Optimizing Flow Characteristics in Power Steering Fluid Systems

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. The need for easier vehicle control led to the development of hydraulic power steering systems in the 1950s.

Hydraulic power steering marked a revolutionary change in automotive technology. It utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. This system significantly reduced the effort required to steer, especially in larger vehicles, improving driver comfort and control. The hydraulic system remained the dominant technology for several decades, with continuous improvements in efficiency and performance.

The late 20th century saw the emergence of electro-hydraulic power steering systems. These hybrid systems combined the hydraulic mechanism with electric pumps, offering better energy efficiency compared to traditional hydraulic systems. The electric pump could operate independently of the engine, providing consistent steering assistance even when the engine was not running or at low speeds.

The most recent significant advancement in power steering technology is the introduction of fully electric power steering (EPS) systems. EPS eliminates the need for hydraulic components, instead using an electric motor to assist steering. This technology offers several advantages, including improved fuel efficiency, as the system only draws power when steering assistance is needed, and enhanced flexibility in tuning steering feel and responsiveness.

The evolution of power steering has not only focused on the mechanism of assistance but also on the optimization of fluid dynamics within these systems. In hydraulic and electro-hydraulic systems, the characteristics of fluid flow play a crucial role in system performance, efficiency, and durability. Engineers have continually worked on improving fluid formulations, optimizing flow paths, and reducing turbulence to enhance overall system effectiveness.

Recent trends in power steering evolution include the integration of advanced sensors and control systems, allowing for adaptive steering assistance based on driving conditions and vehicle speed. Additionally, the development of steer-by-wire technology, which completely eliminates the mechanical connection between the steering wheel and the wheels, represents the cutting edge of steering system evolution, offering unprecedented flexibility in vehicle design and control.

Hydraulic power steering marked a revolutionary change in automotive technology. It utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. This system significantly reduced the effort required to steer, especially in larger vehicles, improving driver comfort and control. The hydraulic system remained the dominant technology for several decades, with continuous improvements in efficiency and performance.

The late 20th century saw the emergence of electro-hydraulic power steering systems. These hybrid systems combined the hydraulic mechanism with electric pumps, offering better energy efficiency compared to traditional hydraulic systems. The electric pump could operate independently of the engine, providing consistent steering assistance even when the engine was not running or at low speeds.

The most recent significant advancement in power steering technology is the introduction of fully electric power steering (EPS) systems. EPS eliminates the need for hydraulic components, instead using an electric motor to assist steering. This technology offers several advantages, including improved fuel efficiency, as the system only draws power when steering assistance is needed, and enhanced flexibility in tuning steering feel and responsiveness.

The evolution of power steering has not only focused on the mechanism of assistance but also on the optimization of fluid dynamics within these systems. In hydraulic and electro-hydraulic systems, the characteristics of fluid flow play a crucial role in system performance, efficiency, and durability. Engineers have continually worked on improving fluid formulations, optimizing flow paths, and reducing turbulence to enhance overall system effectiveness.

Recent trends in power steering evolution include the integration of advanced sensors and control systems, allowing for adaptive steering assistance based on driving conditions and vehicle speed. Additionally, the development of steer-by-wire technology, which completely eliminates the mechanical connection between the steering wheel and the wheels, represents the cutting edge of steering system evolution, offering unprecedented flexibility in vehicle design and control.

Market Demand Analysis

The power steering fluid systems market has been experiencing steady growth due to the increasing demand for comfortable and efficient driving experiences. As automotive technologies advance, there is a growing emphasis on optimizing vehicle performance, including the power steering system. The market for power steering fluid systems is primarily driven by the automotive industry, with passenger vehicles and commercial vehicles being the main segments.

In recent years, there has been a significant shift towards electric power steering (EPS) systems, which has impacted the traditional hydraulic power steering fluid market. However, hydraulic systems still maintain a substantial market share, especially in heavy-duty vehicles and certain regions where EPS adoption is slower. This creates a dual market dynamic, where optimization of flow characteristics in power steering fluid systems remains crucial for both existing hydraulic systems and hybrid solutions.

The global automotive power steering market size was valued at approximately $26.4 billion in 2020 and is projected to reach $38.2 billion by 2027, growing at a CAGR of 5.4% during the forecast period. Within this market, the demand for optimized power steering fluid systems is driven by several factors, including improved fuel efficiency, enhanced vehicle handling, and reduced maintenance requirements.

