The Impact of Power Steering Fluid on Steering Wheel Responsiveness

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in automotive design. This system utilized hydraulic pressure to assist in turning the wheels, significantly reducing the effort required by the driver. The hydraulic power steering fluid played a crucial role in transmitting force and reducing friction within the system.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1980s. These systems replaced the hydraulic components with electric motors, sensors, and control units. EPS offered several advantages, including improved fuel efficiency, reduced maintenance, and the ability to integrate with other vehicle systems.

In the 1990s and 2000s, further refinements in power steering technology led to the development of variable-assist power steering. This innovation allowed the level of steering assistance to adjust based on vehicle speed, providing more assistance at low speeds and less at high speeds for improved road feel and control.

The advent of steer-by-wire technology in the 21st century represented another leap forward. This system eliminates the physical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators. While not yet widely adopted, steer-by-wire offers potential benefits in terms of customization, safety, and vehicle design flexibility.

Recent developments have focused on integrating power steering systems with advanced driver assistance systems (ADAS) and autonomous driving technologies. This integration allows for features such as lane-keeping assist, automated parking, and even fully autonomous steering control.

Throughout this evolution, the role of power steering fluid has remained critical in hydraulic systems, while its importance has diminished in electronic and steer-by-wire systems. However, the impact of power steering fluid on steering wheel responsiveness continues to be a relevant consideration in many modern vehicles, particularly in terms of maintaining optimal system performance and driver comfort.

The first hydraulic power steering system was introduced in the 1950s, marking a revolutionary change in automotive design. This system utilized hydraulic pressure to assist in turning the wheels, significantly reducing the effort required by the driver. The hydraulic power steering fluid played a crucial role in transmitting force and reducing friction within the system.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1980s. These systems replaced the hydraulic components with electric motors, sensors, and control units. EPS offered several advantages, including improved fuel efficiency, reduced maintenance, and the ability to integrate with other vehicle systems.

In the 1990s and 2000s, further refinements in power steering technology led to the development of variable-assist power steering. This innovation allowed the level of steering assistance to adjust based on vehicle speed, providing more assistance at low speeds and less at high speeds for improved road feel and control.

The advent of steer-by-wire technology in the 21st century represented another leap forward. This system eliminates the physical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators. While not yet widely adopted, steer-by-wire offers potential benefits in terms of customization, safety, and vehicle design flexibility.

Recent developments have focused on integrating power steering systems with advanced driver assistance systems (ADAS) and autonomous driving technologies. This integration allows for features such as lane-keeping assist, automated parking, and even fully autonomous steering control.

Throughout this evolution, the role of power steering fluid has remained critical in hydraulic systems, while its importance has diminished in electronic and steer-by-wire systems. However, the impact of power steering fluid on steering wheel responsiveness continues to be a relevant consideration in many modern vehicles, particularly in terms of maintaining optimal system performance and driver comfort.

Market Demand Analysis

The market demand for power steering fluid and its impact on steering wheel responsiveness has been steadily growing in recent years. This growth is primarily driven by the increasing global automotive production and the rising consumer expectations for smoother, more responsive driving experiences.

In the automotive industry, power steering fluid plays a crucial role in ensuring optimal steering performance. As vehicles become more sophisticated, the demand for high-quality power steering fluids that can enhance steering wheel responsiveness has intensified. This trend is particularly evident in the luxury and performance vehicle segments, where drivers expect precise and effortless steering control.

The market for power steering fluid is closely tied to the overall automotive market, which has shown resilience despite recent economic challenges. According to industry reports, the global power steering fluid market is projected to grow at a compound annual growth rate (CAGR) of around 3-4% over the next five years. This growth is attributed to the increasing vehicle production, especially in emerging markets, and the rising adoption of electric power steering systems.

Consumer awareness regarding the importance of regular maintenance and the impact of power steering fluid on vehicle performance has also contributed to market growth. As drivers become more informed about the role of power steering fluid in maintaining steering responsiveness, there is a growing demand for premium-quality fluids that offer enhanced performance and longevity.

