Chemical Characterization Methods for New Power Steering Fluid Formulas

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Fluid Evolution and Objectives

Power steering fluid has undergone significant evolution since its introduction in the automotive industry. Initially developed to reduce the effort required to steer vehicles, these fluids have become increasingly sophisticated to meet the demands of modern steering systems. The primary objective of power steering fluid is to transmit hydraulic power, lubricate moving parts, and protect system components from wear and corrosion.

Early power steering fluids were primarily mineral oil-based, offering basic hydraulic properties and minimal protection against wear. As automotive technology advanced, the requirements for steering fluids became more stringent. This led to the development of synthetic-based fluids in the 1970s and 1980s, which offered improved thermal stability, oxidation resistance, and compatibility with various seal materials.

The advent of electronic power steering systems in the late 1990s and early 2000s brought about a new set of challenges for steering fluid formulations. These systems demanded fluids with enhanced electrical properties, lower viscosity, and improved low-temperature performance. Consequently, the focus shifted towards developing fluids that could maintain consistent viscosity across a wide temperature range and provide better protection against electrical arcing.

In recent years, the automotive industry's push towards sustainability and energy efficiency has further influenced steering fluid evolution. There is a growing emphasis on developing bio-based and environmentally friendly formulations that maintain or exceed the performance of traditional synthetic fluids. These new formulations aim to reduce the environmental impact of power steering systems while meeting increasingly stringent regulatory requirements.

The current objectives for power steering fluid development are multifaceted. Manufacturers are striving to create formulas that offer extended service life, reducing the frequency of fluid changes and minimizing waste. There is also a focus on improving the fluid's ability to dissipate heat, which is crucial for maintaining system efficiency and preventing premature component failure.

Another key objective is to develop universal fluids that are compatible with a wide range of power steering systems, simplifying inventory management for both manufacturers and service centers. This includes ensuring compatibility with new materials used in modern steering components, such as advanced polymers and composites.

As vehicle electrification gains momentum, there is an emerging need for fluids that can operate effectively in hybrid and electric power steering systems. These fluids must be able to withstand the unique challenges posed by electrified components, such as increased electromagnetic interference and higher operating temperatures.

Early power steering fluids were primarily mineral oil-based, offering basic hydraulic properties and minimal protection against wear. As automotive technology advanced, the requirements for steering fluids became more stringent. This led to the development of synthetic-based fluids in the 1970s and 1980s, which offered improved thermal stability, oxidation resistance, and compatibility with various seal materials.

The advent of electronic power steering systems in the late 1990s and early 2000s brought about a new set of challenges for steering fluid formulations. These systems demanded fluids with enhanced electrical properties, lower viscosity, and improved low-temperature performance. Consequently, the focus shifted towards developing fluids that could maintain consistent viscosity across a wide temperature range and provide better protection against electrical arcing.

In recent years, the automotive industry's push towards sustainability and energy efficiency has further influenced steering fluid evolution. There is a growing emphasis on developing bio-based and environmentally friendly formulations that maintain or exceed the performance of traditional synthetic fluids. These new formulations aim to reduce the environmental impact of power steering systems while meeting increasingly stringent regulatory requirements.

The current objectives for power steering fluid development are multifaceted. Manufacturers are striving to create formulas that offer extended service life, reducing the frequency of fluid changes and minimizing waste. There is also a focus on improving the fluid's ability to dissipate heat, which is crucial for maintaining system efficiency and preventing premature component failure.

Another key objective is to develop universal fluids that are compatible with a wide range of power steering systems, simplifying inventory management for both manufacturers and service centers. This includes ensuring compatibility with new materials used in modern steering components, such as advanced polymers and composites.

As vehicle electrification gains momentum, there is an emerging need for fluids that can operate effectively in hybrid and electric power steering systems. These fluids must be able to withstand the unique challenges posed by electrified components, such as increased electromagnetic interference and higher operating temperatures.

Market Demand Analysis

The power steering fluid market has been experiencing steady growth due to the increasing global automotive production and the rising demand for comfortable driving experiences. As vehicle manufacturers continue to innovate and improve their power steering systems, the need for advanced power steering fluids has become more pronounced. This demand is further driven by the growing preference for electric power steering systems, which require specialized fluids to ensure optimal performance and longevity.