Manufacturers are increasingly focusing on developing advanced power steering fluids that can withstand higher temperatures, provide better lubrication, and offer improved flow characteristics. This trend is partly driven by the automotive industry's push towards more compact and efficient engine compartments, which often result in higher operating temperatures for power steering systems.

The commercial vehicle segment, including trucks and buses, presents a particularly strong market for optimized power steering fluid systems. These vehicles often operate under more demanding conditions and require robust steering systems that can handle heavy loads and frequent use. As a result, there is a growing demand for power steering fluids that can maintain optimal performance under high-stress conditions.

Geographically, the Asia-Pacific region is expected to witness the highest growth in the power steering fluid systems market. This is primarily due to the rapid expansion of the automotive industry in countries like China and India, coupled with increasing vehicle production and sales. North America and Europe also remain significant markets, with a focus on technological advancements and stringent regulations driving the demand for more efficient and environmentally friendly power steering solutions.

The aftermarket segment for power steering fluids also presents a substantial opportunity. As vehicle owners become more aware of the importance of regular maintenance, there is an increasing demand for high-quality replacement fluids that can extend the life of power steering systems and improve overall vehicle performance.

In recent years, there has been a significant shift towards electric power steering (EPS) systems, which has impacted the traditional hydraulic power steering fluid market. However, hydraulic systems still maintain a substantial market share, especially in heavy-duty vehicles and certain regions where EPS adoption is slower. This creates a dual market dynamic, where optimization of flow characteristics in power steering fluid systems remains crucial for both existing hydraulic systems and hybrid solutions.

The global automotive power steering market size was valued at approximately $26.4 billion in 2020 and is projected to reach $38.2 billion by 2027, growing at a CAGR of 5.4% during the forecast period. Within this market, the demand for optimized power steering fluid systems is driven by several factors, including improved fuel efficiency, enhanced vehicle handling, and reduced maintenance requirements.

Manufacturers are increasingly focusing on developing advanced power steering fluids that can withstand higher temperatures, provide better lubrication, and offer improved flow characteristics. This trend is partly driven by the automotive industry's push towards more compact and efficient engine compartments, which often result in higher operating temperatures for power steering systems.

The commercial vehicle segment, including trucks and buses, presents a particularly strong market for optimized power steering fluid systems. These vehicles often operate under more demanding conditions and require robust steering systems that can handle heavy loads and frequent use. As a result, there is a growing demand for power steering fluids that can maintain optimal performance under high-stress conditions.

Geographically, the Asia-Pacific region is expected to witness the highest growth in the power steering fluid systems market. This is primarily due to the rapid expansion of the automotive industry in countries like China and India, coupled with increasing vehicle production and sales. North America and Europe also remain significant markets, with a focus on technological advancements and stringent regulations driving the demand for more efficient and environmentally friendly power steering solutions.

The aftermarket segment for power steering fluids also presents a substantial opportunity. As vehicle owners become more aware of the importance of regular maintenance, there is an increasing demand for high-quality replacement fluids that can extend the life of power steering systems and improve overall vehicle performance.

Current Challenges

Power steering fluid systems face several significant challenges in optimizing flow characteristics. One of the primary issues is the variability in fluid viscosity due to temperature fluctuations. As vehicles operate in diverse environmental conditions, from sub-zero temperatures to extreme heat, the fluid's viscosity can change dramatically, affecting its flow properties and, consequently, the steering performance.

Another challenge lies in the design of fluid passages within the power steering system. Complex geometries and tight tolerances can create areas of turbulence or stagnation, leading to inefficient fluid flow and potential wear on components. Engineers must balance the need for compact design with optimal fluid dynamics, a task that becomes increasingly difficult as vehicle designs evolve and space constraints become more pronounced.

The presence of air bubbles in the power steering fluid system poses a significant obstacle to achieving optimal flow characteristics. These bubbles can cause cavitation, leading to erratic steering response and accelerated wear on pump components. Developing effective air purging mechanisms and maintaining a sealed system under various operating conditions remain ongoing challenges for system designers.

Contamination of the power steering fluid is another critical issue affecting flow characteristics. Over time, debris from wear and tear of system components can accumulate in the fluid, potentially clogging narrow passages and altering the fluid's properties. This contamination not only impacts flow efficiency but can also lead to premature failure of power steering components.

