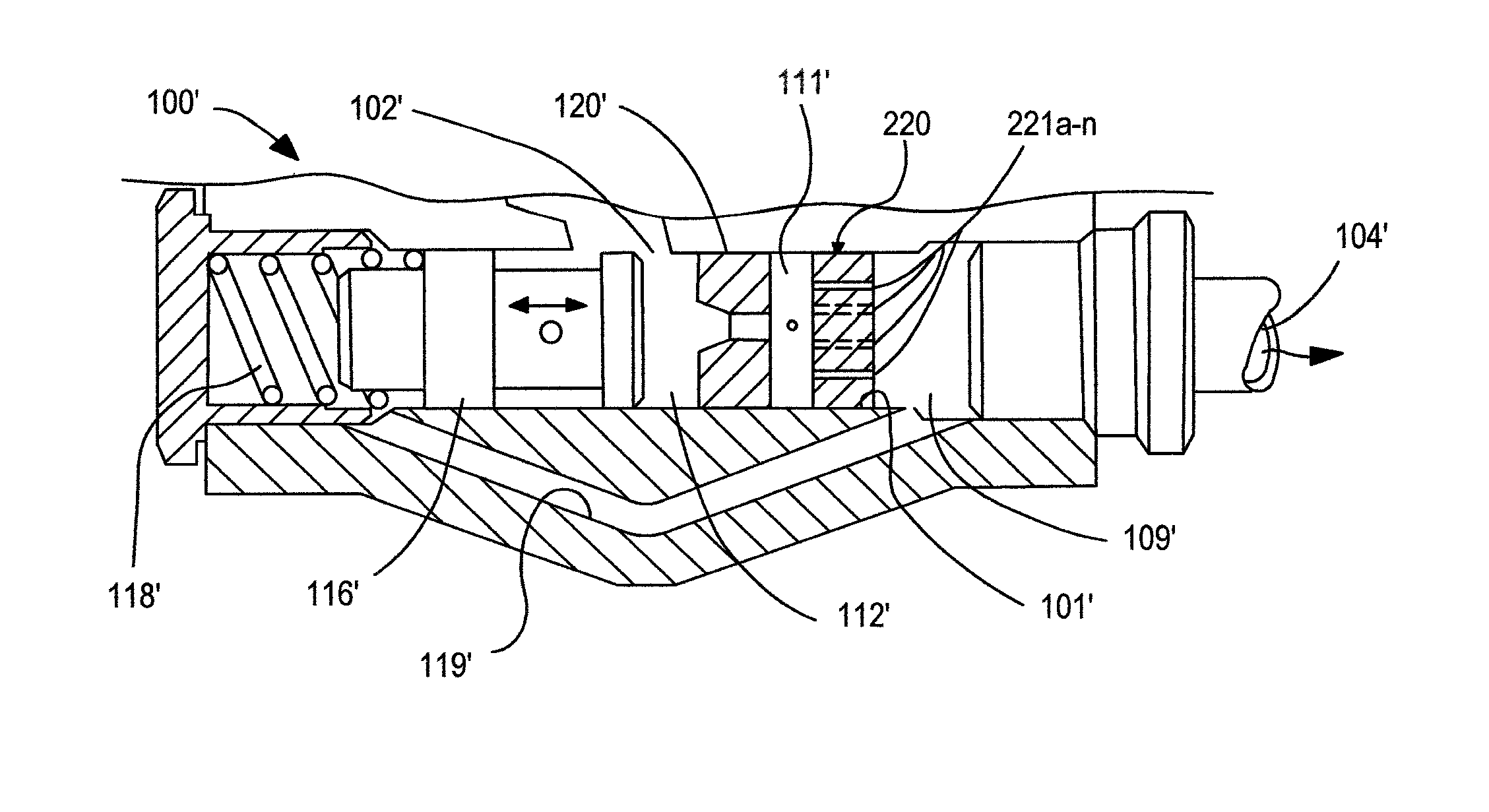

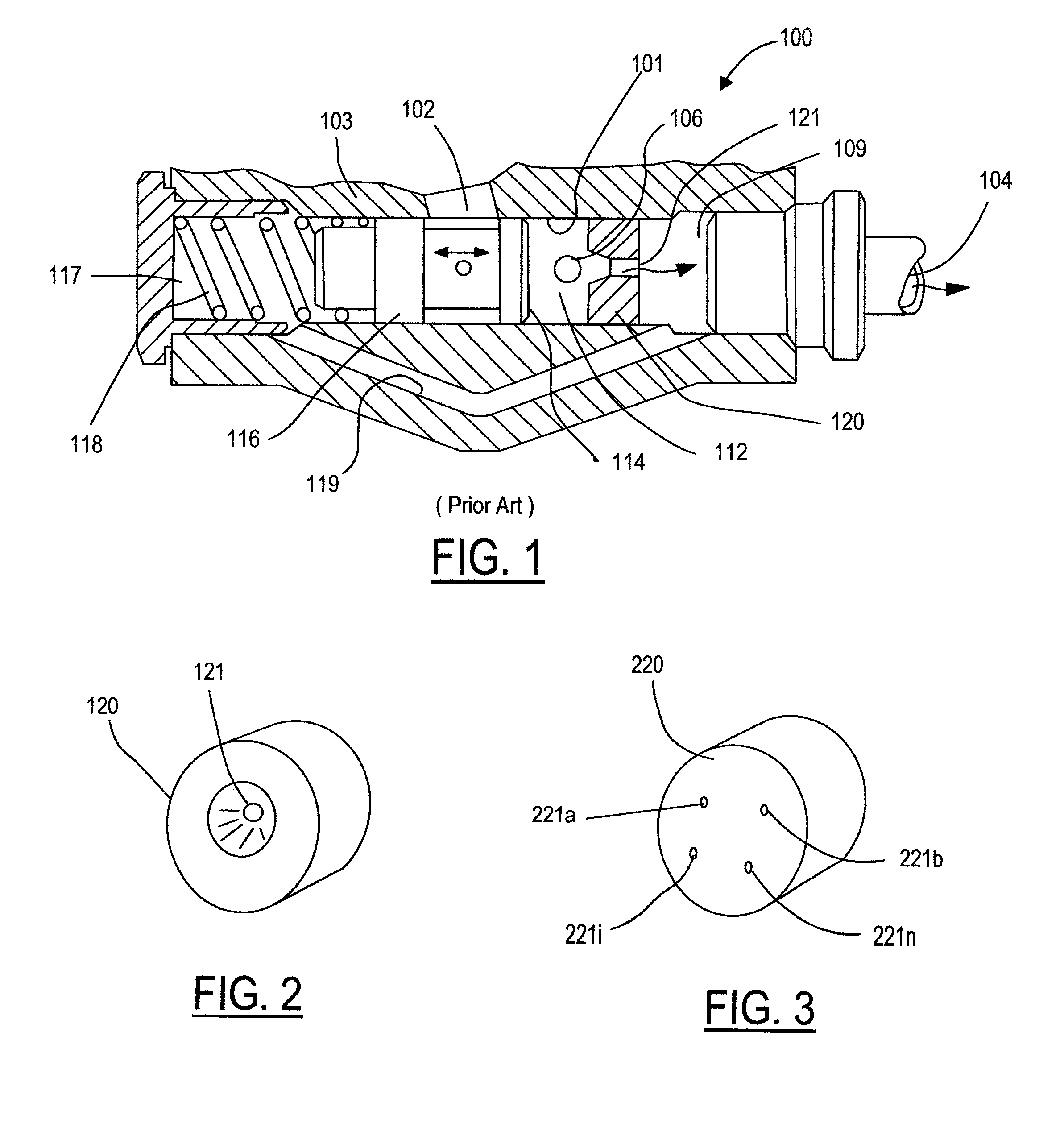

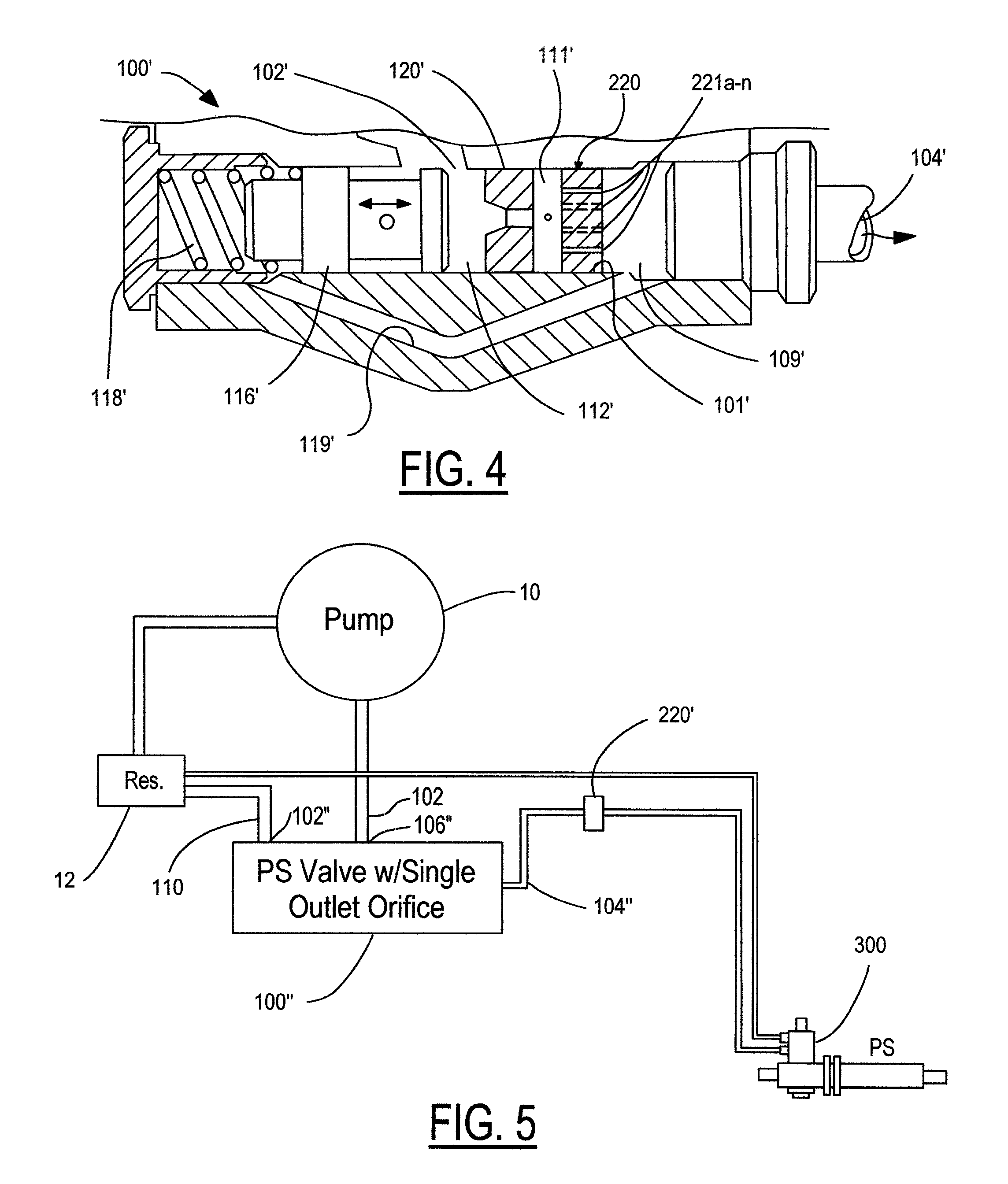

Power steering pump flow control

PatentInactiveUS7993111B2

Innovation

- A multiple passage orifice element is added downstream of a single passage outlet orifice element in a hydraulic flow control valve, providing increased resistance to high viscosity fluid flow through a greater wetted surface area, which prevents pulsation and noise by increasing shear forces and backpressure during cold starts, while maintaining normal operation at higher temperatures.

Environmental Impact

The environmental impact of power steering fluid in off-road vehicles is a critical consideration in the evaluation process. Off-road vehicles often operate in sensitive ecosystems, making the potential for fluid leaks and spills a significant concern. Power steering fluids typically contain synthetic or mineral oils, additives, and other chemicals that can have detrimental effects on soil, water, and wildlife if released into the environment.

