Vibration Reduction Techniques in Power Steering Fluid Systems

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. The need for easier vehicle control led to the development of hydraulic power steering systems in the 1950s.

Hydraulic power steering marked a revolutionary change in automotive technology. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. It significantly reduced the effort required to steer, especially in larger vehicles, improving driver comfort and control. The hydraulic system remained the dominant technology for several decades, with continuous improvements in efficiency and performance.

The late 20th century saw the emergence of electro-hydraulic power steering systems. These hybrid systems combined the traditional hydraulic mechanism with electric pumps, offering better energy efficiency compared to their fully hydraulic predecessors. This transition phase paved the way for the next major leap in steering technology.

The early 2000s witnessed the introduction of fully electric power steering (EPS) systems. EPS eliminated the need for hydraulic components, instead using an electric motor to assist steering. This technology offered several advantages, including improved fuel efficiency, as the system only draws power when steering assistance is needed, and enhanced flexibility in tuning steering feel.

As vehicles became more sophisticated, so did power steering systems. The integration of electronic control units allowed for adaptive steering assistance, adjusting the level of power assist based on vehicle speed, driving conditions, and driver preferences. This marked the beginning of intelligent steering systems, capable of providing variable assistance and even active steering interventions for improved stability and safety.

Recent advancements have focused on enhancing the precision and responsiveness of power steering systems while addressing challenges such as vibration reduction. The development of advanced fluid dynamics models and the use of sophisticated damping mechanisms have contributed to smoother, more refined steering experiences. Additionally, the integration of power steering systems with other vehicle technologies, such as lane-keeping assist and autonomous driving features, has opened new frontiers in vehicle control and safety.

The evolution of power steering technology continues, with ongoing research into steer-by-wire systems that completely eliminate mechanical connections between the steering wheel and the wheels. These systems promise even greater flexibility in vehicle design and enhanced customization of steering feel. As automotive technology progresses towards electrification and autonomy, power steering systems are expected to play a crucial role in shaping the future of vehicle control and driver interaction.

Hydraulic power steering marked a revolutionary change in automotive technology. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. It significantly reduced the effort required to steer, especially in larger vehicles, improving driver comfort and control. The hydraulic system remained the dominant technology for several decades, with continuous improvements in efficiency and performance.

The late 20th century saw the emergence of electro-hydraulic power steering systems. These hybrid systems combined the traditional hydraulic mechanism with electric pumps, offering better energy efficiency compared to their fully hydraulic predecessors. This transition phase paved the way for the next major leap in steering technology.

The early 2000s witnessed the introduction of fully electric power steering (EPS) systems. EPS eliminated the need for hydraulic components, instead using an electric motor to assist steering. This technology offered several advantages, including improved fuel efficiency, as the system only draws power when steering assistance is needed, and enhanced flexibility in tuning steering feel.

As vehicles became more sophisticated, so did power steering systems. The integration of electronic control units allowed for adaptive steering assistance, adjusting the level of power assist based on vehicle speed, driving conditions, and driver preferences. This marked the beginning of intelligent steering systems, capable of providing variable assistance and even active steering interventions for improved stability and safety.

Recent advancements have focused on enhancing the precision and responsiveness of power steering systems while addressing challenges such as vibration reduction. The development of advanced fluid dynamics models and the use of sophisticated damping mechanisms have contributed to smoother, more refined steering experiences. Additionally, the integration of power steering systems with other vehicle technologies, such as lane-keeping assist and autonomous driving features, has opened new frontiers in vehicle control and safety.

The evolution of power steering technology continues, with ongoing research into steer-by-wire systems that completely eliminate mechanical connections between the steering wheel and the wheels. These systems promise even greater flexibility in vehicle design and enhanced customization of steering feel. As automotive technology progresses towards electrification and autonomy, power steering systems are expected to play a crucial role in shaping the future of vehicle control and driver interaction.

Market Demand Analysis

The market demand for vibration reduction techniques in power steering fluid systems has been steadily increasing due to the growing emphasis on vehicle comfort and performance. As automotive manufacturers strive to enhance the driving experience, the need for more sophisticated vibration control solutions has become paramount.