The demand for energy efficiency in modern vehicles presents an additional challenge. Power steering systems must operate with minimal energy consumption while maintaining optimal performance. This requires careful optimization of fluid flow to reduce pumping losses and improve overall system efficiency, a task that often involves trade-offs between performance and energy conservation.

Noise, vibration, and harshness (NVH) considerations also play a crucial role in power steering fluid system design. Achieving smooth, quiet operation while maintaining efficient flow characteristics is a delicate balance. Fluid resonance within the system can lead to unwanted noise and vibrations, necessitating careful tuning of fluid passages and pump designs.

Lastly, the increasing adoption of electric power steering systems poses a challenge to traditional hydraulic systems. While electric systems offer advantages in terms of energy efficiency and packaging, they lack the natural damping properties of fluid-based systems. This has led to a renewed focus on optimizing hybrid systems that combine the benefits of both electric and hydraulic technologies, further complicating the task of fluid flow optimization.

Another challenge lies in the design of fluid passages within the power steering system. Complex geometries and tight tolerances can create areas of turbulence or stagnation, leading to inefficient fluid flow and potential wear on components. Engineers must balance the need for compact design with optimal fluid dynamics, a task that becomes increasingly difficult as vehicle designs evolve and space constraints become more pronounced.

The presence of air bubbles in the power steering fluid system poses a significant obstacle to achieving optimal flow characteristics. These bubbles can cause cavitation, leading to erratic steering response and accelerated wear on pump components. Developing effective air purging mechanisms and maintaining a sealed system under various operating conditions remain ongoing challenges for system designers.

Contamination of the power steering fluid is another critical issue affecting flow characteristics. Over time, debris from wear and tear of system components can accumulate in the fluid, potentially clogging narrow passages and altering the fluid's properties. This contamination not only impacts flow efficiency but can also lead to premature failure of power steering components.

The demand for energy efficiency in modern vehicles presents an additional challenge. Power steering systems must operate with minimal energy consumption while maintaining optimal performance. This requires careful optimization of fluid flow to reduce pumping losses and improve overall system efficiency, a task that often involves trade-offs between performance and energy conservation.

Noise, vibration, and harshness (NVH) considerations also play a crucial role in power steering fluid system design. Achieving smooth, quiet operation while maintaining efficient flow characteristics is a delicate balance. Fluid resonance within the system can lead to unwanted noise and vibrations, necessitating careful tuning of fluid passages and pump designs.

Lastly, the increasing adoption of electric power steering systems poses a challenge to traditional hydraulic systems. While electric systems offer advantages in terms of energy efficiency and packaging, they lack the natural damping properties of fluid-based systems. This has led to a renewed focus on optimizing hybrid systems that combine the benefits of both electric and hydraulic technologies, further complicating the task of fluid flow optimization.

Existing Flow Solutions

01 Flow characteristics measurement and analysis

Power steering fluid systems require precise measurement and analysis of flow characteristics. This involves using sensors and advanced algorithms to monitor fluid flow rates, pressure, and temperature. The data collected is used to optimize system performance, detect anomalies, and predict maintenance needs.- Flow characteristics measurement and analysis: Power steering fluid systems require precise measurement and analysis of flow characteristics. This involves using sensors and advanced algorithms to monitor fluid flow rates, pressure, and temperature. The data collected is used to optimize system performance, detect anomalies, and predict maintenance needs.

- Adaptive control systems for power steering: Adaptive control systems are implemented to adjust power steering fluid flow based on real-time driving conditions. These systems use input from various sensors to modify fluid pressure and flow rate, ensuring optimal steering performance across different speeds and road conditions.

- Energy-efficient fluid flow management: Innovations in power steering fluid systems focus on improving energy efficiency. This includes developing variable flow pumps, implementing electronic control units to regulate fluid flow, and designing systems that reduce power consumption during straight-line driving or low-speed maneuvers.

- Integration of hydraulic and electric power steering: Hybrid power steering systems combine hydraulic and electric components to optimize fluid flow characteristics. These systems aim to provide the benefits of both technologies, such as the natural feel of hydraulic steering and the energy efficiency of electric systems, while managing fluid flow to suit various driving scenarios.

- Advanced fluid composition for improved flow: Research into advanced power steering fluid compositions aims to enhance flow characteristics. These fluids are designed to maintain optimal viscosity across a wide temperature range, reduce friction, and improve overall system efficiency. Some formulations also incorporate additives to extend the lifespan of steering components.

