How Contaminants Alter the Chemical Properties of Power Steering Fluid

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Contamination Background

Power steering fluid is a crucial component in modern vehicle steering systems, facilitating smooth and effortless steering operations. However, the effectiveness and longevity of this hydraulic fluid can be significantly compromised by various contaminants. The issue of contamination in power steering fluid has been a persistent challenge in the automotive industry since the widespread adoption of power steering systems in the mid-20th century.

Contaminants in power steering fluid can originate from multiple sources, including environmental factors, wear and tear of system components, and improper maintenance practices. Common contaminants include moisture, metal particles, rubber particles from deteriorating hoses, and atmospheric dust. These impurities can enter the system through breaches in seals, during fluid top-ups, or as a result of normal component wear over time.

The presence of contaminants in power steering fluid can lead to a cascade of chemical and physical changes that ultimately affect the fluid's performance and the overall steering system's functionality. Moisture, for instance, can cause oxidation and hydrolysis of the base oil and additives, leading to the formation of acids and sludge. Metal particles from worn components can act as catalysts, accelerating the degradation of the fluid and potentially causing abrasive damage to other parts of the system.

The chemical alterations induced by contaminants can manifest in various ways. The fluid's viscosity may change, affecting its ability to flow properly through the system and maintain adequate pressure. The pH level of the fluid can shift, potentially becoming more acidic and corrosive to metal components. Additionally, the fluid's thermal stability and oxidation resistance may be compromised, reducing its ability to withstand high temperatures and prolonged use.

These chemical changes not only impact the fluid's immediate performance but can also lead to long-term issues within the power steering system. Degraded fluid may cause increased wear on pump components, steering gear, and seals. It can also result in the formation of varnish-like deposits on internal surfaces, further impeding the system's efficiency and potentially leading to steering malfunctions.

Understanding the background of power steering fluid contamination is essential for developing effective strategies to mitigate its impact. This knowledge has driven advancements in fluid formulations, filtration technologies, and maintenance protocols over the years. As vehicles become more sophisticated and environmental regulations more stringent, the challenge of maintaining clean and effective power steering fluid continues to evolve, necessitating ongoing research and innovation in this field.

Contaminants in power steering fluid can originate from multiple sources, including environmental factors, wear and tear of system components, and improper maintenance practices. Common contaminants include moisture, metal particles, rubber particles from deteriorating hoses, and atmospheric dust. These impurities can enter the system through breaches in seals, during fluid top-ups, or as a result of normal component wear over time.

The presence of contaminants in power steering fluid can lead to a cascade of chemical and physical changes that ultimately affect the fluid's performance and the overall steering system's functionality. Moisture, for instance, can cause oxidation and hydrolysis of the base oil and additives, leading to the formation of acids and sludge. Metal particles from worn components can act as catalysts, accelerating the degradation of the fluid and potentially causing abrasive damage to other parts of the system.

The chemical alterations induced by contaminants can manifest in various ways. The fluid's viscosity may change, affecting its ability to flow properly through the system and maintain adequate pressure. The pH level of the fluid can shift, potentially becoming more acidic and corrosive to metal components. Additionally, the fluid's thermal stability and oxidation resistance may be compromised, reducing its ability to withstand high temperatures and prolonged use.

These chemical changes not only impact the fluid's immediate performance but can also lead to long-term issues within the power steering system. Degraded fluid may cause increased wear on pump components, steering gear, and seals. It can also result in the formation of varnish-like deposits on internal surfaces, further impeding the system's efficiency and potentially leading to steering malfunctions.

Understanding the background of power steering fluid contamination is essential for developing effective strategies to mitigate its impact. This knowledge has driven advancements in fluid formulations, filtration technologies, and maintenance protocols over the years. As vehicles become more sophisticated and environmental regulations more stringent, the challenge of maintaining clean and effective power steering fluid continues to evolve, necessitating ongoing research and innovation in this field.

Market Analysis of Power Steering Systems

The power steering systems market has experienced significant growth in recent years, driven by the increasing demand for comfortable driving experiences and the rising production of vehicles worldwide. The global power steering market size was valued at approximately $26.5 billion in 2020 and is projected to reach $38.7 billion by 2027, growing at a CAGR of 5.6% during the forecast period.

The market is segmented based on type, vehicle type, and region. By type, the market is divided into hydraulic power steering (HPS), electric power steering (EPS), and electro-hydraulic power steering (EHPS). EPS has been gaining substantial market share due to its improved fuel efficiency, reduced complexity, and enhanced vehicle control. The automotive industry's shift towards electric and hybrid vehicles has further accelerated the adoption of EPS systems.

