Investigating Power Steering Fluid as a Contributor to Steering Lag

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in automotive design. This system utilized a hydraulic pump driven by the engine to provide assistance to the steering mechanism. The power steering fluid, a key component in this system, played a crucial role in transmitting force and reducing steering effort.

As vehicles became heavier and more complex, the demand for more efficient and responsive steering systems grew. This led to the development of various improvements in hydraulic power steering technology throughout the 1960s and 1970s. These advancements focused on enhancing the precision of steering control and reducing the energy consumption of the system.

The 1980s and 1990s saw the introduction of electronic controls in power steering systems. This integration of electronics allowed for variable assist, which could adjust the level of steering assistance based on vehicle speed and other factors. This period also witnessed the emergence of electrohydraulic power steering, a hybrid system that combined hydraulic and electric components to improve efficiency.

The turn of the millennium brought about a significant shift towards electric power steering (EPS) systems. Unlike their hydraulic counterparts, EPS systems use an electric motor to provide steering assistance. This transition was driven by the need for improved fuel efficiency, as EPS systems do not rely on engine power to operate.

Recent years have seen further refinements in EPS technology, including the development of adaptive steering systems that can adjust steering ratios based on driving conditions. Additionally, the integration of EPS with advanced driver assistance systems (ADAS) and autonomous driving technologies has opened new frontiers in vehicle control and safety.

Throughout this evolution, the role of power steering fluid has remained a subject of ongoing research and development. While its importance has diminished in electric systems, it continues to be a critical component in hydraulic and electrohydraulic setups. The investigation into power steering fluid as a contributor to steering lag represents an important aspect of this ongoing evolution, as engineers strive to optimize steering performance and responsiveness in modern vehicles.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in automotive design. This system utilized a hydraulic pump driven by the engine to provide assistance to the steering mechanism. The power steering fluid, a key component in this system, played a crucial role in transmitting force and reducing steering effort.

As vehicles became heavier and more complex, the demand for more efficient and responsive steering systems grew. This led to the development of various improvements in hydraulic power steering technology throughout the 1960s and 1970s. These advancements focused on enhancing the precision of steering control and reducing the energy consumption of the system.

The 1980s and 1990s saw the introduction of electronic controls in power steering systems. This integration of electronics allowed for variable assist, which could adjust the level of steering assistance based on vehicle speed and other factors. This period also witnessed the emergence of electrohydraulic power steering, a hybrid system that combined hydraulic and electric components to improve efficiency.

The turn of the millennium brought about a significant shift towards electric power steering (EPS) systems. Unlike their hydraulic counterparts, EPS systems use an electric motor to provide steering assistance. This transition was driven by the need for improved fuel efficiency, as EPS systems do not rely on engine power to operate.

Recent years have seen further refinements in EPS technology, including the development of adaptive steering systems that can adjust steering ratios based on driving conditions. Additionally, the integration of EPS with advanced driver assistance systems (ADAS) and autonomous driving technologies has opened new frontiers in vehicle control and safety.

Throughout this evolution, the role of power steering fluid has remained a subject of ongoing research and development. While its importance has diminished in electric systems, it continues to be a critical component in hydraulic and electrohydraulic setups. The investigation into power steering fluid as a contributor to steering lag represents an important aspect of this ongoing evolution, as engineers strive to optimize steering performance and responsiveness in modern vehicles.

Market Demand Analysis

The market demand for power steering fluid and related technologies has been steadily growing due to the increasing global automotive production and the rising consumer expectations for smooth, responsive steering systems. As vehicles become more sophisticated, the demand for high-performance power steering fluids that can contribute to reduced steering lag has become a significant focus for both manufacturers and consumers.

The automotive industry has seen a shift towards electric power steering systems in recent years, which has impacted the traditional hydraulic power steering fluid market. However, there remains a substantial market for hydraulic systems, particularly in larger vehicles, commercial trucks, and in developing markets where the transition to electric systems is slower. This dual market dynamic creates opportunities for innovation in power steering fluid formulations that can address steering lag issues in both hydraulic and hybrid steering systems.

Consumer awareness of vehicle performance and safety has led to increased scrutiny of steering responsiveness. Steering lag, even when minimal, can affect driver confidence and overall vehicle handling perception. This has created a niche market for premium power steering fluids that promise to reduce lag and improve steering feel. Aftermarket products targeting this concern have seen growth, indicating a consumer willingness to invest in solutions that enhance steering performance.

