The Influence of Power Steering Fluid on Vehicle Weight Distribution

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. The need for a more efficient and less strenuous steering mechanism led to the development of power steering systems.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in vehicle control. This system utilized a hydraulic pump driven by the engine to provide assistance to the steering mechanism. The power steering fluid, a key component of this system, played a crucial role in transmitting force and reducing steering effort. As vehicles became larger and heavier, the importance of power steering systems grew, leading to widespread adoption across the automotive industry.

In the 1960s and 1970s, advancements in hydraulic power steering systems focused on improving efficiency and reducing the parasitic load on the engine. Engineers worked on optimizing the hydraulic circuits and developing more responsive valves to enhance steering feel and precision. During this period, the impact of power steering fluid on vehicle weight distribution became a subject of interest for automotive designers and engineers.

The 1980s and 1990s saw the introduction of electronic power steering systems, which began to challenge the dominance of hydraulic systems. These new systems used electric motors to provide steering assistance, eliminating the need for hydraulic fluid and reducing the overall weight of the steering system. This shift had significant implications for vehicle weight distribution and fuel efficiency.

As environmental concerns grew in the 21st century, the automotive industry intensified its focus on reducing vehicle weight and improving fuel economy. This led to further refinements in both hydraulic and electric power steering systems. Hydraulic systems became more compact and efficient, while electric systems continued to improve in performance and reliability.

Today, the power steering landscape is dominated by electric power steering (EPS) systems, which offer advantages in terms of weight reduction, energy efficiency, and compatibility with advanced driver assistance systems. However, hydraulic systems still find applications in certain vehicle types, particularly in heavy-duty vehicles where high steering loads are encountered.

The evolution of power steering technology has had a profound impact on vehicle design, driving experience, and overall automotive engineering. As we look to the future, the ongoing development of autonomous vehicles and the push for even greater efficiency are likely to drive further innovations in steering technology, potentially redefining the role of steering systems in modern vehicles.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in vehicle control. This system utilized a hydraulic pump driven by the engine to provide assistance to the steering mechanism. The power steering fluid, a key component of this system, played a crucial role in transmitting force and reducing steering effort. As vehicles became larger and heavier, the importance of power steering systems grew, leading to widespread adoption across the automotive industry.

In the 1960s and 1970s, advancements in hydraulic power steering systems focused on improving efficiency and reducing the parasitic load on the engine. Engineers worked on optimizing the hydraulic circuits and developing more responsive valves to enhance steering feel and precision. During this period, the impact of power steering fluid on vehicle weight distribution became a subject of interest for automotive designers and engineers.

The 1980s and 1990s saw the introduction of electronic power steering systems, which began to challenge the dominance of hydraulic systems. These new systems used electric motors to provide steering assistance, eliminating the need for hydraulic fluid and reducing the overall weight of the steering system. This shift had significant implications for vehicle weight distribution and fuel efficiency.

As environmental concerns grew in the 21st century, the automotive industry intensified its focus on reducing vehicle weight and improving fuel economy. This led to further refinements in both hydraulic and electric power steering systems. Hydraulic systems became more compact and efficient, while electric systems continued to improve in performance and reliability.

Today, the power steering landscape is dominated by electric power steering (EPS) systems, which offer advantages in terms of weight reduction, energy efficiency, and compatibility with advanced driver assistance systems. However, hydraulic systems still find applications in certain vehicle types, particularly in heavy-duty vehicles where high steering loads are encountered.

The evolution of power steering technology has had a profound impact on vehicle design, driving experience, and overall automotive engineering. As we look to the future, the ongoing development of autonomous vehicles and the push for even greater efficiency are likely to drive further innovations in steering technology, potentially redefining the role of steering systems in modern vehicles.

Market Demand Analysis

The market demand for power steering fluid and its impact on vehicle weight distribution has been steadily growing in recent years. This trend is driven by the increasing complexity of modern vehicles and the automotive industry's focus on improving fuel efficiency and performance. As vehicles become more sophisticated, the need for advanced power steering systems that can optimize weight distribution becomes paramount.

