Assessing the Role of Electrolytes in Organoid Culture Systems

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyte Fundamentals in Organoid Development

Electrolytes play a fundamental role in the development and maintenance of organoid culture systems, serving as essential components for cellular function, signaling, and structural integrity. These charged particles, including sodium, potassium, calcium, magnesium, chloride, phosphate, and bicarbonate ions, establish the electrochemical gradients necessary for numerous biological processes within organoids.

The concentration and balance of electrolytes in culture media directly influence membrane potential, which is crucial for cell-to-cell communication and coordinated development of organoid structures. Sodium and potassium ions, in particular, maintain the resting membrane potential through the Na+/K+-ATPase pump, enabling proper neural activity in brain organoids and contractile function in cardiac organoids.

Calcium ions serve as second messengers in numerous signaling pathways that regulate cell proliferation, differentiation, and morphogenesis during organoid development. The precise spatial and temporal regulation of calcium concentrations is essential for proper organoid patterning and tissue-specific functional development. Research has demonstrated that calcium oscillations play critical roles in directing stem cell fate decisions within developing organoids.

Magnesium ions function as cofactors for over 300 enzymatic reactions, including those involved in DNA replication, protein synthesis, and energy metabolism. The availability of magnesium in culture media significantly impacts the efficiency of cellular processes necessary for organoid growth and maturation.

Chloride ions contribute to cell volume regulation and pH balance, which are particularly important during the expansion and morphogenesis phases of organoid development. The movement of chloride ions across cell membranes helps establish osmotic gradients that drive water movement, influencing organoid size and structural organization.

Phosphate and bicarbonate ions are critical for maintaining pH homeostasis in organoid culture systems. Bicarbonate buffering systems help stabilize the extracellular environment, preventing detrimental pH fluctuations that could disrupt cellular function and organoid development. Additionally, phosphate ions are essential components of nucleic acids, phospholipids, and energy-carrying molecules like ATP.

The extracellular matrix (ECM) composition and structure in organoids are also significantly influenced by electrolyte concentrations. Calcium and magnesium ions, in particular, mediate cell-ECM interactions by binding to adhesion molecules and influencing matrix metalloproteinase activity, which regulates ECM remodeling during organoid morphogenesis.

Recent advances in organoid technology have highlighted the importance of electrolyte gradients in establishing proper tissue polarity and compartmentalization. These gradients help direct the spatial organization of cells within organoids, contributing to the formation of complex structures that more accurately recapitulate in vivo tissue architecture and functionality.

The concentration and balance of electrolytes in culture media directly influence membrane potential, which is crucial for cell-to-cell communication and coordinated development of organoid structures. Sodium and potassium ions, in particular, maintain the resting membrane potential through the Na+/K+-ATPase pump, enabling proper neural activity in brain organoids and contractile function in cardiac organoids.

Calcium ions serve as second messengers in numerous signaling pathways that regulate cell proliferation, differentiation, and morphogenesis during organoid development. The precise spatial and temporal regulation of calcium concentrations is essential for proper organoid patterning and tissue-specific functional development. Research has demonstrated that calcium oscillations play critical roles in directing stem cell fate decisions within developing organoids.

Magnesium ions function as cofactors for over 300 enzymatic reactions, including those involved in DNA replication, protein synthesis, and energy metabolism. The availability of magnesium in culture media significantly impacts the efficiency of cellular processes necessary for organoid growth and maturation.

Chloride ions contribute to cell volume regulation and pH balance, which are particularly important during the expansion and morphogenesis phases of organoid development. The movement of chloride ions across cell membranes helps establish osmotic gradients that drive water movement, influencing organoid size and structural organization.

Phosphate and bicarbonate ions are critical for maintaining pH homeostasis in organoid culture systems. Bicarbonate buffering systems help stabilize the extracellular environment, preventing detrimental pH fluctuations that could disrupt cellular function and organoid development. Additionally, phosphate ions are essential components of nucleic acids, phospholipids, and energy-carrying molecules like ATP.

