Examining the Role of Friction Modifiers in Steering Fluid Formulations

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Friction Modifier Background

Friction modifiers have played a crucial role in the development of steering fluid formulations since the early days of automotive engineering. These additives were initially introduced to address the challenges associated with friction and wear in steering systems, which were becoming increasingly complex and demanding as vehicle designs evolved.

The concept of friction modification in steering fluids can be traced back to the 1950s when power steering systems began to gain widespread adoption in automobiles. As these systems became more sophisticated, the need for specialized fluids to reduce friction and improve overall performance became apparent. Early friction modifiers were primarily based on simple organic compounds, such as fatty acids and esters, which formed protective films on metal surfaces.

Throughout the 1960s and 1970s, significant advancements were made in friction modifier technology. Researchers began to explore more complex molecules, including polymeric compounds and organometallic additives, which offered improved stability and performance across a wider range of operating conditions. These developments coincided with the increasing prevalence of rack-and-pinion steering systems, which placed even greater demands on steering fluid formulations.

The 1980s and 1990s saw a shift towards more environmentally friendly and sustainable friction modifiers. This trend was driven by growing concerns about the environmental impact of automotive fluids and stricter regulations on emissions and waste disposal. As a result, researchers began to focus on developing bio-based friction modifiers derived from renewable resources, such as vegetable oils and their derivatives.

In recent years, the role of friction modifiers in steering fluid formulations has become even more critical with the advent of electric power steering systems. These systems require fluids that can maintain their friction-reducing properties under high-stress conditions and over extended periods. This has led to the development of advanced synthetic friction modifiers that offer superior thermal stability and long-term performance.

The evolution of friction modifiers has been closely tied to advancements in surface chemistry and tribology. Modern friction modifiers are designed to interact with metal surfaces at the molecular level, forming durable boundary layers that minimize friction and wear. This approach has enabled the creation of steering fluids that not only reduce energy losses but also extend the lifespan of steering components.

As the automotive industry continues to evolve, with a growing emphasis on electric and autonomous vehicles, the demands placed on steering fluid formulations are likely to increase further. Future friction modifiers will need to address challenges such as compatibility with new materials, enhanced durability under extreme conditions, and reduced environmental impact. The ongoing research in this field promises to yield innovative solutions that will shape the next generation of steering systems and fluid technologies.

The concept of friction modification in steering fluids can be traced back to the 1950s when power steering systems began to gain widespread adoption in automobiles. As these systems became more sophisticated, the need for specialized fluids to reduce friction and improve overall performance became apparent. Early friction modifiers were primarily based on simple organic compounds, such as fatty acids and esters, which formed protective films on metal surfaces.

Throughout the 1960s and 1970s, significant advancements were made in friction modifier technology. Researchers began to explore more complex molecules, including polymeric compounds and organometallic additives, which offered improved stability and performance across a wider range of operating conditions. These developments coincided with the increasing prevalence of rack-and-pinion steering systems, which placed even greater demands on steering fluid formulations.

The 1980s and 1990s saw a shift towards more environmentally friendly and sustainable friction modifiers. This trend was driven by growing concerns about the environmental impact of automotive fluids and stricter regulations on emissions and waste disposal. As a result, researchers began to focus on developing bio-based friction modifiers derived from renewable resources, such as vegetable oils and their derivatives.

In recent years, the role of friction modifiers in steering fluid formulations has become even more critical with the advent of electric power steering systems. These systems require fluids that can maintain their friction-reducing properties under high-stress conditions and over extended periods. This has led to the development of advanced synthetic friction modifiers that offer superior thermal stability and long-term performance.

The evolution of friction modifiers has been closely tied to advancements in surface chemistry and tribology. Modern friction modifiers are designed to interact with metal surfaces at the molecular level, forming durable boundary layers that minimize friction and wear. This approach has enabled the creation of steering fluids that not only reduce energy losses but also extend the lifespan of steering components.

As the automotive industry continues to evolve, with a growing emphasis on electric and autonomous vehicles, the demands placed on steering fluid formulations are likely to increase further. Future friction modifiers will need to address challenges such as compatibility with new materials, enhanced durability under extreme conditions, and reduced environmental impact. The ongoing research in this field promises to yield innovative solutions that will shape the next generation of steering systems and fluid technologies.