The aftermarket segment for power steering fluid has shown significant potential, driven by the aging vehicle fleet in many developed countries. As vehicles age, the need for power steering fluid replacement increases, creating a steady demand in the automotive maintenance sector.

Environmental concerns and regulations have also influenced market dynamics. There is a growing demand for eco-friendly power steering fluids that offer improved biodegradability and reduced environmental impact. This trend has led to the development of new formulations that balance performance with sustainability.

The market demand analysis also reveals regional variations. Developed automotive markets such as North America and Europe show a preference for high-performance, long-lasting power steering fluids. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in demand, driven by increasing vehicle ownership and a growing middle class.

The COVID-19 pandemic temporarily disrupted the automotive supply chain and affected market demand. However, the industry has shown signs of recovery, with a renewed focus on vehicle maintenance and performance enhancement, which bodes well for the power steering fluid market.

In conclusion, the market demand for power steering fluid, particularly in relation to its impact on steering wheel responsiveness, shows a positive trajectory. The combination of technological advancements, consumer awareness, and the global automotive industry's growth continues to drive demand for high-quality power steering fluids that can deliver superior steering performance and responsiveness.

In the automotive industry, power steering fluid plays a crucial role in ensuring optimal steering performance. As vehicles become more sophisticated, the demand for high-quality power steering fluids that can enhance steering wheel responsiveness has intensified. This trend is particularly evident in the luxury and performance vehicle segments, where drivers expect precise and effortless steering control.

The market for power steering fluid is closely tied to the overall automotive market, which has shown resilience despite recent economic challenges. According to industry reports, the global power steering fluid market is projected to grow at a compound annual growth rate (CAGR) of around 3-4% over the next five years. This growth is attributed to the increasing vehicle production, especially in emerging markets, and the rising adoption of electric power steering systems.

Consumer awareness regarding the importance of regular maintenance and the impact of power steering fluid on vehicle performance has also contributed to market growth. As drivers become more informed about the role of power steering fluid in maintaining steering responsiveness, there is a growing demand for premium-quality fluids that offer enhanced performance and longevity.

The aftermarket segment for power steering fluid has shown significant potential, driven by the aging vehicle fleet in many developed countries. As vehicles age, the need for power steering fluid replacement increases, creating a steady demand in the automotive maintenance sector.

Environmental concerns and regulations have also influenced market dynamics. There is a growing demand for eco-friendly power steering fluids that offer improved biodegradability and reduced environmental impact. This trend has led to the development of new formulations that balance performance with sustainability.

The market demand analysis also reveals regional variations. Developed automotive markets such as North America and Europe show a preference for high-performance, long-lasting power steering fluids. In contrast, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in demand, driven by increasing vehicle ownership and a growing middle class.

The COVID-19 pandemic temporarily disrupted the automotive supply chain and affected market demand. However, the industry has shown signs of recovery, with a renewed focus on vehicle maintenance and performance enhancement, which bodes well for the power steering fluid market.

In conclusion, the market demand for power steering fluid, particularly in relation to its impact on steering wheel responsiveness, shows a positive trajectory. The combination of technological advancements, consumer awareness, and the global automotive industry's growth continues to drive demand for high-quality power steering fluids that can deliver superior steering performance and responsiveness.

Current Fluid Challenges

Power steering fluid plays a crucial role in the responsiveness and overall performance of steering systems in modern vehicles. However, several challenges currently exist that impact the effectiveness of these fluids and, consequently, the steering wheel's responsiveness.

One of the primary challenges is fluid degradation over time. Power steering fluid is subjected to high temperatures and pressures within the system, leading to thermal breakdown and oxidation. This degradation process results in the formation of sludge and deposits, which can clog small passages and valves in the steering system. As a result, the fluid's ability to transmit power efficiently is compromised, leading to reduced steering responsiveness and increased effort required to turn the wheel.

