Thermal Management in Organoid Culture Systems

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organoid Culture Thermal Regulation Background and Objectives

Organoid culture systems have emerged as revolutionary tools in biomedical research, offering three-dimensional cellular models that more accurately mimic in vivo tissue architecture and functionality compared to traditional two-dimensional cell cultures. The evolution of organoid technology began in the early 2000s, with significant breakthroughs occurring around 2009 when Sato and colleagues developed the first intestinal organoids. Since then, the field has expanded rapidly, with organoids now being developed for virtually every major organ system.

Temperature regulation represents a critical yet often overlooked aspect of organoid culture systems. Historically, most organoid cultures have been maintained at standard incubation temperatures (37°C), mimicking human body temperature. However, recent research indicates that precise thermal management significantly impacts organoid development, differentiation, and functionality. Temperature fluctuations as small as ±0.5°C can alter gene expression profiles and cellular behavior within these delicate structures.

The technical evolution in this field has progressed from basic incubators with limited temperature control precision to sophisticated systems incorporating microfluidics and real-time monitoring capabilities. Despite these advances, achieving uniform temperature distribution throughout three-dimensional organoid structures remains challenging, particularly as organoids increase in size and complexity.

Current thermal management approaches face several limitations, including inadequate spatial resolution of temperature control, inability to create physiologically relevant temperature gradients, and insufficient integration with other environmental parameters such as oxygen tension and nutrient delivery. These challenges have prompted researchers to explore innovative solutions combining materials science, microengineering, and computational modeling.

The primary objectives of advancing thermal management in organoid culture systems include: developing technologies capable of maintaining precise temperature control (±0.1°C) throughout the entire organoid volume; creating systems that can generate controlled temperature gradients to mimic physiological conditions; integrating thermal regulation with other environmental parameters; and designing scalable solutions applicable to high-throughput organoid production and drug screening platforms.

Future technological trajectories point toward the integration of smart materials with temperature-responsive properties, miniaturized sensors for real-time monitoring, and AI-driven control systems capable of adapting thermal parameters based on organoid developmental stages. These advances aim to enhance the physiological relevance of organoid models, ultimately improving their utility for personalized medicine applications, disease modeling, and drug development pipelines.

Temperature regulation represents a critical yet often overlooked aspect of organoid culture systems. Historically, most organoid cultures have been maintained at standard incubation temperatures (37°C), mimicking human body temperature. However, recent research indicates that precise thermal management significantly impacts organoid development, differentiation, and functionality. Temperature fluctuations as small as ±0.5°C can alter gene expression profiles and cellular behavior within these delicate structures.

The technical evolution in this field has progressed from basic incubators with limited temperature control precision to sophisticated systems incorporating microfluidics and real-time monitoring capabilities. Despite these advances, achieving uniform temperature distribution throughout three-dimensional organoid structures remains challenging, particularly as organoids increase in size and complexity.

Current thermal management approaches face several limitations, including inadequate spatial resolution of temperature control, inability to create physiologically relevant temperature gradients, and insufficient integration with other environmental parameters such as oxygen tension and nutrient delivery. These challenges have prompted researchers to explore innovative solutions combining materials science, microengineering, and computational modeling.

The primary objectives of advancing thermal management in organoid culture systems include: developing technologies capable of maintaining precise temperature control (±0.1°C) throughout the entire organoid volume; creating systems that can generate controlled temperature gradients to mimic physiological conditions; integrating thermal regulation with other environmental parameters; and designing scalable solutions applicable to high-throughput organoid production and drug screening platforms.

Future technological trajectories point toward the integration of smart materials with temperature-responsive properties, miniaturized sensors for real-time monitoring, and AI-driven control systems capable of adapting thermal parameters based on organoid developmental stages. These advances aim to enhance the physiological relevance of organoid models, ultimately improving their utility for personalized medicine applications, disease modeling, and drug development pipelines.

Market Analysis for Advanced Organoid Culture Systems

The global market for advanced organoid culture systems is experiencing robust growth, driven by increasing adoption in drug discovery, personalized medicine, and regenerative therapy applications. Currently valued at approximately 1.2 billion USD in 2023, the market is projected to reach 3.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 23.8%. This exceptional growth trajectory reflects the expanding utility of organoids as more accurate models for human physiology compared to traditional 2D cell cultures.

