The Role of Power Steering Fluid in Reducing Emissions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Evolution and Emission Reduction Goals

Power steering fluid has undergone significant evolution since its introduction in the automotive industry. Initially designed to reduce steering effort, modern power steering fluids now play a crucial role in reducing emissions and improving overall vehicle efficiency. The development of these fluids has been driven by increasingly stringent environmental regulations and the automotive industry's commitment to sustainability.

In the early stages, power steering fluids were primarily mineral oil-based, focusing solely on hydraulic performance. However, as environmental concerns grew, the industry shifted towards synthetic fluids with improved thermal stability and reduced volatility. This transition marked the beginning of power steering fluid's contribution to emission reduction efforts.

The current generation of power steering fluids is designed with multiple objectives in mind. These fluids not only provide excellent lubrication and hydraulic performance but also contribute to reduced fuel consumption and lower emissions. Advanced formulations incorporate additives that minimize friction, reduce wear, and improve energy efficiency within the power steering system.

One of the key goals in power steering fluid evolution is the reduction of volatile organic compound (VOC) emissions. Modern fluids are formulated with low-volatility base oils and additives, significantly decreasing the release of harmful vapors into the atmosphere. This advancement directly contributes to improved air quality and helps automotive manufacturers meet stringent emission standards.

Another important objective is the enhancement of fluid longevity. Extended fluid life reduces the frequency of fluid changes, thereby minimizing waste and the environmental impact associated with fluid disposal. This goal aligns with broader sustainability initiatives in the automotive sector, promoting resource conservation and reducing the carbon footprint of vehicle maintenance.

The development of biodegradable power steering fluids represents a significant milestone in emission reduction efforts. These environmentally friendly formulations break down more readily in the environment, reducing long-term ecological impact. While still in the early stages of adoption, biodegradable fluids show promise in further minimizing the environmental footprint of automotive systems.

Looking ahead, the evolution of power steering fluid continues to focus on emission reduction and sustainability. Research is underway to develop fluids that are compatible with electric power steering systems, which are becoming increasingly common in modern vehicles. These new formulations aim to optimize energy efficiency and reduce the overall environmental impact of vehicle operation.

In the early stages, power steering fluids were primarily mineral oil-based, focusing solely on hydraulic performance. However, as environmental concerns grew, the industry shifted towards synthetic fluids with improved thermal stability and reduced volatility. This transition marked the beginning of power steering fluid's contribution to emission reduction efforts.

The current generation of power steering fluids is designed with multiple objectives in mind. These fluids not only provide excellent lubrication and hydraulic performance but also contribute to reduced fuel consumption and lower emissions. Advanced formulations incorporate additives that minimize friction, reduce wear, and improve energy efficiency within the power steering system.

One of the key goals in power steering fluid evolution is the reduction of volatile organic compound (VOC) emissions. Modern fluids are formulated with low-volatility base oils and additives, significantly decreasing the release of harmful vapors into the atmosphere. This advancement directly contributes to improved air quality and helps automotive manufacturers meet stringent emission standards.

Another important objective is the enhancement of fluid longevity. Extended fluid life reduces the frequency of fluid changes, thereby minimizing waste and the environmental impact associated with fluid disposal. This goal aligns with broader sustainability initiatives in the automotive sector, promoting resource conservation and reducing the carbon footprint of vehicle maintenance.

The development of biodegradable power steering fluids represents a significant milestone in emission reduction efforts. These environmentally friendly formulations break down more readily in the environment, reducing long-term ecological impact. While still in the early stages of adoption, biodegradable fluids show promise in further minimizing the environmental footprint of automotive systems.

Looking ahead, the evolution of power steering fluid continues to focus on emission reduction and sustainability. Research is underway to develop fluids that are compatible with electric power steering systems, which are becoming increasingly common in modern vehicles. These new formulations aim to optimize energy efficiency and reduce the overall environmental impact of vehicle operation.