The extracellular matrix (ECM) composition and structure in organoids are also significantly influenced by electrolyte concentrations. Calcium and magnesium ions, in particular, mediate cell-ECM interactions by binding to adhesion molecules and influencing matrix metalloproteinase activity, which regulates ECM remodeling during organoid morphogenesis.

Recent advances in organoid technology have highlighted the importance of electrolyte gradients in establishing proper tissue polarity and compartmentalization. These gradients help direct the spatial organization of cells within organoids, contributing to the formation of complex structures that more accurately recapitulate in vivo tissue architecture and functionality.

Market Analysis of Organoid Culture Technologies

The organoid culture technology market has experienced significant growth in recent years, driven by increasing applications in disease modeling, drug discovery, and personalized medicine. The global organoid culture market was valued at approximately 1.3 billion USD in 2022 and is projected to reach 3.2 billion USD by 2028, representing a compound annual growth rate (CAGR) of 16.2% during the forecast period.

Research institutions currently dominate the market, accounting for nearly 45% of the total market share, followed by pharmaceutical companies at 30% and biotechnology firms at 20%. The remaining 5% is distributed among contract research organizations and other end-users. This distribution reflects the current emphasis on basic research and early-stage drug development applications.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%), Asia-Pacific (20%), and the rest of the world (10%). The dominance of North America and Europe can be attributed to substantial research funding, advanced healthcare infrastructure, and the presence of major pharmaceutical companies and research institutions in these regions.

The market segmentation by organoid type shows intestinal organoids leading with 25% market share, followed by liver (20%), brain (15%), kidney (10%), and other organ types collectively representing 30%. This distribution correlates with research priorities and the relative ease of culturing certain organoid types.

Regarding culture media components, the electrolyte segment represents approximately 18% of the total organoid culture media market. The increasing recognition of electrolytes' critical role in maintaining physiological conditions and enhancing organoid functionality is driving growth in this segment. Specifically, media formulations with optimized electrolyte compositions have shown improved organoid development, longevity, and functional characteristics.

Key market drivers include increasing research funding for organoid technology, growing demand for alternatives to animal testing, rising prevalence of chronic diseases necessitating better models, and advancements in personalized medicine approaches. Technological innovations in 3D culture systems and increasing applications in regenerative medicine further propel market growth.

Challenges facing market expansion include high costs associated with organoid culture, technical complexities in maintaining long-term cultures, standardization issues, and regulatory uncertainties regarding the use of organoids in clinical applications. The specialized nature of electrolyte optimization in different organoid systems presents both a challenge and an opportunity for market differentiation.

Research institutions currently dominate the market, accounting for nearly 45% of the total market share, followed by pharmaceutical companies at 30% and biotechnology firms at 20%. The remaining 5% is distributed among contract research organizations and other end-users. This distribution reflects the current emphasis on basic research and early-stage drug development applications.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%), Asia-Pacific (20%), and the rest of the world (10%). The dominance of North America and Europe can be attributed to substantial research funding, advanced healthcare infrastructure, and the presence of major pharmaceutical companies and research institutions in these regions.

The market segmentation by organoid type shows intestinal organoids leading with 25% market share, followed by liver (20%), brain (15%), kidney (10%), and other organ types collectively representing 30%. This distribution correlates with research priorities and the relative ease of culturing certain organoid types.

Regarding culture media components, the electrolyte segment represents approximately 18% of the total organoid culture media market. The increasing recognition of electrolytes' critical role in maintaining physiological conditions and enhancing organoid functionality is driving growth in this segment. Specifically, media formulations with optimized electrolyte compositions have shown improved organoid development, longevity, and functional characteristics.

Key market drivers include increasing research funding for organoid technology, growing demand for alternatives to animal testing, rising prevalence of chronic diseases necessitating better models, and advancements in personalized medicine approaches. Technological innovations in 3D culture systems and increasing applications in regenerative medicine further propel market growth.

