Organoid Culture Systems in Waste Reduction Technologies

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organoid Culture Systems Background and Objectives

Organoid culture systems represent a revolutionary advancement in biomedical research, offering three-dimensional cellular structures that mimic the architecture and functionality of native organs. Since their emergence in the early 2000s, these systems have evolved from simple aggregates to complex structures incorporating multiple cell types and extracellular matrices. The technology has progressed through several key developmental phases, from basic proof-of-concept models to the current sophisticated systems capable of recapitulating organ-specific functions and disease states.

The evolution of organoid technology has been driven by advances in stem cell biology, tissue engineering, and biomaterials science. Early organoid systems relied heavily on animal-derived matrices and growth factors, resulting in significant biological waste generation and ethical concerns. Recent technological innovations have focused on developing synthetic alternatives and optimizing culture conditions to enhance reproducibility while reducing resource consumption.

The primary objective of research in organoid culture systems for waste reduction is to develop sustainable, efficient, and scalable methodologies that minimize environmental impact while maintaining or improving biological relevance. This includes the creation of fully defined, animal-free culture systems that eliminate dependence on animal-derived components such as Matrigel, which currently dominates the field despite its batch-to-batch variability and ethical implications.

Another critical goal is the optimization of media formulations to reduce the volume of expensive growth factors and supplements required, thereby decreasing both cost and waste. This involves identifying essential signaling pathways and developing targeted approaches to stimulate specific cellular responses with minimal resource input. The development of recyclable or biodegradable culture vessels and microfluidic systems represents another important objective in reducing plastic waste associated with traditional culture methods.

Furthermore, research aims to establish standardized protocols that enhance reproducibility and reduce experimental failure rates, which constitute a significant source of material waste in current organoid research. This includes the development of quality control metrics and automated systems for monitoring organoid growth and functionality.

The long-term technological trajectory points toward fully integrated, closed-loop systems that incorporate waste recycling mechanisms and utilize renewable resources. These advanced platforms would ideally support high-throughput applications in drug discovery, toxicology testing, and personalized medicine while maintaining minimal environmental footprint. The ultimate objective is to transition organoid technology from resource-intensive research tools to sustainable platforms for widespread clinical and industrial applications.

The evolution of organoid technology has been driven by advances in stem cell biology, tissue engineering, and biomaterials science. Early organoid systems relied heavily on animal-derived matrices and growth factors, resulting in significant biological waste generation and ethical concerns. Recent technological innovations have focused on developing synthetic alternatives and optimizing culture conditions to enhance reproducibility while reducing resource consumption.

The primary objective of research in organoid culture systems for waste reduction is to develop sustainable, efficient, and scalable methodologies that minimize environmental impact while maintaining or improving biological relevance. This includes the creation of fully defined, animal-free culture systems that eliminate dependence on animal-derived components such as Matrigel, which currently dominates the field despite its batch-to-batch variability and ethical implications.

Another critical goal is the optimization of media formulations to reduce the volume of expensive growth factors and supplements required, thereby decreasing both cost and waste. This involves identifying essential signaling pathways and developing targeted approaches to stimulate specific cellular responses with minimal resource input. The development of recyclable or biodegradable culture vessels and microfluidic systems represents another important objective in reducing plastic waste associated with traditional culture methods.

Furthermore, research aims to establish standardized protocols that enhance reproducibility and reduce experimental failure rates, which constitute a significant source of material waste in current organoid research. This includes the development of quality control metrics and automated systems for monitoring organoid growth and functionality.

The long-term technological trajectory points toward fully integrated, closed-loop systems that incorporate waste recycling mechanisms and utilize renewable resources. These advanced platforms would ideally support high-throughput applications in drug discovery, toxicology testing, and personalized medicine while maintaining minimal environmental footprint. The ultimate objective is to transition organoid technology from resource-intensive research tools to sustainable platforms for widespread clinical and industrial applications.

