How Temperature Variability Influences Power Steering Fluid Chemistry

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Temperature Effects on Power Steering Fluid

Power steering fluid plays a crucial role in the smooth operation of a vehicle's steering system. However, its performance and chemical properties are significantly influenced by temperature variations. As temperatures fluctuate, the fluid's viscosity changes, affecting its ability to transmit power efficiently and protect system components.

At low temperatures, power steering fluid tends to thicken, increasing its viscosity. This can lead to sluggish steering response and increased wear on the pump and other components. The fluid may struggle to flow through narrow passages, potentially causing cavitation and reduced system efficiency. In extreme cold, the fluid might even gel, rendering the power steering system inoperable.

Conversely, high temperatures can cause the fluid to thin out excessively. This reduction in viscosity can result in inadequate lubrication and protection for system components. The fluid may also break down more rapidly, forming deposits and sludge that can clog filters and valves. Extreme heat can accelerate oxidation, leading to the degradation of additives and the formation of acids that can corrode metal surfaces within the system.

Temperature fluctuations also affect the fluid's ability to resist foaming and aeration. As the fluid heats up and cools down repeatedly, it may become more prone to forming bubbles, which can lead to erratic steering performance and increased wear on system components. The expansion and contraction of the fluid due to temperature changes can also stress seals and gaskets, potentially leading to leaks over time.

The chemical composition of power steering fluid is carefully formulated to maintain stability across a wide temperature range. Additives such as viscosity index improvers help to minimize viscosity changes with temperature, while anti-wear agents and antioxidants provide protection against component wear and fluid degradation. However, these additives can be affected by extreme temperatures, potentially reducing their effectiveness over time.

Understanding the relationship between temperature variability and power steering fluid chemistry is essential for optimizing vehicle performance and maintenance schedules. Engineers must consider the full range of operating temperatures a vehicle may encounter and design fluids that can maintain their properties and protect the system under these diverse conditions. This knowledge also informs the development of more robust power steering systems and the creation of synthetic fluids with improved temperature stability.

At low temperatures, power steering fluid tends to thicken, increasing its viscosity. This can lead to sluggish steering response and increased wear on the pump and other components. The fluid may struggle to flow through narrow passages, potentially causing cavitation and reduced system efficiency. In extreme cold, the fluid might even gel, rendering the power steering system inoperable.

Conversely, high temperatures can cause the fluid to thin out excessively. This reduction in viscosity can result in inadequate lubrication and protection for system components. The fluid may also break down more rapidly, forming deposits and sludge that can clog filters and valves. Extreme heat can accelerate oxidation, leading to the degradation of additives and the formation of acids that can corrode metal surfaces within the system.

Temperature fluctuations also affect the fluid's ability to resist foaming and aeration. As the fluid heats up and cools down repeatedly, it may become more prone to forming bubbles, which can lead to erratic steering performance and increased wear on system components. The expansion and contraction of the fluid due to temperature changes can also stress seals and gaskets, potentially leading to leaks over time.

The chemical composition of power steering fluid is carefully formulated to maintain stability across a wide temperature range. Additives such as viscosity index improvers help to minimize viscosity changes with temperature, while anti-wear agents and antioxidants provide protection against component wear and fluid degradation. However, these additives can be affected by extreme temperatures, potentially reducing their effectiveness over time.

Understanding the relationship between temperature variability and power steering fluid chemistry is essential for optimizing vehicle performance and maintenance schedules. Engineers must consider the full range of operating temperatures a vehicle may encounter and design fluids that can maintain their properties and protect the system under these diverse conditions. This knowledge also informs the development of more robust power steering systems and the creation of synthetic fluids with improved temperature stability.

Market Analysis of Temperature-Resistant Fluids

The market for temperature-resistant fluids, particularly in the power steering sector, has been experiencing significant growth due to the increasing demand for reliable automotive systems across various climatic conditions. As vehicles are exposed to a wide range of temperatures, from extreme cold in winter to scorching heat in summer, the need for fluids that can maintain their chemical stability and performance has become paramount.

The global power steering fluid market is primarily driven by the automotive industry's expansion, with a particular focus on regions with extreme temperature variations. Developing countries with rapidly growing automotive sectors, such as India, China, and Brazil, are emerging as key markets for temperature-resistant power steering fluids. These regions often experience diverse climatic conditions, necessitating fluids that can withstand temperature fluctuations without compromising vehicle performance.