In terms of vehicle type, the market is categorized into passenger cars, commercial vehicles, and off-highway vehicles. Passenger cars dominate the market share, accounting for over 60% of the total revenue. The increasing production of passenger vehicles, particularly in emerging economies, is a key factor driving this segment's growth.

Geographically, Asia Pacific leads the power steering systems market, followed by North America and Europe. The Asia Pacific region's dominance is attributed to the presence of major automotive manufacturing hubs in countries like China, Japan, and South Korea. Additionally, the rising disposable income and growing urbanization in emerging economies have led to increased vehicle sales, further boosting the demand for power steering systems.

Key players in the power steering systems market include JTEKT Corporation, Robert Bosch GmbH, ZF Friedrichshafen AG, NSK Ltd., and Nexteer Automotive. These companies are focusing on research and development activities to introduce innovative products and gain a competitive edge in the market.

The market is also witnessing several trends, including the integration of advanced driver assistance systems (ADAS) with power steering systems, the development of steer-by-wire technology, and the increasing use of lightweight materials to improve fuel efficiency. These trends are expected to shape the future of the power steering systems market and create new opportunities for growth and innovation.

The market is segmented based on type, vehicle type, and region. By type, the market is divided into hydraulic power steering (HPS), electric power steering (EPS), and electro-hydraulic power steering (EHPS). EPS has been gaining substantial market share due to its improved fuel efficiency, reduced complexity, and enhanced vehicle control. The automotive industry's shift towards electric and hybrid vehicles has further accelerated the adoption of EPS systems.

In terms of vehicle type, the market is categorized into passenger cars, commercial vehicles, and off-highway vehicles. Passenger cars dominate the market share, accounting for over 60% of the total revenue. The increasing production of passenger vehicles, particularly in emerging economies, is a key factor driving this segment's growth.

Geographically, Asia Pacific leads the power steering systems market, followed by North America and Europe. The Asia Pacific region's dominance is attributed to the presence of major automotive manufacturing hubs in countries like China, Japan, and South Korea. Additionally, the rising disposable income and growing urbanization in emerging economies have led to increased vehicle sales, further boosting the demand for power steering systems.

Key players in the power steering systems market include JTEKT Corporation, Robert Bosch GmbH, ZF Friedrichshafen AG, NSK Ltd., and Nexteer Automotive. These companies are focusing on research and development activities to introduce innovative products and gain a competitive edge in the market.

The market is also witnessing several trends, including the integration of advanced driver assistance systems (ADAS) with power steering systems, the development of steer-by-wire technology, and the increasing use of lightweight materials to improve fuel efficiency. These trends are expected to shape the future of the power steering systems market and create new opportunities for growth and innovation.

Current Challenges in Fluid Contamination Detection

The detection of contaminants in power steering fluid presents several significant challenges in the automotive industry. One of the primary difficulties lies in the development of reliable and accurate sensing technologies capable of identifying various types of contaminants in real-time. Current methods often struggle to differentiate between different contaminants, leading to potential misdiagnosis of fluid quality issues.

Another major challenge is the need for robust sensors that can withstand the harsh operating conditions within power steering systems. These sensors must maintain accuracy and reliability under high temperatures, pressures, and constant vibrations. The miniaturization of such sensors while preserving their functionality remains a significant hurdle for researchers and engineers.

The complexity of power steering fluid compositions further complicates contamination detection. Modern fluids contain numerous additives and compounds, making it difficult to isolate and identify specific contaminants without interference from the fluid's inherent chemical properties. This complexity necessitates the development of advanced algorithms and data processing techniques to accurately interpret sensor readings.

Cost-effectiveness is another crucial factor hindering widespread implementation of contamination detection systems. Current high-precision detection methods often involve expensive equipment and complex procedures, making them impractical for routine maintenance or on-board vehicle diagnostics. Striking a balance between accuracy and affordability remains a key challenge in the industry.

The dynamic nature of contamination also poses difficulties. Contaminants can change their chemical and physical properties over time, especially under the influence of heat and pressure within the power steering system. This variability makes it challenging to establish consistent detection thresholds and interpret results accurately across different operating conditions and vehicle models.

Furthermore, the integration of contamination detection systems into existing vehicle architectures presents both technical and logistical challenges. These systems must be seamlessly incorporated without compromising the overall performance or reliability of the power steering system. Additionally, they need to interface effectively with other vehicle diagnostic systems to provide comprehensive fluid health monitoring.