Market Analysis for Sustainable Organoid Technologies

The global market for organoid technologies is experiencing significant growth, driven by increasing applications in drug discovery, personalized medicine, and disease modeling. Currently valued at approximately 1.3 billion USD in 2023, the market is projected to reach 3.2 billion USD by 2028, representing a compound annual growth rate (CAGR) of 19.8%. Within this broader landscape, sustainable organoid culture systems focused on waste reduction are emerging as a critical subsegment with substantial growth potential.

The pharmaceutical and biotechnology sectors represent the largest market share for organoid technologies, accounting for roughly 65% of the total market. These industries are increasingly adopting organoid models to reduce animal testing and improve drug development efficiency, with an estimated 30% reduction in preclinical testing costs when implementing advanced organoid systems. Academic and research institutions constitute approximately 25% of the market, while healthcare providers and other end-users make up the remaining 10%.

Regionally, North America dominates the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, primarily due to increasing research investments in countries like China, Japan, and South Korea.

The sustainable organoid technologies market is being shaped by several key drivers. Stringent environmental regulations regarding laboratory waste management are compelling research facilities to adopt more sustainable practices. The average research laboratory produces approximately 5.5 million tons of plastic waste annually, with organoid research contributing significantly to this figure. Sustainable organoid culture systems can potentially reduce this waste by 40-60%.

Cost considerations also play a crucial role in market dynamics. Traditional organoid culture systems generate substantial operational expenses, with waste disposal costs accounting for approximately 15-20% of total research budgets. Sustainable alternatives offer potential savings of 25-35% on these disposal costs while simultaneously reducing environmental impact.

Consumer and stakeholder pressure for environmentally responsible research practices is intensifying, with over 70% of research institutions reporting increased scrutiny regarding their environmental footprint. This has led to a 40% increase in demand for sustainable laboratory technologies over the past three years.

The market for sustainable organoid technologies faces certain challenges, including higher initial investment costs (typically 30-40% more than conventional systems) and technical limitations in scaling sustainable practices. However, the long-term economic and environmental benefits are driving continued market expansion and technological innovation in this sector.

The pharmaceutical and biotechnology sectors represent the largest market share for organoid technologies, accounting for roughly 65% of the total market. These industries are increasingly adopting organoid models to reduce animal testing and improve drug development efficiency, with an estimated 30% reduction in preclinical testing costs when implementing advanced organoid systems. Academic and research institutions constitute approximately 25% of the market, while healthcare providers and other end-users make up the remaining 10%.

Regionally, North America dominates the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, primarily due to increasing research investments in countries like China, Japan, and South Korea.

The sustainable organoid technologies market is being shaped by several key drivers. Stringent environmental regulations regarding laboratory waste management are compelling research facilities to adopt more sustainable practices. The average research laboratory produces approximately 5.5 million tons of plastic waste annually, with organoid research contributing significantly to this figure. Sustainable organoid culture systems can potentially reduce this waste by 40-60%.

Cost considerations also play a crucial role in market dynamics. Traditional organoid culture systems generate substantial operational expenses, with waste disposal costs accounting for approximately 15-20% of total research budgets. Sustainable alternatives offer potential savings of 25-35% on these disposal costs while simultaneously reducing environmental impact.

Consumer and stakeholder pressure for environmentally responsible research practices is intensifying, with over 70% of research institutions reporting increased scrutiny regarding their environmental footprint. This has led to a 40% increase in demand for sustainable laboratory technologies over the past three years.

The market for sustainable organoid technologies faces certain challenges, including higher initial investment costs (typically 30-40% more than conventional systems) and technical limitations in scaling sustainable practices. However, the long-term economic and environmental benefits are driving continued market expansion and technological innovation in this sector.

Current Challenges in Organoid Waste Management

Organoid culture systems, while revolutionary in biomedical research, face significant waste management challenges that impede their broader adoption and environmental sustainability. The primary concern stems from the extensive use of single-use plastics in culture vessels, pipettes, and other laboratory consumables. These materials, often contaminated with biological substances, require specialized disposal protocols and contribute substantially to research-related waste streams.