Challenges facing market expansion include high costs associated with organoid culture, technical complexities in maintaining long-term cultures, standardization issues, and regulatory uncertainties regarding the use of organoids in clinical applications. The specialized nature of electrolyte optimization in different organoid systems presents both a challenge and an opportunity for market differentiation.

Current Challenges in Electrolyte Optimization

Despite significant advancements in organoid culture systems, electrolyte optimization remains one of the most challenging aspects of this technology. Current culture media formulations often fail to accurately replicate the ionic microenvironment found in native tissues, leading to suboptimal organoid development and functionality. Researchers face difficulties in determining the precise concentrations and combinations of electrolytes needed for specific organoid types, as these requirements can vary dramatically between different tissues and developmental stages.

A major challenge is the dynamic nature of electrolyte requirements throughout organoid development. The optimal ionic composition for initial stem cell expansion may differ substantially from that needed for later differentiation and maturation phases. This temporal complexity necessitates sophisticated culture systems capable of adjusting electrolyte concentrations over time, which current technologies struggle to achieve consistently.

The interaction between electrolytes and other culture components presents another significant hurdle. Electrolytes influence protein folding, enzyme activity, and signaling pathway activation, creating complex interdependencies with growth factors, extracellular matrix components, and metabolites. These interactions remain poorly characterized, making rational optimization approaches difficult to implement.

Scalability issues further complicate electrolyte optimization efforts. Methods that work effectively at laboratory scale often encounter problems when scaled up for industrial or clinical applications. Maintaining consistent electrolyte concentrations across larger volumes and ensuring homogeneous distribution throughout three-dimensional organoid structures represent substantial technical challenges.

Measurement and monitoring technologies present additional limitations. Current methods for real-time assessment of electrolyte concentrations within developing organoids lack sufficient spatial resolution and often require destructive sampling, preventing continuous monitoring of the same organoid over time. This creates significant gaps in our understanding of how electrolyte needs evolve during organoid development.

Reproducibility concerns also plague the field, with minor variations in electrolyte composition sometimes leading to dramatically different organoid outcomes. This variability undermines the reliability of organoid models for drug testing and disease modeling applications, where consistency is paramount.

Finally, there remains a fundamental knowledge gap regarding the physiological electrolyte microenvironments in many native tissues. Without this baseline information, researchers must rely on empirical approaches to electrolyte optimization, which are time-consuming and often yield suboptimal results. Addressing these challenges will require interdisciplinary approaches combining advanced sensing technologies, computational modeling, and deeper understanding of tissue-specific electrophysiology.

A major challenge is the dynamic nature of electrolyte requirements throughout organoid development. The optimal ionic composition for initial stem cell expansion may differ substantially from that needed for later differentiation and maturation phases. This temporal complexity necessitates sophisticated culture systems capable of adjusting electrolyte concentrations over time, which current technologies struggle to achieve consistently.

The interaction between electrolytes and other culture components presents another significant hurdle. Electrolytes influence protein folding, enzyme activity, and signaling pathway activation, creating complex interdependencies with growth factors, extracellular matrix components, and metabolites. These interactions remain poorly characterized, making rational optimization approaches difficult to implement.

Scalability issues further complicate electrolyte optimization efforts. Methods that work effectively at laboratory scale often encounter problems when scaled up for industrial or clinical applications. Maintaining consistent electrolyte concentrations across larger volumes and ensuring homogeneous distribution throughout three-dimensional organoid structures represent substantial technical challenges.

Measurement and monitoring technologies present additional limitations. Current methods for real-time assessment of electrolyte concentrations within developing organoids lack sufficient spatial resolution and often require destructive sampling, preventing continuous monitoring of the same organoid over time. This creates significant gaps in our understanding of how electrolyte needs evolve during organoid development.