Soil contamination is a primary concern when power steering fluid leaks occur. The hydrocarbons present in these fluids can persist in soil for extended periods, altering soil chemistry and potentially inhibiting plant growth. This can lead to long-term ecological damage in off-road areas, particularly in fragile habitats or protected wilderness zones.

Water pollution is another significant risk associated with power steering fluid leaks. Off-road vehicles frequently traverse streams, rivers, and wetlands, increasing the likelihood of fluid contamination in aquatic environments. Even small amounts of power steering fluid can form a thin film on water surfaces, disrupting oxygen exchange and harming aquatic life. The toxicity of certain fluid components can also have direct adverse effects on fish, amphibians, and other water-dependent organisms.

Biodegradability is an essential factor in assessing the environmental impact of power steering fluids. Traditional mineral oil-based fluids have low biodegradability rates, potentially leading to long-lasting environmental effects. In contrast, some newer synthetic and bio-based fluids offer improved biodegradability, reducing the long-term impact of leaks or spills.

The production and disposal of power steering fluids also contribute to their overall environmental footprint. Manufacturing processes may involve energy-intensive operations and the use of non-renewable resources. Proper disposal of used fluids is crucial, as improper handling can lead to widespread contamination. Recycling programs for power steering fluids can help mitigate these impacts, but their effectiveness depends on implementation and adherence.

Climate change considerations are increasingly relevant in the evaluation of power steering fluids. The carbon footprint associated with fluid production, transportation, and disposal contributes to greenhouse gas emissions. Additionally, the potential for increased fluid degradation due to extreme temperatures in changing climates may lead to more frequent fluid changes, exacerbating environmental impacts.

In response to these environmental concerns, there is a growing trend towards developing more eco-friendly power steering fluid formulations. These include biodegradable options, fluids with lower toxicity profiles, and those derived from renewable resources. Such innovations aim to reduce the potential environmental harm while maintaining the performance requirements necessary for off-road vehicle operations.

Soil contamination is a primary concern when power steering fluid leaks occur. The hydrocarbons present in these fluids can persist in soil for extended periods, altering soil chemistry and potentially inhibiting plant growth. This can lead to long-term ecological damage in off-road areas, particularly in fragile habitats or protected wilderness zones.

Water pollution is another significant risk associated with power steering fluid leaks. Off-road vehicles frequently traverse streams, rivers, and wetlands, increasing the likelihood of fluid contamination in aquatic environments. Even small amounts of power steering fluid can form a thin film on water surfaces, disrupting oxygen exchange and harming aquatic life. The toxicity of certain fluid components can also have direct adverse effects on fish, amphibians, and other water-dependent organisms.

Biodegradability is an essential factor in assessing the environmental impact of power steering fluids. Traditional mineral oil-based fluids have low biodegradability rates, potentially leading to long-lasting environmental effects. In contrast, some newer synthetic and bio-based fluids offer improved biodegradability, reducing the long-term impact of leaks or spills.

The production and disposal of power steering fluids also contribute to their overall environmental footprint. Manufacturing processes may involve energy-intensive operations and the use of non-renewable resources. Proper disposal of used fluids is crucial, as improper handling can lead to widespread contamination. Recycling programs for power steering fluids can help mitigate these impacts, but their effectiveness depends on implementation and adherence.

Climate change considerations are increasingly relevant in the evaluation of power steering fluids. The carbon footprint associated with fluid production, transportation, and disposal contributes to greenhouse gas emissions. Additionally, the potential for increased fluid degradation due to extreme temperatures in changing climates may lead to more frequent fluid changes, exacerbating environmental impacts.

In response to these environmental concerns, there is a growing trend towards developing more eco-friendly power steering fluid formulations. These include biodegradable options, fluids with lower toxicity profiles, and those derived from renewable resources. Such innovations aim to reduce the potential environmental harm while maintaining the performance requirements necessary for off-road vehicle operations.

Performance Testing

Performance testing is a critical aspect of evaluating power steering fluid in off-road vehicles. This process involves subjecting the fluid to various conditions that simulate real-world usage scenarios, ensuring its ability to maintain optimal performance under extreme circumstances.