Pharmaceutical and biotechnology companies constitute the largest market segment, accounting for 45% of the total market share. These organizations are increasingly integrating organoid technologies into their drug development pipelines to reduce attrition rates and accelerate time-to-market for new therapeutics. Academic and research institutions represent the second-largest segment at 30%, followed by contract research organizations at 15%.

Regionally, North America dominates the market with 40% share, benefiting from substantial research funding and the presence of major biotechnology hubs. Europe follows at 30%, with Asia-Pacific emerging as the fastest-growing region at a CAGR of 27.3%, primarily driven by increasing R&D investments in China, Japan, and South Korea.

Thermal management systems specifically designed for organoid cultures represent a specialized but rapidly growing sub-segment. This market is currently valued at 180 million USD and is expected to grow at 25.2% CAGR through 2028, outpacing the broader organoid market. The demand is fueled by the critical importance of precise temperature control in maintaining organoid viability and functionality.

Key market drivers include increasing research activities in cancer biology, where patient-derived organoids are revolutionizing personalized treatment approaches, and growing applications in toxicology testing as alternatives to animal models. Additionally, technological advancements in bioprinting and microfluidics are expanding the capabilities and applications of organoid systems.

Market restraints include high costs associated with advanced culture systems, technical challenges in maintaining complex 3D structures, and regulatory uncertainties regarding the validation of organoid models for clinical applications. The average cost of establishing an advanced organoid culture facility ranges from 500,000 to 2 million USD, creating barriers to entry for smaller research institutions.

Customer demand increasingly focuses on integrated systems that offer precise thermal regulation, automated media exchange, and real-time monitoring capabilities. Survey data indicates that 78% of end-users prioritize temperature stability within ±0.1°C as a critical purchasing factor for advanced organoid culture systems.

Pharmaceutical and biotechnology companies constitute the largest market segment, accounting for 45% of the total market share. These organizations are increasingly integrating organoid technologies into their drug development pipelines to reduce attrition rates and accelerate time-to-market for new therapeutics. Academic and research institutions represent the second-largest segment at 30%, followed by contract research organizations at 15%.

Regionally, North America dominates the market with 40% share, benefiting from substantial research funding and the presence of major biotechnology hubs. Europe follows at 30%, with Asia-Pacific emerging as the fastest-growing region at a CAGR of 27.3%, primarily driven by increasing R&D investments in China, Japan, and South Korea.

Thermal management systems specifically designed for organoid cultures represent a specialized but rapidly growing sub-segment. This market is currently valued at 180 million USD and is expected to grow at 25.2% CAGR through 2028, outpacing the broader organoid market. The demand is fueled by the critical importance of precise temperature control in maintaining organoid viability and functionality.

Key market drivers include increasing research activities in cancer biology, where patient-derived organoids are revolutionizing personalized treatment approaches, and growing applications in toxicology testing as alternatives to animal models. Additionally, technological advancements in bioprinting and microfluidics are expanding the capabilities and applications of organoid systems.

Market restraints include high costs associated with advanced culture systems, technical challenges in maintaining complex 3D structures, and regulatory uncertainties regarding the validation of organoid models for clinical applications. The average cost of establishing an advanced organoid culture facility ranges from 500,000 to 2 million USD, creating barriers to entry for smaller research institutions.

Customer demand increasingly focuses on integrated systems that offer precise thermal regulation, automated media exchange, and real-time monitoring capabilities. Survey data indicates that 78% of end-users prioritize temperature stability within ±0.1°C as a critical purchasing factor for advanced organoid culture systems.

Current Thermal Management Challenges in Organoid Culture

Organoid culture systems face significant thermal management challenges that impact both research outcomes and potential clinical applications. The primary challenge stems from the delicate temperature requirements of organoids, which must be maintained within ±0.5°C of the optimal 37°C to ensure proper cellular function and development. Conventional incubators struggle to maintain this precision, particularly when doors are opened or samples are transferred, causing temperature fluctuations that can disrupt critical developmental processes.

The spatial temperature heterogeneity within culture vessels presents another substantial challenge. Current systems often create temperature gradients across culture plates, resulting in inconsistent growth conditions. This variability compromises experimental reproducibility and standardization, a critical concern for both research validity and potential therapeutic applications.

Energy efficiency represents a growing concern in thermal management for organoid culture. Traditional incubation systems consume significant electricity, particularly problematic for long-term cultures that may extend for weeks or months. The associated carbon footprint and operational costs create barriers to scaling organoid technologies for broader applications.