Reproducibility concerns also plague the field, with minor variations in electrolyte composition sometimes leading to dramatically different organoid outcomes. This variability undermines the reliability of organoid models for drug testing and disease modeling applications, where consistency is paramount.

Finally, there remains a fundamental knowledge gap regarding the physiological electrolyte microenvironments in many native tissues. Without this baseline information, researchers must rely on empirical approaches to electrolyte optimization, which are time-consuming and often yield suboptimal results. Addressing these challenges will require interdisciplinary approaches combining advanced sensing technologies, computational modeling, and deeper understanding of tissue-specific electrophysiology.

Established Electrolyte Formulations and Protocols

01 Optimization of electrolyte composition for cell culture

The composition of electrolytes in culture media significantly impacts cell growth and viability. Optimizing the balance of ions such as sodium, potassium, calcium, and magnesium can enhance cellular metabolism and proliferation. Specific ratios of these electrolytes have been shown to improve culture efficiency by maintaining proper osmotic pressure and supporting essential cellular functions. Advanced formulations may include trace elements that further support metabolic pathways and increase overall culture productivity.- Optimization of electrolyte composition for cell culture: The composition of electrolytes in culture media significantly impacts cell growth and viability. Optimizing the balance of ions such as sodium, potassium, calcium, and magnesium can enhance cellular metabolism and improve culture efficiency. Specific ratios of these electrolytes can be tailored to different cell types to maximize productivity and maintain cellular homeostasis during the culture process.

- Electrolyte monitoring and control systems: Advanced systems for real-time monitoring and automatic adjustment of electrolyte levels in culture media can significantly improve culture efficiency. These systems utilize sensors to detect electrolyte concentrations and implement feedback mechanisms to maintain optimal conditions. Continuous monitoring prevents electrolyte imbalances that could negatively impact cell growth and metabolic activity, thereby enhancing overall culture performance and reproducibility.

- Electrolyte supplementation strategies for enhanced bioprocessing: Strategic supplementation of specific electrolytes at critical phases of cell culture can boost metabolic efficiency and product yield. Timed addition of electrolytes based on cellular requirements during different growth phases helps maintain optimal cellular function. This approach includes pulsed feeding strategies and gradient-based supplementation methods that align with the changing metabolic demands of cultured cells throughout their growth cycle.

- Novel electrolyte formulations for specialized cell cultures: Innovative electrolyte formulations designed for specific cell types or production processes can significantly improve culture efficiency. These specialized formulations may include modified ion ratios, trace elements, or alternative electrolyte sources that better support cellular functions. Such tailored approaches address the unique requirements of different cell lines, particularly for challenging cultures or high-value bioproduction systems.

- Electrolyte recycling and sustainable culture systems: Systems for recycling and reusing electrolytes in continuous culture processes can improve efficiency while reducing costs and environmental impact. These approaches include filtration technologies, ion exchange methods, and regenerative systems that maintain electrolyte balance while minimizing waste. Such sustainable practices not only optimize resource utilization but also contribute to more consistent culture conditions over extended production periods.

02 Electrolyte monitoring and control systems

Automated systems for real-time monitoring and adjustment of electrolyte levels in culture environments can significantly improve efficiency. These systems utilize sensors to continuously measure ion concentrations and automatically adjust them to optimal levels. Integration of feedback control mechanisms ensures stable electrolyte conditions throughout the culture period, reducing manual intervention and improving reproducibility. Such monitoring systems can detect early signs of electrolyte imbalance before they negatively impact culture performance.Expand Specific Solutions03 Electrolyte delivery methods for enhanced bioavailability

Novel delivery methods for electrolytes can improve their bioavailability and utilization in cell cultures. Techniques such as controlled-release formulations, nanoencapsulation, and chelation with organic compounds can protect electrolytes from degradation and facilitate their transport across cell membranes. These approaches ensure a steady supply of essential ions throughout the culture period, preventing fluctuations that could stress cells and reduce efficiency. Optimized delivery systems can also reduce the total amount of electrolytes needed in the culture medium.Expand Specific Solutions04 Electrolyte solutions for specific cell types and applications