Market Demand for Eco-Friendly Power Steering Systems

The market demand for eco-friendly power steering systems has been steadily increasing in recent years, driven by stringent environmental regulations and growing consumer awareness of sustainability issues. As automotive manufacturers face mounting pressure to reduce vehicle emissions and improve fuel efficiency, the role of power steering fluid in achieving these goals has come under scrutiny.

Traditional hydraulic power steering systems, which rely on power steering fluid, have been a standard feature in vehicles for decades. However, these systems are known to contribute to increased fuel consumption and, consequently, higher emissions. This has led to a shift in market preferences towards more environmentally friendly alternatives, such as electric power steering (EPS) systems.

The demand for eco-friendly power steering solutions is particularly strong in developed markets, where environmental regulations are more stringent. In the European Union, for instance, the implementation of Euro 6 emission standards has pushed automakers to adopt cleaner technologies across all vehicle components, including power steering systems. Similarly, in the United States, Corporate Average Fuel Economy (CAFE) standards have incentivized the development and adoption of more fuel-efficient power steering solutions.

Emerging markets are also showing increased interest in eco-friendly power steering systems, albeit at a slower pace. As these markets mature and environmental concerns become more prominent, the demand for greener automotive technologies is expected to rise. This trend is particularly evident in countries like China and India, where air quality issues have become a major concern for both policymakers and consumers.

The automotive aftermarket has also seen a growing demand for eco-friendly power steering fluids. Vehicle owners are increasingly seeking products that can improve the efficiency of their existing hydraulic power steering systems, reduce fluid leakage, and minimize environmental impact. This has led to the development of advanced power steering fluids with improved properties, such as better thermal stability and reduced friction.

Fleet operators, particularly those managing large commercial vehicle fleets, are another significant driver of demand for eco-friendly power steering systems. These operators are increasingly focused on reducing their carbon footprint and operating costs, making them more likely to invest in technologies that can improve fuel efficiency and reduce emissions across their entire fleet.

As the automotive industry continues to evolve towards electrification, the demand for eco-friendly power steering solutions is expected to grow further. Electric and hybrid vehicles, which are gaining market share, typically use electric power steering systems that eliminate the need for traditional power steering fluid altogether. This shift is likely to accelerate the transition away from hydraulic systems in the coming years.

Traditional hydraulic power steering systems, which rely on power steering fluid, have been a standard feature in vehicles for decades. However, these systems are known to contribute to increased fuel consumption and, consequently, higher emissions. This has led to a shift in market preferences towards more environmentally friendly alternatives, such as electric power steering (EPS) systems.

The demand for eco-friendly power steering solutions is particularly strong in developed markets, where environmental regulations are more stringent. In the European Union, for instance, the implementation of Euro 6 emission standards has pushed automakers to adopt cleaner technologies across all vehicle components, including power steering systems. Similarly, in the United States, Corporate Average Fuel Economy (CAFE) standards have incentivized the development and adoption of more fuel-efficient power steering solutions.

Emerging markets are also showing increased interest in eco-friendly power steering systems, albeit at a slower pace. As these markets mature and environmental concerns become more prominent, the demand for greener automotive technologies is expected to rise. This trend is particularly evident in countries like China and India, where air quality issues have become a major concern for both policymakers and consumers.

The automotive aftermarket has also seen a growing demand for eco-friendly power steering fluids. Vehicle owners are increasingly seeking products that can improve the efficiency of their existing hydraulic power steering systems, reduce fluid leakage, and minimize environmental impact. This has led to the development of advanced power steering fluids with improved properties, such as better thermal stability and reduced friction.

Fleet operators, particularly those managing large commercial vehicle fleets, are another significant driver of demand for eco-friendly power steering systems. These operators are increasingly focused on reducing their carbon footprint and operating costs, making them more likely to invest in technologies that can improve fuel efficiency and reduce emissions across their entire fleet.

As the automotive industry continues to evolve towards electrification, the demand for eco-friendly power steering solutions is expected to grow further. Electric and hybrid vehicles, which are gaining market share, typically use electric power steering systems that eliminate the need for traditional power steering fluid altogether. This shift is likely to accelerate the transition away from hydraulic systems in the coming years.