The market for power steering fluids is closely tied to the automotive industry's overall health and trends. With the global automotive market projected to grow at a CAGR of 4.5% from 2021 to 2026, the demand for power steering fluids is expected to follow a similar trajectory. This growth is particularly strong in emerging markets such as China, India, and Southeast Asian countries, where rapid urbanization and increasing disposable incomes are fueling automobile sales.

One of the key drivers for new power steering fluid formulas is the push for improved fuel efficiency and reduced environmental impact. As automotive manufacturers strive to meet stringent emissions regulations, there is a growing demand for power steering fluids that can contribute to overall vehicle efficiency. This has led to the development of low-viscosity formulations that reduce power consumption while maintaining optimal steering performance.

Another significant market trend is the increasing adoption of electric power steering systems, which are gradually replacing traditional hydraulic systems in many vehicle models. These electric systems require specialized fluids that can withstand higher temperatures and provide enhanced protection against oxidation and wear. As a result, there is a growing demand for power steering fluids specifically designed for electric and hybrid vehicle applications.

The aftermarket segment for power steering fluids also presents a substantial opportunity. With the average age of vehicles on the road increasing in many countries, there is a rising need for maintenance and replacement of power steering fluids. This trend is particularly evident in mature markets such as North America and Europe, where consumers are keeping their vehicles for longer periods.

In terms of product innovation, there is a clear market demand for power steering fluids that offer extended service life, improved thermal stability, and enhanced protection against wear and corrosion. Manufacturers are investing in research and development to create formulations that can meet these requirements while also addressing environmental concerns. This includes the development of bio-based and synthetic fluids that offer superior performance characteristics compared to traditional mineral-based products.

The market is also seeing increased demand for power steering fluids that are compatible with a wide range of materials used in modern steering systems, including various elastomers and metals. This versatility is crucial for manufacturers looking to develop universal fluids that can be used across different vehicle models and brands, simplifying inventory management for both OEMs and aftermarket suppliers.

The market for power steering fluids is closely tied to the automotive industry's overall health and trends. With the global automotive market projected to grow at a CAGR of 4.5% from 2021 to 2026, the demand for power steering fluids is expected to follow a similar trajectory. This growth is particularly strong in emerging markets such as China, India, and Southeast Asian countries, where rapid urbanization and increasing disposable incomes are fueling automobile sales.

One of the key drivers for new power steering fluid formulas is the push for improved fuel efficiency and reduced environmental impact. As automotive manufacturers strive to meet stringent emissions regulations, there is a growing demand for power steering fluids that can contribute to overall vehicle efficiency. This has led to the development of low-viscosity formulations that reduce power consumption while maintaining optimal steering performance.

Another significant market trend is the increasing adoption of electric power steering systems, which are gradually replacing traditional hydraulic systems in many vehicle models. These electric systems require specialized fluids that can withstand higher temperatures and provide enhanced protection against oxidation and wear. As a result, there is a growing demand for power steering fluids specifically designed for electric and hybrid vehicle applications.

The aftermarket segment for power steering fluids also presents a substantial opportunity. With the average age of vehicles on the road increasing in many countries, there is a rising need for maintenance and replacement of power steering fluids. This trend is particularly evident in mature markets such as North America and Europe, where consumers are keeping their vehicles for longer periods.

In terms of product innovation, there is a clear market demand for power steering fluids that offer extended service life, improved thermal stability, and enhanced protection against wear and corrosion. Manufacturers are investing in research and development to create formulations that can meet these requirements while also addressing environmental concerns. This includes the development of bio-based and synthetic fluids that offer superior performance characteristics compared to traditional mineral-based products.

The market is also seeing increased demand for power steering fluids that are compatible with a wide range of materials used in modern steering systems, including various elastomers and metals. This versatility is crucial for manufacturers looking to develop universal fluids that can be used across different vehicle models and brands, simplifying inventory management for both OEMs and aftermarket suppliers.