The commercial vehicle sector presents a particularly strong demand for advanced power steering fluids. Heavy-duty trucks, buses, and construction equipment require robust steering systems that can handle high loads and frequent use. In these applications, steering lag can significantly impact operator fatigue and productivity. Fleet operators are increasingly looking for power steering fluids that can maintain consistent performance over long periods, reducing maintenance intervals and improving overall fleet efficiency.

Environmental regulations and sustainability concerns are also shaping market demand. There is a growing interest in bio-based and environmentally friendly power steering fluids that can offer the same or better performance in terms of reducing steering lag while meeting stringent environmental standards. This trend is particularly strong in regions with strict environmental regulations, driving research and development in eco-friendly fluid formulations.

The aging vehicle population in many developed markets has created a substantial aftermarket for power steering fluid replacement and upgrades. As vehicles age, steering systems may become less responsive, leading owners to seek solutions that can restore or improve steering performance. This has opened up opportunities for specialized power steering fluids marketed as solutions for reducing steering lag in older vehicles.

In conclusion, the market demand for power steering fluids that address steering lag is multifaceted, driven by factors such as automotive industry trends, consumer expectations, commercial vehicle needs, environmental concerns, and the aftermarket sector. As the automotive landscape continues to evolve, the demand for innovative solutions in this space is likely to persist, presenting opportunities for manufacturers and researchers to develop advanced formulations that can meet these diverse market needs.

The automotive industry has seen a shift towards electric power steering systems in recent years, which has impacted the traditional hydraulic power steering fluid market. However, there remains a substantial market for hydraulic systems, particularly in larger vehicles, commercial trucks, and in developing markets where the transition to electric systems is slower. This dual market dynamic creates opportunities for innovation in power steering fluid formulations that can address steering lag issues in both hydraulic and hybrid steering systems.

Consumer awareness of vehicle performance and safety has led to increased scrutiny of steering responsiveness. Steering lag, even when minimal, can affect driver confidence and overall vehicle handling perception. This has created a niche market for premium power steering fluids that promise to reduce lag and improve steering feel. Aftermarket products targeting this concern have seen growth, indicating a consumer willingness to invest in solutions that enhance steering performance.

The commercial vehicle sector presents a particularly strong demand for advanced power steering fluids. Heavy-duty trucks, buses, and construction equipment require robust steering systems that can handle high loads and frequent use. In these applications, steering lag can significantly impact operator fatigue and productivity. Fleet operators are increasingly looking for power steering fluids that can maintain consistent performance over long periods, reducing maintenance intervals and improving overall fleet efficiency.

Environmental regulations and sustainability concerns are also shaping market demand. There is a growing interest in bio-based and environmentally friendly power steering fluids that can offer the same or better performance in terms of reducing steering lag while meeting stringent environmental standards. This trend is particularly strong in regions with strict environmental regulations, driving research and development in eco-friendly fluid formulations.

The aging vehicle population in many developed markets has created a substantial aftermarket for power steering fluid replacement and upgrades. As vehicles age, steering systems may become less responsive, leading owners to seek solutions that can restore or improve steering performance. This has opened up opportunities for specialized power steering fluids marketed as solutions for reducing steering lag in older vehicles.

In conclusion, the market demand for power steering fluids that address steering lag is multifaceted, driven by factors such as automotive industry trends, consumer expectations, commercial vehicle needs, environmental concerns, and the aftermarket sector. As the automotive landscape continues to evolve, the demand for innovative solutions in this space is likely to persist, presenting opportunities for manufacturers and researchers to develop advanced formulations that can meet these diverse market needs.

Current Challenges

The investigation into power steering fluid as a contributor to steering lag faces several significant challenges in the current automotive engineering landscape. One of the primary obstacles is the complexity of isolating the fluid's role in steering performance from other contributing factors. Steering systems involve multiple components, including mechanical, hydraulic, and electronic elements, making it difficult to pinpoint the exact impact of the fluid alone.

Another challenge lies in the variability of power steering fluid compositions across different manufacturers and vehicle models. This diversity complicates standardized testing and analysis, as results may not be universally applicable. Furthermore, the fluid's properties can change over time due to temperature fluctuations, contamination, and degradation, adding another layer of complexity to long-term studies.

The automotive industry's shift towards electric power steering systems presents an additional hurdle. As more vehicles adopt electric-assisted steering, the relevance of hydraulic fluid-based research may diminish, potentially limiting funding and resources for such investigations. This transition also creates a knowledge gap, as expertise in traditional hydraulic systems may become less common among newer engineers.

Measuring steering lag with precision and consistency poses its own set of challenges. Subtle differences in lag can be difficult to quantify objectively, and human perception of steering responsiveness can vary. Developing standardized, repeatable testing methodologies that account for these subjective elements is crucial for producing reliable data.