The global power steering market, which encompasses fluid-based systems, is projected to grow significantly in the coming years. This growth is driven by the rising production of vehicles worldwide, particularly in emerging economies. The demand for vibration reduction technologies within this market is expected to outpace the overall market growth, as consumers increasingly prioritize smooth and quiet vehicle operation.

One of the key factors driving market demand is the stringent regulatory environment surrounding vehicle noise, vibration, and harshness (NVH) standards. Governments and regulatory bodies worldwide are implementing stricter guidelines for vehicle noise and vibration levels, compelling manufacturers to invest in advanced vibration reduction technologies. This regulatory pressure is particularly evident in developed markets such as North America and Europe, where consumer expectations for vehicle refinement are high.

The automotive industry's shift towards electric and hybrid vehicles has also contributed to the increased focus on vibration reduction in power steering systems. These vehicles often have lower overall noise levels, making any remaining vibrations more noticeable to occupants. As a result, manufacturers are seeking innovative solutions to minimize vibrations in all vehicle systems, including power steering.

In the commercial vehicle sector, the demand for vibration reduction techniques is driven by the need to improve driver comfort and reduce fatigue during long-haul operations. Fleet operators are increasingly recognizing the impact of vehicle vibrations on driver health and productivity, leading to a growing market for advanced power steering systems with enhanced vibration control.

The aftermarket segment also presents significant opportunities for vibration reduction technologies in power steering fluid systems. As vehicles age, the likelihood of experiencing increased vibrations in the steering system grows, creating a market for retrofit solutions and upgrades that can improve the performance of existing vehicles.

Consumer awareness and expectations regarding vehicle comfort and refinement continue to rise, particularly in the premium and luxury vehicle segments. This trend is pushing manufacturers to invest in cutting-edge vibration reduction technologies as a means of differentiation and to justify higher price points in competitive markets.

The integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles are also influencing the demand for vibration reduction in power steering systems. These technologies require precise steering control and minimal interference from vibrations to function optimally, further driving the need for innovative vibration reduction solutions.

The global power steering market, which encompasses fluid-based systems, is projected to grow significantly in the coming years. This growth is driven by the rising production of vehicles worldwide, particularly in emerging economies. The demand for vibration reduction technologies within this market is expected to outpace the overall market growth, as consumers increasingly prioritize smooth and quiet vehicle operation.

One of the key factors driving market demand is the stringent regulatory environment surrounding vehicle noise, vibration, and harshness (NVH) standards. Governments and regulatory bodies worldwide are implementing stricter guidelines for vehicle noise and vibration levels, compelling manufacturers to invest in advanced vibration reduction technologies. This regulatory pressure is particularly evident in developed markets such as North America and Europe, where consumer expectations for vehicle refinement are high.

The automotive industry's shift towards electric and hybrid vehicles has also contributed to the increased focus on vibration reduction in power steering systems. These vehicles often have lower overall noise levels, making any remaining vibrations more noticeable to occupants. As a result, manufacturers are seeking innovative solutions to minimize vibrations in all vehicle systems, including power steering.

In the commercial vehicle sector, the demand for vibration reduction techniques is driven by the need to improve driver comfort and reduce fatigue during long-haul operations. Fleet operators are increasingly recognizing the impact of vehicle vibrations on driver health and productivity, leading to a growing market for advanced power steering systems with enhanced vibration control.

The aftermarket segment also presents significant opportunities for vibration reduction technologies in power steering fluid systems. As vehicles age, the likelihood of experiencing increased vibrations in the steering system grows, creating a market for retrofit solutions and upgrades that can improve the performance of existing vehicles.

Consumer awareness and expectations regarding vehicle comfort and refinement continue to rise, particularly in the premium and luxury vehicle segments. This trend is pushing manufacturers to invest in cutting-edge vibration reduction technologies as a means of differentiation and to justify higher price points in competitive markets.

The integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles are also influencing the demand for vibration reduction in power steering systems. These technologies require precise steering control and minimal interference from vibrations to function optimally, further driving the need for innovative vibration reduction solutions.

Vibration Challenges

Power steering fluid systems in modern vehicles face significant challenges related to vibration, which can impact both performance and user experience. These vibrations primarily originate from various sources within the vehicle's powertrain and suspension systems, and are transmitted through the steering column to the driver.

One of the main challenges is the hydraulic pump-induced vibration. The power steering pump, which is typically driven by the engine's accessory belt, can generate pulsations in the fluid flow. These pulsations are often caused by the pump's internal mechanisms, such as vane or gear movements, and can result in noticeable steering wheel vibrations, especially at idle or low speeds.

Another significant issue is the transmission of road-induced vibrations through the steering system. Uneven road surfaces, potholes, and other irregularities can cause the wheels to vibrate, which is then transferred through the tie rods and steering rack to the steering wheel. The power steering fluid system, while designed to assist steering, can sometimes amplify these vibrations due to its hydraulic nature.

Engine-induced vibrations also pose a challenge for power steering fluid systems. The inherent vibrations from engine operation, particularly in four-cylinder engines or those with unbalanced configurations, can be transmitted through the engine mounts and steering column. These vibrations can be especially problematic at certain engine speeds, creating resonance effects that amplify the perceived vibration at the steering wheel.

The complexity of modern vehicle designs introduces additional vibration challenges. The integration of electric power steering assist systems with traditional hydraulic systems in some hybrid designs can create new sources of vibration or alter the transmission paths of existing vibrations. This complexity makes it more difficult to isolate and address specific vibration sources.

Temperature fluctuations in the power steering fluid can also contribute to vibration issues. As the fluid heats up during operation, its viscosity changes, potentially altering its damping properties and its ability to transmit or absorb vibrations effectively. This can lead to inconsistent steering feel and vibration characteristics across different operating conditions.

Lastly, the aging of power steering components presents ongoing challenges. Over time, wear in pump bearings, loosening of mounting brackets, and degradation of hoses and seals can all contribute to increased vibration levels. These age-related issues can be particularly difficult to diagnose and address, as they may develop gradually and interact with other vibration sources in complex ways.

Addressing these vibration challenges requires a multifaceted approach, combining advanced fluid dynamics, material science, and mechanical engineering solutions. The goal is to develop power steering systems that can effectively isolate, dampen, or counteract these various sources of vibration, ensuring smooth and responsive steering across all operating conditions.

One of the main challenges is the hydraulic pump-induced vibration. The power steering pump, which is typically driven by the engine's accessory belt, can generate pulsations in the fluid flow. These pulsations are often caused by the pump's internal mechanisms, such as vane or gear movements, and can result in noticeable steering wheel vibrations, especially at idle or low speeds.

Another significant issue is the transmission of road-induced vibrations through the steering system. Uneven road surfaces, potholes, and other irregularities can cause the wheels to vibrate, which is then transferred through the tie rods and steering rack to the steering wheel. The power steering fluid system, while designed to assist steering, can sometimes amplify these vibrations due to its hydraulic nature.

Engine-induced vibrations also pose a challenge for power steering fluid systems. The inherent vibrations from engine operation, particularly in four-cylinder engines or those with unbalanced configurations, can be transmitted through the engine mounts and steering column. These vibrations can be especially problematic at certain engine speeds, creating resonance effects that amplify the perceived vibration at the steering wheel.

The complexity of modern vehicle designs introduces additional vibration challenges. The integration of electric power steering assist systems with traditional hydraulic systems in some hybrid designs can create new sources of vibration or alter the transmission paths of existing vibrations. This complexity makes it more difficult to isolate and address specific vibration sources.

Temperature fluctuations in the power steering fluid can also contribute to vibration issues. As the fluid heats up during operation, its viscosity changes, potentially altering its damping properties and its ability to transmit or absorb vibrations effectively. This can lead to inconsistent steering feel and vibration characteristics across different operating conditions.