Current Challenges in Fluid Characterization

The chemical characterization of power steering fluids presents several significant challenges in the current landscape. One of the primary difficulties lies in the complexity of fluid compositions, which often contain a diverse array of additives and base oils. These intricate formulations make it challenging to develop comprehensive analytical methods that can accurately identify and quantify all components simultaneously.

Another major hurdle is the dynamic nature of power steering fluids during operation. The high pressures, temperatures, and shear forces experienced in power steering systems can lead to chemical changes in the fluid over time. This makes it difficult to establish standardized testing protocols that accurately reflect the fluid's performance and degradation under real-world conditions.

The presence of contaminants and wear particles in used power steering fluids further complicates characterization efforts. These impurities can interfere with analytical techniques and mask the detection of critical fluid components. Developing methods to effectively separate and analyze these contaminants without compromising the integrity of the fluid sample remains a significant challenge.

Moreover, the industry faces a lack of universally accepted standards for power steering fluid characterization. Different manufacturers often employ proprietary formulations and testing methods, making it difficult to compare results across different fluid types and brands. This absence of standardization hampers efforts to establish benchmarks for fluid performance and quality control.

The rapid evolution of power steering technologies, including the shift towards electric power steering systems, adds another layer of complexity to fluid characterization. New fluid formulations must be developed to meet the changing demands of these systems, requiring the continuous adaptation and refinement of analytical methods.

Additionally, there is a growing need for more environmentally friendly and sustainable power steering fluids. This trend necessitates the development of new characterization techniques capable of assessing biodegradability, toxicity, and long-term environmental impact. Current analytical methods may not be sufficiently equipped to evaluate these emerging parameters comprehensively.

Lastly, the time and cost associated with comprehensive fluid characterization pose significant challenges, particularly for smaller manufacturers and research institutions. High-end analytical equipment and specialized expertise are often required, limiting the accessibility of advanced characterization techniques across the industry.

Another major hurdle is the dynamic nature of power steering fluids during operation. The high pressures, temperatures, and shear forces experienced in power steering systems can lead to chemical changes in the fluid over time. This makes it difficult to establish standardized testing protocols that accurately reflect the fluid's performance and degradation under real-world conditions.

The presence of contaminants and wear particles in used power steering fluids further complicates characterization efforts. These impurities can interfere with analytical techniques and mask the detection of critical fluid components. Developing methods to effectively separate and analyze these contaminants without compromising the integrity of the fluid sample remains a significant challenge.

Moreover, the industry faces a lack of universally accepted standards for power steering fluid characterization. Different manufacturers often employ proprietary formulations and testing methods, making it difficult to compare results across different fluid types and brands. This absence of standardization hampers efforts to establish benchmarks for fluid performance and quality control.

The rapid evolution of power steering technologies, including the shift towards electric power steering systems, adds another layer of complexity to fluid characterization. New fluid formulations must be developed to meet the changing demands of these systems, requiring the continuous adaptation and refinement of analytical methods.

Additionally, there is a growing need for more environmentally friendly and sustainable power steering fluids. This trend necessitates the development of new characterization techniques capable of assessing biodegradability, toxicity, and long-term environmental impact. Current analytical methods may not be sufficiently equipped to evaluate these emerging parameters comprehensively.

Lastly, the time and cost associated with comprehensive fluid characterization pose significant challenges, particularly for smaller manufacturers and research institutions. High-end analytical equipment and specialized expertise are often required, limiting the accessibility of advanced characterization techniques across the industry.

State-of-the-Art Analytical Techniques

01 Composition of power steering fluid

Power steering fluid typically consists of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives may include viscosity modifiers, anti-wear agents, anti-oxidants, and corrosion inhibitors. The specific composition is designed to maintain proper viscosity, reduce wear on steering components, and protect against oxidation and corrosion.- Composition of power steering fluid: Power steering fluid typically consists of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives can include viscosity modifiers, anti-wear agents, anti-oxidants, and corrosion inhibitors. The specific composition is designed to maintain proper viscosity, reduce wear on steering components, and protect against oxidation and corrosion.