Lastly, the lack of standardized testing protocols and industry-wide acceptance criteria for fluid contamination levels hinders the development and adoption of universal detection solutions. This absence of standardization makes it difficult for manufacturers to establish benchmarks for fluid quality and contamination thresholds, leading to variations in detection methods and interpretations across different vehicle models and brands.

Another major challenge is the need for robust sensors that can withstand the harsh operating conditions within power steering systems. These sensors must maintain accuracy and reliability under high temperatures, pressures, and constant vibrations. The miniaturization of such sensors while preserving their functionality remains a significant hurdle for researchers and engineers.

The complexity of power steering fluid compositions further complicates contamination detection. Modern fluids contain numerous additives and compounds, making it difficult to isolate and identify specific contaminants without interference from the fluid's inherent chemical properties. This complexity necessitates the development of advanced algorithms and data processing techniques to accurately interpret sensor readings.

Cost-effectiveness is another crucial factor hindering widespread implementation of contamination detection systems. Current high-precision detection methods often involve expensive equipment and complex procedures, making them impractical for routine maintenance or on-board vehicle diagnostics. Striking a balance between accuracy and affordability remains a key challenge in the industry.

The dynamic nature of contamination also poses difficulties. Contaminants can change their chemical and physical properties over time, especially under the influence of heat and pressure within the power steering system. This variability makes it challenging to establish consistent detection thresholds and interpret results accurately across different operating conditions and vehicle models.

Furthermore, the integration of contamination detection systems into existing vehicle architectures presents both technical and logistical challenges. These systems must be seamlessly incorporated without compromising the overall performance or reliability of the power steering system. Additionally, they need to interface effectively with other vehicle diagnostic systems to provide comprehensive fluid health monitoring.

Lastly, the lack of standardized testing protocols and industry-wide acceptance criteria for fluid contamination levels hinders the development and adoption of universal detection solutions. This absence of standardization makes it difficult for manufacturers to establish benchmarks for fluid quality and contamination thresholds, leading to variations in detection methods and interpretations across different vehicle models and brands.

Existing Contamination Mitigation Strategies

01 Composition of power steering fluid

Power steering fluid typically consists of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives may include viscosity modifiers, anti-wear agents, anti-oxidants, and corrosion inhibitors. The specific composition is designed to maintain proper viscosity across a range of temperatures and provide protection for the power steering system components.- Composition of power steering fluid: Power steering fluid typically consists of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives can include viscosity modifiers, anti-wear agents, anti-oxidants, and corrosion inhibitors. The specific composition is designed to maintain proper viscosity across a range of temperatures and provide lubrication and protection for the power steering system components.

- Viscosity characteristics: The viscosity of power steering fluid is a crucial property that affects its performance. It must maintain appropriate flow characteristics across a wide temperature range, from cold start-up to high operating temperatures. The fluid's viscosity index is carefully controlled to ensure smooth operation of the power steering system under various conditions.

- Thermal stability and oxidation resistance: Power steering fluid must exhibit excellent thermal stability and oxidation resistance to withstand the high temperatures and pressures encountered in power steering systems. These properties help prevent fluid breakdown, sludge formation, and maintain the fluid's performance over extended periods of use.

- Compatibility with system materials: The chemical properties of power steering fluid must ensure compatibility with various materials used in power steering systems, including metals, rubber seals, and hoses. The fluid should not cause corrosion, degradation, or swelling of these components, maintaining the integrity of the entire system.

- Environmental and safety considerations: Modern power steering fluids are formulated with consideration for environmental impact and safety. This includes biodegradability, low toxicity, and reduced volatility. Some formulations may also incorporate fire-resistant properties to enhance safety in the event of a leak or accident.

02 Viscosity characteristics

The viscosity of power steering fluid is a crucial property that affects its performance. It must maintain appropriate flow characteristics across a wide temperature range, from cold start-up to high operating temperatures. The fluid's viscosity index is carefully controlled to ensure smooth operation and proper lubrication of the power steering system under various conditions.Expand Specific Solutions03 Thermal stability and oxidation resistance

Power steering fluid must exhibit excellent thermal stability and oxidation resistance to withstand the high temperatures and pressures encountered in modern power steering systems. These properties help prevent fluid breakdown, sludge formation, and maintain the fluid's performance over extended periods of use.Expand Specific Solutions04 Compatibility with system materials