02 Adaptive control systems for power steering

Adaptive control systems are implemented to adjust power steering fluid flow based on various driving conditions. These systems use real-time data to modify fluid pressure and flow rates, ensuring optimal steering performance and efficiency across different scenarios such as low-speed maneuvering or high-speed highway driving.Expand Specific Solutions03 Energy-efficient fluid flow management

Innovations in power steering fluid systems focus on improving energy efficiency. This includes developing variable flow pumps, implementing electronic control units, and utilizing regenerative systems to minimize power consumption while maintaining responsive steering assistance.Expand Specific Solutions04 Hydraulic circuit design for improved flow

Advanced hydraulic circuit designs are crucial for optimizing fluid flow in power steering systems. These designs incorporate features such as flow-dividing valves, pressure-compensating mechanisms, and strategically placed reservoirs to ensure smooth and consistent fluid distribution throughout the system.Expand Specific Solutions05 Fluid property optimization for flow performance

Research into power steering fluid properties aims to enhance flow characteristics. This includes developing fluids with improved viscosity indices, thermal stability, and anti-foaming properties. These advancements contribute to more consistent fluid flow across various operating temperatures and conditions, leading to better overall steering system performance.Expand Specific Solutions

Key Industry Players

The optimization of flow characteristics in power steering fluid systems is currently in a mature development stage, with a substantial market size driven by the automotive industry's continuous growth. The technology's maturity is evident from the involvement of established players like Ford Global Technologies, Visteon, and Robert Bosch GmbH, who have extensive experience in automotive systems. However, emerging companies and research institutions, such as Nanjing University of Aeronautics & Astronautics and KSB SE & Co. KGaA, are also contributing to advancements in fluid dynamics and system optimization. This competitive landscape suggests ongoing innovation potential, particularly in areas of efficiency improvement and integration with electric power steering systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced power steering fluid system that utilizes a variable-displacement pump and an electronic control unit to optimize flow characteristics. The system employs adaptive algorithms to adjust fluid flow based on vehicle speed, steering angle, and driver input[1]. This results in a more responsive and efficient power steering system. Ford's technology also incorporates a pressure relief valve that prevents excessive fluid pressure, reducing wear on components and improving overall system longevity[3]. Additionally, the company has implemented a thermal management system that maintains optimal fluid temperature, ensuring consistent performance across various operating conditions[5].

Strengths: Improved efficiency, responsive steering, and reduced wear on components. Weaknesses: Increased system complexity and potential higher initial costs.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered an innovative power steering fluid system that incorporates a high-precision electromagnetic valve to control fluid flow. This system, known as Servotronic, adjusts steering assistance based on vehicle speed and driver input[2]. The company has also developed a unique fluid composition that reduces friction and improves thermal stability, enhancing overall system efficiency[4]. Bosch's system utilizes advanced sensors to monitor fluid pressure and temperature, allowing for real-time adjustments to optimize performance and reduce energy consumption[6]. Furthermore, the company has implemented a regenerative braking system that captures energy during deceleration to power the steering assist, further improving fuel efficiency[8].

Strengths: High precision control, energy efficiency, and advanced fluid composition. Weaknesses: Potentially higher manufacturing costs and complexity in maintenance.

Core Fluid Dynamics

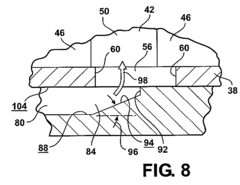

Power steering pump having intake channels with enhanced flow characteristics and/or a pressure balancing fluid communication channel

PatentInactiveEP2108840A3

Innovation

- The design incorporates a unique intake flow channel configuration with a thrust plate having openings with opposed terminal ends, and a pressure balancing fluid communication channel to equalize fluid pressures, reducing turbulence and enhancing durability.