Current State and Challenges in Power Steering Fluid Technology

Power steering fluid technology has made significant advancements in recent years, particularly in its role in reducing emissions. The current state of this technology is characterized by a focus on developing more environmentally friendly fluids that maintain or improve vehicle performance while minimizing environmental impact.

One of the primary challenges in power steering fluid technology is the development of synthetic fluids that can withstand higher temperatures and pressures without breaking down. These advanced fluids are designed to reduce friction and wear within the power steering system, thereby improving overall efficiency and reducing energy consumption. This, in turn, contributes to lower emissions by reducing the load on the engine.

Another significant development is the introduction of biodegradable power steering fluids. These fluids are formulated using renewable resources and are designed to break down naturally in the environment, reducing the potential for long-term pollution. However, ensuring that these biodegradable fluids maintain the same level of performance and longevity as traditional petroleum-based fluids remains a challenge.

The industry is also exploring the use of nanotechnology in power steering fluid formulations. Nanoparticles added to the fluid can potentially enhance its lubricating properties, further reducing friction and wear. This technology is still in its early stages, and researchers are working to overcome challenges related to the stability of nanoparticles in the fluid and their long-term effects on system components.

A significant challenge facing the industry is the need to develop power steering fluids that are compatible with a wide range of vehicle types, including hybrid and electric vehicles. As the automotive industry shifts towards electrification, power steering systems are evolving, and fluid technologies must adapt to meet the unique requirements of these new systems.

Regulatory pressures are also driving innovation in power steering fluid technology. Stricter emissions standards and environmental regulations are pushing manufacturers to develop fluids that not only perform well but also contribute to overall vehicle efficiency and reduced emissions. This has led to increased research into low-viscosity fluids that can reduce pumping losses and improve fuel economy.

Despite these advancements, several challenges remain. One of the most pressing is the need to balance performance, longevity, and environmental impact. Developing fluids that can maintain their properties over extended periods while still being environmentally friendly is an ongoing challenge. Additionally, the industry must address the issue of fluid disposal and recycling, as improper handling of used power steering fluid can lead to environmental contamination.

One of the primary challenges in power steering fluid technology is the development of synthetic fluids that can withstand higher temperatures and pressures without breaking down. These advanced fluids are designed to reduce friction and wear within the power steering system, thereby improving overall efficiency and reducing energy consumption. This, in turn, contributes to lower emissions by reducing the load on the engine.

Another significant development is the introduction of biodegradable power steering fluids. These fluids are formulated using renewable resources and are designed to break down naturally in the environment, reducing the potential for long-term pollution. However, ensuring that these biodegradable fluids maintain the same level of performance and longevity as traditional petroleum-based fluids remains a challenge.

The industry is also exploring the use of nanotechnology in power steering fluid formulations. Nanoparticles added to the fluid can potentially enhance its lubricating properties, further reducing friction and wear. This technology is still in its early stages, and researchers are working to overcome challenges related to the stability of nanoparticles in the fluid and their long-term effects on system components.

A significant challenge facing the industry is the need to develop power steering fluids that are compatible with a wide range of vehicle types, including hybrid and electric vehicles. As the automotive industry shifts towards electrification, power steering systems are evolving, and fluid technologies must adapt to meet the unique requirements of these new systems.

Regulatory pressures are also driving innovation in power steering fluid technology. Stricter emissions standards and environmental regulations are pushing manufacturers to develop fluids that not only perform well but also contribute to overall vehicle efficiency and reduced emissions. This has led to increased research into low-viscosity fluids that can reduce pumping losses and improve fuel economy.

Despite these advancements, several challenges remain. One of the most pressing is the need to balance performance, longevity, and environmental impact. Developing fluids that can maintain their properties over extended periods while still being environmentally friendly is an ongoing challenge. Additionally, the industry must address the issue of fluid disposal and recycling, as improper handling of used power steering fluid can lead to environmental contamination.