Media composition presents another critical challenge, as organoid cultures typically require complex, nutrient-rich environments containing growth factors, extracellular matrix components, and supplements. The disposal of unused or expired media raises concerns regarding potential biological contamination and pharmaceutical residues entering wastewater systems. Current regulations often mandate chemical treatment before disposal, adding complexity and cost to waste management protocols.

Extracellular matrix (ECM) components, particularly Matrigel and similar hydrogels derived from animal sources, represent both a scientific and waste management challenge. These temperature-sensitive materials require careful handling and, once used, contain cellular material that necessitates biohazard treatment. The animal-derived nature of these substances also raises ethical considerations and regulatory complications for waste processing.

Cross-contamination risks further complicate waste management strategies. Organoids from different sources or those genetically modified must be handled according to distinct containment protocols, requiring segregated waste streams and specialized treatment methods. This differentiation increases the complexity of laboratory waste management systems and demands additional resources for compliance.

Scale-up issues emerge as organoid technologies transition from research to industrial applications. While laboratory-scale waste can be managed through existing protocols, commercial-scale organoid production generates substantially larger waste volumes that current systems are ill-equipped to handle efficiently. The absence of standardized waste reduction protocols specifically designed for large-scale organoid culture operations represents a significant gap in the field.

Economic barriers also hinder progress in waste reduction. The high cost of organoid culture components incentivizes researchers to prioritize experimental success over waste minimization. Additionally, the specialized equipment required for waste processing and treatment represents a substantial investment that many research institutions find difficult to justify, particularly when waste management does not directly contribute to research outcomes.

Regulatory inconsistencies across different regions create additional complications, as varying standards for biological waste disposal necessitate different approaches depending on geographic location. This regulatory fragmentation impedes the development of universal waste reduction strategies and complicates compliance for multinational research organizations.

Media composition presents another critical challenge, as organoid cultures typically require complex, nutrient-rich environments containing growth factors, extracellular matrix components, and supplements. The disposal of unused or expired media raises concerns regarding potential biological contamination and pharmaceutical residues entering wastewater systems. Current regulations often mandate chemical treatment before disposal, adding complexity and cost to waste management protocols.

Extracellular matrix (ECM) components, particularly Matrigel and similar hydrogels derived from animal sources, represent both a scientific and waste management challenge. These temperature-sensitive materials require careful handling and, once used, contain cellular material that necessitates biohazard treatment. The animal-derived nature of these substances also raises ethical considerations and regulatory complications for waste processing.

Cross-contamination risks further complicate waste management strategies. Organoids from different sources or those genetically modified must be handled according to distinct containment protocols, requiring segregated waste streams and specialized treatment methods. This differentiation increases the complexity of laboratory waste management systems and demands additional resources for compliance.

Scale-up issues emerge as organoid technologies transition from research to industrial applications. While laboratory-scale waste can be managed through existing protocols, commercial-scale organoid production generates substantially larger waste volumes that current systems are ill-equipped to handle efficiently. The absence of standardized waste reduction protocols specifically designed for large-scale organoid culture operations represents a significant gap in the field.

Economic barriers also hinder progress in waste reduction. The high cost of organoid culture components incentivizes researchers to prioritize experimental success over waste minimization. Additionally, the specialized equipment required for waste processing and treatment represents a substantial investment that many research institutions find difficult to justify, particularly when waste management does not directly contribute to research outcomes.

Regulatory inconsistencies across different regions create additional complications, as varying standards for biological waste disposal necessitate different approaches depending on geographic location. This regulatory fragmentation impedes the development of universal waste reduction strategies and complicates compliance for multinational research organizations.

Current Waste Reduction Solutions for Organoid Systems

01 Optimized media recycling systems

Advanced systems for recycling culture media in organoid cultivation can significantly reduce waste. These systems filter and replenish depleted nutrients while removing metabolic waste products, allowing the same base media to be used for multiple culture cycles. This approach not only minimizes the volume of discarded media but also reduces the consumption of expensive growth factors and supplements, making organoid culture more sustainable and cost-effective.- Optimized media recycling systems: Advanced systems for recycling culture media in organoid systems can significantly reduce waste. These systems filter and replenish depleted nutrients while removing metabolic waste products, allowing the media to be reused for multiple culture cycles. This approach not only reduces the volume of discarded media but also maintains optimal growth conditions for organoids, ensuring experimental consistency while minimizing environmental impact.