Another significant challenge is the compatibility of power steering fluids with various system components. Modern vehicles often use a diverse range of materials in their steering systems, including different types of rubber seals, plastics, and metals. Ensuring that the fluid remains compatible with all these materials throughout its service life is crucial. Incompatibility can lead to seal degradation, causing leaks and a loss of system pressure, which directly impacts steering responsiveness.

Moisture contamination presents an ongoing challenge for power steering fluids. Water ingress can occur due to condensation or environmental factors, leading to corrosion of metal components and the formation of acids within the fluid. This not only accelerates fluid degradation but also poses a risk to the integrity of the steering system components. The presence of moisture can also cause foaming, which reduces the fluid's ability to transmit power effectively and may result in erratic steering behavior.

The viscosity stability of power steering fluid across a wide temperature range is another critical challenge. In cold climates, the fluid must maintain sufficient flow to ensure immediate steering response upon vehicle start-up. Conversely, in high-temperature conditions, the fluid must retain its viscosity to provide adequate lubrication and power transmission. Achieving this balance is essential for consistent steering performance across various operating conditions.

Furthermore, the increasing trend towards electrification in vehicles poses new challenges for power steering fluid technology. As hybrid and electric vehicles become more prevalent, there is a need for fluids that can operate effectively in systems that may experience less frequent use or different thermal profiles compared to traditional internal combustion engine vehicles.

Lastly, environmental concerns and regulations are driving the need for more sustainable and biodegradable power steering fluids. Developing fluids that meet performance requirements while also addressing environmental considerations presents a significant challenge for fluid manufacturers and automotive engineers.

Addressing these challenges is crucial for improving steering wheel responsiveness and overall vehicle performance. Ongoing research and development efforts are focused on creating advanced fluid formulations that can overcome these issues, ensuring optimal steering system performance throughout the vehicle's lifecycle.

One of the primary challenges is fluid degradation over time. Power steering fluid is subjected to high temperatures and pressures within the system, leading to thermal breakdown and oxidation. This degradation process results in the formation of sludge and deposits, which can clog small passages and valves in the steering system. As a result, the fluid's ability to transmit power efficiently is compromised, leading to reduced steering responsiveness and increased effort required to turn the wheel.

Another significant challenge is the compatibility of power steering fluids with various system components. Modern vehicles often use a diverse range of materials in their steering systems, including different types of rubber seals, plastics, and metals. Ensuring that the fluid remains compatible with all these materials throughout its service life is crucial. Incompatibility can lead to seal degradation, causing leaks and a loss of system pressure, which directly impacts steering responsiveness.

Moisture contamination presents an ongoing challenge for power steering fluids. Water ingress can occur due to condensation or environmental factors, leading to corrosion of metal components and the formation of acids within the fluid. This not only accelerates fluid degradation but also poses a risk to the integrity of the steering system components. The presence of moisture can also cause foaming, which reduces the fluid's ability to transmit power effectively and may result in erratic steering behavior.

The viscosity stability of power steering fluid across a wide temperature range is another critical challenge. In cold climates, the fluid must maintain sufficient flow to ensure immediate steering response upon vehicle start-up. Conversely, in high-temperature conditions, the fluid must retain its viscosity to provide adequate lubrication and power transmission. Achieving this balance is essential for consistent steering performance across various operating conditions.

Furthermore, the increasing trend towards electrification in vehicles poses new challenges for power steering fluid technology. As hybrid and electric vehicles become more prevalent, there is a need for fluids that can operate effectively in systems that may experience less frequent use or different thermal profiles compared to traditional internal combustion engine vehicles.

Lastly, environmental concerns and regulations are driving the need for more sustainable and biodegradable power steering fluids. Developing fluids that meet performance requirements while also addressing environmental considerations presents a significant challenge for fluid manufacturers and automotive engineers.

Addressing these challenges is crucial for improving steering wheel responsiveness and overall vehicle performance. Ongoing research and development efforts are focused on creating advanced fluid formulations that can overcome these issues, ensuring optimal steering system performance throughout the vehicle's lifecycle.