- Synthetic power steering fluids: Synthetic power steering fluids are formulated using synthetic base oils, which offer improved performance characteristics compared to traditional mineral oil-based fluids. These synthetic fluids often provide better thermal stability, oxidation resistance, and low-temperature performance. They may also include specialized additives to enhance their properties and extend the life of steering system components.

- Biodegradable power steering fluids: Environmentally friendly power steering fluids are being developed using biodegradable base oils and additives. These fluids aim to reduce environmental impact while maintaining the necessary performance characteristics. They may incorporate vegetable-based oils or other renewable resources as base fluids, combined with carefully selected additives that meet biodegradability standards.

- Additives for power steering fluids: Various additives are used in power steering fluids to enhance their performance and protect steering system components. These can include anti-foam agents to prevent fluid aeration, extreme pressure additives to reduce wear under high loads, and seal conditioners to maintain the integrity of seals and gaskets. The specific combination and concentration of additives are tailored to meet the requirements of different vehicle manufacturers and operating conditions.

- Testing and analysis of power steering fluids: Chemical characterization of power steering fluids involves various testing methods to assess their properties and performance. These may include viscosity measurements at different temperatures, oxidation stability tests, wear testing, and analysis of additive content. Advanced analytical techniques such as spectroscopy and chromatography can be used to identify and quantify specific chemical components in the fluid, ensuring quality control and compliance with specifications.

02 Synthetic power steering fluids

Synthetic power steering fluids are formulated using synthetic base oils, which offer improved performance characteristics compared to conventional mineral oil-based fluids. These synthetic fluids often provide better thermal stability, oxidation resistance, and low-temperature performance. They may also include specialized additives to enhance their properties and extend the life of steering system components.Expand Specific Solutions03 Biodegradable power steering fluids

Environmentally friendly power steering fluids are being developed using biodegradable base oils and additives. These fluids aim to reduce environmental impact while maintaining the necessary performance characteristics. They may incorporate vegetable-based oils or other renewable resources as base fluids, combined with carefully selected additives that meet biodegradability standards.Expand Specific Solutions04 Additives for power steering fluids

Various additives are used in power steering fluids to enhance their performance and protect steering system components. These may include anti-wear agents to reduce friction and wear, viscosity index improvers to maintain fluid consistency across temperature ranges, anti-foam agents to prevent foaming, and seal conditioners to maintain seal integrity. The specific combination and concentration of additives are tailored to meet the requirements of different vehicle manufacturers and operating conditions.Expand Specific Solutions05 Testing and analysis methods for power steering fluids

Chemical characterization of power steering fluids involves various testing and analysis methods to evaluate their properties and performance. These may include viscosity measurements at different temperatures, oxidation stability tests, wear testing, corrosion resistance evaluations, and chemical analysis of additive packages. Advanced analytical techniques such as spectroscopy and chromatography may be used to identify and quantify specific components in the fluid formulation.Expand Specific Solutions

Key Industry Players

The chemical characterization of new power steering fluid formulas is a rapidly evolving field, driven by the automotive industry's demand for improved performance and sustainability. The market is in a growth phase, with increasing focus on eco-friendly and high-performance solutions. Key players like PetroChina, Sinopec, and Saudi Aramco are leveraging their extensive R&D capabilities to develop advanced formulations. Universities such as Southwest Petroleum University and China University of Petroleum are contributing valuable research. Specialized companies like Dow Global Technologies and Corbion Biotech are bringing innovative approaches to fluid characterization. The technology is maturing, with major oil companies and research institutions collaborating to refine testing methods and improve fluid properties for next-generation automotive applications.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has innovated in chemical characterization for power steering fluids by implementing a multi-faceted approach. They use Fourier-transform infrared spectroscopy (FTIR) for rapid identification of functional groups and contaminants in fluid samples[5]. Gas chromatography-mass spectrometry (GC-MS) is employed for detailed analysis of volatile components and additives[6]. Dow also utilizes thermogravimetric analysis (TGA) to study the thermal stability and decomposition characteristics of new fluid formulas[7]. Their methods include dynamic mechanical analysis (DMA) to assess viscoelastic properties under varying temperatures and frequencies, crucial for understanding fluid behavior in power steering systems[8].