Environmental factors also complicate the research process. Power steering fluid performance can be affected by ambient temperature, humidity, and altitude, necessitating extensive testing across various conditions. This requirement increases the time and cost associated with comprehensive studies.

Regulatory considerations present another obstacle. As automotive safety standards evolve, any findings related to steering lag must be evaluated within the context of current and future regulations. This may require additional testing and validation to ensure compliance with safety requirements across different markets.

Lastly, the interdisciplinary nature of this research demands collaboration between fluid dynamics experts, mechanical engineers, and automotive designers. Coordinating these diverse teams and integrating their insights can be challenging, potentially slowing progress and increasing project complexity.

Another challenge lies in the variability of power steering fluid compositions across different manufacturers and vehicle models. This diversity complicates standardized testing and analysis, as results may not be universally applicable. Furthermore, the fluid's properties can change over time due to temperature fluctuations, contamination, and degradation, adding another layer of complexity to long-term studies.

The automotive industry's shift towards electric power steering systems presents an additional hurdle. As more vehicles adopt electric-assisted steering, the relevance of hydraulic fluid-based research may diminish, potentially limiting funding and resources for such investigations. This transition also creates a knowledge gap, as expertise in traditional hydraulic systems may become less common among newer engineers.

Measuring steering lag with precision and consistency poses its own set of challenges. Subtle differences in lag can be difficult to quantify objectively, and human perception of steering responsiveness can vary. Developing standardized, repeatable testing methodologies that account for these subjective elements is crucial for producing reliable data.

Environmental factors also complicate the research process. Power steering fluid performance can be affected by ambient temperature, humidity, and altitude, necessitating extensive testing across various conditions. This requirement increases the time and cost associated with comprehensive studies.

Regulatory considerations present another obstacle. As automotive safety standards evolve, any findings related to steering lag must be evaluated within the context of current and future regulations. This may require additional testing and validation to ensure compliance with safety requirements across different markets.

Lastly, the interdisciplinary nature of this research demands collaboration between fluid dynamics experts, mechanical engineers, and automotive designers. Coordinating these diverse teams and integrating their insights can be challenging, potentially slowing progress and increasing project complexity.

Existing Fluid Solutions

01 Fluid composition and additives

Improving power steering fluid composition by incorporating specific additives can help reduce steering lag. These additives may include viscosity modifiers, anti-wear agents, and friction modifiers that enhance the fluid's performance under various operating conditions, resulting in smoother steering response and reduced lag.- Fluid composition and additives: Improving the composition of power steering fluid by adding specific additives can help reduce steering lag. These additives may include viscosity modifiers, anti-wear agents, and friction modifiers that enhance the fluid's performance under various operating conditions.

- Hydraulic system design: Optimizing the hydraulic system design in power steering can minimize fluid-related lag. This may involve improving pump efficiency, reducing fluid resistance in lines and valves, and enhancing the overall hydraulic circuit layout to ensure faster response times.

- Temperature management: Implementing effective temperature management systems for power steering fluid can help maintain optimal viscosity and reduce lag. This may include cooling systems, heat exchangers, or temperature-responsive valves to ensure consistent fluid performance across various operating temperatures.

- Fluid circulation and filtration: Enhancing fluid circulation and filtration systems can help maintain fluid quality and reduce steering lag. This may involve improved pump designs, advanced filtration methods, or innovative circulation patterns to ensure clean, well-distributed fluid throughout the system.

- Electronic control integration: Integrating electronic control systems with hydraulic power steering can help compensate for fluid-related lag. This may include adaptive algorithms, sensor-based feedback systems, or variable assist mechanisms that adjust steering response based on driving conditions and fluid performance.

02 Hydraulic system design

Optimizing the hydraulic system design in power steering can minimize steering lag. This may involve improving pump efficiency, redesigning valve systems, or incorporating advanced flow control mechanisms to ensure rapid and consistent fluid delivery, resulting in more responsive steering.Expand Specific Solutions03 Electronic control integration

Integrating electronic control systems with hydraulic power steering can help reduce steering lag. These systems can use sensors and actuators to optimize fluid pressure and flow based on driving conditions, vehicle speed, and steering input, resulting in improved steering response and reduced lag.Expand Specific Solutions04 Fluid circulation and cooling

Enhancing fluid circulation and cooling within the power steering system can help maintain optimal fluid properties and reduce steering lag. This may involve improved heat exchanger designs, optimized fluid routing, or the incorporation of auxiliary cooling systems to prevent fluid degradation and maintain consistent steering performance.Expand Specific Solutions05 Steering mechanism design

