Thermal Dynamics in Organoid Culture Systems for Medicine

OCT 10, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organoid Thermal Regulation Background and Objectives

Organoid culture systems represent a revolutionary advancement in biomedical research, offering three-dimensional cellular structures that mimic the architecture and functionality of native organs. The evolution of this technology traces back to the early 2000s, with significant breakthroughs occurring around 2009 when the first intestinal organoids were successfully cultured. Since then, the field has expanded exponentially, with researchers developing organoid models for virtually every major organ system.

Thermal regulation in organoid culture systems has emerged as a critical factor influencing organoid development, differentiation, and functionality. Historically, most organoid cultures have been maintained at standard incubation temperatures (37°C), mirroring conventional cell culture practices. However, recent research indicates that precise thermal control may be essential for recapitulating organ-specific microenvironments and physiological responses.

The technical evolution in this domain has progressed from basic temperature-controlled incubators to sophisticated systems incorporating microfluidic platforms with integrated thermal elements. These advancements allow for spatial and temporal temperature gradients that more accurately reflect in vivo conditions. Additionally, the integration of real-time temperature monitoring systems has enabled researchers to correlate thermal fluctuations with specific organoid behaviors and developmental milestones.

Current research objectives in organoid thermal regulation focus on several key areas. First, establishing organ-specific optimal temperature profiles that account for the natural thermal gradients present in different body regions. Second, investigating the impact of controlled temperature fluctuations on organoid maturation and functionality, particularly for organs with known temperature-dependent processes. Third, developing advanced thermal regulation technologies that can be integrated into existing organoid culture platforms without compromising other essential parameters.

The ultimate goal of this technical domain is to enhance the physiological relevance of organoid models for applications in drug discovery, toxicology testing, personalized medicine, and regenerative therapies. By precisely controlling thermal dynamics, researchers aim to create organoid systems that more faithfully recapitulate human organ function and disease states, thereby improving the translational value of these models.

Looking forward, the field is trending toward the development of integrated systems that combine thermal regulation with other microenvironmental factors such as mechanical forces, electrical stimulation, and chemical gradients. This holistic approach recognizes that organoid development is influenced by multiple interacting physical and biochemical parameters, with temperature serving as a fundamental but often overlooked regulatory element.

Thermal regulation in organoid culture systems has emerged as a critical factor influencing organoid development, differentiation, and functionality. Historically, most organoid cultures have been maintained at standard incubation temperatures (37°C), mirroring conventional cell culture practices. However, recent research indicates that precise thermal control may be essential for recapitulating organ-specific microenvironments and physiological responses.

The technical evolution in this domain has progressed from basic temperature-controlled incubators to sophisticated systems incorporating microfluidic platforms with integrated thermal elements. These advancements allow for spatial and temporal temperature gradients that more accurately reflect in vivo conditions. Additionally, the integration of real-time temperature monitoring systems has enabled researchers to correlate thermal fluctuations with specific organoid behaviors and developmental milestones.

Current research objectives in organoid thermal regulation focus on several key areas. First, establishing organ-specific optimal temperature profiles that account for the natural thermal gradients present in different body regions. Second, investigating the impact of controlled temperature fluctuations on organoid maturation and functionality, particularly for organs with known temperature-dependent processes. Third, developing advanced thermal regulation technologies that can be integrated into existing organoid culture platforms without compromising other essential parameters.

The ultimate goal of this technical domain is to enhance the physiological relevance of organoid models for applications in drug discovery, toxicology testing, personalized medicine, and regenerative therapies. By precisely controlling thermal dynamics, researchers aim to create organoid systems that more faithfully recapitulate human organ function and disease states, thereby improving the translational value of these models.

Looking forward, the field is trending toward the development of integrated systems that combine thermal regulation with other microenvironmental factors such as mechanical forces, electrical stimulation, and chemical gradients. This holistic approach recognizes that organoid development is influenced by multiple interacting physical and biochemical parameters, with temperature serving as a fundamental but often overlooked regulatory element.