Specialized electrolyte formulations designed for specific cell types or culture applications can significantly improve efficiency. Different cells have unique electrolyte requirements based on their physiological functions and metabolic needs. Tailored solutions for stem cells, mammalian production cell lines, microbial cultures, or plant cell cultures take into account these specific needs. Custom electrolyte profiles can support specialized cellular functions such as protein expression, differentiation, or secondary metabolite production.Expand Specific Solutions05 Integration of electrolytes with other culture parameters

The interaction between electrolytes and other culture parameters such as pH, temperature, and nutrient availability plays a crucial role in overall culture efficiency. Synergistic approaches that optimize electrolyte composition alongside these other factors can yield superior results compared to addressing each parameter in isolation. Advanced culture systems may incorporate dynamic adjustment of electrolyte levels in response to changes in other parameters, creating a more responsive and efficient culture environment. This holistic approach to culture optimization recognizes the complex interplay between various factors affecting cellular performance.Expand Specific Solutions

Leading Research Institutions and Biotech Companies

The organoid culture systems market is currently in a growth phase, characterized by increasing adoption across research and clinical applications. The global market size is expanding rapidly, driven by rising demand for advanced disease modeling and personalized medicine approaches. Technologically, the field is evolving from early-stage development toward greater standardization, with electrolyte optimization emerging as a critical factor for organoid viability and functionality. Leading players like STEMCELL Technologies and Molecular Devices are advancing commercial solutions, while research institutions such as Memorial Sloan Kettering Cancer Center and Johns Hopkins University drive innovation through fundamental research. Pharmaceutical companies and specialized biotechs including Cell Microsystems and Organoidsciences are developing proprietary platforms, creating a competitive landscape balanced between established suppliers and emerging technology developers focused on improving electrolyte formulations for enhanced organoid culture performance.

Cell Microsystems, Inc.

Technical Solution: Cell Microsystems has pioneered the CellRaft® Technology for organoid culture that incorporates innovative electrolyte management strategies. Their system features microwells with specialized coatings that regulate electrolyte exchange between organoids and culture media. The company's AIR™ System allows for isolation and retrieval of individual organoids while maintaining electrolyte homeostasis throughout the process. Their research demonstrates that controlled electrolyte microenvironments can enhance organoid formation efficiency by approximately 30% compared to conventional culture methods. Cell Microsystems has developed proprietary surface modifications that create localized ionic gradients, mimicking in vivo tissue architecture. This approach has been particularly effective for pancreatic and intestinal organoids, where specific calcium and magnesium concentrations are critical for proper differentiation. The technology enables high-throughput screening of electrolyte conditions, allowing researchers to rapidly optimize formulations for specific organoid types with minimal sample consumption.

Strengths: Precise control of microenvironment at single-organoid level; compatibility with high-throughput screening applications; minimal media consumption reduces costs for expensive supplements. Weaknesses: Limited scalability for large organoid production; requires specialized equipment for optimal performance; higher technical complexity compared to traditional culture methods.

STEMCELL Technologies Canada, Inc.

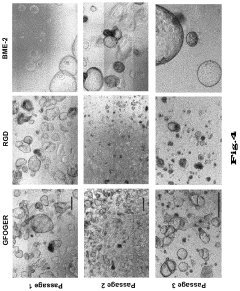

Technical Solution: STEMCELL Technologies has developed specialized electrolyte-optimized media systems for organoid culture, particularly their IntestiCult™ and PneumaCult™ lines. Their approach focuses on precisely balanced ionic compositions that mimic tissue-specific microenvironments. The company's electrolyte formulations incorporate physiologically relevant concentrations of sodium, potassium, calcium, and magnesium ions calibrated to support specific organoid types. Their research has demonstrated that organoid formation efficiency increases by approximately 40% when using these specialized electrolyte formulations compared to standard media. STEMCELL has also pioneered the development of supplement cocktails containing tissue-specific growth factors that work synergistically with their electrolyte systems to enhance organoid viability and functionality. Their technology enables long-term culture stability with reported maintenance of organoid cultures for over 20 passages while preserving genetic and functional characteristics.