Lastly, the aging of power steering components presents ongoing challenges. Over time, wear in pump bearings, loosening of mounting brackets, and degradation of hoses and seals can all contribute to increased vibration levels. These age-related issues can be particularly difficult to diagnose and address, as they may develop gradually and interact with other vibration sources in complex ways.

Addressing these vibration challenges requires a multifaceted approach, combining advanced fluid dynamics, material science, and mechanical engineering solutions. The goal is to develop power steering systems that can effectively isolate, dampen, or counteract these various sources of vibration, ensuring smooth and responsive steering across all operating conditions.

Current Reduction Methods

01 Vibration dampening in power steering systems

Various methods are employed to reduce vibrations in power steering fluid systems. These can include the use of specialized dampeners, fluid reservoirs designed to absorb vibrations, and optimized pump designs that minimize pulsations in the fluid flow. Such solutions aim to improve the overall performance and comfort of the power steering system.- Vibration dampening in power steering systems: Various methods are employed to reduce vibrations in power steering fluid systems. These can include using specialized dampening components, optimizing fluid flow paths, and implementing advanced control algorithms to minimize oscillations and improve overall system stability.

- Fluid reservoir design for power steering systems: The design of fluid reservoirs plays a crucial role in managing vibrations in power steering systems. Innovations in reservoir shape, internal baffles, and mounting techniques can help reduce fluid sloshing and minimize the transmission of vibrations throughout the system.

- Pump design and optimization for power steering systems: Advancements in power steering pump design focus on reducing vibrations at the source. This includes improvements in impeller geometry, housing design, and the integration of vibration-absorbing materials to minimize the generation and transmission of vibrations within the fluid system.

- Hydraulic control valves for vibration reduction: Specialized hydraulic control valves are developed to manage fluid flow and pressure fluctuations in power steering systems. These valves can help dampen vibrations by regulating fluid dynamics and responding to changes in system pressure and flow rates.

- Electronic control systems for vibration mitigation: Advanced electronic control systems are implemented to actively monitor and adjust power steering fluid dynamics. These systems use sensors and actuators to detect and counteract vibrations in real-time, improving overall steering feel and reducing unwanted feedback to the driver.

02 Fluid flow control mechanisms

Implementing advanced fluid flow control mechanisms can help mitigate vibrations in power steering systems. This may involve the use of flow regulators, pressure relief valves, or variable-assist mechanisms that adjust fluid flow based on steering input and vehicle speed. These controls help maintain consistent steering feel and reduce unwanted vibrations.Expand Specific Solutions03 Pump design optimization

Improving the design of power steering pumps can significantly reduce system vibrations. This may include using balanced rotors, optimized vane configurations, or incorporating noise-reducing features within the pump housing. Advanced pump designs aim to minimize pressure fluctuations and provide smoother fluid delivery to the steering system.Expand Specific Solutions04 Hydraulic circuit modifications

Modifications to the hydraulic circuit of power steering systems can help reduce vibrations. This may involve the strategic placement of accumulators, the use of tuned fluid lines, or the incorporation of expansion chambers. These modifications aim to absorb pressure spikes and dampen fluid-borne noise within the system.Expand Specific Solutions05 Electronic control integration

Integrating electronic control systems with hydraulic power steering can help mitigate vibrations. This may involve using sensors to detect vibrations and actively adjusting fluid pressure or flow to counteract them. Electronic control can also enable adaptive steering assistance that minimizes vibrations across various driving conditions.Expand Specific Solutions

Key Industry Players

The vibration reduction techniques in power steering fluid systems market is in a mature stage, with established players and ongoing innovation. The global market size for automotive steering systems is substantial, estimated to be over $30 billion annually. Technologically, the field is advancing with a focus on electronic power steering and autonomous driving capabilities. Key players like GM, Toyota, Ford, and Bosch are leading innovation, while specialized companies such as JTEKT, ZF Friedrichshafen, and Hyundai Mobis are also significant contributors. These companies are investing heavily in R&D to improve efficiency, reduce noise and vibration, and integrate advanced driver assistance systems into steering technologies.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative Magnetic Ride Control system that uses magnetorheological fluid to reduce vibrations in power steering systems. This technology employs electromagnets to alter the viscosity of the fluid in real-time, adapting to road conditions and steering inputs. The system includes advanced sensors and control algorithms to detect and counteract vibrations, resulting in smoother steering performance and improved driver comfort[1][3]. GM has also implemented a dual-path fluid circuit design, which separates the high-pressure and low-pressure fluid paths, minimizing pressure fluctuations and reducing system noise[5].