The global power steering fluid market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is attributed to the rising production of vehicles worldwide, particularly in emerging economies. The automotive industry's shift towards electric power steering systems has also created new opportunities for specialized power steering fluids that can enhance the performance and longevity of these systems.

Consumer demand for improved vehicle handling and comfort has been a key driver in the development of power steering fluids that can influence weight distribution. As drivers seek more responsive and stable vehicles, manufacturers are investing in research and development to create power steering fluids that can optimize weight transfer during cornering, acceleration, and braking. This has led to a growing market for high-performance power steering fluids designed specifically for sports cars and luxury vehicles.

The commercial vehicle segment has also shown increased demand for power steering fluids that can improve weight distribution. Fleet operators are recognizing the potential for enhanced fuel efficiency and reduced tire wear through optimized weight distribution, leading to a rise in the adoption of advanced power steering systems and fluids in trucks and buses.

Environmental concerns and regulatory pressures have further shaped the market demand for power steering fluids. There is a growing preference for eco-friendly and biodegradable fluids that can maintain performance while reducing environmental impact. This trend has spurred innovation in the development of bio-based power steering fluids, which are expected to gain significant market share in the coming years.

The aftermarket segment for power steering fluids has shown robust growth, driven by increased vehicle ownership and the need for regular maintenance. As consumers become more aware of the importance of proper power steering fluid in maintaining vehicle performance and weight distribution, there has been a rise in demand for high-quality replacement fluids and professional servicing.

In conclusion, the market demand for power steering fluids that can influence vehicle weight distribution is multifaceted, driven by technological advancements, consumer preferences, environmental concerns, and the overall growth of the automotive industry. As vehicle manufacturers continue to prioritize performance and efficiency, the role of power steering fluids in optimizing weight distribution is expected to become increasingly significant, shaping future market trends and product development in the automotive sector.

The global power steering fluid market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is attributed to the rising production of vehicles worldwide, particularly in emerging economies. The automotive industry's shift towards electric power steering systems has also created new opportunities for specialized power steering fluids that can enhance the performance and longevity of these systems.

Consumer demand for improved vehicle handling and comfort has been a key driver in the development of power steering fluids that can influence weight distribution. As drivers seek more responsive and stable vehicles, manufacturers are investing in research and development to create power steering fluids that can optimize weight transfer during cornering, acceleration, and braking. This has led to a growing market for high-performance power steering fluids designed specifically for sports cars and luxury vehicles.

The commercial vehicle segment has also shown increased demand for power steering fluids that can improve weight distribution. Fleet operators are recognizing the potential for enhanced fuel efficiency and reduced tire wear through optimized weight distribution, leading to a rise in the adoption of advanced power steering systems and fluids in trucks and buses.

Environmental concerns and regulatory pressures have further shaped the market demand for power steering fluids. There is a growing preference for eco-friendly and biodegradable fluids that can maintain performance while reducing environmental impact. This trend has spurred innovation in the development of bio-based power steering fluids, which are expected to gain significant market share in the coming years.

The aftermarket segment for power steering fluids has shown robust growth, driven by increased vehicle ownership and the need for regular maintenance. As consumers become more aware of the importance of proper power steering fluid in maintaining vehicle performance and weight distribution, there has been a rise in demand for high-quality replacement fluids and professional servicing.

In conclusion, the market demand for power steering fluids that can influence vehicle weight distribution is multifaceted, driven by technological advancements, consumer preferences, environmental concerns, and the overall growth of the automotive industry. As vehicle manufacturers continue to prioritize performance and efficiency, the role of power steering fluids in optimizing weight distribution is expected to become increasingly significant, shaping future market trends and product development in the automotive sector.

Current Challenges

The current challenges in understanding and optimizing the influence of power steering fluid on vehicle weight distribution are multifaceted and complex. One of the primary issues is the dynamic nature of fluid movement within the power steering system during various driving conditions. As vehicles navigate turns, accelerate, or brake, the fluid's distribution can shift, potentially altering the vehicle's weight balance in real-time. This presents a significant challenge for engineers attempting to model and predict the system's behavior accurately.