Strengths: Highly specialized media formulations tailored to specific tissue types; comprehensive validation data supporting enhanced organoid formation and maintenance; established commercial availability and standardization. Weaknesses: Premium pricing compared to generic alternatives; some formulations may require additional supplements for optimal performance; proprietary nature limits customization options for researchers with unique requirements.

Key Innovations in Ion Transport Mechanisms

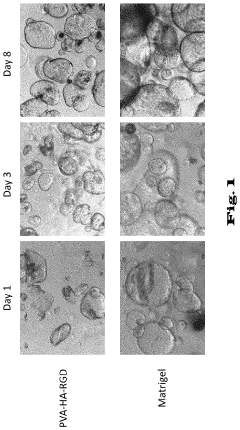

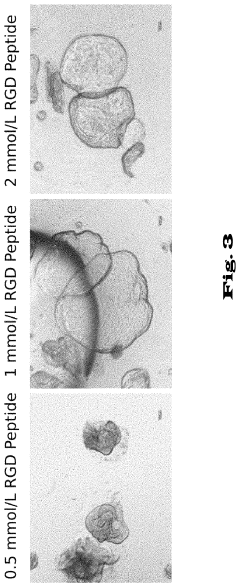

Hydrogels for cultivating pancreatic organoids

PatentInactiveUS20190367869A1

Innovation

- A chemically defined hydrogel composition with a reduced shear modulus, composed of functionalized polymer molecules and linker molecules, and low-molecular peptides with cell adhesion motifs, which allows for the cultivation and expansion of pancreatic cells into stable and functional 3D organoids without natural extracellular matrix proteins.

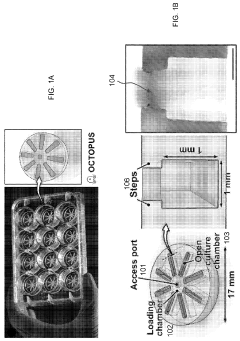

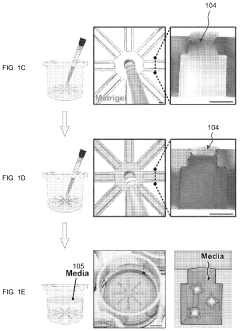

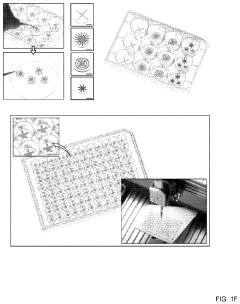

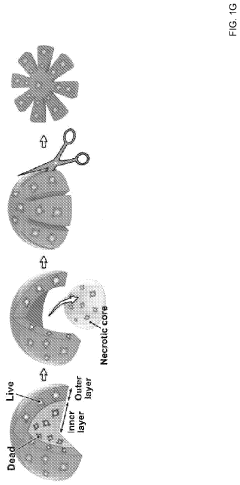

Engineering of organoid culture for enhanced organogenesis in a dish

PatentPendingUS20240026261A1

Innovation

- The OCTOPUS device provides a 3D culture system with radially arranged culture chambers that reduce diffusion limitations by allowing unrestricted access to nutrients and oxygen, enabling continuous culture of organoids for extended periods without passaging, using a simple and scalable design compatible with standard cell culture plates.