In mature markets like North America and Europe, the demand for temperature-resistant fluids is fueled by the increasing adoption of advanced power steering systems in high-end vehicles and the growing emphasis on vehicle safety and performance. The aftermarket segment also contributes significantly to the market, as vehicle owners seek high-quality replacement fluids to maintain their vehicles' steering systems.

The market for temperature-resistant power steering fluids is characterized by a shift towards synthetic and semi-synthetic formulations. These advanced fluids offer superior thermal stability, oxidation resistance, and overall performance compared to conventional mineral-based fluids. This trend is particularly evident in premium and luxury vehicle segments, where manufacturers prioritize high-performance components.

Environmental regulations and sustainability concerns are also shaping the market landscape. There is a growing demand for eco-friendly, biodegradable power steering fluids that maintain their temperature-resistant properties. This has led to increased research and development efforts in bio-based and renewable fluid technologies.

The commercial vehicle sector represents another significant market segment for temperature-resistant power steering fluids. Heavy-duty trucks and buses operating in diverse climates require fluids that can withstand extreme temperature variations while maintaining optimal performance under high-stress conditions. This sector's growth, particularly in emerging economies, is expected to drive further demand for advanced, temperature-resistant fluids.

As automotive technologies continue to evolve, the integration of electric power steering systems in modern vehicles is influencing the power steering fluid market. While these systems generally require less fluid, they still demand high-performance, temperature-resistant formulations to ensure longevity and reliability, especially in extreme temperature conditions.

The global power steering fluid market is primarily driven by the automotive industry's expansion, with a particular focus on regions with extreme temperature variations. Developing countries with rapidly growing automotive sectors, such as India, China, and Brazil, are emerging as key markets for temperature-resistant power steering fluids. These regions often experience diverse climatic conditions, necessitating fluids that can withstand temperature fluctuations without compromising vehicle performance.

In mature markets like North America and Europe, the demand for temperature-resistant fluids is fueled by the increasing adoption of advanced power steering systems in high-end vehicles and the growing emphasis on vehicle safety and performance. The aftermarket segment also contributes significantly to the market, as vehicle owners seek high-quality replacement fluids to maintain their vehicles' steering systems.

The market for temperature-resistant power steering fluids is characterized by a shift towards synthetic and semi-synthetic formulations. These advanced fluids offer superior thermal stability, oxidation resistance, and overall performance compared to conventional mineral-based fluids. This trend is particularly evident in premium and luxury vehicle segments, where manufacturers prioritize high-performance components.

Environmental regulations and sustainability concerns are also shaping the market landscape. There is a growing demand for eco-friendly, biodegradable power steering fluids that maintain their temperature-resistant properties. This has led to increased research and development efforts in bio-based and renewable fluid technologies.

The commercial vehicle sector represents another significant market segment for temperature-resistant power steering fluids. Heavy-duty trucks and buses operating in diverse climates require fluids that can withstand extreme temperature variations while maintaining optimal performance under high-stress conditions. This sector's growth, particularly in emerging economies, is expected to drive further demand for advanced, temperature-resistant fluids.

As automotive technologies continue to evolve, the integration of electric power steering systems in modern vehicles is influencing the power steering fluid market. While these systems generally require less fluid, they still demand high-performance, temperature-resistant formulations to ensure longevity and reliability, especially in extreme temperature conditions.

Current Challenges in Fluid Stability

Power steering fluid stability presents significant challenges in the automotive industry, particularly due to temperature variability. The fluid's chemistry is highly sensitive to temperature fluctuations, which can lead to degradation and compromised performance. One of the primary issues is oxidation, which accelerates at higher temperatures. As the fluid heats up during operation, it becomes more susceptible to oxidative processes, resulting in the formation of sludge and deposits that can clog system components and reduce efficiency.

Viscosity changes pose another major challenge. Power steering fluids are designed to maintain optimal viscosity across a range of temperatures, but extreme conditions can push them beyond their limits. In cold temperatures, the fluid may become too thick, leading to sluggish steering response and increased wear on the pump. Conversely, high temperatures can cause the fluid to thin excessively, potentially resulting in inadequate lubrication and increased friction within the system.