Existing Solutions for Low-Emission Power Steering Fluids

01 Power steering fluid composition

Specialized fluid compositions for power steering systems are developed to reduce emissions and improve performance. These fluids may include additives to enhance lubrication, reduce wear, and minimize environmental impact.- Power steering fluid composition: Specialized fluid compositions for power steering systems are developed to reduce emissions and improve performance. These fluids may include additives to enhance lubrication, reduce wear, and minimize environmental impact.

- Emission control in power steering systems: Various technologies are implemented to control and reduce emissions from power steering systems. This includes improved sealing mechanisms, vapor recovery systems, and advanced fluid circulation designs to minimize fluid loss and emissions.

- Power steering pump design: Innovative pump designs are developed to enhance efficiency and reduce emissions in power steering systems. These designs may incorporate features such as variable displacement, improved sealing, and optimized fluid flow paths.

- Integration with engine systems: Power steering systems are integrated with engine systems to optimize overall vehicle performance and reduce emissions. This may include shared fluid reservoirs, heat exchange systems, or electronic control integration.

- Electric power steering systems: Electric power steering systems are developed as an alternative to hydraulic systems to eliminate fluid-related emissions. These systems use electric motors and control units to provide steering assistance without the need for hydraulic fluid.

02 Emission control in power steering systems

Various technologies are implemented to control and reduce emissions from power steering systems. This includes improved sealing mechanisms, vapor recovery systems, and advanced fluid circulation designs to minimize fluid loss and emissions.Expand Specific Solutions03 Power steering pump design

Innovative pump designs are developed to enhance efficiency and reduce emissions in power steering systems. These designs focus on minimizing fluid leakage, improving fluid flow, and reducing overall system pressure to decrease emissions.Expand Specific Solutions04 Hydraulic circuit optimization

Optimization of hydraulic circuits in power steering systems aims to reduce fluid consumption and emissions. This includes the use of advanced valves, flow control mechanisms, and circuit designs that minimize fluid loss and improve overall system efficiency.Expand Specific Solutions05 Electric power steering systems

The development of electric power steering systems as an alternative to hydraulic systems aims to eliminate fluid-related emissions entirely. These systems use electric motors and control units to provide steering assistance without the need for hydraulic fluid.Expand Specific Solutions

Key Players in Automotive Fluid and Emission Reduction Industry

The power steering fluid technology market is in a mature stage, with a global market size estimated to be in the billions of dollars. Major automotive manufacturers like Ford, Hyundai, and Mercedes-Benz, along with specialized component suppliers such as ZF, ThyssenKrupp, and JTEKT, dominate the competitive landscape. These companies are focusing on developing more efficient and environmentally friendly power steering systems to reduce emissions. The technology is well-established, but ongoing research and development efforts are aimed at improving performance, reducing energy consumption, and integrating with electric and hybrid vehicle platforms.

Ford Global Technologies LLC

Technical Solution: Ford has introduced an innovative Adaptive Steering technology that works in conjunction with their electric power steering (EPS) system to reduce emissions. This system uses a precision-controlled actuator placed inside the steering wheel, which can add to or subtract from the driver's steering inputs. By optimizing the steering ratio continuously, the system reduces the energy required for steering, particularly in low-speed maneuvers and parking situations. Ford's EPS system eliminates the need for traditional power steering fluid, reducing the vehicle's weight and improving fuel efficiency. The company reports that their EPS technology can improve fuel economy by up to 3% compared to hydraulic systems [9]. Ford has also developed a smart energy management system that integrates with the EPS to predict steering assist requirements, further optimizing power consumption and reducing emissions [10].

Strengths: Adaptive technology improves efficiency across various driving conditions. Integrates with vehicle's smart energy management system. Improves vehicle handling and maneuverability. Weaknesses: More complex than standard EPS systems. May require specialized training for maintenance and repairs.