Strengths: Wide range of analytical techniques, strong focus on thermal and mechanical properties. Weaknesses: May require extensive sample preparation and interpretation expertise for complex fluid formulations.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed a suite of chemical characterization methods tailored for new power steering fluid formulas. They employ two-dimensional gas chromatography (GC×GC) coupled with time-of-flight mass spectrometry for ultra-high resolution analysis of complex fluid mixtures[17]. Their approach includes advanced rheological characterization using oscillatory and extensional rheometry to assess fluid behavior under extreme shear conditions[18]. IFP also utilizes atomic force microscopy (AFM) to study surface interactions between fluid components and steering system materials at the nanoscale[19]. Additionally, they have developed chemometric methods for multivariate analysis of spectroscopic data, enabling rapid quality control and formula optimization[20].

Strengths: Cutting-edge analytical techniques, strong focus on molecular-level characterization and fluid-surface interactions. Weaknesses: High complexity of data interpretation, potentially requiring specialized expertise for routine analysis.

Innovative Characterization Approaches

Power transmission fluids

PatentInactiveEP1577370A3

Innovation

- Formulating power transmission fluids with a base oil and an additive composition containing an ester of phosphonic acid, a succinimide dispersant, and optionally a metal-based detergent devoid of calcium cations, which provides improved extreme pressure performance for metal-to-metal contact situations.

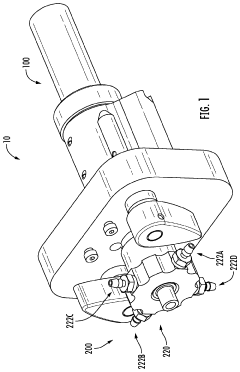

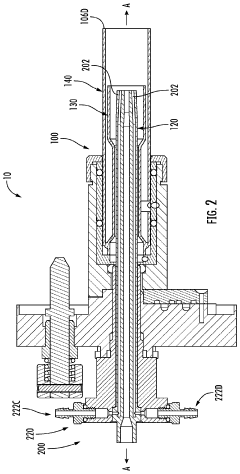

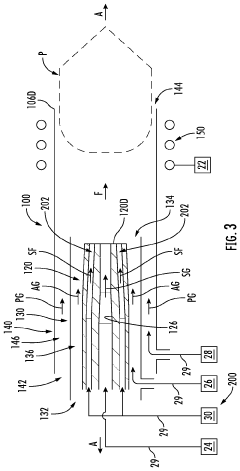

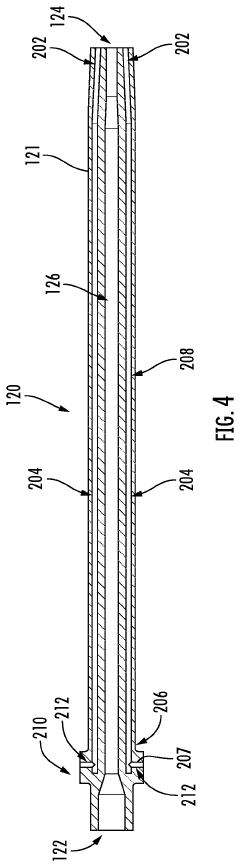

Steered inductively coupled plasma

PatentInactiveUS20240074024A1

Innovation

- The use of a plasma steering system with angled nozzles and a steering fluid to redirect the ionized sample, eliminating the need for mechanical motion controls by using a fluid to align the plasma with the interface or orifice, thereby reducing the number of parts and costs.

Environmental Impact Assessment

The environmental impact assessment of chemical characterization methods for new power steering fluid formulas is a critical aspect of their development and implementation. These methods, while essential for ensuring the quality and performance of power steering fluids, can have significant environmental implications that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with these characterization methods is the potential release of hazardous chemicals into the environment. Many of the analytical techniques used in power steering fluid analysis involve the use of solvents, reagents, and other chemicals that may be toxic or harmful to ecosystems if not properly managed. For instance, gas chromatography and mass spectrometry, commonly used for fluid composition analysis, often require organic solvents that can contribute to air pollution and pose risks to aquatic environments if improperly disposed of.