Another critical challenge lies in the variability of power steering fluid properties across different environmental conditions. Temperature fluctuations can significantly affect the fluid's viscosity, which in turn impacts its flow characteristics and distribution within the system. This variability makes it difficult to maintain consistent performance and weight distribution across diverse operating environments, from frigid arctic conditions to scorching desert heat.

The integration of power steering systems with modern vehicle technologies poses additional challenges. As automotive manufacturers increasingly adopt electric power steering (EPS) systems, the traditional hydraulic fluid-based systems are being phased out in many vehicle models. This transition creates a need for comprehensive comparative studies to understand how the weight distribution dynamics differ between hydraulic and electric systems, and how these differences affect overall vehicle handling and performance.

Furthermore, the pursuit of lightweight vehicle designs to improve fuel efficiency and reduce emissions conflicts with the need for robust power steering systems. Engineers face the challenge of optimizing the amount of power steering fluid used while maintaining system effectiveness. Reducing fluid volume can lead to potential performance issues and increased wear on components, while excess fluid adds unnecessary weight to the vehicle.

The complexity of modern vehicle designs also complicates the analysis of power steering fluid's impact on weight distribution. With the integration of numerous subsystems and components, isolating the specific effects of power steering fluid becomes increasingly difficult. This complexity necessitates sophisticated modeling and simulation tools, as well as extensive real-world testing to validate theoretical findings.

Lastly, there is a growing need to address the environmental impact of power steering fluids. As automotive manufacturers strive to meet stringent environmental regulations, finding eco-friendly alternatives to traditional power steering fluids without compromising performance or weight distribution characteristics presents a significant challenge. This includes developing biodegradable fluids or exploring entirely new technologies that could eliminate the need for fluid-based systems altogether.

Another critical challenge lies in the variability of power steering fluid properties across different environmental conditions. Temperature fluctuations can significantly affect the fluid's viscosity, which in turn impacts its flow characteristics and distribution within the system. This variability makes it difficult to maintain consistent performance and weight distribution across diverse operating environments, from frigid arctic conditions to scorching desert heat.

The integration of power steering systems with modern vehicle technologies poses additional challenges. As automotive manufacturers increasingly adopt electric power steering (EPS) systems, the traditional hydraulic fluid-based systems are being phased out in many vehicle models. This transition creates a need for comprehensive comparative studies to understand how the weight distribution dynamics differ between hydraulic and electric systems, and how these differences affect overall vehicle handling and performance.

Furthermore, the pursuit of lightweight vehicle designs to improve fuel efficiency and reduce emissions conflicts with the need for robust power steering systems. Engineers face the challenge of optimizing the amount of power steering fluid used while maintaining system effectiveness. Reducing fluid volume can lead to potential performance issues and increased wear on components, while excess fluid adds unnecessary weight to the vehicle.

The complexity of modern vehicle designs also complicates the analysis of power steering fluid's impact on weight distribution. With the integration of numerous subsystems and components, isolating the specific effects of power steering fluid becomes increasingly difficult. This complexity necessitates sophisticated modeling and simulation tools, as well as extensive real-world testing to validate theoretical findings.

Lastly, there is a growing need to address the environmental impact of power steering fluids. As automotive manufacturers strive to meet stringent environmental regulations, finding eco-friendly alternatives to traditional power steering fluids without compromising performance or weight distribution characteristics presents a significant challenge. This includes developing biodegradable fluids or exploring entirely new technologies that could eliminate the need for fluid-based systems altogether.

Existing Fluid Solutions

01 Power steering fluid composition

The composition of power steering fluid plays a crucial role in weight distribution and overall system performance. Specialized formulations can improve viscosity, reduce friction, and enhance heat dissipation, contributing to better weight balance and efficiency in the power steering system.- Power steering fluid distribution systems: Various systems and methods for distributing power steering fluid in vehicles. These systems aim to optimize the flow and pressure of the fluid to enhance steering performance and efficiency. They may include specialized pumps, valves, and reservoirs designed to maintain proper fluid distribution throughout the steering system.