ZF Automotive Germany GmbH

Technical Solution: ZF has pioneered a revolutionary steer-by-wire system that completely eliminates the need for traditional power steering fluid, significantly reducing emissions. This system replaces the mechanical connection between the steering wheel and the wheels with electronic controls and actuators. ZF's steer-by-wire technology can reduce vehicle weight by up to 4kg and improve fuel efficiency by up to 3% [5]. The system also allows for variable steering ratios, enhancing maneuverability at low speeds and stability at high speeds. ZF has integrated advanced safety features, including redundant electronic control units and fail-operational modes, ensuring reliability [6]. Their latest iteration incorporates AI-driven predictive steering assistance, further optimizing energy usage based on road conditions and driver behavior.

Strengths: Eliminates all hydraulic components, maximizing emission reduction. Allows for customizable steering feel and advanced driver assistance features. Significant weight reduction. Weaknesses: Requires extensive changes to vehicle architecture. May face regulatory challenges in some markets.

Core Innovations in Emission-Reducing Power Steering Fluids

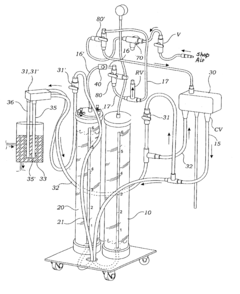

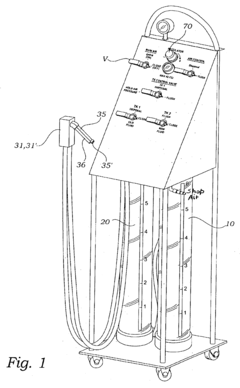

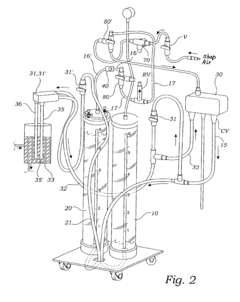

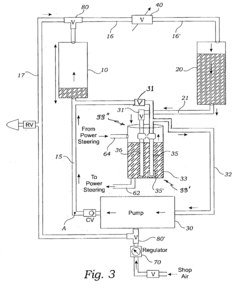

Power steering fluid exchange system and method of use

PatentInactiveUS6772803B2

Innovation

- An apparatus comprising a fluid receiving container, a fluid supply container, a utility fluid pump, and a pressure actuated fluid valve, where air is compressed by spent fluid to open the valve when 80-90% of spent fluid is removed, allowing replacement fluid to enter the power steering system, ensuring minimal mixing with the spent fluid.

Power steering apparatus, and method of supplying operating oil for same

PatentWO2014073048A1

Innovation

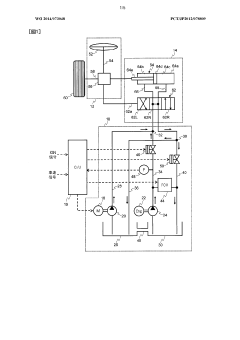

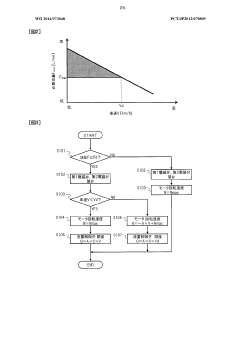

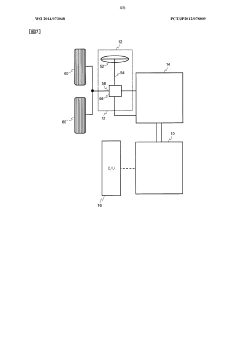

- A power steering system incorporating an electric motor-driven first hydraulic pump and an engine-driven second hydraulic pump, with a control device that adjusts the flow rates of hydraulic fluid supplied by both pumps based on vehicle operating state to optimize hydraulic pressure assistance.

Environmental Regulations Impact on Power Steering Fluid

Environmental regulations have significantly impacted the development and use of power steering fluid in recent years. As governments worldwide intensify efforts to reduce greenhouse gas emissions and combat climate change, the automotive industry has faced increasing pressure to improve vehicle efficiency and reduce environmental impact. This regulatory landscape has led to a shift in focus towards more environmentally friendly power steering fluid formulations and systems.