Strengths: Rapid response to changing conditions, highly adaptable, and improved ride quality. Weaknesses: Complexity of the system may lead to higher costs and potential maintenance challenges.

Toyota Motor Corp.

Technical Solution: Toyota has developed a Variable Flow Control (VFC) power steering system that actively adjusts the fluid flow rate based on vehicle speed and steering input. This system incorporates a flow control valve that reduces fluid flow at high speeds, minimizing unnecessary power consumption and heat generation. At low speeds, the system increases fluid flow to provide more steering assistance. Toyota has also implemented a high-efficiency pump design with optimized vane geometry to reduce cavitation and fluid turbulence, further reducing vibrations in the system[2][4]. Additionally, Toyota uses advanced fluid formulations with enhanced shear stability and anti-foaming properties to maintain consistent performance and reduce noise[6].

Strengths: Improved energy efficiency, reduced system wear, and enhanced steering feel across various driving conditions. Weaknesses: Potential for increased system complexity and higher initial costs.

Innovative Technologies

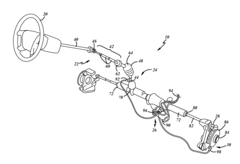

Apparatus for reducing vibration of motor driven power steering and method thereof

PatentActiveKR1020210009123A

Innovation

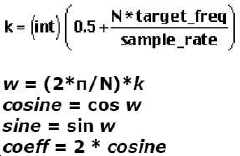

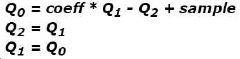

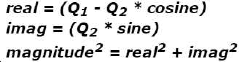

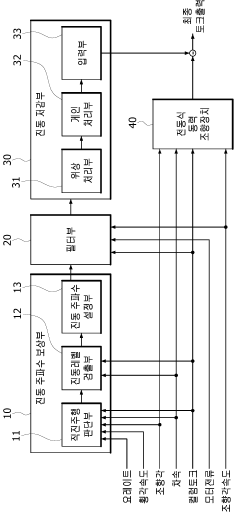

- An apparatus and method that includes a filter unit with an adaptive bandwidth filter and vibration reduction unit to extract and inversely compensate for noise frequencies using phase and gain processing, based on vehicle speed and steering conditions, to reduce vibrations in the electric power steering system.

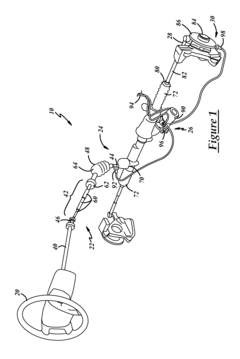

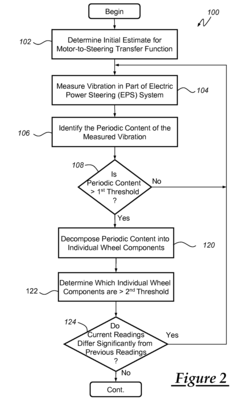

Reducing The Effects Of Vibrations In An Electric Power Steering (EPS) System

PatentInactiveUS20090294206A1

Innovation

- An EPS system and method that involves measuring vibrations, identifying periodic content, and using an electric motor to generate counter-acting vibrations, driven by an electronic controller, to cancel out these unwanted vibrations.

Noise Pollution Regulations

Noise pollution regulations play a crucial role in shaping the development and implementation of vibration reduction techniques in power steering fluid systems. As automotive manufacturers strive to meet increasingly stringent noise standards, the focus on minimizing vibrations and associated noise in power steering systems has intensified.