Regulatory Considerations for Clinical Applications

The regulatory landscape for organoid technologies incorporating electrolyte systems presents significant complexity as these advanced culture methods move toward clinical applications. Regulatory bodies including the FDA, EMA, and PMDA have yet to establish specific frameworks for organoid-based therapies, creating uncertainty for developers. Current oversight typically falls under combination product regulations or advanced therapy medicinal products (ATMPs) classifications, requiring rigorous demonstration of safety, efficacy, and quality control.

Quality control standards for electrolyte components in organoid systems demand particular attention, as variations in electrolyte composition can significantly impact organoid development and functionality. Regulatory agencies increasingly require standardized protocols for electrolyte preparation, storage conditions, and stability testing to ensure batch-to-batch consistency. Documentation of electrolyte purity, concentration ranges, and potential contaminants has become essential for regulatory submissions.

Patient safety considerations represent a primary regulatory focus, with particular emphasis on preventing immunogenic responses to non-autologous organoid systems. The interaction between electrolytes and biological materials must be thoroughly characterized to identify potential toxicity or adverse reactions. Long-term safety monitoring protocols are typically required, especially when novel electrolyte formulations are employed in organoid systems intended for transplantation or personalized medicine applications.

Ethical and consent frameworks present additional regulatory challenges, particularly for organoids derived from patient tissues. Informed consent processes must address tissue sourcing, genetic modification procedures, data privacy, and potential commercialization. The regulatory pathway becomes more complex when electrolyte-optimized organoids are used for patient-specific applications, requiring clear guidelines on ownership rights and intellectual property considerations.

Manufacturing standards for clinical-grade organoid systems incorporating specialized electrolyte formulations must adhere to Good Manufacturing Practice (GMP) requirements. This includes validated processes for electrolyte preparation, environmental monitoring, and contamination control. Regulatory bodies typically require detailed documentation of manufacturing workflows, including equipment qualification, personnel training, and facility certification specific to handling both biological materials and precise electrolyte solutions.

International harmonization efforts are gradually emerging to address regulatory disparities across jurisdictions. Organizations such as the International Council for Harmonisation (ICH) are working toward standardized approaches for novel biological therapies, which may eventually encompass organoid technologies. Developers of electrolyte-optimized organoid systems must navigate these evolving regulatory frameworks while maintaining flexibility to adapt to region-specific requirements.

Quality control standards for electrolyte components in organoid systems demand particular attention, as variations in electrolyte composition can significantly impact organoid development and functionality. Regulatory agencies increasingly require standardized protocols for electrolyte preparation, storage conditions, and stability testing to ensure batch-to-batch consistency. Documentation of electrolyte purity, concentration ranges, and potential contaminants has become essential for regulatory submissions.

Patient safety considerations represent a primary regulatory focus, with particular emphasis on preventing immunogenic responses to non-autologous organoid systems. The interaction between electrolytes and biological materials must be thoroughly characterized to identify potential toxicity or adverse reactions. Long-term safety monitoring protocols are typically required, especially when novel electrolyte formulations are employed in organoid systems intended for transplantation or personalized medicine applications.

Ethical and consent frameworks present additional regulatory challenges, particularly for organoids derived from patient tissues. Informed consent processes must address tissue sourcing, genetic modification procedures, data privacy, and potential commercialization. The regulatory pathway becomes more complex when electrolyte-optimized organoids are used for patient-specific applications, requiring clear guidelines on ownership rights and intellectual property considerations.

Manufacturing standards for clinical-grade organoid systems incorporating specialized electrolyte formulations must adhere to Good Manufacturing Practice (GMP) requirements. This includes validated processes for electrolyte preparation, environmental monitoring, and contamination control. Regulatory bodies typically require detailed documentation of manufacturing workflows, including equipment qualification, personnel training, and facility certification specific to handling both biological materials and precise electrolyte solutions.

International harmonization efforts are gradually emerging to address regulatory disparities across jurisdictions. Organizations such as the International Council for Harmonisation (ICH) are working toward standardized approaches for novel biological therapies, which may eventually encompass organoid technologies. Developers of electrolyte-optimized organoid systems must navigate these evolving regulatory frameworks while maintaining flexibility to adapt to region-specific requirements.