- Weight distribution in power steering systems: Techniques for managing weight distribution in power steering systems to improve vehicle handling and stability. This may involve strategic placement of components, use of lightweight materials, or adjustable mechanisms to balance the weight of the steering system across the vehicle.

- Electronic control of power steering fluid: Implementation of electronic control systems to regulate power steering fluid pressure and flow. These systems may use sensors and actuators to adjust fluid distribution based on driving conditions, vehicle speed, and steering input, optimizing performance and efficiency.

- Power steering fluid composition: Development of specialized power steering fluid compositions to improve performance and longevity of steering systems. These fluids may have specific viscosity characteristics, additives for wear protection, or properties that enhance weight distribution and overall system efficiency.

- Integration of power steering with vehicle weight management: Approaches to integrate power steering systems with overall vehicle weight management strategies. This may include adaptive systems that adjust steering assistance based on vehicle load, or designs that contribute to optimal weight distribution for improved handling and fuel efficiency.

02 Weight distribution in vehicle design

Proper weight distribution, including the consideration of power steering fluid weight, is essential in vehicle design. Optimizing the placement of components and fluid reservoirs can improve handling, stability, and overall performance of the vehicle.Expand Specific Solutions03 Power steering system configuration

The configuration of the power steering system, including fluid reservoirs and lines, affects weight distribution. Innovative designs can minimize fluid volume while maintaining performance, contributing to better overall vehicle balance.Expand Specific Solutions04 Electronic power steering systems

Electronic power steering systems can reduce the reliance on hydraulic fluid, potentially improving weight distribution. These systems use electric motors and sensors to assist steering, minimizing the need for traditional power steering fluid.Expand Specific Solutions05 Adaptive power steering systems

Adaptive power steering systems can adjust fluid pressure and flow based on driving conditions, potentially optimizing weight distribution. These systems can vary assistance levels, improving efficiency and potentially reducing the overall fluid weight required.Expand Specific Solutions

Key Industry Players

The power steering fluid's influence on vehicle weight distribution is a mature technology in the automotive industry, with a well-established market. The competitive landscape is characterized by a mix of global automotive giants and specialized component manufacturers. Companies like ZF Friedrichshafen AG, JTEKT Corp., and Bosch Rexroth Co. Ltd. are key players in this field, leveraging their extensive experience in automotive systems. The market is in a stable growth phase, driven by continuous improvements in vehicle handling and safety. As automakers like Toyota, GM, and Ford focus on optimizing vehicle performance, the demand for advanced power steering solutions continues to evolve, pushing companies to innovate in areas such as electric power steering and weight reduction technologies.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced Electric Power Steering (EPS) system that significantly reduces the impact of power steering fluid on vehicle weight distribution. The system utilizes a compact electric motor and control unit, eliminating the need for traditional hydraulic fluid and associated components. This innovation has led to a weight reduction of up to 3-4 kg compared to conventional hydraulic systems[1]. GM's EPS technology incorporates adaptive steering algorithms that adjust steering assist based on vehicle speed and driver input, ensuring optimal performance across various driving conditions[2]. The system also features a fail-operational mode, which maintains partial steering assistance even in the event of a primary system failure, enhancing overall vehicle safety[3].

Strengths: Significant weight reduction, improved fuel efficiency, and enhanced vehicle dynamics. Weaknesses: Higher initial cost and potential complexity in system integration for certain vehicle models.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered an innovative Adaptive Steering system that addresses the influence of power steering fluid on vehicle weight distribution. This technology uses a precision-controlled actuator placed inside the steering wheel, working in conjunction with an electric power steering motor. The system dynamically adjusts the steering ratio based on vehicle speed and driver input, reducing the need for a large reservoir of power steering fluid[4]. Ford's approach has resulted in a more compact steering system, with fluid volume reduced by up to 30% compared to traditional setups[5]. Additionally, Ford has implemented a variable-assist power steering pump that adjusts fluid pressure based on steering demand, further optimizing fluid usage and reducing unnecessary weight[6].