Market Analysis for Thermally Optimized Organoid Culture Systems

The global market for thermally optimized organoid culture systems is experiencing robust growth, driven by increasing adoption of organoid technology in drug discovery, personalized medicine, and disease modeling. Current market valuation stands at approximately 1.2 billion USD with a compound annual growth rate projected at 22.3% through 2028, significantly outpacing traditional cell culture markets.

Pharmaceutical and biotechnology companies represent the largest market segment, accounting for nearly 45% of the total market share. These organizations are increasingly investing in organoid platforms to reduce drug development costs and timelines by providing more physiologically relevant testing models. Academic and research institutions constitute the second-largest segment at 30%, focusing primarily on fundamental research and method development.

Regionally, North America dominates the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. The Asia-Pacific region, particularly China, South Korea, and Singapore, is expected to witness the fastest growth due to increasing research funding and expanding biotechnology sectors.

Demand analysis reveals several key market drivers. First, the push for alternatives to animal testing has accelerated adoption of organoid systems. Second, the growing emphasis on precision medicine has created substantial demand for patient-derived organoid models. Third, technological advancements in bioprinting and microfluidics have expanded the capabilities and applications of organoid systems.

Customer needs assessment indicates that thermal regulation precision remains a critical factor influencing purchasing decisions. End-users require systems capable of maintaining temperature stability within ±0.1°C, as even minor thermal fluctuations can significantly impact organoid development and experimental reproducibility. Additionally, customers increasingly demand integrated solutions that combine thermal control with other environmental parameters such as oxygen tension and nutrient delivery.

Market barriers include high initial investment costs, technical complexity requiring specialized training, and regulatory uncertainties surrounding organoid-based drug testing validation. The average cost of implementing a comprehensive thermally controlled organoid culture system ranges from $50,000 to $200,000, creating adoption challenges for smaller research institutions.

Future market trends point toward integration of artificial intelligence for predictive thermal management, development of high-throughput systems capable of maintaining precise thermal conditions across multiple organoid cultures simultaneously, and increasing focus on closed-loop systems that automatically adjust thermal parameters based on real-time organoid monitoring.

Pharmaceutical and biotechnology companies represent the largest market segment, accounting for nearly 45% of the total market share. These organizations are increasingly investing in organoid platforms to reduce drug development costs and timelines by providing more physiologically relevant testing models. Academic and research institutions constitute the second-largest segment at 30%, focusing primarily on fundamental research and method development.

Regionally, North America dominates the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. The Asia-Pacific region, particularly China, South Korea, and Singapore, is expected to witness the fastest growth due to increasing research funding and expanding biotechnology sectors.

Demand analysis reveals several key market drivers. First, the push for alternatives to animal testing has accelerated adoption of organoid systems. Second, the growing emphasis on precision medicine has created substantial demand for patient-derived organoid models. Third, technological advancements in bioprinting and microfluidics have expanded the capabilities and applications of organoid systems.

Customer needs assessment indicates that thermal regulation precision remains a critical factor influencing purchasing decisions. End-users require systems capable of maintaining temperature stability within ±0.1°C, as even minor thermal fluctuations can significantly impact organoid development and experimental reproducibility. Additionally, customers increasingly demand integrated solutions that combine thermal control with other environmental parameters such as oxygen tension and nutrient delivery.

Market barriers include high initial investment costs, technical complexity requiring specialized training, and regulatory uncertainties surrounding organoid-based drug testing validation. The average cost of implementing a comprehensive thermally controlled organoid culture system ranges from $50,000 to $200,000, creating adoption challenges for smaller research institutions.

Future market trends point toward integration of artificial intelligence for predictive thermal management, development of high-throughput systems capable of maintaining precise thermal conditions across multiple organoid cultures simultaneously, and increasing focus on closed-loop systems that automatically adjust thermal parameters based on real-time organoid monitoring.

Current Thermal Control Challenges in Organoid Technology

The thermal environment in organoid culture systems represents a critical yet often underappreciated factor affecting cellular behavior, differentiation patterns, and overall organoid development. Current thermal control technologies face significant limitations in maintaining precise temperature gradients necessary for mimicking in vivo conditions. Conventional incubators provide only bulk temperature regulation, typically at a uniform 37°C, failing to replicate the natural thermal heterogeneity found in human tissues and organs.