In recent years, many countries have implemented stricter noise pollution regulations for vehicles. The European Union, for instance, has set limits on vehicle noise emissions through its Regulation (EU) No 540/2014. This regulation specifies maximum sound levels for different vehicle categories and mandates a gradual reduction in these levels over time. Similarly, the United States Environmental Protection Agency (EPA) enforces noise emission standards for motor vehicles under the Noise Control Act of 1972.

These regulations have direct implications for power steering fluid systems, as they contribute significantly to overall vehicle noise. The hydraulic components in these systems, such as pumps and valves, can generate considerable noise and vibrations, especially at high operating pressures. As a result, automotive engineers are compelled to develop innovative vibration reduction techniques to comply with these regulations.

One approach to meeting noise pollution standards involves the use of advanced fluid formulations. Manufacturers are developing power steering fluids with improved damping properties, which can help absorb and dissipate vibrations more effectively. These fluids often incorporate specialized additives that modify their viscosity and compressibility characteristics, resulting in reduced noise transmission through the hydraulic system.

Another strategy focuses on optimizing the design of power steering components. Engineers are employing computational fluid dynamics (CFD) simulations to analyze fluid flow patterns and identify areas of turbulence that contribute to noise generation. This analysis allows for the redesign of pump impellers, valve geometries, and fluid passages to minimize turbulence and associated vibrations.

The integration of electronic control systems in power steering has also emerged as a promising approach to meet noise regulations. By precisely controlling the hydraulic pressure and flow rates in response to driving conditions, these systems can reduce unnecessary fluid movement and associated noise. Some advanced systems even incorporate active noise cancellation technologies to counteract specific frequencies of vibration-induced noise.

As noise pollution regulations continue to evolve, the automotive industry is likely to see further advancements in vibration reduction techniques for power steering fluid systems. This may include the development of hybrid hydraulic-electric systems that combine the benefits of both technologies while minimizing noise emissions. Additionally, the trend towards fully electric power steering systems is expected to accelerate, as these systems inherently produce less noise and vibration compared to their hydraulic counterparts.

In recent years, many countries have implemented stricter noise pollution regulations for vehicles. The European Union, for instance, has set limits on vehicle noise emissions through its Regulation (EU) No 540/2014. This regulation specifies maximum sound levels for different vehicle categories and mandates a gradual reduction in these levels over time. Similarly, the United States Environmental Protection Agency (EPA) enforces noise emission standards for motor vehicles under the Noise Control Act of 1972.

These regulations have direct implications for power steering fluid systems, as they contribute significantly to overall vehicle noise. The hydraulic components in these systems, such as pumps and valves, can generate considerable noise and vibrations, especially at high operating pressures. As a result, automotive engineers are compelled to develop innovative vibration reduction techniques to comply with these regulations.

One approach to meeting noise pollution standards involves the use of advanced fluid formulations. Manufacturers are developing power steering fluids with improved damping properties, which can help absorb and dissipate vibrations more effectively. These fluids often incorporate specialized additives that modify their viscosity and compressibility characteristics, resulting in reduced noise transmission through the hydraulic system.

Another strategy focuses on optimizing the design of power steering components. Engineers are employing computational fluid dynamics (CFD) simulations to analyze fluid flow patterns and identify areas of turbulence that contribute to noise generation. This analysis allows for the redesign of pump impellers, valve geometries, and fluid passages to minimize turbulence and associated vibrations.

The integration of electronic control systems in power steering has also emerged as a promising approach to meet noise regulations. By precisely controlling the hydraulic pressure and flow rates in response to driving conditions, these systems can reduce unnecessary fluid movement and associated noise. Some advanced systems even incorporate active noise cancellation technologies to counteract specific frequencies of vibration-induced noise.