The energy consumption of analytical instruments is another important factor to consider in the environmental impact assessment. High-performance liquid chromatography (HPLC) systems, spectrophotometers, and other advanced analytical tools used in power steering fluid characterization can be energy-intensive, contributing to increased carbon emissions if powered by non-renewable energy sources. This underscores the importance of implementing energy-efficient practices and considering the use of renewable energy in laboratory settings.

Waste generation is a significant environmental concern in chemical characterization processes. The analysis of power steering fluids often produces both liquid and solid waste, including used sample vials, contaminated filters, and spent reagents. Proper waste management protocols, including segregation, treatment, and disposal, are crucial to minimize the environmental footprint of these methods. Additionally, the development of green chemistry techniques that reduce waste generation and promote the use of environmentally benign reagents should be prioritized in the evolution of characterization methods.

Water consumption and potential water pollution are also important considerations in the environmental impact assessment. Many analytical techniques require high-purity water for sample preparation and instrument operation. The production and disposal of this water can strain local water resources and potentially introduce contaminants into water systems if not properly managed. Implementing water recycling systems and optimizing analytical methods to reduce water usage can help mitigate these impacts.

Lastly, the lifecycle assessment of the chemicals and materials used in power steering fluid characterization should be considered. This includes evaluating the environmental impacts associated with the production, transportation, use, and disposal of reagents, standards, and consumables used in the analytical processes. Choosing suppliers with strong environmental credentials and opting for more sustainable alternatives where possible can help reduce the overall environmental footprint of these characterization methods.

In conclusion, while chemical characterization methods are indispensable for developing and maintaining high-quality power steering fluids, their environmental impacts must be carefully managed. By implementing best practices in waste management, energy efficiency, and green chemistry, and by continuously seeking more sustainable analytical techniques, the environmental footprint of these methods can be significantly reduced, aligning with broader sustainability goals in the automotive industry.

One of the primary environmental concerns associated with these characterization methods is the potential release of hazardous chemicals into the environment. Many of the analytical techniques used in power steering fluid analysis involve the use of solvents, reagents, and other chemicals that may be toxic or harmful to ecosystems if not properly managed. For instance, gas chromatography and mass spectrometry, commonly used for fluid composition analysis, often require organic solvents that can contribute to air pollution and pose risks to aquatic environments if improperly disposed of.

The energy consumption of analytical instruments is another important factor to consider in the environmental impact assessment. High-performance liquid chromatography (HPLC) systems, spectrophotometers, and other advanced analytical tools used in power steering fluid characterization can be energy-intensive, contributing to increased carbon emissions if powered by non-renewable energy sources. This underscores the importance of implementing energy-efficient practices and considering the use of renewable energy in laboratory settings.

Waste generation is a significant environmental concern in chemical characterization processes. The analysis of power steering fluids often produces both liquid and solid waste, including used sample vials, contaminated filters, and spent reagents. Proper waste management protocols, including segregation, treatment, and disposal, are crucial to minimize the environmental footprint of these methods. Additionally, the development of green chemistry techniques that reduce waste generation and promote the use of environmentally benign reagents should be prioritized in the evolution of characterization methods.

Water consumption and potential water pollution are also important considerations in the environmental impact assessment. Many analytical techniques require high-purity water for sample preparation and instrument operation. The production and disposal of this water can strain local water resources and potentially introduce contaminants into water systems if not properly managed. Implementing water recycling systems and optimizing analytical methods to reduce water usage can help mitigate these impacts.

Lastly, the lifecycle assessment of the chemicals and materials used in power steering fluid characterization should be considered. This includes evaluating the environmental impacts associated with the production, transportation, use, and disposal of reagents, standards, and consumables used in the analytical processes. Choosing suppliers with strong environmental credentials and opting for more sustainable alternatives where possible can help reduce the overall environmental footprint of these characterization methods.

In conclusion, while chemical characterization methods are indispensable for developing and maintaining high-quality power steering fluids, their environmental impacts must be carefully managed. By implementing best practices in waste management, energy efficiency, and green chemistry, and by continuously seeking more sustainable analytical techniques, the environmental footprint of these methods can be significantly reduced, aligning with broader sustainability goals in the automotive industry.