Thermal breakdown of additives is a critical concern. Modern power steering fluids contain complex additive packages designed to enhance performance and protect system components. However, these additives can break down under prolonged exposure to high temperatures, reducing their effectiveness over time. This degradation can lead to increased wear, corrosion, and overall system deterioration.

Moisture contamination exacerbates stability issues, particularly in environments with significant temperature swings. As temperatures fluctuate, condensation can form within the power steering system, introducing water into the fluid. This moisture can promote corrosion, accelerate fluid breakdown, and interfere with the fluid's lubricating properties.

The challenge of maintaining fluid stability is further complicated by the diverse operating conditions vehicles encounter. From extreme cold in winter to scorching heat in summer, and from stop-and-go city traffic to high-speed highway driving, power steering fluids must perform consistently across a wide range of scenarios. This variability makes it difficult to formulate a single fluid that can maintain optimal stability under all conditions.

Addressing these challenges requires innovative approaches in fluid chemistry. Researchers are exploring advanced synthetic base oils and novel additive technologies to improve thermal stability and oxidation resistance. Additionally, efforts are being made to develop adaptive fluid formulations that can better respond to temperature changes, potentially through the use of smart polymers or temperature-sensitive additives. However, balancing these improvements with cost-effectiveness and compatibility with existing power steering systems remains an ongoing challenge for the industry.

Viscosity changes pose another major challenge. Power steering fluids are designed to maintain optimal viscosity across a range of temperatures, but extreme conditions can push them beyond their limits. In cold temperatures, the fluid may become too thick, leading to sluggish steering response and increased wear on the pump. Conversely, high temperatures can cause the fluid to thin excessively, potentially resulting in inadequate lubrication and increased friction within the system.

Thermal breakdown of additives is a critical concern. Modern power steering fluids contain complex additive packages designed to enhance performance and protect system components. However, these additives can break down under prolonged exposure to high temperatures, reducing their effectiveness over time. This degradation can lead to increased wear, corrosion, and overall system deterioration.

Moisture contamination exacerbates stability issues, particularly in environments with significant temperature swings. As temperatures fluctuate, condensation can form within the power steering system, introducing water into the fluid. This moisture can promote corrosion, accelerate fluid breakdown, and interfere with the fluid's lubricating properties.

The challenge of maintaining fluid stability is further complicated by the diverse operating conditions vehicles encounter. From extreme cold in winter to scorching heat in summer, and from stop-and-go city traffic to high-speed highway driving, power steering fluids must perform consistently across a wide range of scenarios. This variability makes it difficult to formulate a single fluid that can maintain optimal stability under all conditions.

Addressing these challenges requires innovative approaches in fluid chemistry. Researchers are exploring advanced synthetic base oils and novel additive technologies to improve thermal stability and oxidation resistance. Additionally, efforts are being made to develop adaptive fluid formulations that can better respond to temperature changes, potentially through the use of smart polymers or temperature-sensitive additives. However, balancing these improvements with cost-effectiveness and compatibility with existing power steering systems remains an ongoing challenge for the industry.

Existing Temperature Compensation Solutions

01 Composition of power steering fluids

Power steering fluids typically consist of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives may include viscosity modifiers, anti-wear agents, antioxidants, and corrosion inhibitors. The specific composition is designed to provide optimal performance and protection for power steering systems.- Composition of power steering fluids: Power steering fluids typically consist of a base oil, such as mineral oil or synthetic oil, combined with various additives. These additives may include viscosity modifiers, anti-wear agents, antioxidants, and corrosion inhibitors. The specific composition is designed to provide optimal performance and protection for power steering systems.

- Hydraulic systems in power steering: Power steering systems utilize hydraulic principles to assist in steering. The fluid acts as a medium for transmitting force and reducing friction in the system. The design of hydraulic components, such as pumps, valves, and cylinders, is crucial for efficient power steering operation.

- Temperature management in power steering fluids: Power steering fluids must maintain their properties across a wide range of temperatures. This includes low-temperature fluidity for cold starts and high-temperature stability to prevent breakdown during operation. Additives and base oil selection play a crucial role in achieving the desired temperature performance.

- Environmental considerations in fluid formulation: Modern power steering fluid formulations take into account environmental factors. This includes the development of biodegradable fluids, reduction of harmful additives, and improved longevity to reduce fluid changes. These considerations aim to minimize the environmental impact of power steering systems.