The chemical properties of power steering fluid must ensure compatibility with various materials used in the power steering system, including metals, rubber seals, and plastic components. This compatibility is essential to prevent corrosion, seal degradation, and other material interactions that could compromise system integrity.Expand Specific Solutions05 Anti-wear and extreme pressure properties

Power steering fluids incorporate additives that provide anti-wear and extreme pressure properties. These additives form protective films on metal surfaces, reducing friction and wear in high-pressure contact areas within the power steering system. This helps extend the life of components and maintain system efficiency over time.Expand Specific Solutions

Key Players in Automotive Fluid Industry

The competition landscape for addressing "How Contaminants Alter the Chemical Properties of Power Steering Fluid" is in a mature stage, with a significant market size due to the widespread use of power steering systems in vehicles. The technology is well-established, with major players like PetroChina, Sinopec, and Ecolab USA leading research and development efforts. Automotive giants such as Toyota and Peugeot are also involved, indicating the importance of this issue in the industry. Universities like Southwest Petroleum University and China University of Petroleum contribute to academic research, while specialized companies like Tianjin Pengling Group focus on automotive fluid components.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed advanced contamination detection and mitigation techniques for power steering fluids. Their approach involves using spectroscopic analysis to identify contaminants in real-time, allowing for immediate corrective action. They have also implemented a multi-stage filtration system that can remove particles as small as 1 micron, significantly reducing the risk of fluid degradation[1]. Additionally, PetroChina has formulated a proprietary additive package that enhances the fluid's resistance to oxidation and thermal breakdown, even in the presence of common contaminants like water and metal particles[2]. This technology has shown to extend the service life of power steering fluids by up to 50% in field tests[3].

Strengths: Real-time contamination detection, advanced filtration system, and proprietary additive technology. Weaknesses: May require specialized equipment for implementation, potentially higher initial costs.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to mitigate the effects of contaminants on power steering fluid. Their research focuses on nano-additives that can actively neutralize harmful contaminants. These additives, composed of engineered nanoparticles, can bind to and isolate contaminants, preventing them from altering the fluid's chemical properties[4]. Sinopec has also introduced a smart fluid monitoring system that uses AI algorithms to predict fluid degradation based on operating conditions and contamination levels[5]. This predictive maintenance approach has been shown to reduce unexpected failures by up to 30% in industrial applications[6].

Strengths: Innovative nano-additive technology, AI-driven predictive maintenance. Weaknesses: Potential environmental concerns with nanoparticles, may require frequent fluid analysis.