Steering Fluid Market Analysis

The steering fluid market has experienced significant growth in recent years, driven by the increasing demand for automotive vehicles worldwide. As the global automotive industry continues to expand, particularly in emerging markets, the need for high-quality steering fluids has risen correspondingly. The market is characterized by a diverse range of products, including mineral-based, synthetic, and bio-based steering fluids, each catering to specific vehicle requirements and environmental considerations.

A key factor influencing market dynamics is the growing emphasis on vehicle safety and performance. Steering fluids play a crucial role in ensuring smooth and responsive steering systems, directly impacting driver control and overall vehicle handling. This has led to increased investment in research and development by manufacturers to enhance fluid formulations, with a particular focus on friction modifiers to optimize steering performance.

The market is also being shaped by stringent environmental regulations and a shift towards more sustainable automotive solutions. This trend has spurred the development of eco-friendly steering fluid formulations, including biodegradable options and those with reduced environmental impact. Manufacturers are increasingly incorporating advanced friction modifiers that not only improve steering performance but also contribute to reduced fuel consumption and lower emissions.

Regional market analysis reveals varying patterns of adoption and growth. Mature automotive markets such as North America and Europe show steady demand for high-performance steering fluids, with a growing preference for synthetic formulations. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth, driven by increasing vehicle production and a rising middle class with greater purchasing power.

The competitive landscape of the steering fluid market is characterized by a mix of established global players and regional manufacturers. Major automotive fluid suppliers are investing in product innovation and strategic partnerships to maintain their market position. Smaller, specialized manufacturers are carving out niches by focusing on specific formulations or catering to particular vehicle segments.

Looking ahead, the steering fluid market is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth will likely be fueled by technological advancements in friction modifier technology, the expansion of electric and hybrid vehicle markets, and the ongoing development of autonomous driving systems, all of which will require specialized steering fluid formulations to meet their unique performance requirements.

A key factor influencing market dynamics is the growing emphasis on vehicle safety and performance. Steering fluids play a crucial role in ensuring smooth and responsive steering systems, directly impacting driver control and overall vehicle handling. This has led to increased investment in research and development by manufacturers to enhance fluid formulations, with a particular focus on friction modifiers to optimize steering performance.

The market is also being shaped by stringent environmental regulations and a shift towards more sustainable automotive solutions. This trend has spurred the development of eco-friendly steering fluid formulations, including biodegradable options and those with reduced environmental impact. Manufacturers are increasingly incorporating advanced friction modifiers that not only improve steering performance but also contribute to reduced fuel consumption and lower emissions.

Regional market analysis reveals varying patterns of adoption and growth. Mature automotive markets such as North America and Europe show steady demand for high-performance steering fluids, with a growing preference for synthetic formulations. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth, driven by increasing vehicle production and a rising middle class with greater purchasing power.

The competitive landscape of the steering fluid market is characterized by a mix of established global players and regional manufacturers. Major automotive fluid suppliers are investing in product innovation and strategic partnerships to maintain their market position. Smaller, specialized manufacturers are carving out niches by focusing on specific formulations or catering to particular vehicle segments.

Looking ahead, the steering fluid market is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth will likely be fueled by technological advancements in friction modifier technology, the expansion of electric and hybrid vehicle markets, and the ongoing development of autonomous driving systems, all of which will require specialized steering fluid formulations to meet their unique performance requirements.

Friction Modifier Challenges

Friction modifiers play a crucial role in steering fluid formulations, yet they present several significant challenges that researchers and manufacturers must address. One of the primary issues is achieving the delicate balance between reducing friction and maintaining the necessary viscosity of the steering fluid. Excessive friction reduction can lead to a loss of steering feel and control, while insufficient modification may result in poor performance and increased wear on steering components.

Another challenge lies in the long-term stability of friction modifiers within the steering fluid. Over time, these additives can break down or separate from the base fluid, leading to a gradual decrease in their effectiveness. This degradation can result in inconsistent steering performance and potentially compromise the safety of the vehicle. Developing friction modifiers that maintain their efficacy throughout the fluid's lifespan is an ongoing area of research and development.

The compatibility of friction modifiers with other additives in the steering fluid formulation presents yet another hurdle. Steering fluids often contain a complex blend of additives, including anti-wear agents, antioxidants, and corrosion inhibitors. Ensuring that friction modifiers do not interfere with or negate the effects of these other components is critical for overall fluid performance. This challenge requires extensive testing and careful formulation to achieve the optimal balance of additives.