Fluid Solution Overview

01 Fluid composition for improved responsiveness

Specialized fluid compositions can enhance power steering responsiveness. These formulations may include additives that reduce friction, improve viscosity characteristics, or enhance thermal stability. Such improvements in fluid properties can lead to more precise and responsive steering control.- Fluid composition for improved responsiveness: Specialized fluid compositions can enhance power steering responsiveness. These formulations may include additives that reduce friction, improve viscosity characteristics, or enhance thermal stability. Such improvements in fluid properties can lead to more precise and responsive steering control.

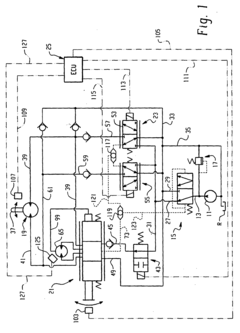

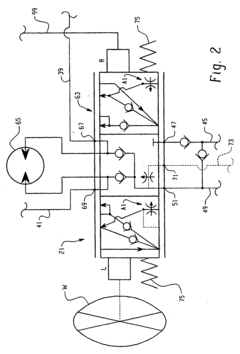

- Hydraulic system design for enhanced responsiveness: The design of the hydraulic system in power steering can significantly impact responsiveness. This may involve optimizing valve configurations, pump designs, or flow control mechanisms to ensure rapid and accurate steering response. Advanced hydraulic system designs can minimize lag and improve overall steering feel.

- Electronic control systems for power steering: Integration of electronic control systems can greatly enhance power steering responsiveness. These systems can adjust steering assistance based on vehicle speed, driver input, and road conditions. Advanced algorithms and sensors can provide more precise and adaptive steering control.

- Variable assist power steering systems: Variable assist systems can modulate the level of power steering assistance based on driving conditions. This approach allows for lighter steering at low speeds and firmer control at high speeds, improving overall responsiveness and driver feel across various driving scenarios.

- Pressure regulation and flow control in power steering: Effective pressure regulation and flow control mechanisms are crucial for power steering responsiveness. This may involve advanced pressure relief valves, flow control valves, or adaptive pressure management systems. These components help maintain optimal fluid pressure and flow rates, ensuring consistent and responsive steering performance.

02 Hydraulic system design for enhanced responsiveness

The design of the hydraulic system in power steering can significantly impact responsiveness. This may involve optimizing valve configurations, pump designs, or flow control mechanisms to ensure rapid and accurate transmission of steering inputs to the wheels.Expand Specific Solutions03 Electronic control systems for power steering

Integration of electronic control systems can improve power steering responsiveness. These systems can adjust steering assistance based on vehicle speed, driver input, and road conditions, providing more precise and adaptive steering control.Expand Specific Solutions04 Pressure management in power steering systems

Effective pressure management within the power steering system can enhance responsiveness. This may involve pressure relief valves, accumulators, or variable pressure pumps to maintain optimal pressure levels for different steering conditions.Expand Specific Solutions05 Temperature control for power steering fluid

Maintaining optimal temperature of the power steering fluid can improve system responsiveness. This may involve cooling systems, heat exchangers, or temperature-responsive valves to ensure the fluid operates within its ideal temperature range for best performance.Expand Specific Solutions

Key Industry Players

The power steering fluid market is in a mature stage, with a global size estimated to exceed $1 billion. The technology is well-established, with major players like Eaton Corp., Bosch Rexroth, and ZF Friedrichshafen dominating the market. These companies have extensive experience in automotive systems and continue to innovate in steering responsiveness. Emerging players such as BYD and Geely are also entering the space, particularly in the electric vehicle segment. The market is seeing a shift towards electric power steering systems, which are gradually replacing traditional hydraulic systems. This transition is driving research into new fluid formulations and electronic control systems to further enhance steering performance and efficiency.

Bosch Rexroth Co. Ltd.