One of the primary drivers of change has been the implementation of stricter emissions standards, such as the European Union's Euro 6 regulations and the United States Environmental Protection Agency's Tier 3 standards. These regulations have set increasingly stringent limits on vehicle emissions, including those related to volatile organic compounds (VOCs) and particulate matter. As a result, manufacturers have been compelled to reevaluate the composition of power steering fluids to ensure compliance with these new standards.

The push for reduced emissions has led to the development of low-volatility power steering fluids. These fluids are designed to minimize evaporative emissions, which can contribute to air pollution and smog formation. By using fluids with lower vapor pressure and higher boiling points, manufacturers can reduce the release of harmful VOCs into the atmosphere. This shift has necessitated changes in fluid formulations, often incorporating synthetic base oils and advanced additive packages to maintain performance while meeting environmental requirements.

Another significant impact of environmental regulations has been the increased focus on energy efficiency in vehicle systems. Power steering systems, traditionally known for their energy consumption, have come under scrutiny as automakers seek to improve overall vehicle efficiency to meet fuel economy standards. This has led to the development of electric power steering (EPS) systems, which eliminate the need for traditional hydraulic power steering fluid altogether. While EPS systems have gained popularity, especially in smaller vehicles, hydraulic and electro-hydraulic systems still play a crucial role in many larger vehicles and heavy-duty applications.

For vehicles that continue to use hydraulic power steering systems, regulations have prompted the development of more efficient fluids. These advanced formulations aim to reduce internal friction and improve power transmission, thereby minimizing the energy required to operate the power steering system. By reducing the load on the engine, these fluids contribute to improved fuel efficiency and, consequently, lower emissions.

Environmental regulations have also influenced the lifecycle management of power steering fluids. Increased emphasis on proper disposal and recycling of automotive fluids has led to the development of more biodegradable and environmentally friendly formulations. Manufacturers are now exploring bio-based alternatives and renewable resources in fluid production, aligning with broader sustainability goals and circular economy principles.

In conclusion, environmental regulations have been a catalyst for innovation in power steering fluid technology. The industry's response to these regulatory challenges has resulted in cleaner, more efficient, and environmentally conscious solutions that contribute to overall vehicle emission reduction efforts while maintaining or improving performance standards.

One of the primary drivers of change has been the implementation of stricter emissions standards, such as the European Union's Euro 6 regulations and the United States Environmental Protection Agency's Tier 3 standards. These regulations have set increasingly stringent limits on vehicle emissions, including those related to volatile organic compounds (VOCs) and particulate matter. As a result, manufacturers have been compelled to reevaluate the composition of power steering fluids to ensure compliance with these new standards.

The push for reduced emissions has led to the development of low-volatility power steering fluids. These fluids are designed to minimize evaporative emissions, which can contribute to air pollution and smog formation. By using fluids with lower vapor pressure and higher boiling points, manufacturers can reduce the release of harmful VOCs into the atmosphere. This shift has necessitated changes in fluid formulations, often incorporating synthetic base oils and advanced additive packages to maintain performance while meeting environmental requirements.

Another significant impact of environmental regulations has been the increased focus on energy efficiency in vehicle systems. Power steering systems, traditionally known for their energy consumption, have come under scrutiny as automakers seek to improve overall vehicle efficiency to meet fuel economy standards. This has led to the development of electric power steering (EPS) systems, which eliminate the need for traditional hydraulic power steering fluid altogether. While EPS systems have gained popularity, especially in smaller vehicles, hydraulic and electro-hydraulic systems still play a crucial role in many larger vehicles and heavy-duty applications.

For vehicles that continue to use hydraulic power steering systems, regulations have prompted the development of more efficient fluids. These advanced formulations aim to reduce internal friction and improve power transmission, thereby minimizing the energy required to operate the power steering system. By reducing the load on the engine, these fluids contribute to improved fuel efficiency and, consequently, lower emissions.