- Integration with electric power steering systems: As automotive technology advances, there is a trend towards electric power steering systems. However, some hybrid systems still utilize hydraulic components in conjunction with electric motors. The chemistry of power steering fluids is being adapted to meet the requirements of these evolving systems, focusing on compatibility with electrical components and reduced fluid volumes.

02 Hydraulic properties of power steering fluids

Power steering fluids are formulated to maintain specific hydraulic properties, such as viscosity and compressibility, across a wide range of temperatures and operating conditions. These properties are crucial for ensuring smooth and responsive steering performance, as well as protecting the power steering system components from wear and damage.Expand Specific Solutions03 Compatibility with power steering system materials

The chemistry of power steering fluids is designed to be compatible with various materials used in power steering systems, including metals, rubber seals, and plastic components. This compatibility helps prevent degradation of system components and ensures long-term reliability of the power steering system.Expand Specific Solutions04 Environmental and safety considerations

Modern power steering fluid formulations take into account environmental and safety concerns. This includes the development of biodegradable fluids, reduction of volatile organic compounds, and minimization of toxicity. These considerations aim to reduce the environmental impact of power steering fluids and improve safety for users and technicians.Expand Specific Solutions05 Performance enhancement additives

Specialized additives are incorporated into power steering fluids to enhance performance and extend the life of the power steering system. These may include friction modifiers to improve steering feel, extreme pressure additives to protect against high loads, and foam inhibitors to prevent fluid aeration. The specific blend of additives is tailored to meet the requirements of different vehicle manufacturers and operating conditions.Expand Specific Solutions

Key Players in Automotive Fluid Industry

The power steering fluid chemistry market is in a mature stage, with established players and well-developed technologies. However, ongoing research into temperature variability effects indicates potential for innovation. The global market size is estimated to be over $1 billion, driven by increasing vehicle production and aftermarket demand. Technologically, companies like China Petroleum & Chemical Corp., PetroChina, and Air Products & Chemicals lead in fluid formulations, while automotive giants such as Ford, Mitsubishi Electric, and ZF Friedrichshafen focus on system integration. Universities like Southwest Petroleum University contribute to fundamental research, enhancing the industry's technical capabilities. The interplay between fluid chemistry and temperature variability remains a key area for advancement, with potential to improve power steering performance and longevity.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced temperature-adaptive power steering fluid system that maintains optimal viscosity across a wide range of temperatures. The system utilizes a blend of synthetic base oils and advanced polymer additives that respond dynamically to temperature changes[1]. This innovative fluid chemistry incorporates shear-stable viscosity modifiers that expand at higher temperatures to maintain fluid thickness, while contracting at lower temperatures to ensure smooth flow[2]. Ford's system also includes corrosion inhibitors and anti-wear agents that remain stable across temperature fluctuations, ensuring consistent protection of steering components[3]. The company has implemented real-time fluid monitoring sensors that adjust the fluid's properties based on ambient and operating temperatures, optimizing steering performance and efficiency[4].

Strengths: Adaptive viscosity across temperature ranges, improved steering performance, and extended component life. Weaknesses: Potentially higher cost compared to conventional fluids, and may require specialized maintenance procedures.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has engineered a temperature-compensating power steering fluid system that leverages advanced nanotechnology. Their solution incorporates thermally responsive nanoparticles suspended in a carefully formulated base fluid[1]. These nanoparticles actively modify the fluid's properties in response to temperature changes, ensuring consistent steering feel and performance across diverse climatic conditions[2]. The company's proprietary fluid composition includes self-assembling molecular structures that reorganize at different temperatures to maintain optimal viscosity and lubrication properties[3]. Mitsubishi's system also features an intelligent thermal management subsystem that preemptively adjusts fluid characteristics based on predictive temperature modeling, minimizing the impact of rapid temperature fluctuations on steering performance[4].

Strengths: Highly responsive to temperature changes, advanced nanotechnology integration, and predictive thermal management. Weaknesses: Potential for higher production costs and complexity in fluid maintenance and replacement.