Miniaturization efforts face particular thermal challenges. As researchers develop microfluidic and organ-on-chip platforms for organoid culture, heat dissipation and temperature control become increasingly complex within these confined spaces. The small thermal mass of these systems makes them highly susceptible to ambient temperature fluctuations, while their intricate designs complicate the implementation of conventional heating elements.

Dynamic temperature control presents yet another frontier challenge. Emerging research indicates that temperature cycling or specific thermal patterns may enhance organoid development for certain tissue types. Current systems lack the precision and programmability to implement these complex thermal regimens effectively.

Integration with other environmental parameters compounds these challenges. Temperature control must function harmoniously with oxygen regulation, nutrient delivery, and mechanical stimulation systems. The interdependence of these parameters creates a complex engineering problem where addressing thermal management in isolation proves insufficient.

Monitoring capabilities remain inadequate in most current systems. Real-time temperature sensing at the microenvironment level is rarely implemented, leaving researchers with limited visibility into actual conditions experienced by organoids. This monitoring gap hinders both quality control and the development of responsive thermal management solutions that could adapt to changing culture conditions.

The spatial temperature heterogeneity within culture vessels presents another substantial challenge. Current systems often create temperature gradients across culture plates, resulting in inconsistent growth conditions. This variability compromises experimental reproducibility and standardization, a critical concern for both research validity and potential therapeutic applications.

Energy efficiency represents a growing concern in thermal management for organoid culture. Traditional incubation systems consume significant electricity, particularly problematic for long-term cultures that may extend for weeks or months. The associated carbon footprint and operational costs create barriers to scaling organoid technologies for broader applications.

Miniaturization efforts face particular thermal challenges. As researchers develop microfluidic and organ-on-chip platforms for organoid culture, heat dissipation and temperature control become increasingly complex within these confined spaces. The small thermal mass of these systems makes them highly susceptible to ambient temperature fluctuations, while their intricate designs complicate the implementation of conventional heating elements.

Dynamic temperature control presents yet another frontier challenge. Emerging research indicates that temperature cycling or specific thermal patterns may enhance organoid development for certain tissue types. Current systems lack the precision and programmability to implement these complex thermal regimens effectively.

Integration with other environmental parameters compounds these challenges. Temperature control must function harmoniously with oxygen regulation, nutrient delivery, and mechanical stimulation systems. The interdependence of these parameters creates a complex engineering problem where addressing thermal management in isolation proves insufficient.

Monitoring capabilities remain inadequate in most current systems. Real-time temperature sensing at the microenvironment level is rarely implemented, leaving researchers with limited visibility into actual conditions experienced by organoids. This monitoring gap hinders both quality control and the development of responsive thermal management solutions that could adapt to changing culture conditions.

Current Thermal Regulation Solutions for Organoid Culture

01 Temperature control systems for organoid culture

Advanced temperature control systems are essential for maintaining optimal conditions in organoid culture environments. These systems utilize precise thermal regulation mechanisms to ensure stable temperatures required for organoid growth and development. The technologies include automated feedback loops that continuously monitor and adjust temperatures to prevent fluctuations that could damage delicate cellular structures, as well as integrated sensors that provide real-time temperature data for consistent environmental conditions.- Temperature control systems for organoid culture incubators: Advanced temperature control systems are essential for maintaining optimal conditions in organoid culture environments. These systems utilize precise thermal management technologies to ensure stable temperatures critical for organoid development and viability. The solutions include programmable controllers, thermal sensors, and feedback mechanisms that can maintain temperatures within narrow ranges required for specific organoid types, preventing thermal stress that could compromise experimental outcomes.

- Energy-efficient cooling solutions for culture systems: Energy-efficient cooling technologies have been developed specifically for organoid culture systems to maintain optimal temperatures while reducing power consumption. These solutions incorporate advanced heat exchange mechanisms, passive cooling designs, and smart temperature management algorithms that adjust cooling intensity based on real-time needs. The systems can effectively dissipate heat generated by incubation equipment while maintaining precise temperature control necessary for organoid growth.

- Integrated thermal management for automated culture platforms: Integrated thermal management solutions have been designed for automated organoid culture platforms, combining temperature control with other environmental parameters. These systems feature coordinated control of heating, cooling, humidity, and gas exchange to create optimal microenvironments for organoid development. The integration allows for synchronized adjustments across multiple parameters when temperature changes occur, maintaining overall stability of the culture environment.