One major challenge lies in the inability to create localized temperature variations within the same culture vessel. Human organs naturally exhibit temperature differences across their structure, which influence cellular metabolism, protein expression, and signaling pathways. For instance, the liver demonstrates temperature gradients that affect zonation and metabolic function, yet current organoid systems cannot replicate these subtle thermal microenvironments.

Temperature fluctuations during media changes and imaging procedures represent another significant hurdle. Even brief exposure to room temperature can trigger stress responses in organoid cells, altering gene expression profiles and potentially compromising experimental reproducibility. Studies have shown that temperature shifts as small as 2°C can significantly impact stem cell differentiation trajectories and organoid maturation processes.

The integration of heating elements with microfluidic platforms presents technical difficulties related to material compatibility, heat distribution, and potential electromagnetic interference with sensitive monitoring equipment. Polymers commonly used in microfluidic devices often have poor thermal conductivity properties, creating challenges for rapid and uniform temperature adjustments across the culture area.

Scaling thermal control systems for high-throughput organoid production introduces additional complexities. Current technologies struggle to maintain consistent thermal conditions across multiple culture vessels simultaneously, leading to batch-to-batch variability that hampers clinical translation efforts. This inconsistency becomes particularly problematic when developing organoids for personalized medicine applications.

Real-time temperature monitoring at the microscale remains technically challenging. Most available sensors are either too large to integrate into organoid culture systems without disrupting cellular architecture or lack the sensitivity to detect subtle thermal gradients. Non-invasive thermal imaging techniques often lack the spatial resolution required for precise measurement within three-dimensional organoid structures.

Energy efficiency concerns also plague current thermal control systems. Maintaining stable temperatures in conventional incubators requires significant power consumption, presenting sustainability challenges for large-scale organoid production facilities. This energy demand increases substantially when attempting to implement more sophisticated temperature control strategies beyond simple bulk heating.

AI: The thermal environment in organoid culture systems represents a critical yet often underappreciated factor affecting cellular behavior, differentiation patterns, and overall organoid development. Current thermal control technologies face significant limitations in maintaining precise temperature gradients necessary for mimicking in vivo conditions. Conventional incubators provide only bulk temperature regulation, typically at a uniform 37°C, failing to replicate the natural thermal heterogeneity found in human tissues and organs.

One major challenge lies in the inability to create localized temperature variations within the same culture vessel. Human organs naturally exhibit temperature differences across their structure, which influence cellular metabolism, protein expression, and signaling pathways. For instance, the liver demonstrates temperature gradients that affect zonation and metabolic function, yet current organoid systems cannot replicate these subtle thermal microenvironments.

Temperature fluctuations during media changes and imaging procedures represent another significant hurdle. Even brief exposure to room temperature can trigger stress responses in organoid cells, altering gene expression profiles and potentially compromising experimental reproducibility. Studies have shown that temperature shifts as small as 2°C can significantly impact stem cell differentiation trajectories and organoid maturation processes.

The integration of heating elements with microfluidic platforms presents technical difficulties related to material compatibility, heat distribution, and potential electromagnetic interference with sensitive monitoring equipment. Polymers commonly used in microfluidic devices often have poor thermal conductivity properties, creating challenges for rapid and uniform temperature adjustments across the culture area.

Scaling thermal control systems for high-throughput organoid production introduces additional complexities. Current technologies struggle to maintain consistent thermal conditions across multiple culture vessels simultaneously, leading to batch-to-batch variability that hampers clinical translation efforts. This inconsistency becomes particularly problematic when developing organoids for personalized medicine applications.

Real-time temperature monitoring at the microscale remains technically challenging. Most available sensors are either too large to integrate into organoid culture systems without disrupting cellular architecture or lack the sensitivity to detect subtle thermal gradients. Non-invasive thermal imaging techniques often lack the spatial resolution required for precise measurement within three-dimensional organoid structures.

Energy efficiency concerns also plague current thermal control systems. Maintaining stable temperatures in conventional incubators requires significant power consumption, presenting sustainability challenges for large-scale organoid production facilities. This energy demand increases substantially when attempting to implement more sophisticated temperature control strategies beyond simple bulk heating.