Innovations in Fluid Property Analysis

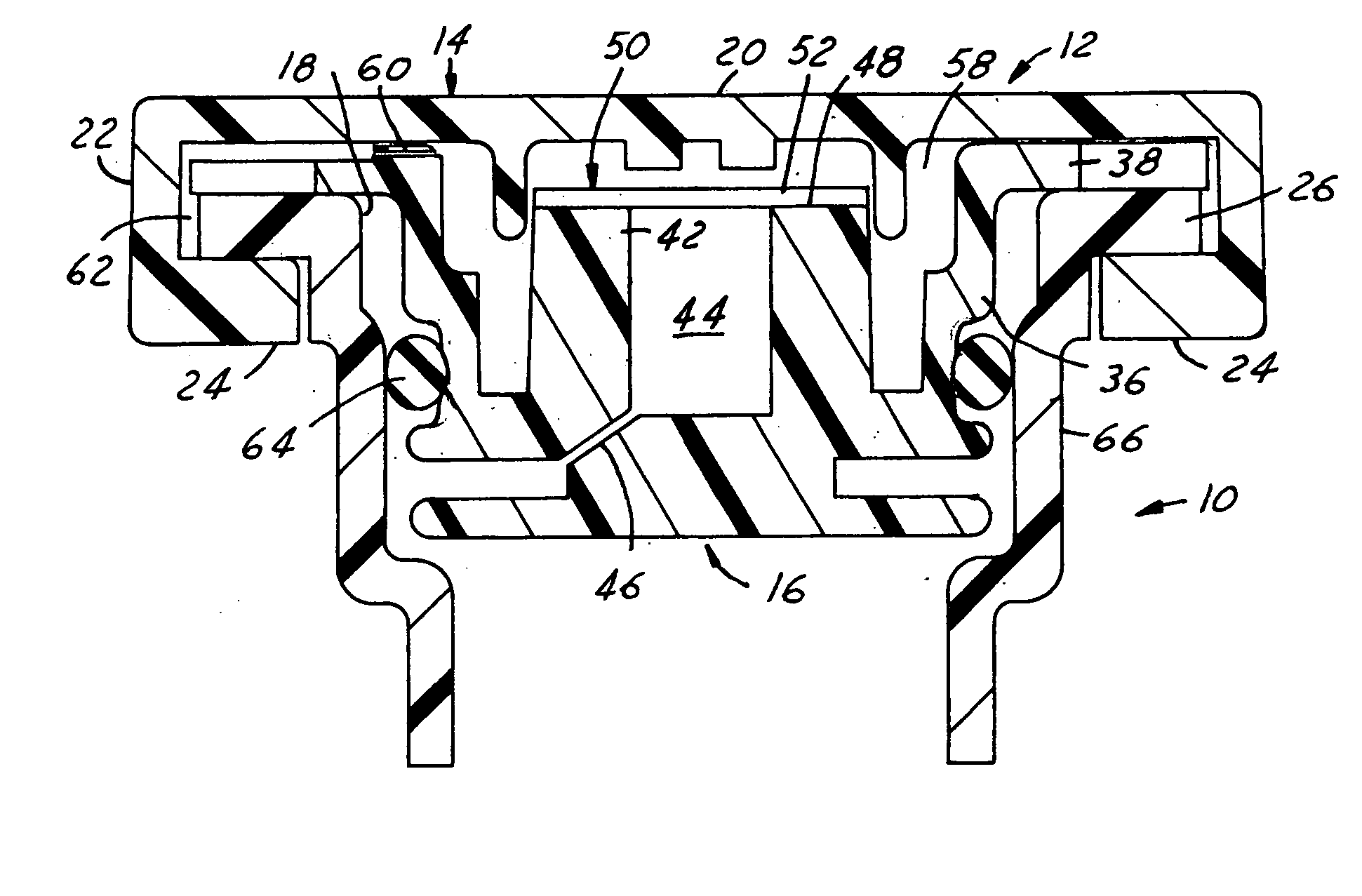

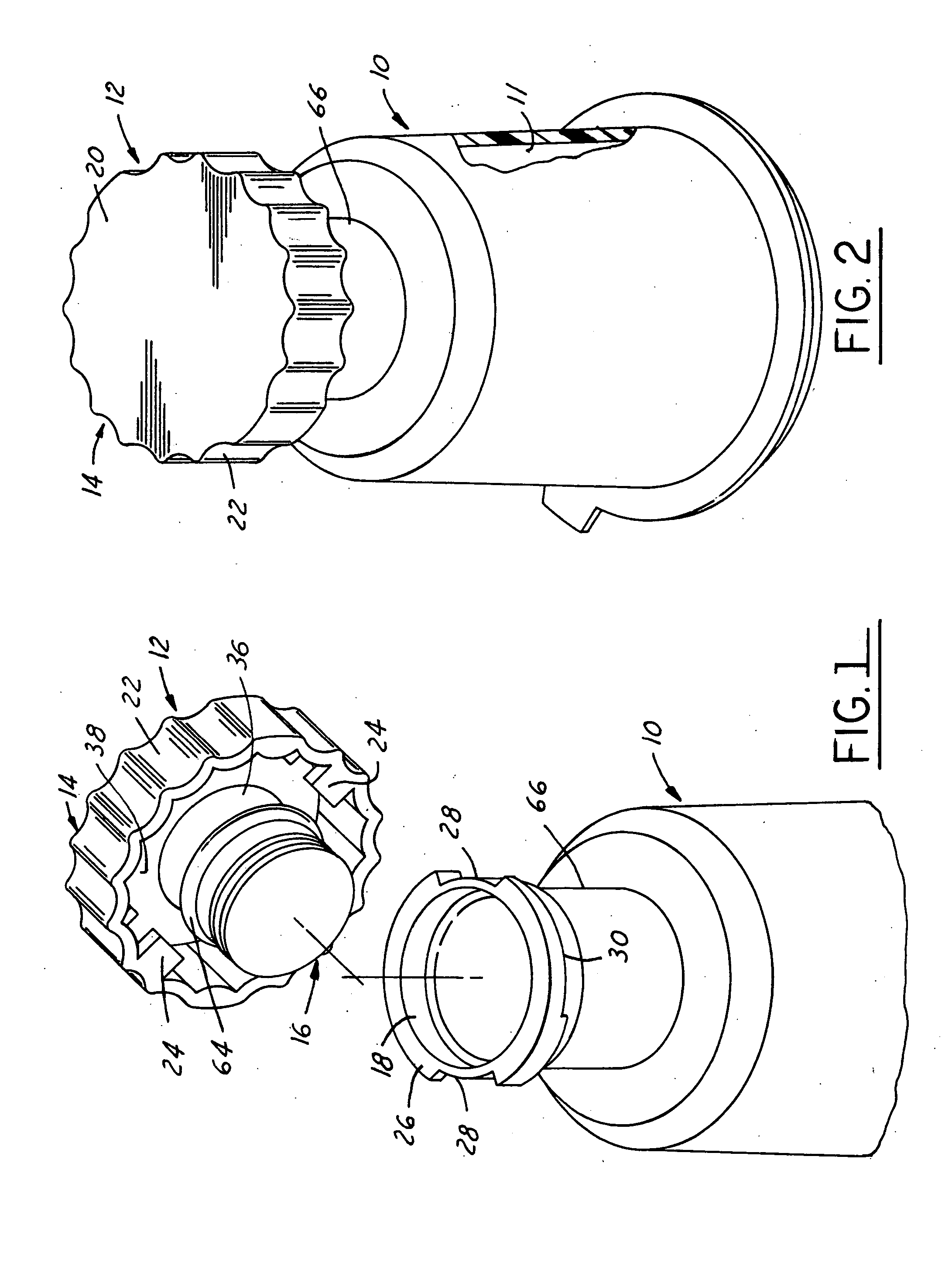

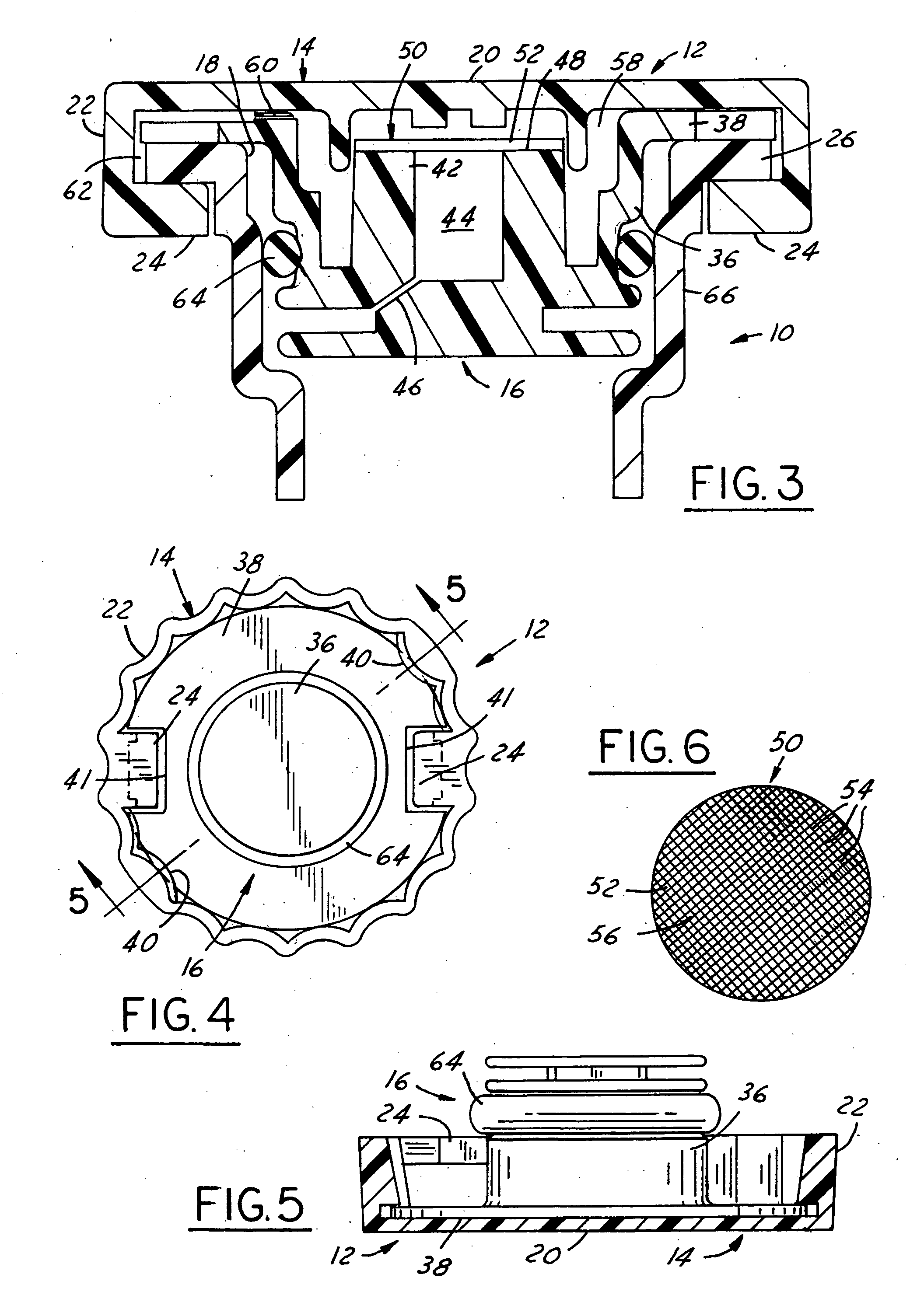

Power steering fluid reservoir

PatentInactiveUS6286545B1

Innovation

- A compact fluid reservoir with a filtration unit located in the return line, utilizing a swirling fluid motion to mix heated and cool fluid temperatures evenly, and a filtration media with 40 micron porosity to prevent cavitation and pulsations, while minimizing noise through controlled back pressure and de-aeration.

Power steering fluid reservoir cap with a mist condensing filter

PatentInactiveUS20050091950A1

Innovation

- A cap assembly with a passageway for air venting that includes a filter with a mesh screen of crossing fibers, allowing air to pass while preventing mist from power steering fluid, which condenses and returns to the reservoir, comprising an outer and inner cap with a well, chamber, and vents to manage air and mist effectively.

Environmental Impact of Contaminated Fluids

The contamination of power steering fluid and its subsequent release into the environment can have significant ecological consequences. When power steering fluid becomes contaminated and leaks or is improperly disposed of, it can infiltrate soil and water systems, leading to various environmental impacts.

Contaminated power steering fluid often contains a mixture of harmful substances, including heavy metals, petroleum hydrocarbons, and synthetic additives. These contaminants can persist in the environment for extended periods, causing long-term damage to ecosystems. When introduced into soil, they can alter its chemical composition, affecting plant growth and soil microorganisms essential for maintaining healthy ecosystems.