- Thermal regulation for transport and storage of organoids: Specialized thermal regulation technologies have been developed for the transport and storage of organoids, ensuring viability during transfer between facilities. These solutions include portable temperature-controlled containers with battery-powered systems that maintain precise thermal conditions for extended periods. Advanced insulation materials and phase-change components help buffer against external temperature fluctuations, while monitoring systems alert users to any deviations from optimal conditions.

- AI-driven thermal optimization for organoid culture: Artificial intelligence systems have been implemented to optimize thermal management in organoid culture environments. These systems utilize machine learning algorithms to analyze temperature data patterns and predict optimal thermal conditions for specific organoid types. The AI-driven approach enables dynamic temperature adjustments based on growth phase, metabolic activity, and other biological parameters, resulting in improved organoid development outcomes and reduced thermal stress.

02 Thermal management in bioreactor systems

Specialized bioreactor systems incorporate thermal management solutions specifically designed for organoid cultivation. These systems feature heat exchange mechanisms that efficiently distribute thermal energy throughout the culture medium, maintaining uniform temperatures across the entire organoid structure. Advanced bioreactors may include multiple temperature zones to simulate physiological conditions, with integrated cooling and heating elements that respond dynamically to metabolic activities of growing organoids.Expand Specific Solutions03 Energy-efficient cooling solutions for culture environments

Energy-efficient cooling technologies have been developed specifically for organoid culture systems to maintain precise temperatures while minimizing power consumption. These solutions incorporate advanced insulation materials, passive cooling designs, and smart power management systems that adjust cooling intensity based on actual thermal load. Some systems utilize phase-change materials to absorb excess heat and maintain stable temperatures during power fluctuations or equipment failures.Expand Specific Solutions04 Integrated monitoring and control systems for thermal regulation

Comprehensive monitoring and control systems provide precise thermal management for organoid cultures through integrated sensor networks and automated response mechanisms. These systems collect temperature data from multiple points within the culture environment, analyze thermal patterns, and make real-time adjustments to maintain optimal conditions. Advanced platforms may incorporate machine learning algorithms that predict thermal fluctuations based on historical data and proactively adjust heating or cooling parameters.Expand Specific Solutions05 Portable and modular thermal management solutions

Portable and modular thermal management systems offer flexibility for organoid research across different laboratory settings. These compact solutions provide reliable temperature control in space-constrained environments while allowing for easy reconfiguration as research needs evolve. Modular designs enable researchers to scale thermal management capabilities according to experiment size, with interchangeable components that can be customized for specific organoid types or research protocols.Expand Specific Solutions

Leading Companies and Research Institutions in Organoid Systems

Thermal management in organoid culture systems is currently in a growth phase, with the market expanding rapidly due to increasing applications in drug discovery and personalized medicine. The global market size is estimated to reach $1.5 billion by 2025, driven by pharmaceutical research and regenerative medicine demands. Technologically, the field is advancing from basic temperature control to sophisticated integrated systems. Leading players like STEMCELL Technologies and Molecular Devices are developing advanced platforms with precise thermal regulation, while emerging companies such as Chuangxin International Biotechnology and Shanghai Ruiyu Biotech are introducing innovative solutions. Academic institutions including University of Michigan and Eberhard Karls Universität Tübingen are contributing significant research advancements, creating a competitive landscape balanced between established manufacturers and new entrants.

Qingdao Haier Biomedical Co., Ltd.

Technical Solution: Qingdao Haier Biomedical has developed comprehensive thermal management solutions for organoid culture systems through their advanced biomedical refrigeration and incubation technologies. Their systems feature precision temperature control with multi-zone regulation capabilities specifically designed for the demanding requirements of organoid culture. The company's thermal management approach incorporates advanced compressor technology with variable frequency drives that allow for rapid temperature adjustments while maintaining ±0.1°C stability[5]. Their organoid culture platforms utilize microprocessor-controlled air circulation systems that eliminate hot or cold spots within the culture environment, ensuring uniform thermal conditions across all samples. Haier Biomedical has also integrated humidity control systems that work in conjunction with their thermal management technology to prevent evaporation issues that commonly affect organoid cultures during extended incubation periods[6]. Their systems include comprehensive data logging and remote monitoring capabilities, allowing researchers to track thermal conditions throughout the entire organoid development process and receive alerts if parameters deviate from set ranges.