Scalability and Standardization Challenges

The scaling of organoid culture systems presents significant challenges that must be addressed for widespread adoption in research and clinical applications. Current electrolyte-based organoid culture methods often demonstrate inconsistent results when scaled beyond small laboratory batches. This variability stems from difficulties in maintaining precise electrolyte concentrations across larger volumes, where diffusion rates and concentration gradients become more pronounced. As production scales increase, even minor fluctuations in sodium, potassium, calcium, and other critical ions can dramatically affect organoid development, resulting in heterogeneous populations with variable functionality.

Standardization remains equally problematic, with different laboratories employing diverse protocols for electrolyte composition in culture media. The absence of universally accepted standards for electrolyte formulations creates barriers to reproducibility across research institutions and impedes clinical translation. Notably, the interaction between electrolytes and matrix components introduces additional complexity, as scaling affects the distribution and availability of ions within three-dimensional structures.

Commercial implementation faces further hurdles related to shelf-life and stability of electrolyte-containing media. Many electrolyte solutions demonstrate time-dependent degradation profiles that become more pronounced in large-scale production scenarios. This necessitates the development of specialized storage protocols and stabilizing agents that maintain consistent ionic environments without introducing confounding variables to the culture system.

Regulatory considerations compound these challenges, particularly for clinical applications. Current regulatory frameworks lack specific guidelines for electrolyte composition in organoid culture systems intended for therapeutic use. The establishment of acceptable ranges for each electrolyte species, along with validated testing methodologies, represents a critical gap in the pathway toward standardized manufacturing processes.

Automation offers promising solutions to scaling and standardization challenges. Advanced microfluidic systems capable of continuous monitoring and adjustment of electrolyte concentrations could maintain homeostasis across larger culture volumes. However, the integration of such technologies requires substantial investment in specialized equipment and expertise, creating potential barriers to adoption for smaller research facilities.

Cost considerations also impact scalability, as high-purity electrolyte components and precise monitoring systems represent significant expenses that increase disproportionately with scale. The development of cost-effective alternatives that maintain necessary quality standards will be essential for broader implementation of organoid technologies across diverse research and clinical settings.

Standardization remains equally problematic, with different laboratories employing diverse protocols for electrolyte composition in culture media. The absence of universally accepted standards for electrolyte formulations creates barriers to reproducibility across research institutions and impedes clinical translation. Notably, the interaction between electrolytes and matrix components introduces additional complexity, as scaling affects the distribution and availability of ions within three-dimensional structures.

Commercial implementation faces further hurdles related to shelf-life and stability of electrolyte-containing media. Many electrolyte solutions demonstrate time-dependent degradation profiles that become more pronounced in large-scale production scenarios. This necessitates the development of specialized storage protocols and stabilizing agents that maintain consistent ionic environments without introducing confounding variables to the culture system.

Regulatory considerations compound these challenges, particularly for clinical applications. Current regulatory frameworks lack specific guidelines for electrolyte composition in organoid culture systems intended for therapeutic use. The establishment of acceptable ranges for each electrolyte species, along with validated testing methodologies, represents a critical gap in the pathway toward standardized manufacturing processes.

Automation offers promising solutions to scaling and standardization challenges. Advanced microfluidic systems capable of continuous monitoring and adjustment of electrolyte concentrations could maintain homeostasis across larger culture volumes. However, the integration of such technologies requires substantial investment in specialized equipment and expertise, creating potential barriers to adoption for smaller research facilities.

Cost considerations also impact scalability, as high-purity electrolyte components and precise monitoring systems represent significant expenses that increase disproportionately with scale. The development of cost-effective alternatives that maintain necessary quality standards will be essential for broader implementation of organoid technologies across diverse research and clinical settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!