Water bodies are particularly vulnerable to contamination from power steering fluid. When the fluid enters aquatic environments, it can form a film on the water surface, reducing oxygen exchange and impacting aquatic life. The contaminants can also dissolve in water, leading to the bioaccumulation of toxic substances in aquatic organisms. This can result in adverse effects on fish, amphibians, and other aquatic species, potentially disrupting entire food chains.

Groundwater contamination is another significant concern. As contaminated power steering fluid seeps into the ground, it can reach underground water sources, potentially affecting drinking water supplies for both humans and wildlife. The removal of these contaminants from groundwater is often a complex and costly process, highlighting the importance of preventing contamination in the first place.

The environmental impact extends beyond immediate ecosystems. Contaminated fluids can contribute to air pollution through the release of volatile organic compounds (VOCs) as they evaporate. These VOCs can participate in the formation of ground-level ozone, a key component of smog, which can have detrimental effects on both human health and vegetation.

Furthermore, the improper disposal of contaminated power steering fluid can lead to the creation of hazardous waste sites. These sites require extensive remediation efforts and can pose long-term risks to surrounding communities and ecosystems. The cleanup process often involves complex treatment methods and can be both time-consuming and expensive.

To mitigate these environmental impacts, it is crucial to implement proper handling, storage, and disposal practices for power steering fluid. This includes regular maintenance of vehicles to prevent leaks, the use of appropriate containment systems during fluid changes, and the proper disposal of contaminated fluids through authorized recycling or treatment facilities. Additionally, the development of more environmentally friendly power steering fluid formulations could help reduce the potential for environmental harm in cases of contamination or leakage.

Contaminated power steering fluid often contains a mixture of harmful substances, including heavy metals, petroleum hydrocarbons, and synthetic additives. These contaminants can persist in the environment for extended periods, causing long-term damage to ecosystems. When introduced into soil, they can alter its chemical composition, affecting plant growth and soil microorganisms essential for maintaining healthy ecosystems.

Water bodies are particularly vulnerable to contamination from power steering fluid. When the fluid enters aquatic environments, it can form a film on the water surface, reducing oxygen exchange and impacting aquatic life. The contaminants can also dissolve in water, leading to the bioaccumulation of toxic substances in aquatic organisms. This can result in adverse effects on fish, amphibians, and other aquatic species, potentially disrupting entire food chains.