Strengths: Exceptional temperature uniformity across large culture areas; integrated humidity control prevents evaporation issues common in organoid culture; comprehensive monitoring and data logging capabilities for regulatory compliance. Weaknesses: Larger footprint compared to some specialized organoid culture systems; higher energy consumption; some advanced features require connection to facility management systems for optimal performance.

STEMCELL Technologies Canada, Inc.

Technical Solution: STEMCELL Technologies has developed advanced thermal management solutions for organoid culture systems through their STEMdiff™ Organoid platforms. Their technology incorporates precise temperature control mechanisms that maintain optimal thermal conditions throughout the entire organoid development process. The system utilizes microfluidic temperature regulation channels integrated with their culture vessels, allowing for temperature gradients that mimic in vivo conditions. Their thermal management approach includes automated feedback systems that continuously monitor and adjust temperatures with ±0.1°C precision, critical for maintaining stem cell differentiation pathways and preventing unwanted cell death[1]. The company has also pioneered specialized thermal-responsive matrices that provide temperature-dependent mechanical properties, allowing for easier organoid harvesting without enzymatic disruption[3]. Their systems are compatible with both suspension and embedded culture methods, providing versatile thermal management across different organoid types.

Strengths: Exceptional temperature precision (±0.1°C) critical for sensitive developmental processes; integrated systems approach combining thermal management with specialized media formulations; extensive validation across multiple organoid types. Weaknesses: Higher cost compared to conventional systems; requires specialized training for optimal use; some proprietary components limit customization options for researchers with unique requirements.

Key Thermal Management Technologies and Patents Analysis

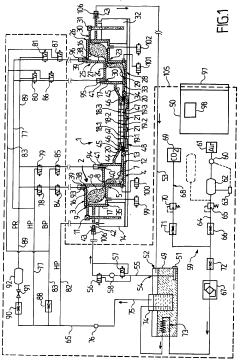

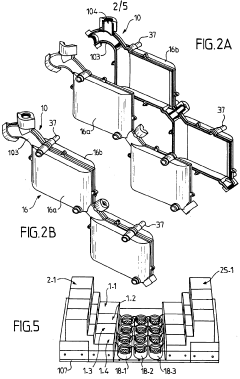

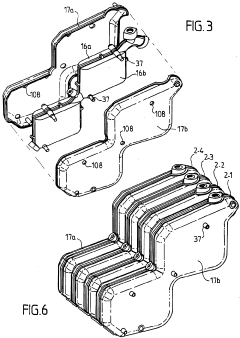

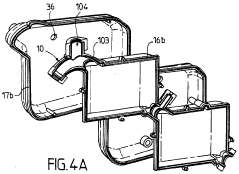

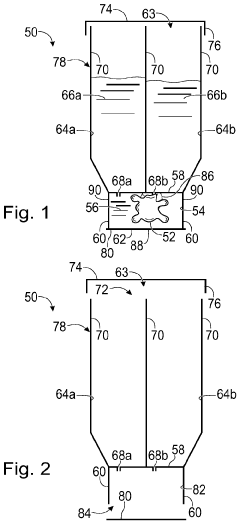

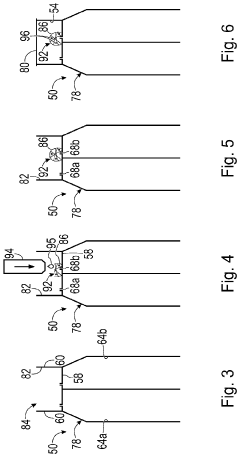

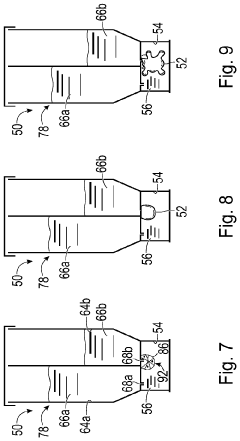

Thermally operated cell and tissue culture device

PatentWO2002088295A1

Innovation

- A thermally regulated cell and tissue culture device with controlled temperature management within the culture wells and/or culture fluid, using a fluidic heating circuit and electric heating elements, allowing for independent temperature control of the wells and culture fluid to minimize thermal disturbances.