Strengths: Improved steering response, reduced system weight, and enhanced maneuverability. Weaknesses: Increased system complexity and potential higher maintenance costs for specialized components.

Innovative Fluid Formulas

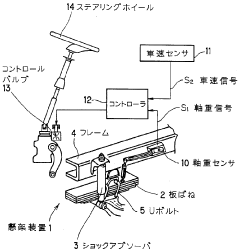

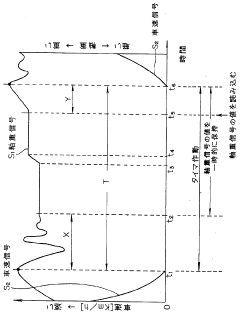

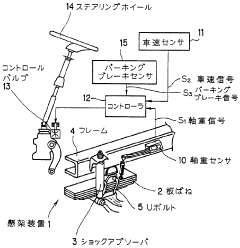

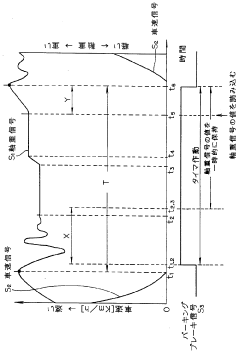

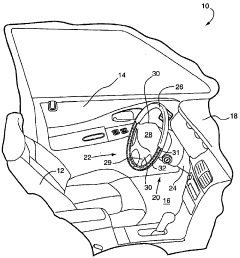

Vehicle weight responding type power steering device

PatentWO1996036521A1

Innovation

- Implementing a control mechanism that stores detection outputs from load and vehicle state sensors for a predetermined period, adjusting the steering assist force only when the vehicle is in a stable stopped state, using two distinct time sets to filter out vibrations and ensure accurate load detection, thereby maintaining consistent assist force during operation.

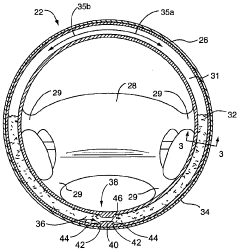

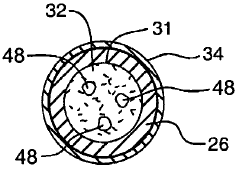

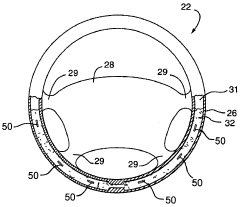

Steering wheel damper

PatentWO2005073051A1

Innovation

- A cost-effective damping system is implemented by placing a damping fluid within the outer rim of the steering wheel, allowing for adjustment of weight and inertia, using a central member connected to a steering column with an outer rim that encircles it, featuring internal chambers filled with liquids or gels of varying viscosities to dampen vibrations and provide desired inertia.

Vehicle Dynamics Impact

The influence of power steering fluid on vehicle weight distribution has significant implications for vehicle dynamics. As power steering systems have evolved, the impact of fluid weight and distribution has become an increasingly important consideration in vehicle design and performance optimization.

Power steering fluid, while essential for the smooth operation of the steering system, contributes to the overall weight of the vehicle. The location and volume of the fluid reservoir, as well as the distribution of fluid throughout the steering system, can affect the vehicle's center of gravity and weight balance. This, in turn, influences various aspects of vehicle dynamics, including handling, stability, and overall performance.

In modern vehicles, the trend towards electric power steering systems has reduced the reliance on hydraulic fluid, leading to changes in weight distribution. However, many vehicles still utilize hydraulic or hybrid systems, making the consideration of fluid weight and placement crucial. The positioning of the fluid reservoir and the routing of hydraulic lines can impact weight distribution between the front and rear axles, as well as between the left and right sides of the vehicle.