Innovations in Fluid Chemistry

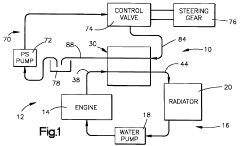

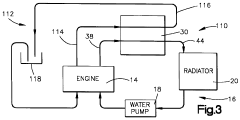

Power steering fluid temperature control

PatentInactiveUS5839398A

Innovation

- A fluid temperature control system utilizing an engine coolant de-gas bottle with a cooler tube immersed in engine coolant, acting as a liquid to liquid heat exchanger, to regulate the temperature of power steering fluid or engine lubricating oil, maintaining them within a stable temperature range of 220-235 degrees F.

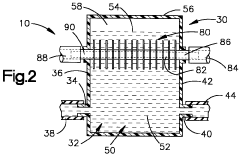

Electro-hydraulic power steering control with fluid temperature and motor speed compensation of power steering load signal

PatentInactiveEP0913317A3

Innovation

- A vehicle power steering system with an electric motor-driven pump that uses a speed control mechanism to derive a command speed signal from an input load signal, incorporating sensors for temperature and motor speed to modify the load signal and compensate for losses, allowing precise switching between low and high motor speeds based on power assist demands.

Environmental Impact of Fluid Degradation

The environmental impact of power steering fluid degradation due to temperature variability is a significant concern in the automotive industry. As power steering fluid chemistry changes with temperature fluctuations, it can lead to increased fluid breakdown and the release of harmful substances into the environment. This degradation process often results in the formation of sludge and varnish, which can contaminate soil and water systems when improperly disposed of or leaked from vehicles.

Temperature variations can accelerate the oxidation of power steering fluid, leading to the formation of acidic compounds. These acids not only corrode internal components of the power steering system but can also leach into the environment, potentially affecting soil pH levels and plant growth in areas where fluid leaks occur. Furthermore, the breakdown of additives in the fluid due to thermal stress can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potentially harming local ecosystems.

The disposal of degraded power steering fluid presents another environmental challenge. When fluid is changed due to degradation, it often contains higher levels of heavy metals and other contaminants that have accumulated over time. Improper disposal can lead to these pollutants entering groundwater systems or surface waters, posing risks to aquatic life and potentially entering the food chain.

Moreover, the increased frequency of fluid changes necessitated by temperature-induced degradation leads to a higher consumption of petroleum-based products. This not only depletes non-renewable resources but also increases the carbon footprint associated with the production, transportation, and disposal of power steering fluid. The energy required for these processes contributes to greenhouse gas emissions and climate change.

The environmental impact extends to wildlife as well. Animals that come into contact with leaked or improperly disposed of degraded fluid may suffer from poisoning or other health issues. Birds and small mammals are particularly vulnerable to ingesting contaminated soil or water, which can lead to bioaccumulation of toxins in the food web.

To mitigate these environmental concerns, research into more temperature-stable fluid formulations is crucial. Developing fluids that can withstand wider temperature ranges without significant degradation could reduce the frequency of fluid changes and the associated environmental risks. Additionally, improving recycling and disposal methods for used power steering fluid can help minimize its impact on ecosystems and natural resources.

Temperature variations can accelerate the oxidation of power steering fluid, leading to the formation of acidic compounds. These acids not only corrode internal components of the power steering system but can also leach into the environment, potentially affecting soil pH levels and plant growth in areas where fluid leaks occur. Furthermore, the breakdown of additives in the fluid due to thermal stress can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potentially harming local ecosystems.

The disposal of degraded power steering fluid presents another environmental challenge. When fluid is changed due to degradation, it often contains higher levels of heavy metals and other contaminants that have accumulated over time. Improper disposal can lead to these pollutants entering groundwater systems or surface waters, posing risks to aquatic life and potentially entering the food chain.

Moreover, the increased frequency of fluid changes necessitated by temperature-induced degradation leads to a higher consumption of petroleum-based products. This not only depletes non-renewable resources but also increases the carbon footprint associated with the production, transportation, and disposal of power steering fluid. The energy required for these processes contributes to greenhouse gas emissions and climate change.

The environmental impact extends to wildlife as well. Animals that come into contact with leaked or improperly disposed of degraded fluid may suffer from poisoning or other health issues. Birds and small mammals are particularly vulnerable to ingesting contaminated soil or water, which can lead to bioaccumulation of toxins in the food web.