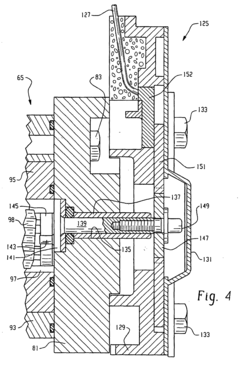

Technical Solution: Bosch Rexroth has innovated in power steering fluid technology with their Electrohydraulic Power Steering (EHPS) system. This system combines traditional hydraulic power steering with electronic control, optimizing the use of power steering fluid. The EHPS uses a variable displacement pump that adjusts fluid flow based on steering demand, reducing energy consumption and improving overall efficiency[4]. Bosch Rexroth's power steering fluid is specially formulated to work with this system, featuring low-foaming properties and high thermal stability. The fluid's composition includes advanced anti-wear additives that protect steering components, extending system lifespan[5]. Furthermore, their system incorporates a closed-loop feedback mechanism that continuously monitors fluid pressure and adjusts it in real-time, ensuring optimal steering responsiveness under varying driving conditions[6].

Strengths: Energy-efficient variable displacement pump, advanced fluid formulation, and real-time pressure adjustment. Weaknesses: Complexity of the system may lead to higher maintenance costs in the long term.

JTEKT Corp.

Technical Solution: JTEKT Corporation has developed a cutting-edge power steering fluid system that focuses on enhancing steering wheel responsiveness through advanced fluid dynamics. Their system utilizes a proprietary fluid composition that maintains optimal viscosity across a wide range of operating temperatures, ensuring consistent steering performance in various climates[7]. JTEKT's technology incorporates a dual-circuit design that separates the high-pressure and low-pressure fluid paths, reducing system noise and improving overall efficiency. This design also allows for quicker fluid response times, translating to more immediate steering feedback[8]. Additionally, JTEKT has implemented an intelligent fluid temperature management system that actively regulates fluid temperature, preventing overheating and maintaining optimal fluid properties even under extreme driving conditions[9].

Strengths: Consistent performance across temperature ranges, reduced system noise, and intelligent temperature management. Weaknesses: The dual-circuit design may increase system complexity and potentially lead to higher manufacturing costs.

Fluid Innovation Patents

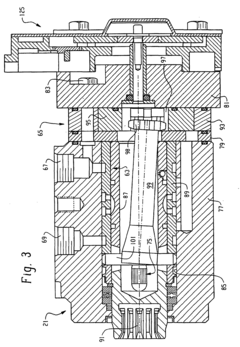

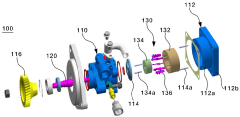

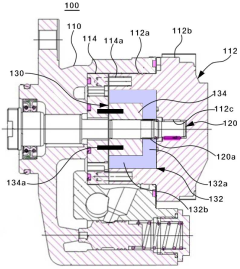

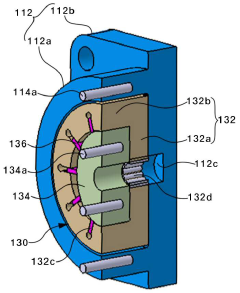

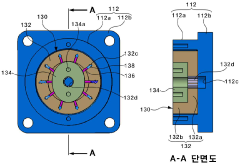

Hydrostatic steering system having improved steering sensing

PatentInactiveEP1231128B1

Innovation

- A rotary fluid pressure device with an internally-toothed ring member and externally-toothed star member, along with a sensor assembly that generates a higher resolution command position signal by sensing the speed of the star member's orbital and rotational movement, reducing the need for additional structure and improving fluid control.

Power steering pump

PatentActiveKR1020200021653A

Innovation

- A speed-sensitive power steering pump design featuring a rotating ring, fixed cam, and vanes that adjust hydraulic pressure based on engine speed, forming low-pressure during high-speed driving and high-pressure during low-speed driving to stabilize steering and improve feel.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and use of power steering fluid, significantly impacting steering wheel responsiveness. These regulations aim to protect the environment and human health while ensuring optimal vehicle performance.