One major challenge lies in the inability to create localized temperature variations within the same culture vessel. Human organs naturally exhibit temperature differences across their structure, which influence cellular metabolism, protein expression, and signaling pathways. For instance, the liver demonstrates temperature gradients that affect zonation and metabolic function, yet current organoid systems cannot replicate these subtle thermal microenvironments.

Temperature fluctuations during media changes and imaging procedures represent another significant hurdle. Even brief exposure to room temperature can trigger stress responses in organoid cells, altering gene expression profiles and potentially compromising experimental reproducibility. Studies have shown that temperature shifts as small as 2°C can significantly impact stem cell differentiation trajectories and organoid maturation processes.

The integration of heating elements with microfluidic platforms presents technical difficulties related to material compatibility, heat distribution, and potential electromagnetic interference with sensitive monitoring equipment. Polymers commonly used in microfluidic devices often have poor thermal conductivity properties, creating challenges for rapid and uniform temperature adjustments across the culture area.

Scaling thermal control systems for high-throughput organoid production introduces additional complexities. Current technologies struggle to maintain consistent thermal conditions across multiple culture vessels simultaneously, leading to batch-to-batch variability that hampers clinical translation efforts. This inconsistency becomes particularly problematic when developing organoids for personalized medicine applications.

Real-time temperature monitoring at the microscale remains technically challenging. Most available sensors are either too large to integrate into organoid culture systems without disrupting cellular architecture or lack the sensitivity to detect subtle thermal gradients. Non-invasive thermal imaging techniques often lack the spatial resolution required for precise measurement within three-dimensional organoid structures.

Energy efficiency concerns also plague current thermal control systems. Maintaining stable temperatures in conventional incubators requires significant power consumption, presenting sustainability challenges for large-scale organoid production facilities. This energy demand increases substantially when attempting to implement more sophisticated temperature control strategies beyond simple bulk heating.

AI: The thermal environment in organoid culture systems represents a critical yet often underappreciated factor affecting cellular behavior, differentiation patterns, and overall organoid development. Current thermal control technologies face significant limitations in maintaining precise temperature gradients necessary for mimicking in vivo conditions. Conventional incubators provide only bulk temperature regulation, typically at a uniform 37°C, failing to replicate the natural thermal heterogeneity found in human tissues and organs.

One major challenge lies in the inability to create localized temperature variations within the same culture vessel. Human organs naturally exhibit temperature differences across their structure, which influence cellular metabolism, protein expression, and signaling pathways. For instance, the liver demonstrates temperature gradients that affect zonation and metabolic function, yet current organoid systems cannot replicate these subtle thermal microenvironments.

Temperature fluctuations during media changes and imaging procedures represent another significant hurdle. Even brief exposure to room temperature can trigger stress responses in organoid cells, altering gene expression profiles and potentially compromising experimental reproducibility. Studies have shown that temperature shifts as small as 2°C can significantly impact stem cell differentiation trajectories and organoid maturation processes.

The integration of heating elements with microfluidic platforms presents technical difficulties related to material compatibility, heat distribution, and potential electromagnetic interference with sensitive monitoring equipment. Polymers commonly used in microfluidic devices often have poor thermal conductivity properties, creating challenges for rapid and uniform temperature adjustments across the culture area.

Scaling thermal control systems for high-throughput organoid production introduces additional complexities. Current technologies struggle to maintain consistent thermal conditions across multiple culture vessels simultaneously, leading to batch-to-batch variability that hampers clinical translation efforts. This inconsistency becomes particularly problematic when developing organoids for personalized medicine applications.

Real-time temperature monitoring at the microscale remains technically challenging. Most available sensors are either too large to integrate into organoid culture systems without disrupting cellular architecture or lack the sensitivity to detect subtle thermal gradients. Non-invasive thermal imaging techniques often lack the spatial resolution required for precise measurement within three-dimensional organoid structures.

Energy efficiency concerns also plague current thermal control systems. Maintaining stable temperatures in conventional incubators requires significant power consumption, presenting sustainability challenges for large-scale organoid production facilities. This energy demand increases substantially when attempting to implement more sophisticated temperature control strategies beyond simple bulk heating.