To mitigate these environmental concerns, research into more temperature-stable fluid formulations is crucial. Developing fluids that can withstand wider temperature ranges without significant degradation could reduce the frequency of fluid changes and the associated environmental risks. Additionally, improving recycling and disposal methods for used power steering fluid can help minimize its impact on ecosystems and natural resources.

Safety Standards for Automotive Fluids

Safety standards for automotive fluids play a crucial role in ensuring the reliability and performance of power steering systems across varying temperature conditions. These standards are designed to address the challenges posed by temperature variability on power steering fluid chemistry. The Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) have established comprehensive guidelines for power steering fluids, focusing on their thermal stability, viscosity characteristics, and chemical composition.

One of the primary safety standards for power steering fluids is the SAE J1703, which specifies the minimum performance requirements for brake fluids used in hydraulic brake systems. While primarily focused on brake fluids, this standard also influences power steering fluid formulations due to similarities in operating conditions. The standard addresses the fluid's boiling point, viscosity, and corrosion protection properties, all of which are critical factors affected by temperature variations.

ISO 7308 is another important standard that specifically deals with power steering fluids. This standard outlines the requirements for mineral oil-based hydraulic fluids used in power steering systems. It covers aspects such as viscosity index, low-temperature performance, and oxidation stability, which are essential for maintaining fluid integrity across a wide range of temperatures.

The American Society for Testing and Materials (ASTM) has developed several test methods to evaluate the performance of power steering fluids under different temperature conditions. ASTM D445, for instance, is used to measure the kinematic viscosity of transparent and opaque liquids, including power steering fluids. This test is crucial for assessing how the fluid's flow characteristics change with temperature, ensuring optimal performance in both cold start-up and high-temperature operating conditions.

Furthermore, the ASTM D2270 standard is employed to calculate the viscosity index of power steering fluids. This index is a measure of how the fluid's viscosity changes with temperature, which is vital for maintaining consistent steering performance across various climate conditions. Fluids with a higher viscosity index exhibit less variation in viscosity with temperature changes, making them more suitable for use in power steering systems exposed to extreme temperature fluctuations.

To address the specific challenges of temperature variability, manufacturers often incorporate additives into power steering fluids. These additives are designed to improve the fluid's thermal stability, reduce oxidation, and maintain proper viscosity across a broad temperature range. The effectiveness of these additives and their compliance with safety standards are typically evaluated using accelerated aging tests, such as those outlined in ASTM D943, which assesses the oxidation stability of inhibited mineral oils.

One of the primary safety standards for power steering fluids is the SAE J1703, which specifies the minimum performance requirements for brake fluids used in hydraulic brake systems. While primarily focused on brake fluids, this standard also influences power steering fluid formulations due to similarities in operating conditions. The standard addresses the fluid's boiling point, viscosity, and corrosion protection properties, all of which are critical factors affected by temperature variations.

ISO 7308 is another important standard that specifically deals with power steering fluids. This standard outlines the requirements for mineral oil-based hydraulic fluids used in power steering systems. It covers aspects such as viscosity index, low-temperature performance, and oxidation stability, which are essential for maintaining fluid integrity across a wide range of temperatures.

The American Society for Testing and Materials (ASTM) has developed several test methods to evaluate the performance of power steering fluids under different temperature conditions. ASTM D445, for instance, is used to measure the kinematic viscosity of transparent and opaque liquids, including power steering fluids. This test is crucial for assessing how the fluid's flow characteristics change with temperature, ensuring optimal performance in both cold start-up and high-temperature operating conditions.

Furthermore, the ASTM D2270 standard is employed to calculate the viscosity index of power steering fluids. This index is a measure of how the fluid's viscosity changes with temperature, which is vital for maintaining consistent steering performance across various climate conditions. Fluids with a higher viscosity index exhibit less variation in viscosity with temperature changes, making them more suitable for use in power steering systems exposed to extreme temperature fluctuations.

To address the specific challenges of temperature variability, manufacturers often incorporate additives into power steering fluids. These additives are designed to improve the fluid's thermal stability, reduce oxidation, and maintain proper viscosity across a broad temperature range. The effectiveness of these additives and their compliance with safety standards are typically evaluated using accelerated aging tests, such as those outlined in ASTM D943, which assesses the oxidation stability of inhibited mineral oils.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!