Improving the design of steering mechanisms, such as rack and pinion systems or rotary valve assemblies, can help reduce steering lag. This may involve optimizing gear ratios, reducing friction in moving parts, or incorporating advanced materials to enhance overall steering responsiveness and reduce lag.Expand Specific Solutions

Key Industry Players

The power steering fluid technology market is in a mature stage, with a global market size estimated in the billions of dollars. Major automotive manufacturers and suppliers like Ford, GM, Eaton, and JTEKT dominate the competitive landscape, leveraging their extensive R&D capabilities and established market presence. These companies have achieved high levels of technical maturity in power steering systems, continuously refining fluid formulations and steering mechanisms to enhance performance and reduce lag. Emerging players from Asia, such as Hitachi and NSK, are also making significant strides in this space, introducing innovative solutions to address steering responsiveness. The market is characterized by ongoing efforts to improve steering precision, reduce energy consumption, and integrate advanced driver assistance features.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced power steering fluid monitoring system that utilizes real-time sensors to detect changes in fluid viscosity and contamination levels. This system employs machine learning algorithms to analyze fluid data and predict potential steering lag issues before they become noticeable to the driver[1]. Additionally, Ford has introduced a new power steering fluid formulation with enhanced thermal stability and anti-wear properties, designed to maintain consistent performance across a wide range of operating conditions[2]. The company has also implemented a variable-assist electric power steering system that adjusts steering effort based on vehicle speed and driver input, which can help mitigate the effects of fluid-related steering lag[3].

Strengths: Proactive monitoring system, advanced fluid formulation, and adaptive steering assistance. Weaknesses: Potential increased complexity and cost of implementation, may require more frequent fluid changes.

GM Global Technology Operations LLC

Technical Solution: GM has developed a dual-circuit power steering system that incorporates both hydraulic and electric assistance. This hybrid approach allows for redundancy and improved responsiveness, potentially reducing the impact of steering fluid-related lag[4]. The company has also introduced a smart power steering fluid circulation system that actively manages fluid temperature and pressure to optimize performance and reduce the likelihood of steering lag[5]. GM's research into nanotechnology-enhanced power steering fluids has shown promise in reducing friction and improving overall system efficiency, which could contribute to minimizing steering lag[6].

Strengths: Redundant system design, active fluid management, and innovative fluid technology. Weaknesses: Increased system complexity may lead to higher maintenance costs and potential reliability concerns.