Existing Thermal Regulation Solutions for Organoid Systems

01 Temperature control systems for organoid culture

Advanced temperature control systems are essential for maintaining optimal thermal conditions in organoid culture environments. These systems incorporate precise heating and cooling mechanisms to regulate temperature within narrow ranges required for organoid development. The technology includes thermal sensors, feedback control loops, and specialized incubation chambers that can maintain stable temperatures while allowing for programmed thermal fluctuations when needed for specific developmental stages.- Temperature control systems for organoid culture: Advanced temperature control systems are essential for maintaining optimal thermal conditions in organoid culture environments. These systems utilize precise heating and cooling mechanisms to regulate temperature within narrow ranges required for organoid development. The technology includes thermal sensors, feedback control loops, and specialized incubation chambers that can maintain stable temperatures over extended periods, which is critical for proper cellular differentiation and organoid formation.

- Thermal dynamics in bioreactor systems for organoid growth: Bioreactor systems designed for organoid culture incorporate sophisticated thermal management to ensure uniform heat distribution throughout the culture medium. These systems often feature integrated heating elements, circulation mechanisms to prevent temperature gradients, and real-time monitoring capabilities. The thermal dynamics within these bioreactors are carefully engineered to mimic physiological conditions while accommodating the metabolic heat generated by growing organoids, thereby supporting more accurate in vitro modeling of tissue development.

- Thermal cycling technologies for organoid differentiation: Thermal cycling technologies apply programmed temperature variations to influence organoid differentiation pathways. These systems can simulate natural temperature fluctuations that occur in developing tissues, potentially enhancing organoid maturation and functionality. The controlled application of thermal stress or specific temperature patterns can trigger cellular responses that promote desired tissue-specific characteristics, making thermal cycling an important tool for directing organoid development toward specific tissue types.

- Energy-efficient thermal management for long-term organoid culture: Energy-efficient thermal management solutions are being developed for sustainable long-term organoid culture. These innovations focus on reducing power consumption while maintaining precise temperature control through improved insulation, smart heating algorithms, and energy recovery systems. Such approaches are particularly important for extended culture periods required for complex organoid maturation, enabling research facilities to reduce operational costs while maintaining optimal growth conditions.

- Portable thermal regulation devices for organoid transportation: Portable thermal regulation devices enable the safe transportation of organoids between research facilities while maintaining critical temperature parameters. These systems incorporate battery-powered temperature control, insulation technologies, and shock absorption to protect delicate organoid structures during transit. Advanced models may include remote monitoring capabilities and backup systems to ensure temperature stability even under variable external conditions, facilitating collaborative research and clinical applications of organoid technology.

02 Thermal dynamics in 3D organoid culture platforms

Three-dimensional culture platforms for organoids require specialized thermal management to ensure uniform heat distribution throughout the matrix. These platforms incorporate innovative materials and designs that facilitate consistent thermal conditions across the 3D structure, preventing temperature gradients that could affect organoid development. The systems may include thermally conductive materials, microfluidic channels for heat exchange, and specialized scaffolds that optimize thermal transfer to the growing organoids.Expand Specific Solutions03 Real-time thermal monitoring for organoid development

Real-time monitoring systems track thermal dynamics in organoid cultures, allowing researchers to observe temperature fluctuations and their effects on development. These systems employ advanced sensors integrated with imaging technologies to correlate thermal conditions with organoid growth patterns. The monitoring platforms can detect microscale temperature variations and provide data for adjusting culture conditions to optimize organoid formation and functionality.Expand Specific Solutions04 Energy-efficient thermal regulation for long-term organoid culture

Energy-efficient systems for long-term maintenance of organoid cultures incorporate innovative approaches to thermal regulation that minimize power consumption while maintaining precise temperature control. These systems may utilize phase-change materials, thermal insulation technologies, and smart power management to create stable environments for extended culture periods. The designs focus on reducing thermal fluctuations while optimizing energy usage for sustainable laboratory operations.Expand Specific Solutions05 Thermal gradient applications in organoid differentiation