- Miniaturized culture platforms: Miniaturized organoid culture platforms utilize microfluidic technology and specialized vessel designs to dramatically reduce the required volumes of growth media and reagents. These systems maintain organoid viability and functionality while using a fraction of the materials needed in conventional culture methods. The reduced scale leads to significant waste reduction while potentially improving experimental throughput and reducing costs associated with expensive growth factors and supplements.

- Biodegradable and sustainable culture materials: The development of biodegradable and sustainable materials for organoid culture vessels, matrices, and accessories addresses the environmental impact of plastic waste in laboratory settings. These innovations include plant-derived hydrogels as alternatives to animal-derived matrices, compostable culture plates, and recyclable support structures. Such materials maintain the necessary properties for successful organoid culture while significantly reducing non-biodegradable waste generation.

- Automated culture management systems: Automated systems for organoid culture management incorporate sensors and precision control mechanisms to optimize media usage and reduce waste. These systems monitor nutrient levels, metabolite concentrations, and organoid health in real-time, dispensing exact amounts of media and supplements only when needed. The precision control eliminates excess media preparation and reduces disposal of unused reagents, while maintaining optimal growth conditions for organoids.

- Cryopreservation and biobanking optimization: Advanced cryopreservation techniques specifically designed for organoids enable long-term storage with improved viability upon thawing. These methods reduce waste by eliminating the need for continuous culture maintenance and repeated generation of organoids. Optimized freezing protocols, specialized cryoprotectants, and controlled thawing procedures ensure that valuable organoid cultures can be preserved efficiently, reducing the resources required for ongoing culture and minimizing disposal of excess biological material.

02 Miniaturized culture platforms

Miniaturized organoid culture platforms utilize microfluidic technology and specialized vessel designs to dramatically reduce the required volumes of media and reagents. These systems maintain optimal growth conditions while using a fraction of the materials needed in conventional culture methods. By scaling down the culture environment without compromising organoid development or function, these platforms significantly decrease waste generation while enabling higher throughput experimentation.Expand Specific Solutions03 Biodegradable and sustainable scaffolding materials

Incorporating biodegradable scaffolding materials in organoid culture systems reduces environmental impact. These materials provide structural support for organoid development and can be naturally broken down after use, minimizing non-recyclable waste. Sustainable alternatives to traditional petroleum-based plastics include plant-derived hydrogels, cellulose-based matrices, and other biocompatible polymers that maintain optimal growth conditions while reducing the ecological footprint of organoid research.Expand Specific Solutions04 Automated culture maintenance systems

Automated systems for organoid culture maintenance optimize resource usage through precise control of environmental conditions and feeding schedules. These systems use sensors to monitor nutrient levels, pH, and metabolic activity, dispensing exact amounts of media and supplements only when needed. By eliminating human error and preventing over-feeding, automated maintenance systems reduce waste while improving reproducibility and standardization in organoid culture.Expand Specific Solutions05 Cryopreservation and biobanking optimization

Improved cryopreservation techniques for organoids minimize waste by reducing the need for continuous culture maintenance. These methods allow researchers to freeze organoids at various developmental stages for later use, decreasing the resources required for ongoing cultivation. Optimized freezing protocols and cryoprotectants maintain organoid viability and functionality after thawing, enabling more efficient use of materials and reducing the environmental impact of long-term organoid research programs.Expand Specific Solutions

Leading Organizations in Sustainable Organoid Research

The organoid culture systems market for waste reduction technologies is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding rapidly, driven by the growing demand for sustainable waste management solutions and the integration of biotechnology in environmental applications. Technologically, the field is still evolving, with varying degrees of maturity across different applications. Leading players like FUJIFILM Corp. and Molecular Devices are advancing hardware platforms, while research-focused entities such as Genome Research Ltd. and Cell Microsystems are developing specialized culture systems. Academic-industry partnerships, exemplified by collaborations with institutions like University of Washington and Oxford University Innovation, are accelerating technology transfer. Companies like Organoidsciences Ltd. and CYTOO SA are pioneering specialized organoid applications, indicating a competitive landscape that balances established biotech firms with innovative startups.