Environmental concerns also pose significant challenges in the development of friction modifiers for steering fluids. As regulations become more stringent, there is a growing need for environmentally friendly additives that maintain high performance standards. Biodegradability, reduced toxicity, and sustainable sourcing are becoming increasingly important factors in the selection and development of friction modifiers.

The varying operating conditions of steering systems further complicate the development of effective friction modifiers. Steering fluids must perform consistently across a wide range of temperatures, pressures, and load conditions. Developing friction modifiers that can maintain their effectiveness under these diverse conditions, without compromising other fluid properties, remains a significant technical challenge.

Lastly, the cost-effectiveness of friction modifiers in steering fluid formulations presents an ongoing challenge. While high-performance additives may offer superior friction reduction and stability, their cost can be prohibitive for mass-market applications. Striking a balance between performance and affordability is crucial for widespread adoption of advanced friction modifier technologies in steering fluids.

Another challenge lies in the long-term stability of friction modifiers within the steering fluid. Over time, these additives can break down or separate from the base fluid, leading to a gradual decrease in their effectiveness. This degradation can result in inconsistent steering performance and potentially compromise the safety of the vehicle. Developing friction modifiers that maintain their efficacy throughout the fluid's lifespan is an ongoing area of research and development.

The compatibility of friction modifiers with other additives in the steering fluid formulation presents yet another hurdle. Steering fluids often contain a complex blend of additives, including anti-wear agents, antioxidants, and corrosion inhibitors. Ensuring that friction modifiers do not interfere with or negate the effects of these other components is critical for overall fluid performance. This challenge requires extensive testing and careful formulation to achieve the optimal balance of additives.

Environmental concerns also pose significant challenges in the development of friction modifiers for steering fluids. As regulations become more stringent, there is a growing need for environmentally friendly additives that maintain high performance standards. Biodegradability, reduced toxicity, and sustainable sourcing are becoming increasingly important factors in the selection and development of friction modifiers.

The varying operating conditions of steering systems further complicate the development of effective friction modifiers. Steering fluids must perform consistently across a wide range of temperatures, pressures, and load conditions. Developing friction modifiers that can maintain their effectiveness under these diverse conditions, without compromising other fluid properties, remains a significant technical challenge.

Lastly, the cost-effectiveness of friction modifiers in steering fluid formulations presents an ongoing challenge. While high-performance additives may offer superior friction reduction and stability, their cost can be prohibitive for mass-market applications. Striking a balance between performance and affordability is crucial for widespread adoption of advanced friction modifier technologies in steering fluids.

Current Friction Modifiers

01 Organic friction modifiers

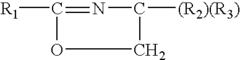

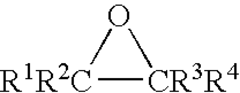

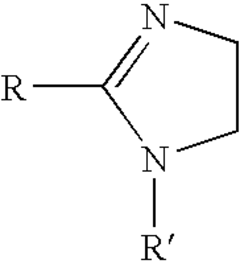

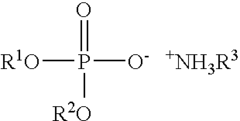

Organic compounds are used as friction modifiers in lubricating compositions. These modifiers can include fatty acids, esters, amides, and other organic molecules that form a protective film on metal surfaces, reducing friction and wear. They are particularly effective in boundary lubrication conditions and can improve fuel efficiency in engines and other mechanical systems.- Organic friction modifiers: Organic compounds are used as friction modifiers in lubricating compositions. These include fatty acids, esters, amides, and other organic molecules that can form a protective film on metal surfaces, reducing friction and wear. The specific molecular structure and chain length of these compounds can be optimized for different applications and operating conditions.

- Nanoparticle-based friction modifiers: Nanoparticles are incorporated into lubricants as friction modifiers. These can include metal oxides, carbon-based materials, or other engineered nanostructures. The small size of these particles allows them to fill surface asperities and create a smooth interface between moving parts, effectively reducing friction and improving wear resistance.

- Polymer-based friction modifiers: Polymeric compounds are used as friction modifiers in various applications. These can include polymethacrylates, polyisobutylenes, or other synthetic polymers. The long-chain structure of these molecules helps to maintain a stable lubricating film and can provide additional benefits such as viscosity modification and dispersancy.