Fluid Property Research

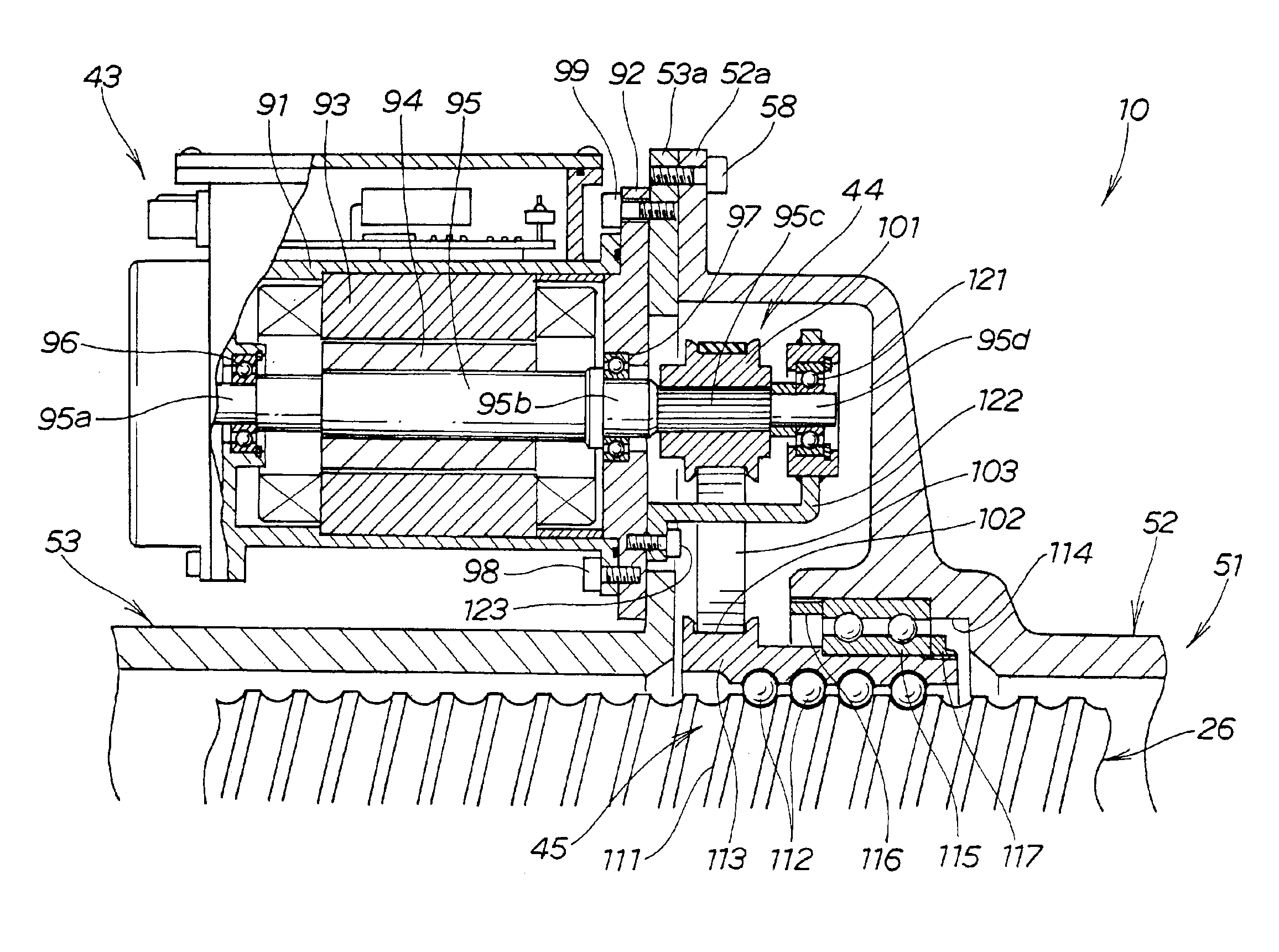

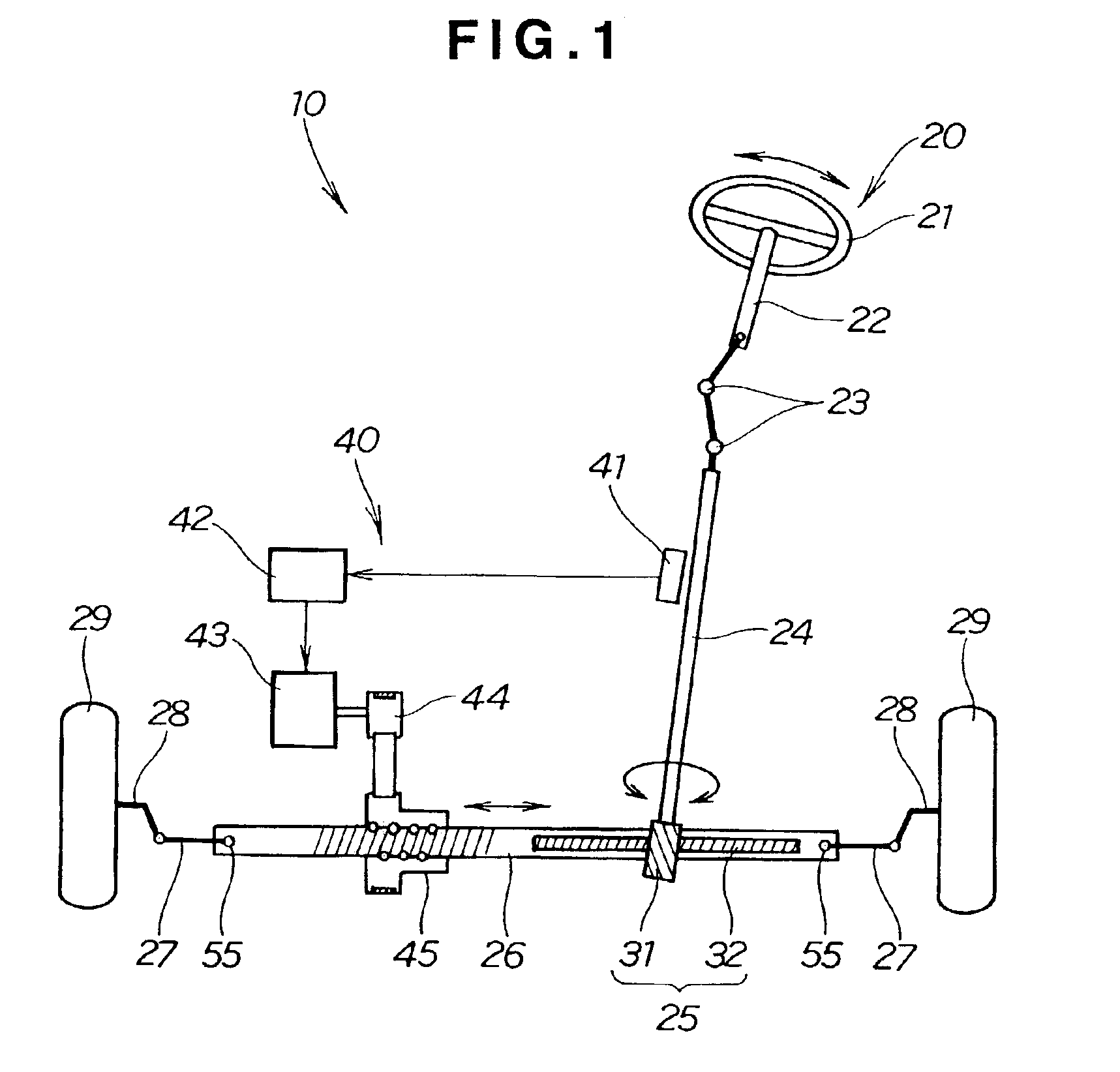

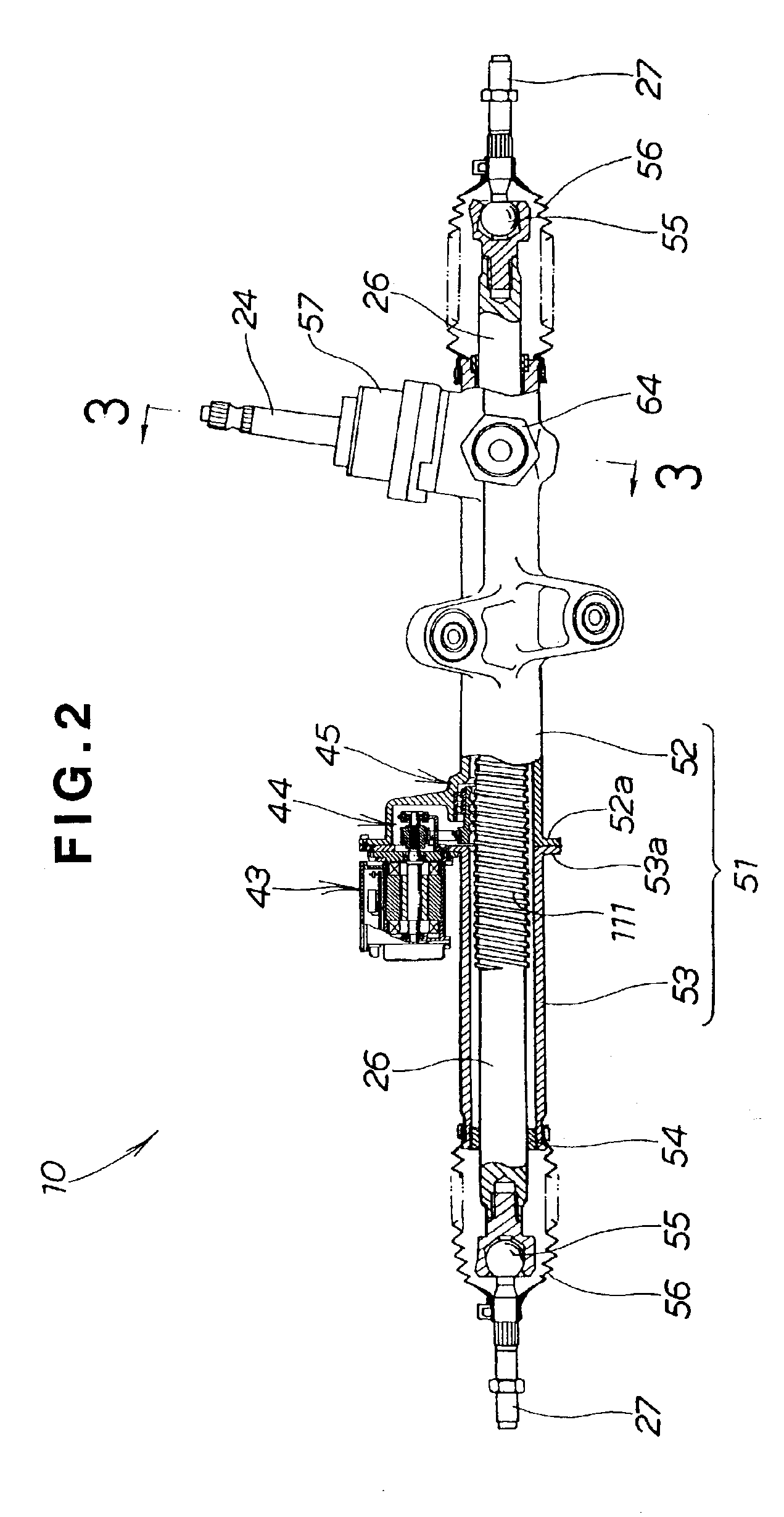

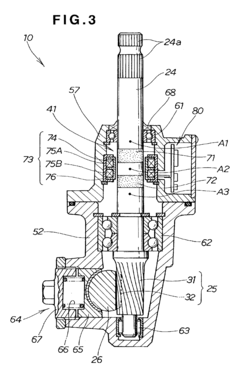

Electric power steering apparatus

PatentInactiveUS6868936B2

Innovation

- The motor shaft is rotatably supported on both sides of the driving pulley, enhancing its bending rigidity to that of a straddle-mounted shaft, and a magnetostriction type torque detection device is used to detect and convert twist in the pinion shaft, allowing for rapid and precise detection of steering torque, thereby improving responsiveness and reducing time lag.

Environmental Impact

The environmental impact of power steering fluid as a contributor to steering lag is a critical consideration in the automotive industry. Power steering fluid, typically composed of mineral oil or synthetic compounds, can have significant environmental consequences when improperly managed or leaked. Fluid leaks from power steering systems can contaminate soil and water sources, potentially harming ecosystems and wildlife. The production and disposal of power steering fluid also contribute to the overall environmental footprint of vehicles.

When power steering fluid degrades or becomes contaminated, it may lead to increased steering lag, prompting more frequent fluid changes. This cycle of replacement and disposal exacerbates the environmental impact, as used fluid must be properly recycled or disposed of to prevent ecological harm. Improper disposal can result in the release of harmful chemicals into the environment, potentially affecting groundwater and aquatic habitats.