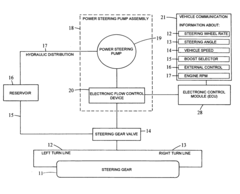

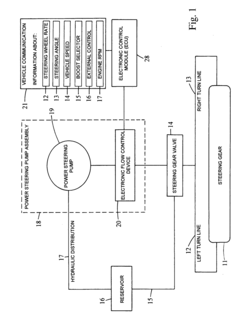

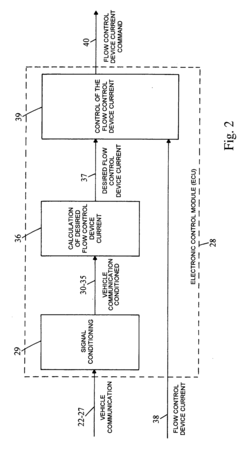

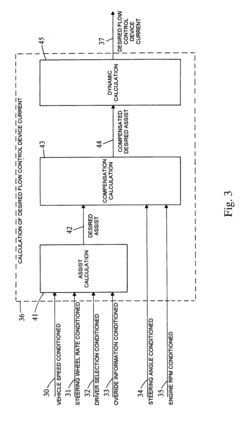

Fuel efficient power steering control system and method

PatentInactiveUS20040226769A1

Innovation

- An electronic control unit with a PID control algorithm calculates and adjusts the current for an electronic flow control device to manage fluid flow from the power steering pump to the steering gear, optimizing fuel economy by minimizing fluid flow during low steering assist and increasing it during dynamic maneuvers, while considering vehicle speed, steering wheel rate, and driver preferences.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of power steering fluid systems. As automotive manufacturers strive to optimize flow characteristics, they must also navigate an increasingly complex landscape of environmental standards and guidelines.

The primary focus of environmental regulations in this context is the reduction of harmful emissions and the promotion of sustainable practices. Power steering fluid systems, while essential for vehicle performance, can contribute to environmental pollution through leaks, improper disposal, and the use of non-biodegradable materials. Regulatory bodies worldwide have implemented stringent measures to address these concerns.

One of the key areas of regulation is the composition of power steering fluids. Traditional mineral-based fluids are being phased out in favor of synthetic and biodegradable alternatives. These newer formulations not only offer improved flow characteristics but also reduce the environmental impact in case of leaks or spills. Manufacturers are required to meet specific standards for biodegradability, toxicity, and overall environmental footprint.

Emissions regulations also indirectly affect power steering fluid systems. As automakers work to improve fuel efficiency and reduce vehicle weight to meet stringent emissions standards, there is a growing demand for more compact and efficient power steering systems. This, in turn, necessitates the development of fluids that can maintain optimal flow characteristics under higher pressures and temperatures.

Waste management and disposal regulations have significant implications for the power steering fluid industry. Proper handling and recycling of used fluids are mandated to prevent soil and water contamination. This has led to the development of closed-loop systems and improved sealing technologies to minimize fluid loss and extend service intervals.

The global nature of the automotive industry means that manufacturers must comply with a diverse array of regional and national environmental regulations. This includes standards set by organizations such as the Environmental Protection Agency (EPA) in the United States, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, and similar bodies in other major markets.

Looking ahead, the trend towards electrification in the automotive sector is likely to bring about new environmental considerations for power steering systems. While electric power steering reduces the need for hydraulic fluids, it introduces new challenges related to the sourcing and disposal of electronic components and rare earth materials used in electric motors.

In conclusion, environmental regulations are a driving force in the optimization of flow characteristics in power steering fluid systems. They necessitate continuous innovation in fluid formulations, system design, and manufacturing processes to meet both performance requirements and environmental standards.

The primary focus of environmental regulations in this context is the reduction of harmful emissions and the promotion of sustainable practices. Power steering fluid systems, while essential for vehicle performance, can contribute to environmental pollution through leaks, improper disposal, and the use of non-biodegradable materials. Regulatory bodies worldwide have implemented stringent measures to address these concerns.

One of the key areas of regulation is the composition of power steering fluids. Traditional mineral-based fluids are being phased out in favor of synthetic and biodegradable alternatives. These newer formulations not only offer improved flow characteristics but also reduce the environmental impact in case of leaks or spills. Manufacturers are required to meet specific standards for biodegradability, toxicity, and overall environmental footprint.

Emissions regulations also indirectly affect power steering fluid systems. As automakers work to improve fuel efficiency and reduce vehicle weight to meet stringent emissions standards, there is a growing demand for more compact and efficient power steering systems. This, in turn, necessitates the development of fluids that can maintain optimal flow characteristics under higher pressures and temperatures.

Waste management and disposal regulations have significant implications for the power steering fluid industry. Proper handling and recycling of used fluids are mandated to prevent soil and water contamination. This has led to the development of closed-loop systems and improved sealing technologies to minimize fluid loss and extend service intervals.

The global nature of the automotive industry means that manufacturers must comply with a diverse array of regional and national environmental regulations. This includes standards set by organizations such as the Environmental Protection Agency (EPA) in the United States, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, and similar bodies in other major markets.