- Friction modifiers for fuel efficiency: Specialized friction modifiers are developed to improve fuel efficiency in automotive applications. These additives work by reducing friction in engine components, transmission systems, and other drivetrain parts. The result is decreased energy loss due to friction, leading to improved overall fuel economy and reduced emissions.

- Synergistic friction modifier combinations: Combinations of different types of friction modifiers are used to achieve synergistic effects. This approach can involve mixing organic and inorganic modifiers, or combining modifiers with different mechanisms of action. The goal is to provide enhanced friction reduction across a wider range of operating conditions and to address multiple aspects of tribological performance simultaneously.

02 Nanoparticle-based friction modifiers

Nanoparticles are incorporated into lubricants as friction modifiers. These can include materials such as graphene, carbon nanotubes, or metal oxide nanoparticles. The small size of these particles allows them to fill surface asperities and create a smooth, low-friction interface. They can significantly reduce wear and friction in various mechanical applications.Expand Specific Solutions03 Polymer-based friction modifiers

Polymeric compounds are used as friction modifiers in lubricating compositions. These can include various types of polymers and copolymers that adhere to surfaces and provide a cushioning effect between moving parts. They are particularly useful in high-pressure applications and can improve the viscosity index of the lubricant.Expand Specific Solutions04 Friction modifiers for specific applications

Specialized friction modifiers are developed for specific applications such as automotive transmissions, industrial gearboxes, or wind turbine bearings. These modifiers are tailored to the unique operating conditions and requirements of each application, considering factors such as temperature, pressure, and speed. They can significantly improve the efficiency and lifespan of the machinery.Expand Specific Solutions05 Synergistic friction modifier combinations

Combinations of different types of friction modifiers are used to achieve synergistic effects. For example, organic friction modifiers might be combined with nanoparticles or polymers to create a more effective lubricating system. These combinations can provide better performance across a wider range of operating conditions than single-component systems.Expand Specific Solutions

Key Steering Fluid Players

The competition landscape for friction modifiers in steering fluid formulations is characterized by a mature market with established players and ongoing technological advancements. The market is dominated by major oil and chemical companies, including The Lubrizol Corp., Shell, Afton Chemical Corp., ExxonMobil, and Chevron Oronite. These companies leverage their extensive R&D capabilities and global presence to maintain market share. The industry is in a consolidation phase, with a focus on developing high-performance, environmentally friendly formulations. While the market size is substantial due to the automotive industry's demands, growth is moderate, driven by innovations in electric power steering systems and the need for improved fuel efficiency and reduced emissions in conventional vehicles.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed advanced friction modifier technologies for steering fluid formulations. Their approach involves using organic molybdenum compounds combined with phosphorus-containing additives to create a synergistic effect[1]. This formulation creates a robust boundary lubrication film on metal surfaces, reducing friction and wear in steering systems. The company has also introduced nano-sized friction modifiers, which can penetrate smaller clearances and provide more uniform coverage[2]. These nano-modifiers are particularly effective in high-pressure areas of steering mechanisms, where traditional additives may struggle to maintain a consistent film[3].

Strengths: Superior boundary lubrication, enhanced wear protection, and improved efficiency in high-pressure applications. Weaknesses: Potential higher cost due to advanced chemistry, and possible compatibility issues with some seal materials.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered the use of organic friction modifiers (OFMs) in steering fluid formulations. Their technology focuses on long-chain molecules that adhere to metal surfaces, creating a low-friction layer[4]. These OFMs are designed to work synergistically with anti-wear additives, providing both friction reduction and component protection. Shell has also developed temperature-responsive friction modifiers that adjust their performance based on operating conditions, ensuring optimal steering feel across various climates[5]. Additionally, they have introduced bio-based friction modifiers derived from renewable sources, addressing environmental concerns while maintaining performance[6].

Strengths: Environmentally friendly options, adaptable performance across temperature ranges, and good synergy with other additives. Weaknesses: Potential limitations in extreme pressure conditions and possible higher production costs for bio-based modifiers.

Innovative Friction Modifiers

Friction modifiers for improved Anti-shudder performance and high static friction in transmission fluids

PatentWO2004007652A1

Innovation

- A friction modifier is developed by condensing a carboxylic acid or its reactive equivalent with an amino alcohol, such as isostearic acid with tris-hydroxymethylaminomethane, to create molecules with two hydrocarbyl groups, enhancing static friction and durability in transmission fluids.