As noise pollution regulations continue to evolve, the automotive industry is likely to see further advancements in vibration reduction techniques for power steering fluid systems. This may include the development of hybrid hydraulic-electric systems that combine the benefits of both technologies while minimizing noise emissions. Additionally, the trend towards fully electric power steering systems is expected to accelerate, as these systems inherently produce less noise and vibration compared to their hydraulic counterparts.

Energy Efficiency Impact

The implementation of vibration reduction techniques in power steering fluid systems has a significant impact on energy efficiency. By minimizing vibrations, these systems can reduce energy losses and improve overall vehicle performance. The primary mechanism through which vibration reduction contributes to energy efficiency is by decreasing the amount of energy dissipated as heat due to fluid friction and mechanical oscillations.

In power steering systems, vibrations can lead to increased fluid turbulence and cavitation, which result in higher energy consumption. By employing advanced vibration reduction techniques, such as tuned mass dampers or active vibration control systems, the fluid flow becomes more laminar, reducing energy losses associated with turbulent flow. This smoother fluid movement translates to less power required from the engine to operate the power steering system, thereby improving fuel efficiency.

Furthermore, vibration reduction techniques can enhance the efficiency of power steering pumps. By minimizing oscillations in the pump components, these methods reduce wear and tear, leading to sustained performance over time. This longevity contributes to energy efficiency by maintaining optimal operation and reducing the need for frequent replacements or repairs, which would otherwise consume additional resources and energy.

The implementation of vibration reduction techniques also allows for the use of lighter materials in power steering components without compromising structural integrity. Lighter components require less energy to move and operate, further contributing to overall energy efficiency. Additionally, by reducing vibrations, these techniques enable more precise control of the steering system, potentially allowing for the use of smaller, more energy-efficient motors or pumps without sacrificing performance.

Another aspect of energy efficiency impacted by vibration reduction is the vehicle's aerodynamics. Excessive vibrations in the steering system can lead to slight but continuous adjustments in the vehicle's direction, increasing air resistance and fuel consumption. By minimizing these vibrations, the vehicle maintains a more stable course, reducing unnecessary energy expenditure due to constant micro-corrections in steering.

Lastly, the reduction of vibrations in power steering fluid systems contributes to energy efficiency by improving the overall driving experience. A smoother, more responsive steering system reduces driver fatigue, potentially leading to more efficient driving behaviors and better fuel economy. This human factor, while indirect, plays a role in the holistic approach to energy efficiency in vehicle design and operation.

In power steering systems, vibrations can lead to increased fluid turbulence and cavitation, which result in higher energy consumption. By employing advanced vibration reduction techniques, such as tuned mass dampers or active vibration control systems, the fluid flow becomes more laminar, reducing energy losses associated with turbulent flow. This smoother fluid movement translates to less power required from the engine to operate the power steering system, thereby improving fuel efficiency.

Furthermore, vibration reduction techniques can enhance the efficiency of power steering pumps. By minimizing oscillations in the pump components, these methods reduce wear and tear, leading to sustained performance over time. This longevity contributes to energy efficiency by maintaining optimal operation and reducing the need for frequent replacements or repairs, which would otherwise consume additional resources and energy.

The implementation of vibration reduction techniques also allows for the use of lighter materials in power steering components without compromising structural integrity. Lighter components require less energy to move and operate, further contributing to overall energy efficiency. Additionally, by reducing vibrations, these techniques enable more precise control of the steering system, potentially allowing for the use of smaller, more energy-efficient motors or pumps without sacrificing performance.

Another aspect of energy efficiency impacted by vibration reduction is the vehicle's aerodynamics. Excessive vibrations in the steering system can lead to slight but continuous adjustments in the vehicle's direction, increasing air resistance and fuel consumption. By minimizing these vibrations, the vehicle maintains a more stable course, reducing unnecessary energy expenditure due to constant micro-corrections in steering.

Lastly, the reduction of vibrations in power steering fluid systems contributes to energy efficiency by improving the overall driving experience. A smoother, more responsive steering system reduces driver fatigue, potentially leading to more efficient driving behaviors and better fuel economy. This human factor, while indirect, plays a role in the holistic approach to energy efficiency in vehicle design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!