The dynamic nature of power steering fluid movement during vehicle operation adds another layer of complexity to its impact on vehicle dynamics. As the steering wheel is turned, fluid moves through the system, causing subtle shifts in weight distribution. These shifts, while minor, can influence the vehicle's behavior during cornering, especially in high-performance driving scenarios or emergency maneuvers.

Engineers must carefully consider the placement of power steering components to optimize weight distribution and minimize negative effects on vehicle dynamics. This includes strategic positioning of the fluid reservoir, pump, and hydraulic lines to maintain balance and reduce unsprung weight. Additionally, the volume of fluid used in the system must be optimized to ensure proper function while minimizing unnecessary weight.

The impact of power steering fluid on vehicle dynamics extends beyond static weight distribution. The fluid's viscosity and temperature characteristics can affect steering feel and responsiveness, which are critical aspects of vehicle dynamics. Changes in fluid properties due to temperature fluctuations or aging can alter steering performance, potentially impacting the driver's ability to control the vehicle effectively.

As vehicle manufacturers strive for improved fuel efficiency and performance, the role of power steering fluid in weight distribution becomes increasingly important. Advanced simulation tools and testing methodologies are employed to analyze and optimize the impact of steering system components, including fluid, on overall vehicle dynamics. This holistic approach ensures that power steering systems contribute positively to vehicle handling and stability while minimizing any adverse effects on weight distribution and performance.

Power steering fluid, while essential for the smooth operation of the steering system, contributes to the overall weight of the vehicle. The location and volume of the fluid reservoir, as well as the distribution of fluid throughout the steering system, can affect the vehicle's center of gravity and weight balance. This, in turn, influences various aspects of vehicle dynamics, including handling, stability, and overall performance.

In modern vehicles, the trend towards electric power steering systems has reduced the reliance on hydraulic fluid, leading to changes in weight distribution. However, many vehicles still utilize hydraulic or hybrid systems, making the consideration of fluid weight and placement crucial. The positioning of the fluid reservoir and the routing of hydraulic lines can impact weight distribution between the front and rear axles, as well as between the left and right sides of the vehicle.

The dynamic nature of power steering fluid movement during vehicle operation adds another layer of complexity to its impact on vehicle dynamics. As the steering wheel is turned, fluid moves through the system, causing subtle shifts in weight distribution. These shifts, while minor, can influence the vehicle's behavior during cornering, especially in high-performance driving scenarios or emergency maneuvers.

Engineers must carefully consider the placement of power steering components to optimize weight distribution and minimize negative effects on vehicle dynamics. This includes strategic positioning of the fluid reservoir, pump, and hydraulic lines to maintain balance and reduce unsprung weight. Additionally, the volume of fluid used in the system must be optimized to ensure proper function while minimizing unnecessary weight.

The impact of power steering fluid on vehicle dynamics extends beyond static weight distribution. The fluid's viscosity and temperature characteristics can affect steering feel and responsiveness, which are critical aspects of vehicle dynamics. Changes in fluid properties due to temperature fluctuations or aging can alter steering performance, potentially impacting the driver's ability to control the vehicle effectively.

As vehicle manufacturers strive for improved fuel efficiency and performance, the role of power steering fluid in weight distribution becomes increasingly important. Advanced simulation tools and testing methodologies are employed to analyze and optimize the impact of steering system components, including fluid, on overall vehicle dynamics. This holistic approach ensures that power steering systems contribute positively to vehicle handling and stability while minimizing any adverse effects on weight distribution and performance.

Environmental Regulations

Environmental regulations play a significant role in shaping the automotive industry's approach to power steering fluid and its impact on vehicle weight distribution. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers are compelled to optimize every aspect of vehicle design, including the power steering system.

The use of power steering fluid is subject to various environmental regulations due to its potential environmental impact. These fluids often contain petroleum-based or synthetic compounds that can be harmful if released into the environment. Consequently, regulations have been established to govern the production, use, and disposal of power steering fluids.

One of the primary concerns addressed by environmental regulations is the prevention of fluid leaks. Manufacturers are required to design power steering systems with improved seals and containment measures to minimize the risk of fluid leakage. This has led to the development of more robust and efficient power steering systems, which indirectly influences vehicle weight distribution by reducing the overall fluid volume required.