In recent years, there has been a growing emphasis on reducing the environmental impact of automotive fluids, including power steering fluid. Many countries have implemented strict regulations on the composition and disposal of these fluids. For instance, the European Union's End-of-Life Vehicles Directive requires that power steering fluids be easily removable and recyclable, promoting the use of more environmentally friendly formulations.

The United States Environmental Protection Agency (EPA) has also established guidelines for the proper handling and disposal of power steering fluid. These regulations have led to the development of biodegradable and less toxic alternatives to traditional petroleum-based fluids. Manufacturers are now focusing on creating synthetic and semi-synthetic power steering fluids that offer improved performance while meeting environmental standards.

Environmental regulations have also influenced the design of power steering systems themselves. There is a growing trend towards electric power steering systems, which eliminate the need for hydraulic fluid altogether. This shift is partly driven by environmental concerns, as electric systems reduce the risk of fluid leaks and subsequent environmental contamination.

The impact of these regulations on steering wheel responsiveness is multifaceted. On one hand, the development of advanced, environmentally friendly fluids has led to improved performance characteristics. These new formulations often offer better thermal stability and reduced friction, which can enhance steering responsiveness and feel. On the other hand, the transition to electric power steering systems has changed the nature of steering feedback, with some drivers reporting a loss of road feel compared to traditional hydraulic systems.

Manufacturers must now balance environmental compliance with performance requirements when developing power steering systems and fluids. This has led to increased research and development efforts focused on creating solutions that meet both environmental and performance standards. As a result, we are seeing the emergence of hybrid systems that combine the benefits of hydraulic and electric power steering, offering a compromise between environmental concerns and steering responsiveness.

In conclusion, environmental regulations have significantly influenced the evolution of power steering fluid and systems, driving innovation in fluid formulations and steering technologies. While these regulations present challenges, they also create opportunities for developing more sustainable and efficient solutions that maintain or even improve steering wheel responsiveness.

In recent years, there has been a growing emphasis on reducing the environmental impact of automotive fluids, including power steering fluid. Many countries have implemented strict regulations on the composition and disposal of these fluids. For instance, the European Union's End-of-Life Vehicles Directive requires that power steering fluids be easily removable and recyclable, promoting the use of more environmentally friendly formulations.

The United States Environmental Protection Agency (EPA) has also established guidelines for the proper handling and disposal of power steering fluid. These regulations have led to the development of biodegradable and less toxic alternatives to traditional petroleum-based fluids. Manufacturers are now focusing on creating synthetic and semi-synthetic power steering fluids that offer improved performance while meeting environmental standards.

Environmental regulations have also influenced the design of power steering systems themselves. There is a growing trend towards electric power steering systems, which eliminate the need for hydraulic fluid altogether. This shift is partly driven by environmental concerns, as electric systems reduce the risk of fluid leaks and subsequent environmental contamination.

The impact of these regulations on steering wheel responsiveness is multifaceted. On one hand, the development of advanced, environmentally friendly fluids has led to improved performance characteristics. These new formulations often offer better thermal stability and reduced friction, which can enhance steering responsiveness and feel. On the other hand, the transition to electric power steering systems has changed the nature of steering feedback, with some drivers reporting a loss of road feel compared to traditional hydraulic systems.

Manufacturers must now balance environmental compliance with performance requirements when developing power steering systems and fluids. This has led to increased research and development efforts focused on creating solutions that meet both environmental and performance standards. As a result, we are seeing the emergence of hybrid systems that combine the benefits of hydraulic and electric power steering, offering a compromise between environmental concerns and steering responsiveness.

In conclusion, environmental regulations have significantly influenced the evolution of power steering fluid and systems, driving innovation in fluid formulations and steering technologies. While these regulations present challenges, they also create opportunities for developing more sustainable and efficient solutions that maintain or even improve steering wheel responsiveness.