The testing typically begins with baseline measurements of the fluid's viscosity, thermal stability, and shear resistance. These properties are crucial for maintaining consistent steering performance across a wide range of temperatures and operating conditions. Off-road vehicles often encounter extreme temperature fluctuations, from sub-zero temperatures in arctic environments to scorching heat in desert terrains. Therefore, the fluid must demonstrate stable viscosity characteristics to ensure smooth and responsive steering at all times.

Durability tests form a significant part of the performance evaluation. These tests involve running the power steering system continuously for extended periods, often exceeding 500 hours, to assess the fluid's ability to maintain its properties over time. During these tests, the fluid is subjected to high pressures and temperatures, mimicking the demanding conditions experienced in off-road use. The fluid's resistance to oxidation and thermal breakdown is closely monitored, as these factors can lead to decreased performance and potential system failure.

Contamination resistance is another crucial aspect of performance testing. Off-road vehicles are frequently exposed to dust, dirt, and moisture, which can infiltrate the power steering system. Test procedures involve introducing controlled amounts of contaminants into the fluid and evaluating its ability to maintain performance and protect system components. This includes assessing the fluid's capacity to suspend and disperse particles, prevent corrosion, and maintain seal integrity.

Load-bearing capacity tests are conducted to ensure the fluid can withstand the high loads encountered during off-road maneuvers. These tests simulate scenarios such as rock crawling, where the steering system experiences sudden, high-pressure demands. The fluid's ability to maintain a consistent film strength under these conditions is critical for preventing wear and ensuring responsive steering.

Compatibility testing is also an essential component of the evaluation process. The power steering fluid must demonstrate compatibility with various materials used in the steering system, including metals, plastics, and elastomers. Long-term exposure tests are conducted to ensure the fluid does not cause degradation or swelling of seals and hoses, which could lead to leaks or system failure.

Finally, comparative performance testing against industry-standard fluids and competitor products is carried out. This involves side-by-side evaluations under identical conditions to benchmark the fluid's performance across all key parameters. The results of these tests provide valuable insights into the fluid's competitive advantages and areas for potential improvement.

The testing typically begins with baseline measurements of the fluid's viscosity, thermal stability, and shear resistance. These properties are crucial for maintaining consistent steering performance across a wide range of temperatures and operating conditions. Off-road vehicles often encounter extreme temperature fluctuations, from sub-zero temperatures in arctic environments to scorching heat in desert terrains. Therefore, the fluid must demonstrate stable viscosity characteristics to ensure smooth and responsive steering at all times.

Durability tests form a significant part of the performance evaluation. These tests involve running the power steering system continuously for extended periods, often exceeding 500 hours, to assess the fluid's ability to maintain its properties over time. During these tests, the fluid is subjected to high pressures and temperatures, mimicking the demanding conditions experienced in off-road use. The fluid's resistance to oxidation and thermal breakdown is closely monitored, as these factors can lead to decreased performance and potential system failure.

Contamination resistance is another crucial aspect of performance testing. Off-road vehicles are frequently exposed to dust, dirt, and moisture, which can infiltrate the power steering system. Test procedures involve introducing controlled amounts of contaminants into the fluid and evaluating its ability to maintain performance and protect system components. This includes assessing the fluid's capacity to suspend and disperse particles, prevent corrosion, and maintain seal integrity.

Load-bearing capacity tests are conducted to ensure the fluid can withstand the high loads encountered during off-road maneuvers. These tests simulate scenarios such as rock crawling, where the steering system experiences sudden, high-pressure demands. The fluid's ability to maintain a consistent film strength under these conditions is critical for preventing wear and ensuring responsive steering.

Compatibility testing is also an essential component of the evaluation process. The power steering fluid must demonstrate compatibility with various materials used in the steering system, including metals, plastics, and elastomers. Long-term exposure tests are conducted to ensure the fluid does not cause degradation or swelling of seals and hoses, which could lead to leaks or system failure.

Finally, comparative performance testing against industry-standard fluids and competitor products is carried out. This involves side-by-side evaluations under identical conditions to benchmark the fluid's performance across all key parameters. The results of these tests provide valuable insights into the fluid's competitive advantages and areas for potential improvement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!