Organoidsciences Ltd.

Technical Solution: Organoidsciences has developed a closed-loop organoid culture system that significantly reduces waste through automated media recycling and purification. Their platform incorporates microfluidic technology that continuously filters and replenishes culture media while removing metabolic waste products, reducing media consumption by up to 70% compared to traditional methods. The system features integrated sensors that monitor nutrient levels and cellular metabolites in real-time, allowing precise control over media exchange rates and minimizing unnecessary disposal. Additionally, their biodegradable scaffolding materials are designed to support organoid growth while being environmentally sustainable, breaking down into non-toxic components after use.

Strengths: Highly specialized in organoid-specific waste reduction; closed-loop system significantly reduces media consumption; real-time monitoring enables precise resource management. Weaknesses: Specialized equipment may require substantial initial investment; system complexity could present maintenance challenges; technology may be limited to specific organoid types.

CYTOO SA

Technical Solution: CYTOO SA has developed an advanced micropattern-based organoid culture system that substantially reduces waste through precise control of cellular microenvironments. Their technology utilizes micropatterned adhesive islands that guide organoid formation with minimal matrix requirements, reducing extracellular matrix waste by approximately 60%. The system incorporates a gradient-generating microfluidic platform that creates optimized microenvironments with minimal media consumption, allowing for up to 75% reduction in culture media usage compared to conventional methods. CYTOO's approach also features reusable culture chambers with specialized surface treatments that maintain functionality through multiple sterilization cycles, significantly reducing plastic waste. Their platform includes automated media exchange systems that recycle and repurify spent media, extracting valuable components while removing waste products.

Strengths: Precise microenvironment control enables significant reduction in matrix materials; reusable components dramatically reduce plastic waste; automated systems optimize media recycling. Weaknesses: Higher technical complexity may limit accessibility; requires specialized equipment for optimal performance; initial setup costs may be prohibitive for smaller laboratories.

Key Innovations in Organoid Culture Efficiency

Engineering of organoid culture for enhanced organogenesis in a dish

PatentPendingUS20240026261A1

Innovation

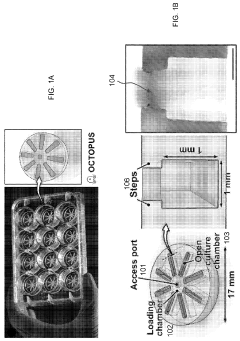

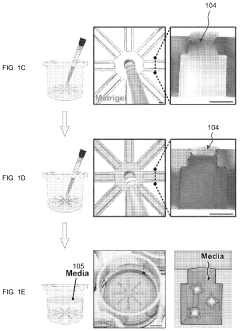

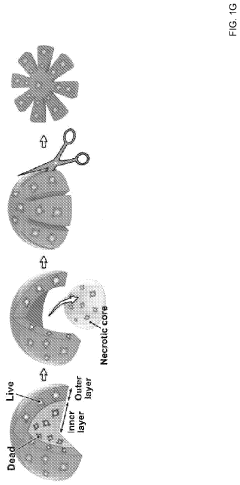

- The OCTOPUS device provides a 3D culture system with radially arranged culture chambers that reduce diffusion limitations by allowing unrestricted access to nutrients and oxygen, enabling continuous culture of organoids for extended periods without passaging, using a simple and scalable design compatible with standard cell culture plates.

An automated system and method to produce a personalized 3D printed organoids

PatentWO2024189652A1

Innovation

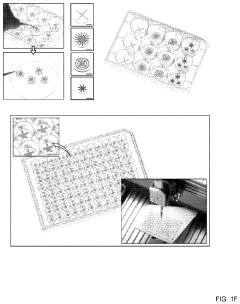

- A completely automated controller-assisted bioreactor system capable of digesting and 3D printing patient-derived biopsies or cell lines to produce personalized, patient-specific organoids that mimic disease models, incorporating a bioink preparation unit, magnetic sorting, and precise environmental control for cell proliferation and bio-ink extrusion.