Furthermore, regulations promoting the use of environmentally friendly alternatives have spurred innovation in power steering fluid formulations. Bio-based fluids and synthetic alternatives with lower environmental impact are gaining traction in the market. These new formulations often have different viscosities and thermal properties compared to traditional fluids, potentially affecting the weight distribution and performance characteristics of the power steering system.

The push for increased fuel efficiency has also influenced power steering fluid regulations. As vehicle manufacturers strive to meet stringent fuel economy standards, they are exploring ways to reduce the power consumption of auxiliary systems, including power steering. This has led to the development of electric power steering systems, which eliminate the need for traditional hydraulic fluid altogether. The shift towards electric power steering significantly alters the weight distribution of vehicles, as it removes the fluid reservoir and associated hydraulic components.

Regulations regarding end-of-life vehicle recycling and disposal have also impacted power steering fluid considerations. Manufacturers are now required to design vehicles with improved recyclability, including easier removal and proper disposal of fluids. This has led to innovations in power steering system design that facilitate fluid drainage and replacement, potentially affecting the placement and configuration of fluid reservoirs within the vehicle.

In response to these regulations, the automotive industry has invested heavily in research and development to create more efficient and environmentally friendly power steering systems. This includes the exploration of variable-assist power steering technologies that optimize fluid usage based on driving conditions, further influencing weight distribution dynamics.

As environmental regulations continue to evolve, the automotive industry must remain adaptable in its approach to power steering fluid and its impact on vehicle weight distribution. Future regulations may further emphasize the use of sustainable materials, closed-loop recycling systems, and advanced fluid management technologies, all of which will continue to shape the relationship between power steering fluid and vehicle design.

The use of power steering fluid is subject to various environmental regulations due to its potential environmental impact. These fluids often contain petroleum-based or synthetic compounds that can be harmful if released into the environment. Consequently, regulations have been established to govern the production, use, and disposal of power steering fluids.

One of the primary concerns addressed by environmental regulations is the prevention of fluid leaks. Manufacturers are required to design power steering systems with improved seals and containment measures to minimize the risk of fluid leakage. This has led to the development of more robust and efficient power steering systems, which indirectly influences vehicle weight distribution by reducing the overall fluid volume required.

Furthermore, regulations promoting the use of environmentally friendly alternatives have spurred innovation in power steering fluid formulations. Bio-based fluids and synthetic alternatives with lower environmental impact are gaining traction in the market. These new formulations often have different viscosities and thermal properties compared to traditional fluids, potentially affecting the weight distribution and performance characteristics of the power steering system.

The push for increased fuel efficiency has also influenced power steering fluid regulations. As vehicle manufacturers strive to meet stringent fuel economy standards, they are exploring ways to reduce the power consumption of auxiliary systems, including power steering. This has led to the development of electric power steering systems, which eliminate the need for traditional hydraulic fluid altogether. The shift towards electric power steering significantly alters the weight distribution of vehicles, as it removes the fluid reservoir and associated hydraulic components.

Regulations regarding end-of-life vehicle recycling and disposal have also impacted power steering fluid considerations. Manufacturers are now required to design vehicles with improved recyclability, including easier removal and proper disposal of fluids. This has led to innovations in power steering system design that facilitate fluid drainage and replacement, potentially affecting the placement and configuration of fluid reservoirs within the vehicle.

In response to these regulations, the automotive industry has invested heavily in research and development to create more efficient and environmentally friendly power steering systems. This includes the exploration of variable-assist power steering technologies that optimize fluid usage based on driving conditions, further influencing weight distribution dynamics.

As environmental regulations continue to evolve, the automotive industry must remain adaptable in its approach to power steering fluid and its impact on vehicle weight distribution. Future regulations may further emphasize the use of sustainable materials, closed-loop recycling systems, and advanced fluid management technologies, all of which will continue to shape the relationship between power steering fluid and vehicle design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!