Furthermore, the manufacturing process of power steering fluid involves the extraction and processing of raw materials, which contributes to resource depletion and energy consumption. The transportation of these fluids also adds to carbon emissions, further impacting the environment. As steering lag issues may lead to increased fluid consumption, this indirectly amplifies the environmental burden associated with power steering systems.

In response to these environmental concerns, there is a growing trend towards the development of more eco-friendly power steering fluids. These alternatives often utilize biodegradable base oils and additives, reducing the potential for long-term environmental damage in case of leaks or spills. Additionally, some manufacturers are exploring fluid formulations that offer extended service life, thereby reducing the frequency of fluid changes and associated waste.

The automotive industry is also investigating alternative power steering technologies, such as electric power steering systems, which eliminate the need for hydraulic fluid altogether. These systems not only reduce the environmental impact associated with fluid production and disposal but also contribute to improved fuel efficiency by reducing the parasitic load on the engine.

As environmental regulations become more stringent, the impact of power steering fluid on the environment is likely to face increased scrutiny. This may drive further innovation in fluid formulations and steering system designs, aiming to minimize environmental risks while maintaining or improving steering performance. The challenge lies in balancing the need for effective steering systems with the imperative to reduce environmental impact, a consideration that will continue to shape research and development efforts in the automotive sector.

When power steering fluid degrades or becomes contaminated, it may lead to increased steering lag, prompting more frequent fluid changes. This cycle of replacement and disposal exacerbates the environmental impact, as used fluid must be properly recycled or disposed of to prevent ecological harm. Improper disposal can result in the release of harmful chemicals into the environment, potentially affecting groundwater and aquatic habitats.

Furthermore, the manufacturing process of power steering fluid involves the extraction and processing of raw materials, which contributes to resource depletion and energy consumption. The transportation of these fluids also adds to carbon emissions, further impacting the environment. As steering lag issues may lead to increased fluid consumption, this indirectly amplifies the environmental burden associated with power steering systems.

In response to these environmental concerns, there is a growing trend towards the development of more eco-friendly power steering fluids. These alternatives often utilize biodegradable base oils and additives, reducing the potential for long-term environmental damage in case of leaks or spills. Additionally, some manufacturers are exploring fluid formulations that offer extended service life, thereby reducing the frequency of fluid changes and associated waste.

The automotive industry is also investigating alternative power steering technologies, such as electric power steering systems, which eliminate the need for hydraulic fluid altogether. These systems not only reduce the environmental impact associated with fluid production and disposal but also contribute to improved fuel efficiency by reducing the parasitic load on the engine.