Controlled thermal gradients can be applied to direct organoid differentiation and development. These systems create intentional temperature variations across culture platforms to mimic developmental cues found in vivo. By precisely controlling spatial and temporal thermal patterns, researchers can influence cell fate decisions and tissue organization within developing organoids. The technology includes programmable heating elements, directional heat flow mechanisms, and computational models to predict thermal effects on cellular differentiation.Expand Specific Solutions

Leading Organizations in Organoid Culture Technology

The thermal dynamics in organoid culture systems for medicine is currently in a growth phase, with the market expanding rapidly due to increasing applications in drug discovery, personalized medicine, and disease modeling. The global market size is estimated to reach several billion dollars by 2025, driven by pharmaceutical research and regenerative medicine advancements. Technologically, the field is progressing from early-stage development toward maturity, with key players demonstrating varying levels of expertise. Academic institutions like Johns Hopkins University, Beihang University, and University of Michigan are pioneering fundamental research, while commercial entities such as STEMCELL Technologies, Takeda Pharmaceutical, and Tempus AI are developing scalable applications. Medical centers including Memorial Sloan Kettering and specialized companies like CYTOO SA are bridging research-to-clinical translation, creating a competitive ecosystem that balances innovation with practical implementation.

STEMCELL Technologies Canada, Inc.

Technical Solution: STEMCELL Technologies has developed advanced thermal regulation systems for organoid culture that maintain precise temperature gradients essential for mimicking in vivo conditions. Their STEMdiff™ Organoid platforms incorporate microfluidic thermal control mechanisms that allow for temperature variations across different regions of the organoid culture, simulating natural tissue environments. The company's thermal regulation technology includes specialized incubation chambers with multi-zone temperature control that can create physiologically relevant thermal gradients (±0.1°C precision) across culture matrices. This enables researchers to study how temperature variations affect organoid development and drug responses. Their systems also feature real-time thermal monitoring with feedback loops that automatically adjust heating elements to maintain stable conditions during extended culture periods, critical for studying disease progression and therapeutic interventions.

Strengths: Industry-leading precision in temperature control allowing for complex thermal gradient creation; integrated monitoring systems that reduce experimental variability; scalable platforms suitable for both research and clinical applications. Weaknesses: Higher cost compared to conventional systems; requires specialized training for optimal utilization; limited compatibility with some third-party culture components.

Molecular Devices (Austria) GmbH

Technical Solution: Molecular Devices has pioneered thermal imaging and regulation technology specifically for organoid culture systems with their CellX Thermal Dynamics platform. This system integrates infrared thermal imaging with precision temperature control mechanisms to maintain optimal growth conditions while allowing for programmed thermal fluctuations that mimic physiological states. Their technology employs a network of micro-scale Peltier elements distributed throughout the culture platform that can create localized temperature zones with transitions as small as 0.5°C between adjacent areas. This enables researchers to study how thermal gradients influence organoid differentiation and function. The system also incorporates AI-driven predictive temperature management that anticipates thermal drift based on metabolic activity within the organoids, adjusting heating/cooling elements proactively rather than reactively to maintain stable conditions during critical developmental phases.

Strengths: Unparalleled spatial resolution in thermal control; advanced imaging capabilities that allow simultaneous visualization of thermal patterns and cellular responses; automated adaptation to metabolic changes. Weaknesses: Complex setup procedure requiring technical expertise; higher energy consumption than conventional systems; limited throughput for large-scale screening applications.

Key Thermal Dynamics Patents and Research in Organoid Culture

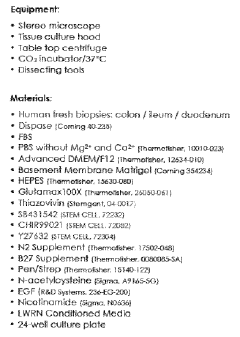

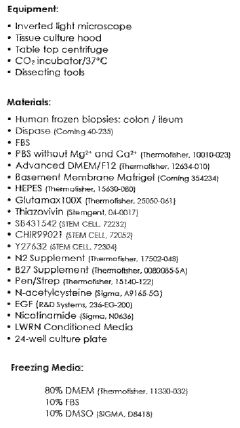

Compositions and method for establishing organoid cultures from cryogenically preserved tissue

PatentWO2019027834A1

Innovation

- Cryopreservation of human biopsy tissue using a simple freezing medium and procedure, allowing for long-term organoid culture establishment upon thawing, which enables shipping and storage of frozen samples for global research and therapeutic applications.