Friction modifiers for improved anti-shudder performance and high static friction in transmission fluids

PatentInactiveUS7381691B2

Innovation

- A friction modifier is developed by condensing a carboxylic acid or its reactive equivalent with an amino alcohol, such as isostearic acid with tris-hydroxymethylaminomethane, to create molecules with multiple hydrocarbyl groups, enhancing static friction and durability in transmission fluids.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and application of friction modifiers in steering fluid formulations. As global awareness of environmental issues continues to grow, regulatory bodies worldwide have implemented increasingly stringent standards to minimize the ecological impact of automotive fluids, including power steering fluids.

One of the primary concerns addressed by environmental regulations is the potential for fluid leakage and subsequent contamination of soil and water resources. Steering fluids containing traditional friction modifiers may pose risks to aquatic ecosystems if released into the environment. Consequently, regulations have been established to limit the use of certain chemicals and promote the development of more environmentally friendly alternatives.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential in this regard. REACH requires manufacturers to assess and manage the risks associated with chemicals used in their products, including friction modifiers in steering fluids. This has led to a shift towards more sustainable and biodegradable friction modifier formulations.

In the United States, the Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) that impact the use of certain chemicals in automotive fluids. These regulations have prompted manufacturers to invest in research and development of friction modifiers that meet both performance requirements and environmental standards.

The automotive industry has responded to these regulatory pressures by developing new generations of friction modifiers that offer improved environmental profiles. These include bio-based additives derived from renewable resources, which can reduce the carbon footprint of steering fluid formulations. Additionally, efforts have been made to enhance the biodegradability of friction modifiers, ensuring that they break down more readily in the environment if released.

Regulations have also driven improvements in the overall efficiency of steering systems, indirectly affecting friction modifier formulations. As automakers strive to meet increasingly stringent fuel efficiency standards, there is a growing demand for steering fluids that can contribute to reduced energy consumption. This has led to the development of friction modifiers that can maintain optimal performance while minimizing power losses in the steering system.

Furthermore, environmental regulations have influenced the disposal and recycling practices for used steering fluids. Many jurisdictions now require proper handling and disposal of these fluids to prevent environmental contamination. This has encouraged the development of friction modifiers that are more easily separated from the base fluid during recycling processes, facilitating the recovery and reuse of steering fluid components.

As environmental regulations continue to evolve, the friction modifier industry faces ongoing challenges and opportunities. Manufacturers must balance the need for high-performance steering fluids with the imperative to minimize environmental impact. This dynamic regulatory landscape is likely to drive further innovation in friction modifier technology, potentially leading to more sustainable and eco-friendly steering fluid formulations in the future.

One of the primary concerns addressed by environmental regulations is the potential for fluid leakage and subsequent contamination of soil and water resources. Steering fluids containing traditional friction modifiers may pose risks to aquatic ecosystems if released into the environment. Consequently, regulations have been established to limit the use of certain chemicals and promote the development of more environmentally friendly alternatives.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential in this regard. REACH requires manufacturers to assess and manage the risks associated with chemicals used in their products, including friction modifiers in steering fluids. This has led to a shift towards more sustainable and biodegradable friction modifier formulations.

In the United States, the Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) that impact the use of certain chemicals in automotive fluids. These regulations have prompted manufacturers to invest in research and development of friction modifiers that meet both performance requirements and environmental standards.

The automotive industry has responded to these regulatory pressures by developing new generations of friction modifiers that offer improved environmental profiles. These include bio-based additives derived from renewable resources, which can reduce the carbon footprint of steering fluid formulations. Additionally, efforts have been made to enhance the biodegradability of friction modifiers, ensuring that they break down more readily in the environment if released.

Regulations have also driven improvements in the overall efficiency of steering systems, indirectly affecting friction modifier formulations. As automakers strive to meet increasingly stringent fuel efficiency standards, there is a growing demand for steering fluids that can contribute to reduced energy consumption. This has led to the development of friction modifiers that can maintain optimal performance while minimizing power losses in the steering system.

Furthermore, environmental regulations have influenced the disposal and recycling practices for used steering fluids. Many jurisdictions now require proper handling and disposal of these fluids to prevent environmental contamination. This has encouraged the development of friction modifiers that are more easily separated from the base fluid during recycling processes, facilitating the recovery and reuse of steering fluid components.