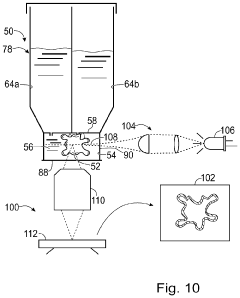

System and method for organoid culture

PatentPendingUS20230089445A1

Innovation

- A system comprising a vessel with a receptacle and sealing member to create a chamber for organoid culture, allowing for media exchange and imaging, using 3D printing to form scaffolds and integrate optical windows for light-sheet microscopy, enabling efficient growth, monitoring, and analysis of large organoids.

Regulatory Standards for Organoid Culture Environment Control

The regulatory landscape for organoid culture systems is evolving rapidly as these three-dimensional cellular models gain prominence in research and clinical applications. Currently, there is no unified global regulatory framework specifically addressing thermal management in organoid culture systems, creating challenges for standardization across laboratories and industries.

In the United States, the Food and Drug Administration (FDA) has begun developing guidance documents for advanced in vitro models, including organoids, through its Advancing Regulatory Science initiative. These guidelines emphasize the importance of maintaining precise temperature control (±0.5°C) throughout the culture period to ensure reproducibility of results. Similarly, the European Medicines Agency (EMA) has published position papers on the validation requirements for advanced cell culture systems, specifying temperature stability as a critical parameter for quality assurance.

The International Organization for Standardization (ISO) has established ISO 17025 for laboratory testing and calibration, which includes requirements for environmental monitoring in biological systems. While not organoid-specific, these standards provide a foundation for temperature management protocols. Additionally, the International Conference on Harmonisation (ICH) guidelines for Good Laboratory Practice (GLP) outline requirements for equipment validation and environmental monitoring that apply to organoid culture systems.

Industry consortia such as the Organ-on-a-Chip Network and the European Organ-on-Chip Society have developed voluntary standards for microenvironmental control in advanced culture systems. These include recommendations for continuous temperature monitoring, calibration frequencies, and acceptable deviation thresholds specific to different organoid types.

Regulatory bodies increasingly require documentation of temperature mapping studies for incubators and bioreactors used in organoid culture, with particular attention to spatial temperature distribution and recovery times after door openings. The National Institute of Standards and Technology (NIST) provides reference materials and calibration services that serve as benchmarks for temperature measurement accuracy in biological systems.

For clinical applications of organoids, more stringent regulations apply. The Clinical Laboratory Improvement Amendments (CLIA) in the US and the In Vitro Diagnostic Regulation (IVDR) in Europe mandate comprehensive environmental control validation, including temperature stability documentation throughout the entire workflow from sample preparation to analysis.

Emerging regulations are beginning to address the unique challenges of long-term organoid culture, with specific requirements for temperature cycling protocols and documentation of thermal stress responses. These standards recognize that different organoid types (brain, liver, intestinal) may require specific temperature regimes for optimal functionality and physiological relevance.

In the United States, the Food and Drug Administration (FDA) has begun developing guidance documents for advanced in vitro models, including organoids, through its Advancing Regulatory Science initiative. These guidelines emphasize the importance of maintaining precise temperature control (±0.5°C) throughout the culture period to ensure reproducibility of results. Similarly, the European Medicines Agency (EMA) has published position papers on the validation requirements for advanced cell culture systems, specifying temperature stability as a critical parameter for quality assurance.

The International Organization for Standardization (ISO) has established ISO 17025 for laboratory testing and calibration, which includes requirements for environmental monitoring in biological systems. While not organoid-specific, these standards provide a foundation for temperature management protocols. Additionally, the International Conference on Harmonisation (ICH) guidelines for Good Laboratory Practice (GLP) outline requirements for equipment validation and environmental monitoring that apply to organoid culture systems.

Industry consortia such as the Organ-on-a-Chip Network and the European Organ-on-Chip Society have developed voluntary standards for microenvironmental control in advanced culture systems. These include recommendations for continuous temperature monitoring, calibration frequencies, and acceptable deviation thresholds specific to different organoid types.

Regulatory bodies increasingly require documentation of temperature mapping studies for incubators and bioreactors used in organoid culture, with particular attention to spatial temperature distribution and recovery times after door openings. The National Institute of Standards and Technology (NIST) provides reference materials and calibration services that serve as benchmarks for temperature measurement accuracy in biological systems.

For clinical applications of organoids, more stringent regulations apply. The Clinical Laboratory Improvement Amendments (CLIA) in the US and the In Vitro Diagnostic Regulation (IVDR) in Europe mandate comprehensive environmental control validation, including temperature stability documentation throughout the entire workflow from sample preparation to analysis.