Safety Considerations

Safety considerations are paramount when evaluating the impact of power steering fluid on steering wheel responsiveness. The quality and condition of power steering fluid directly affect the overall safety of a vehicle's steering system. Proper maintenance and regular checks of power steering fluid levels are crucial to ensure optimal steering performance and prevent potential safety hazards.

One of the primary safety concerns related to power steering fluid is the risk of sudden steering failure. If the fluid level becomes too low or the fluid quality deteriorates significantly, it can lead to a loss of power assistance, making the steering wheel much harder to turn. This sudden change in steering effort can be particularly dangerous in emergency situations or during high-speed maneuvers, potentially causing accidents or loss of vehicle control.

Contamination of power steering fluid is another critical safety issue. Over time, debris, metal particles, and other contaminants can accumulate in the fluid, potentially causing damage to the power steering pump, valves, and other components. This contamination can lead to erratic steering behavior, increased steering effort, or even complete system failure, all of which pose significant safety risks to drivers and passengers.

The viscosity of power steering fluid also plays a crucial role in safety. If the fluid becomes too thick or too thin due to temperature changes or degradation, it can affect the responsiveness of the steering system. This can result in delayed steering inputs or over-sensitive steering, both of which can compromise the driver's ability to maintain precise control of the vehicle, especially in challenging driving conditions.

Leaks in the power steering system present another safety concern. Even small leaks can lead to a gradual loss of fluid, potentially resulting in sudden steering failure if left unaddressed. Regular inspections for leaks and prompt repairs are essential to maintain the integrity of the power steering system and ensure consistent steering performance.

The type of power steering fluid used is also a critical safety consideration. Using the wrong type of fluid can cause damage to seals and other components, leading to premature wear and potential system failure. It's crucial to use the manufacturer-recommended fluid to ensure compatibility with the vehicle's specific power steering system and maintain optimal performance and safety.

In conclusion, the safety implications of power steering fluid on steering wheel responsiveness are significant and multifaceted. Regular maintenance, proper fluid selection, and prompt addressing of any issues are essential to ensure the safety and reliability of a vehicle's steering system. Drivers and vehicle owners should be educated about the importance of power steering fluid maintenance to promote overall road safety.

One of the primary safety concerns related to power steering fluid is the risk of sudden steering failure. If the fluid level becomes too low or the fluid quality deteriorates significantly, it can lead to a loss of power assistance, making the steering wheel much harder to turn. This sudden change in steering effort can be particularly dangerous in emergency situations or during high-speed maneuvers, potentially causing accidents or loss of vehicle control.

Contamination of power steering fluid is another critical safety issue. Over time, debris, metal particles, and other contaminants can accumulate in the fluid, potentially causing damage to the power steering pump, valves, and other components. This contamination can lead to erratic steering behavior, increased steering effort, or even complete system failure, all of which pose significant safety risks to drivers and passengers.

The viscosity of power steering fluid also plays a crucial role in safety. If the fluid becomes too thick or too thin due to temperature changes or degradation, it can affect the responsiveness of the steering system. This can result in delayed steering inputs or over-sensitive steering, both of which can compromise the driver's ability to maintain precise control of the vehicle, especially in challenging driving conditions.

Leaks in the power steering system present another safety concern. Even small leaks can lead to a gradual loss of fluid, potentially resulting in sudden steering failure if left unaddressed. Regular inspections for leaks and prompt repairs are essential to maintain the integrity of the power steering system and ensure consistent steering performance.

The type of power steering fluid used is also a critical safety consideration. Using the wrong type of fluid can cause damage to seals and other components, leading to premature wear and potential system failure. It's crucial to use the manufacturer-recommended fluid to ensure compatibility with the vehicle's specific power steering system and maintain optimal performance and safety.

In conclusion, the safety implications of power steering fluid on steering wheel responsiveness are significant and multifaceted. Regular maintenance, proper fluid selection, and prompt addressing of any issues are essential to ensure the safety and reliability of a vehicle's steering system. Drivers and vehicle owners should be educated about the importance of power steering fluid maintenance to promote overall road safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!