Groundwater contamination is another significant concern. As contaminated power steering fluid seeps into the ground, it can reach underground water sources, potentially affecting drinking water supplies for both humans and wildlife. The removal of these contaminants from groundwater is often a complex and costly process, highlighting the importance of preventing contamination in the first place.

The environmental impact extends beyond immediate ecosystems. Contaminated fluids can contribute to air pollution through the release of volatile organic compounds (VOCs) as they evaporate. These VOCs can participate in the formation of ground-level ozone, a key component of smog, which can have detrimental effects on both human health and vegetation.

Furthermore, the improper disposal of contaminated power steering fluid can lead to the creation of hazardous waste sites. These sites require extensive remediation efforts and can pose long-term risks to surrounding communities and ecosystems. The cleanup process often involves complex treatment methods and can be both time-consuming and expensive.

To mitigate these environmental impacts, it is crucial to implement proper handling, storage, and disposal practices for power steering fluid. This includes regular maintenance of vehicles to prevent leaks, the use of appropriate containment systems during fluid changes, and the proper disposal of contaminated fluids through authorized recycling or treatment facilities. Additionally, the development of more environmentally friendly power steering fluid formulations could help reduce the potential for environmental harm in cases of contamination or leakage.

Regulatory Standards for Automotive Fluids

Regulatory standards for automotive fluids play a crucial role in ensuring the safety, performance, and environmental impact of vehicles. In the context of power steering fluid, these standards are designed to maintain the integrity of the fluid's chemical properties and prevent contamination that could compromise the steering system's functionality.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum requirements for fluid composition, performance characteristics, and compatibility with various materials used in power steering systems. They also outline testing procedures to evaluate the fluid's resistance to contamination and degradation over time.

In addition to SAE standards, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's European Committee for Standardization (CEN) have implemented regulations governing the use and quality of automotive fluids. These regulations often reference industry standards and may impose additional requirements for fluid labeling, packaging, and disposal.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA), have also established guidelines for the handling and disposal of automotive fluids, including power steering fluid. These regulations aim to prevent environmental contamination and promote proper recycling practices.

Manufacturers of power steering fluids must adhere to these regulatory standards throughout the production process. This includes rigorous quality control measures to ensure that the fluid meets or exceeds the required specifications. Regular testing is conducted to verify the fluid's resistance to contamination, its ability to maintain viscosity under various temperature conditions, and its compatibility with seals and other components in the power steering system.

Regulatory standards also address the issue of fluid contamination by setting limits on the presence of foreign particles, water content, and other potential contaminants. These limits are crucial in maintaining the fluid's chemical properties and preventing the degradation of the power steering system's performance.

As vehicle technologies evolve, regulatory standards for automotive fluids continue to adapt. For instance, the increasing adoption of electric power steering systems has led to the development of new fluid formulations and corresponding standards. These standards take into account the unique requirements of electric systems, such as enhanced electrical insulation properties and compatibility with different materials used in modern steering components.

The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, including SAE J1703 and SAE J1704. These standards define the minimum requirements for fluid composition, performance characteristics, and compatibility with various materials used in power steering systems. They also outline testing procedures to evaluate the fluid's resistance to contamination and degradation over time.

In addition to SAE standards, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's European Committee for Standardization (CEN) have implemented regulations governing the use and quality of automotive fluids. These regulations often reference industry standards and may impose additional requirements for fluid labeling, packaging, and disposal.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA), have also established guidelines for the handling and disposal of automotive fluids, including power steering fluid. These regulations aim to prevent environmental contamination and promote proper recycling practices.

Manufacturers of power steering fluids must adhere to these regulatory standards throughout the production process. This includes rigorous quality control measures to ensure that the fluid meets or exceeds the required specifications. Regular testing is conducted to verify the fluid's resistance to contamination, its ability to maintain viscosity under various temperature conditions, and its compatibility with seals and other components in the power steering system.

Regulatory standards also address the issue of fluid contamination by setting limits on the presence of foreign particles, water content, and other potential contaminants. These limits are crucial in maintaining the fluid's chemical properties and preventing the degradation of the power steering system's performance.

As vehicle technologies evolve, regulatory standards for automotive fluids continue to adapt. For instance, the increasing adoption of electric power steering systems has led to the development of new fluid formulations and corresponding standards. These standards take into account the unique requirements of electric systems, such as enhanced electrical insulation properties and compatibility with different materials used in modern steering components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!