Environmental Impact Assessment of Organoid Research

The environmental impact of organoid research extends far beyond the laboratory walls, encompassing both positive and negative effects on our ecosystem. Organoid culture systems, while revolutionary for biomedical research, generate significant waste streams that require careful management and innovative reduction strategies.

Traditional cell culture methods typically produce substantial plastic waste, including disposable culture plates, pipettes, and media containers. Organoid research often amplifies this issue due to the complex three-dimensional culture systems required, which may involve specialized matrices, growth factors, and maintenance protocols. Preliminary assessments indicate that a single organoid research laboratory can generate up to 1-2 tons of plastic waste annually, contributing to the broader environmental challenges facing scientific research.

Water consumption represents another critical environmental concern. Organoid culture systems require frequent media changes and washing steps, resulting in substantial water usage and contaminated wastewater containing biological materials and chemical compounds. This wastewater often contains residual growth factors, antibiotics, and cellular debris that may pose environmental risks if not properly treated before discharge.

Energy consumption in organoid research also warrants attention. The maintenance of sterile conditions, precise temperature control, and continuous monitoring systems all contribute to a significant carbon footprint. Incubators, biosafety cabinets, and automated culture systems operate continuously, consuming electricity and contributing to greenhouse gas emissions when powered by non-renewable energy sources.

Chemical waste from organoid research presents unique environmental challenges. Specialized growth factors, extracellular matrix components, and differentiation agents may contain compounds with unknown environmental persistence and ecotoxicological profiles. The disposal of these materials requires careful consideration to prevent potential ecosystem disruption or bioaccumulation in environmental compartments.

Recent life cycle assessments of organoid research facilities have identified opportunities for environmental impact reduction. Implementing closed-loop systems for media recycling could reduce both water consumption and chemical waste generation by 30-40%. Additionally, transitioning to biodegradable or reusable culture materials could significantly decrease plastic waste, though such alternatives must maintain the sterility and precision required for successful organoid development.

The environmental footprint of organoid research must be balanced against its potential benefits in reducing animal testing and accelerating therapeutic development. Comprehensive environmental management strategies, including waste reduction protocols, energy efficiency measures, and responsible disposal practices, are essential for ensuring that advances in organoid technology contribute positively to both human health and environmental sustainability.

Traditional cell culture methods typically produce substantial plastic waste, including disposable culture plates, pipettes, and media containers. Organoid research often amplifies this issue due to the complex three-dimensional culture systems required, which may involve specialized matrices, growth factors, and maintenance protocols. Preliminary assessments indicate that a single organoid research laboratory can generate up to 1-2 tons of plastic waste annually, contributing to the broader environmental challenges facing scientific research.

Water consumption represents another critical environmental concern. Organoid culture systems require frequent media changes and washing steps, resulting in substantial water usage and contaminated wastewater containing biological materials and chemical compounds. This wastewater often contains residual growth factors, antibiotics, and cellular debris that may pose environmental risks if not properly treated before discharge.

Energy consumption in organoid research also warrants attention. The maintenance of sterile conditions, precise temperature control, and continuous monitoring systems all contribute to a significant carbon footprint. Incubators, biosafety cabinets, and automated culture systems operate continuously, consuming electricity and contributing to greenhouse gas emissions when powered by non-renewable energy sources.

Chemical waste from organoid research presents unique environmental challenges. Specialized growth factors, extracellular matrix components, and differentiation agents may contain compounds with unknown environmental persistence and ecotoxicological profiles. The disposal of these materials requires careful consideration to prevent potential ecosystem disruption or bioaccumulation in environmental compartments.

Recent life cycle assessments of organoid research facilities have identified opportunities for environmental impact reduction. Implementing closed-loop systems for media recycling could reduce both water consumption and chemical waste generation by 30-40%. Additionally, transitioning to biodegradable or reusable culture materials could significantly decrease plastic waste, though such alternatives must maintain the sterility and precision required for successful organoid development.