Looking ahead, the trend towards electrification in the automotive sector is likely to bring about new environmental considerations for power steering systems. While electric power steering reduces the need for hydraulic fluids, it introduces new challenges related to the sourcing and disposal of electronic components and rare earth materials used in electric motors.

In conclusion, environmental regulations are a driving force in the optimization of flow characteristics in power steering fluid systems. They necessitate continuous innovation in fluid formulations, system design, and manufacturing processes to meet both performance requirements and environmental standards.

Safety Considerations

Safety considerations are paramount in the optimization of flow characteristics in power steering fluid systems. The primary concern is to ensure that any modifications or improvements to the system do not compromise the overall safety of the vehicle and its occupants. One critical aspect is maintaining consistent steering performance under various operating conditions, including extreme temperatures and high-stress situations such as emergency maneuvers.

The viscosity of the power steering fluid plays a crucial role in safety. If the fluid becomes too thin at high temperatures or too thick at low temperatures, it can lead to inconsistent steering response, potentially endangering the driver and passengers. Therefore, any optimization efforts must consider the fluid's behavior across a wide temperature range to maintain reliable steering assistance in all climates.

Pressure management within the system is another vital safety consideration. Excessive pressure can lead to component failure, while insufficient pressure may result in inadequate steering assistance. Engineers must carefully balance these factors to ensure optimal performance without risking system integrity. This includes designing robust seals and connections to prevent fluid leaks, which could lead to sudden loss of steering assistance.

The compatibility of power steering fluids with system components is also a critical safety factor. Any new formulations or modifications to existing fluids must be thoroughly tested to ensure they do not cause degradation of seals, hoses, or other components over time. This degradation could lead to system failures, potentially resulting in loss of steering control.

Contamination prevention is another key safety aspect. The power steering fluid system must be designed to minimize the ingress of contaminants, as these can cause wear on components, clog small passages, and interfere with proper fluid flow. This includes considerations for filtration systems and the overall cleanliness of the manufacturing and assembly processes.

Noise, vibration, and harshness (NVH) characteristics are also important safety considerations. Excessive noise or vibration in the steering system can be distracting to the driver and may mask other important auditory cues from the vehicle or environment. Optimizing flow characteristics should aim to reduce turbulence and cavitation, which can contribute to NVH issues.

Lastly, fail-safe mechanisms must be incorporated into the system design. In the event of a fluid system failure, the vehicle should maintain some level of steering control to allow the driver to safely maneuver to a stop. This may involve mechanical backup systems or carefully designed hydraulic circuits that prioritize essential steering functions even under compromised conditions.

The viscosity of the power steering fluid plays a crucial role in safety. If the fluid becomes too thin at high temperatures or too thick at low temperatures, it can lead to inconsistent steering response, potentially endangering the driver and passengers. Therefore, any optimization efforts must consider the fluid's behavior across a wide temperature range to maintain reliable steering assistance in all climates.

Pressure management within the system is another vital safety consideration. Excessive pressure can lead to component failure, while insufficient pressure may result in inadequate steering assistance. Engineers must carefully balance these factors to ensure optimal performance without risking system integrity. This includes designing robust seals and connections to prevent fluid leaks, which could lead to sudden loss of steering assistance.

The compatibility of power steering fluids with system components is also a critical safety factor. Any new formulations or modifications to existing fluids must be thoroughly tested to ensure they do not cause degradation of seals, hoses, or other components over time. This degradation could lead to system failures, potentially resulting in loss of steering control.

Contamination prevention is another key safety aspect. The power steering fluid system must be designed to minimize the ingress of contaminants, as these can cause wear on components, clog small passages, and interfere with proper fluid flow. This includes considerations for filtration systems and the overall cleanliness of the manufacturing and assembly processes.

Noise, vibration, and harshness (NVH) characteristics are also important safety considerations. Excessive noise or vibration in the steering system can be distracting to the driver and may mask other important auditory cues from the vehicle or environment. Optimizing flow characteristics should aim to reduce turbulence and cavitation, which can contribute to NVH issues.

Lastly, fail-safe mechanisms must be incorporated into the system design. In the event of a fluid system failure, the vehicle should maintain some level of steering control to allow the driver to safely maneuver to a stop. This may involve mechanical backup systems or carefully designed hydraulic circuits that prioritize essential steering functions even under compromised conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!