Emerging regulations are beginning to address the unique challenges of long-term organoid culture, with specific requirements for temperature cycling protocols and documentation of thermal stress responses. These standards recognize that different organoid types (brain, liver, intestinal) may require specific temperature regimes for optimal functionality and physiological relevance.

Sustainability Aspects of Thermal Management Technologies

The sustainability of thermal management technologies in organoid culture systems represents a critical dimension that intersects environmental responsibility with scientific advancement. Current thermal regulation systems in laboratory settings often consume significant energy, particularly in maintaining precise temperature conditions required for organoid development. This energy consumption translates to substantial carbon footprints, with conventional incubators and thermal cyclers accounting for approximately 30-40% of laboratory energy usage.

Material selection for thermal management components presents another sustainability challenge. Many traditional heat transfer materials contain rare earth elements or toxic compounds that pose environmental hazards during both manufacturing and disposal phases. The lifecycle assessment of these materials reveals concerning environmental impacts, particularly in extraction processes and end-of-life management.

Water consumption represents a frequently overlooked sustainability aspect of thermal management systems. Water-cooled systems, while efficient for heat dissipation, can consume thousands of gallons annually in larger laboratory settings. This consumption becomes particularly problematic in regions experiencing water scarcity, raising ethical questions about resource allocation.

Emerging sustainable alternatives show promising developments in addressing these challenges. Passive cooling technologies utilizing phase-change materials can reduce energy requirements by 40-60% compared to active cooling systems. Additionally, biomimetic cooling designs inspired by natural thermal regulation mechanisms demonstrate efficiency improvements while minimizing environmental impact.

Circular economy principles are increasingly being applied to thermal management technologies. Modular design approaches facilitate component replacement rather than whole-system disposal, while advanced materials research focuses on biodegradable or recyclable alternatives to traditional heat transfer materials. These innovations extend equipment lifespan and reduce waste generation.

Regulatory frameworks and certification systems are evolving to address sustainability in laboratory equipment. Standards such as ENERGY STAR for laboratory equipment and the EU's Ecodesign Directive increasingly incorporate thermal management efficiency metrics. These frameworks drive industry innovation toward more sustainable thermal regulation technologies while providing researchers with transparent sustainability performance indicators.

The economic implications of sustainable thermal management extend beyond initial investment considerations. While sustainable technologies often carry higher upfront costs, lifecycle cost analyses demonstrate long-term economic advantages through reduced energy consumption, extended equipment lifespan, and decreased waste management expenses. These economic benefits align sustainability objectives with financial incentives for research institutions.

Material selection for thermal management components presents another sustainability challenge. Many traditional heat transfer materials contain rare earth elements or toxic compounds that pose environmental hazards during both manufacturing and disposal phases. The lifecycle assessment of these materials reveals concerning environmental impacts, particularly in extraction processes and end-of-life management.

Water consumption represents a frequently overlooked sustainability aspect of thermal management systems. Water-cooled systems, while efficient for heat dissipation, can consume thousands of gallons annually in larger laboratory settings. This consumption becomes particularly problematic in regions experiencing water scarcity, raising ethical questions about resource allocation.

Emerging sustainable alternatives show promising developments in addressing these challenges. Passive cooling technologies utilizing phase-change materials can reduce energy requirements by 40-60% compared to active cooling systems. Additionally, biomimetic cooling designs inspired by natural thermal regulation mechanisms demonstrate efficiency improvements while minimizing environmental impact.

Circular economy principles are increasingly being applied to thermal management technologies. Modular design approaches facilitate component replacement rather than whole-system disposal, while advanced materials research focuses on biodegradable or recyclable alternatives to traditional heat transfer materials. These innovations extend equipment lifespan and reduce waste generation.

Regulatory frameworks and certification systems are evolving to address sustainability in laboratory equipment. Standards such as ENERGY STAR for laboratory equipment and the EU's Ecodesign Directive increasingly incorporate thermal management efficiency metrics. These frameworks drive industry innovation toward more sustainable thermal regulation technologies while providing researchers with transparent sustainability performance indicators.

The economic implications of sustainable thermal management extend beyond initial investment considerations. While sustainable technologies often carry higher upfront costs, lifecycle cost analyses demonstrate long-term economic advantages through reduced energy consumption, extended equipment lifespan, and decreased waste management expenses. These economic benefits align sustainability objectives with financial incentives for research institutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!