Regulatory Compliance Framework

The regulatory compliance framework for chemical characterization methods of new power steering fluid formulas is a critical aspect that manufacturers must navigate to ensure their products meet safety and environmental standards. This framework is primarily governed by international and national regulatory bodies, including the Environmental Protection Agency (EPA), the European Chemicals Agency (ECHA), and various automotive industry standards organizations.

At the core of this framework is the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. REACH requires manufacturers to register chemical substances and provide detailed information on their properties, hazards, and safe use. For power steering fluids, this means comprehensive testing and documentation of all components, including additives and base oils.

In the United States, the Toxic Substances Control Act (TSCA) plays a similar role, mandating the reporting, record-keeping, and testing requirements for chemical substances. Manufacturers must submit premanufacture notices for new chemical substances before they can be commercially distributed.

The automotive industry has its own set of standards that intersect with these regulatory requirements. The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, such as SAE J1703 and SAE J1704, which define performance criteria and testing methods. These standards often become de facto regulatory requirements as they are adopted by automotive manufacturers.

Environmental considerations are increasingly important in the regulatory landscape. The Clean Air Act and Clean Water Act in the US, along with similar legislation in other countries, set limits on emissions and discharges that may result from the production or use of power steering fluids. This necessitates the development of characterization methods that can accurately detect and quantify potential pollutants.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA), also impact the chemical characterization methods. These regulations require detailed safety data sheets (SDS) that include information on the composition, hazards, and safe handling of power steering fluids.

To comply with this complex regulatory framework, manufacturers must employ a range of chemical characterization methods. These typically include gas chromatography-mass spectrometry (GC-MS) for analyzing volatile organic compounds, inductively coupled plasma mass spectrometry (ICP-MS) for metal content analysis, and various spectroscopic techniques for identifying and quantifying specific chemical components.

The regulatory landscape is dynamic, with new regulations and updates to existing ones occurring regularly. Manufacturers must stay informed about changes in global and regional regulations, as well as industry standards, to ensure ongoing compliance. This often requires a proactive approach to chemical characterization, anticipating future regulatory trends and developing methods that can adapt to evolving requirements.

At the core of this framework is the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. REACH requires manufacturers to register chemical substances and provide detailed information on their properties, hazards, and safe use. For power steering fluids, this means comprehensive testing and documentation of all components, including additives and base oils.

In the United States, the Toxic Substances Control Act (TSCA) plays a similar role, mandating the reporting, record-keeping, and testing requirements for chemical substances. Manufacturers must submit premanufacture notices for new chemical substances before they can be commercially distributed.

The automotive industry has its own set of standards that intersect with these regulatory requirements. The Society of Automotive Engineers (SAE) has established specific standards for power steering fluids, such as SAE J1703 and SAE J1704, which define performance criteria and testing methods. These standards often become de facto regulatory requirements as they are adopted by automotive manufacturers.

Environmental considerations are increasingly important in the regulatory landscape. The Clean Air Act and Clean Water Act in the US, along with similar legislation in other countries, set limits on emissions and discharges that may result from the production or use of power steering fluids. This necessitates the development of characterization methods that can accurately detect and quantify potential pollutants.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA), also impact the chemical characterization methods. These regulations require detailed safety data sheets (SDS) that include information on the composition, hazards, and safe handling of power steering fluids.

To comply with this complex regulatory framework, manufacturers must employ a range of chemical characterization methods. These typically include gas chromatography-mass spectrometry (GC-MS) for analyzing volatile organic compounds, inductively coupled plasma mass spectrometry (ICP-MS) for metal content analysis, and various spectroscopic techniques for identifying and quantifying specific chemical components.

The regulatory landscape is dynamic, with new regulations and updates to existing ones occurring regularly. Manufacturers must stay informed about changes in global and regional regulations, as well as industry standards, to ensure ongoing compliance. This often requires a proactive approach to chemical characterization, anticipating future regulatory trends and developing methods that can adapt to evolving requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!