The environmental footprint of organoid research must be balanced against its potential benefits in reducing animal testing and accelerating therapeutic development. Comprehensive environmental management strategies, including waste reduction protocols, energy efficiency measures, and responsible disposal practices, are essential for ensuring that advances in organoid technology contribute positively to both human health and environmental sustainability.

Regulatory Framework for Biomedical Waste Management

The regulatory landscape governing organoid culture systems in biomedical waste management is complex and multifaceted, spanning international, national, and local jurisdictions. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides the foundational framework for managing biomedical waste across borders, with specific provisions that can be applied to organoid research waste.

In the United States, the Environmental Protection Agency (EPA) under the Resource Conservation and Recovery Act (RCRA) classifies biomedical waste from organoid research as potentially hazardous, requiring specific handling protocols. Complementing this, the Occupational Safety and Health Administration (OSHA) has established Bloodborne Pathogens Standards that directly impact laboratories working with human-derived organoids, mandating strict waste segregation and disposal procedures.

The European Union operates under the Waste Framework Directive (2008/98/EC) and has recently updated its regulations through Directive 2018/851 to specifically address emerging biotechnologies, including organoid culture systems. These directives emphasize waste hierarchy principles—prevention, reuse, recycling, recovery, and disposal—with particular emphasis on minimizing hazardous waste generation from advanced biological research.

Asian regulatory frameworks show significant variation, with Japan's Waste Management and Public Cleansing Law and China's National Catalogue of Hazardous Wastes both recently updated to incorporate provisions for advanced biological research waste. Singapore has emerged as a leader in this space, implementing the Environmental Public Health (Toxic Industrial Waste) Regulations with specific provisions for biomedical research facilities engaged in organoid research.

Regulatory compliance for organoid culture systems typically requires comprehensive waste management plans that include detailed documentation of waste generation, segregation protocols based on risk categories, treatment methodologies, and final disposal verification. Many jurisdictions mandate regular audits and reporting of waste volumes and disposal methods, with significant penalties for non-compliance.

Recent regulatory trends indicate a shift toward more stringent oversight of biomedical waste from advanced research platforms, with increasing focus on environmental impact assessments and sustainability metrics. Several jurisdictions are developing specialized guidelines for organoid research waste that balance biosafety concerns with sustainability objectives, recognizing the unique challenges posed by these innovative culture systems.

In the United States, the Environmental Protection Agency (EPA) under the Resource Conservation and Recovery Act (RCRA) classifies biomedical waste from organoid research as potentially hazardous, requiring specific handling protocols. Complementing this, the Occupational Safety and Health Administration (OSHA) has established Bloodborne Pathogens Standards that directly impact laboratories working with human-derived organoids, mandating strict waste segregation and disposal procedures.

The European Union operates under the Waste Framework Directive (2008/98/EC) and has recently updated its regulations through Directive 2018/851 to specifically address emerging biotechnologies, including organoid culture systems. These directives emphasize waste hierarchy principles—prevention, reuse, recycling, recovery, and disposal—with particular emphasis on minimizing hazardous waste generation from advanced biological research.

Asian regulatory frameworks show significant variation, with Japan's Waste Management and Public Cleansing Law and China's National Catalogue of Hazardous Wastes both recently updated to incorporate provisions for advanced biological research waste. Singapore has emerged as a leader in this space, implementing the Environmental Public Health (Toxic Industrial Waste) Regulations with specific provisions for biomedical research facilities engaged in organoid research.

Regulatory compliance for organoid culture systems typically requires comprehensive waste management plans that include detailed documentation of waste generation, segregation protocols based on risk categories, treatment methodologies, and final disposal verification. Many jurisdictions mandate regular audits and reporting of waste volumes and disposal methods, with significant penalties for non-compliance.

Recent regulatory trends indicate a shift toward more stringent oversight of biomedical waste from advanced research platforms, with increasing focus on environmental impact assessments and sustainability metrics. Several jurisdictions are developing specialized guidelines for organoid research waste that balance biosafety concerns with sustainability objectives, recognizing the unique challenges posed by these innovative culture systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!