As environmental regulations continue to evolve, the friction modifier industry faces ongoing challenges and opportunities. Manufacturers must balance the need for high-performance steering fluids with the imperative to minimize environmental impact. This dynamic regulatory landscape is likely to drive further innovation in friction modifier technology, potentially leading to more sustainable and eco-friendly steering fluid formulations in the future.

Performance Testing Methods

Performance testing methods for friction modifiers in steering fluid formulations are crucial for evaluating their effectiveness and ensuring optimal performance in automotive steering systems. These methods typically involve a combination of laboratory tests and real-world simulations to assess various aspects of the friction modifiers' performance.

One of the primary testing methods is the use of tribometers, which measure friction coefficients and wear rates under controlled conditions. These devices simulate the contact between steering system components, such as the rack and pinion, allowing researchers to evaluate how different friction modifier formulations affect the overall friction characteristics. Tribometer tests can be conducted under various temperatures, pressures, and speeds to mimic real-world operating conditions.

Another essential testing method is the use of hydraulic test benches specifically designed for power steering systems. These benches allow for the measurement of fluid pressure, flow rates, and temperature changes during simulated steering operations. By comparing the performance of steering fluids with different friction modifier formulations, researchers can assess their impact on system efficiency and responsiveness.

Viscosity testing is also a critical component of performance evaluation. Brookfield viscometers and rotational viscometers are commonly used to measure the viscosity of steering fluids at different temperatures and shear rates. This data helps in understanding how friction modifiers affect the fluid's flow characteristics and its ability to maintain proper lubrication under various operating conditions.

Thermal stability tests are conducted to evaluate the performance of friction modifiers at elevated temperatures. These tests typically involve cycling the fluid through high-temperature conditions and measuring changes in viscosity, oxidation resistance, and overall performance. This information is crucial for ensuring that the steering fluid maintains its effectiveness throughout the vehicle's lifespan.

Compatibility testing is another vital aspect of performance evaluation. This involves assessing how the friction modifiers interact with other components of the steering system, such as seals, hoses, and metal surfaces. Accelerated aging tests and material compatibility studies help identify any potential issues that may arise from long-term exposure to the modified steering fluid.

Field testing and vehicle trials represent the final stage of performance evaluation. These tests involve installing the friction modifier-enhanced steering fluid in actual vehicles and conducting extensive road tests under various driving conditions. Data logging equipment is used to monitor steering performance, power consumption, and overall system behavior. This real-world validation is essential for confirming the laboratory findings and ensuring that the friction modifiers deliver the expected benefits in practical applications.

One of the primary testing methods is the use of tribometers, which measure friction coefficients and wear rates under controlled conditions. These devices simulate the contact between steering system components, such as the rack and pinion, allowing researchers to evaluate how different friction modifier formulations affect the overall friction characteristics. Tribometer tests can be conducted under various temperatures, pressures, and speeds to mimic real-world operating conditions.

Another essential testing method is the use of hydraulic test benches specifically designed for power steering systems. These benches allow for the measurement of fluid pressure, flow rates, and temperature changes during simulated steering operations. By comparing the performance of steering fluids with different friction modifier formulations, researchers can assess their impact on system efficiency and responsiveness.

Viscosity testing is also a critical component of performance evaluation. Brookfield viscometers and rotational viscometers are commonly used to measure the viscosity of steering fluids at different temperatures and shear rates. This data helps in understanding how friction modifiers affect the fluid's flow characteristics and its ability to maintain proper lubrication under various operating conditions.

Thermal stability tests are conducted to evaluate the performance of friction modifiers at elevated temperatures. These tests typically involve cycling the fluid through high-temperature conditions and measuring changes in viscosity, oxidation resistance, and overall performance. This information is crucial for ensuring that the steering fluid maintains its effectiveness throughout the vehicle's lifespan.

Compatibility testing is another vital aspect of performance evaluation. This involves assessing how the friction modifiers interact with other components of the steering system, such as seals, hoses, and metal surfaces. Accelerated aging tests and material compatibility studies help identify any potential issues that may arise from long-term exposure to the modified steering fluid.

Field testing and vehicle trials represent the final stage of performance evaluation. These tests involve installing the friction modifier-enhanced steering fluid in actual vehicles and conducting extensive road tests under various driving conditions. Data logging equipment is used to monitor steering performance, power consumption, and overall system behavior. This real-world validation is essential for confirming the laboratory findings and ensuring that the friction modifiers deliver the expected benefits in practical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!