As environmental regulations become more stringent, the impact of power steering fluid on the environment is likely to face increased scrutiny. This may drive further innovation in fluid formulations and steering system designs, aiming to minimize environmental risks while maintaining or improving steering performance. The challenge lies in balancing the need for effective steering systems with the imperative to reduce environmental impact, a consideration that will continue to shape research and development efforts in the automotive sector.

Safety Regulations

Safety regulations play a crucial role in the automotive industry, particularly concerning power steering systems and their components. As the investigation into power steering fluid as a potential contributor to steering lag progresses, it is essential to consider the regulatory landscape that governs this area.

The National Highway Traffic Safety Administration (NHTSA) in the United States is the primary regulatory body responsible for establishing and enforcing safety standards for motor vehicles. Under Federal Motor Vehicle Safety Standards (FMVSS), specific requirements are set for steering control systems, including power steering. These standards aim to ensure the safe operation of vehicles and minimize the risk of accidents due to steering system failures.

In the context of power steering fluid and its potential impact on steering lag, several regulatory considerations come into play. FMVSS No. 203 and 204 address steering control systems and steering column displacement, respectively. While these standards do not explicitly mention power steering fluid, they set performance requirements that could be affected by fluid-related issues.

The European Union also has stringent regulations concerning vehicle safety, including Regulation (EU) 2018/858, which covers the approval and market surveillance of motor vehicles. This regulation includes provisions for steering systems and their components, which would encompass power steering fluid as a critical element.

Manufacturers are required to comply with these regulations and demonstrate that their vehicles meet the necessary safety standards. This includes conducting thorough testing and providing documentation on the performance of steering systems under various conditions. Any potential contribution of power steering fluid to steering lag would need to be addressed within this regulatory framework.

Moreover, regulatory bodies often work in collaboration with industry stakeholders to develop and update standards as new technologies and potential safety concerns emerge. The Society of Automotive Engineers (SAE) provides technical standards and recommended practices that often inform regulatory decisions. SAE J1273, for instance, offers guidelines for power steering fluid performance.

As research into the relationship between power steering fluid and steering lag continues, it may lead to updates in safety regulations. Regulatory bodies might consider implementing more specific requirements for power steering fluid properties, maintenance intervals, or monitoring systems to detect potential issues before they impact vehicle safety.

In addition to vehicle-specific regulations, environmental considerations also come into play. The disposal and recycling of power steering fluid are subject to environmental regulations, as improper handling can lead to pollution. Any changes in fluid formulations or usage patterns resulting from this investigation would need to align with existing environmental protection laws.

The National Highway Traffic Safety Administration (NHTSA) in the United States is the primary regulatory body responsible for establishing and enforcing safety standards for motor vehicles. Under Federal Motor Vehicle Safety Standards (FMVSS), specific requirements are set for steering control systems, including power steering. These standards aim to ensure the safe operation of vehicles and minimize the risk of accidents due to steering system failures.

In the context of power steering fluid and its potential impact on steering lag, several regulatory considerations come into play. FMVSS No. 203 and 204 address steering control systems and steering column displacement, respectively. While these standards do not explicitly mention power steering fluid, they set performance requirements that could be affected by fluid-related issues.

The European Union also has stringent regulations concerning vehicle safety, including Regulation (EU) 2018/858, which covers the approval and market surveillance of motor vehicles. This regulation includes provisions for steering systems and their components, which would encompass power steering fluid as a critical element.

Manufacturers are required to comply with these regulations and demonstrate that their vehicles meet the necessary safety standards. This includes conducting thorough testing and providing documentation on the performance of steering systems under various conditions. Any potential contribution of power steering fluid to steering lag would need to be addressed within this regulatory framework.

Moreover, regulatory bodies often work in collaboration with industry stakeholders to develop and update standards as new technologies and potential safety concerns emerge. The Society of Automotive Engineers (SAE) provides technical standards and recommended practices that often inform regulatory decisions. SAE J1273, for instance, offers guidelines for power steering fluid performance.

As research into the relationship between power steering fluid and steering lag continues, it may lead to updates in safety regulations. Regulatory bodies might consider implementing more specific requirements for power steering fluid properties, maintenance intervals, or monitoring systems to detect potential issues before they impact vehicle safety.

In addition to vehicle-specific regulations, environmental considerations also come into play. The disposal and recycling of power steering fluid are subject to environmental regulations, as improper handling can lead to pollution. Any changes in fluid formulations or usage patterns resulting from this investigation would need to align with existing environmental protection laws.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!