Environmental regulations have also influenced the lifecycle management of power steering fluids. Increased emphasis on proper disposal and recycling of automotive fluids has led to the development of more biodegradable and environmentally friendly formulations. Manufacturers are now exploring bio-based alternatives and renewable resources in fluid production, aligning with broader sustainability goals and circular economy principles.

In conclusion, environmental regulations have been a catalyst for innovation in power steering fluid technology. The industry's response to these regulatory challenges has resulted in cleaner, more efficient, and environmentally conscious solutions that contribute to overall vehicle emission reduction efforts while maintaining or improving performance standards.

Life Cycle Assessment of Power Steering Fluids

Life Cycle Assessment (LCA) of power steering fluids is a comprehensive approach to evaluating the environmental impacts associated with these fluids throughout their entire lifecycle. This assessment typically covers the extraction of raw materials, manufacturing processes, distribution, use phase, and end-of-life disposal or recycling. The primary goal of conducting an LCA for power steering fluids is to identify and quantify the environmental burdens at each stage, enabling informed decision-making for sustainable product development and management.

In the context of power steering fluids, the LCA begins with the sourcing and extraction of base oils and additives. These components often originate from petroleum-based or synthetic sources, each with its own environmental footprint. The manufacturing phase involves the blending and processing of these ingredients, which requires energy and may result in emissions. Distribution of the final product to retailers and end-users contributes to transportation-related impacts.

The use phase of power steering fluids is particularly significant in the LCA. During vehicle operation, these fluids play a crucial role in reducing friction and wear within the power steering system. Efficient power steering fluids can contribute to improved fuel economy and reduced emissions by minimizing the energy required for steering operations. However, potential leaks or the need for periodic fluid changes can lead to environmental concerns.

End-of-life considerations for power steering fluids include proper disposal methods and potential recycling opportunities. Improper disposal can lead to soil and water contamination, while effective recycling programs can reduce the overall environmental impact by reclaiming and reprocessing used fluids.

The LCA also examines the potential for alternative formulations, such as bio-based or synthetic fluids, which may offer improved environmental performance. These alternatives are evaluated across all lifecycle stages to determine their net environmental impact compared to conventional petroleum-based fluids.

By conducting a thorough LCA, manufacturers and policymakers can identify hotspots in the lifecycle where environmental impacts are most significant. This information can guide efforts to improve formulations, optimize manufacturing processes, enhance recycling programs, and develop more sustainable power steering systems overall. The results of an LCA can also inform consumers about the environmental implications of their vehicle maintenance choices, potentially influencing market demand for more eco-friendly power steering fluid options.

In the context of power steering fluids, the LCA begins with the sourcing and extraction of base oils and additives. These components often originate from petroleum-based or synthetic sources, each with its own environmental footprint. The manufacturing phase involves the blending and processing of these ingredients, which requires energy and may result in emissions. Distribution of the final product to retailers and end-users contributes to transportation-related impacts.

The use phase of power steering fluids is particularly significant in the LCA. During vehicle operation, these fluids play a crucial role in reducing friction and wear within the power steering system. Efficient power steering fluids can contribute to improved fuel economy and reduced emissions by minimizing the energy required for steering operations. However, potential leaks or the need for periodic fluid changes can lead to environmental concerns.

End-of-life considerations for power steering fluids include proper disposal methods and potential recycling opportunities. Improper disposal can lead to soil and water contamination, while effective recycling programs can reduce the overall environmental impact by reclaiming and reprocessing used fluids.

The LCA also examines the potential for alternative formulations, such as bio-based or synthetic fluids, which may offer improved environmental performance. These alternatives are evaluated across all lifecycle stages to determine their net environmental impact compared to conventional petroleum-based fluids.

By conducting a thorough LCA, manufacturers and policymakers can identify hotspots in the lifecycle where environmental impacts are most significant. This information can guide efforts to improve formulations, optimize manufacturing processes, enhance recycling programs, and develop more sustainable power steering systems overall. The results of an LCA can also inform consumers about the environmental implications of their vehicle maintenance choices, potentially influencing market demand for more eco-friendly power steering fluid options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!