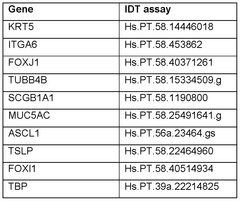

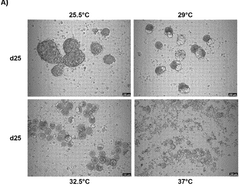

Compositions and methods for improved generation of organoids

PatentWO2025065097A1

Innovation

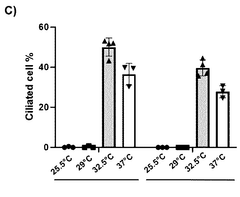

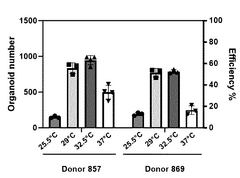

- A method involving culturing cells in a specific culture medium under non-adherent conditions and exposing them to an unconventional incubation temperature between 26°C and 36°C, which enhances differentiation and organoid generation.

Regulatory Framework for Medical Organoid Applications

The regulatory landscape for organoid technologies in medicine presents a complex framework that continues to evolve as these three-dimensional cellular models gain prominence in research and clinical applications. Currently, the FDA and EMA have not established specific regulatory pathways dedicated to organoid-based technologies, instead applying existing frameworks for biological products, medical devices, or combination products depending on the intended use. This regulatory gap creates challenges for developers navigating approval processes for organoid-based diagnostic tools, drug screening platforms, and potential therapeutic applications.

Key considerations within the regulatory framework include safety validation protocols, which must address the unique thermal dynamics of organoid culture systems. Temperature fluctuations during cultivation can significantly impact cellular differentiation, metabolic activity, and overall organoid architecture, necessitating standardized thermal monitoring and control systems that meet regulatory requirements for reproducibility and reliability.

Quality control standards represent another critical regulatory component, with authorities increasingly requiring demonstration of batch-to-batch consistency in organoid production. This includes validation of thermal stability throughout the manufacturing process, as temperature variations can introduce unpredictable phenotypic changes that compromise product integrity and patient safety.

For clinical applications, regulatory bodies are developing guidelines that address the ethical implications of organoid technologies, particularly those derived from patient tissues. These frameworks must balance innovation with patient protection, incorporating informed consent procedures that acknowledge the unique nature of organoid-derived data and potential therapeutic applications.

International harmonization efforts are underway to establish consistent regulatory approaches across jurisdictions. The International Council for Harmonisation (ICH) has initiated discussions on adapting existing guidelines to accommodate organoid technologies, with particular attention to thermal validation parameters that ensure consistent performance across different laboratory environments and clinical settings.

Looking forward, regulatory evolution will likely include the development of specialized pathways for organoid-based products, with thermal dynamics protocols forming a cornerstone of validation requirements. Industry stakeholders are actively engaging with regulatory authorities to shape these frameworks, advocating for risk-based approaches that recognize the transformative potential of organoid technologies while ensuring appropriate safeguards for patient safety and product efficacy.

Key considerations within the regulatory framework include safety validation protocols, which must address the unique thermal dynamics of organoid culture systems. Temperature fluctuations during cultivation can significantly impact cellular differentiation, metabolic activity, and overall organoid architecture, necessitating standardized thermal monitoring and control systems that meet regulatory requirements for reproducibility and reliability.

Quality control standards represent another critical regulatory component, with authorities increasingly requiring demonstration of batch-to-batch consistency in organoid production. This includes validation of thermal stability throughout the manufacturing process, as temperature variations can introduce unpredictable phenotypic changes that compromise product integrity and patient safety.

For clinical applications, regulatory bodies are developing guidelines that address the ethical implications of organoid technologies, particularly those derived from patient tissues. These frameworks must balance innovation with patient protection, incorporating informed consent procedures that acknowledge the unique nature of organoid-derived data and potential therapeutic applications.

International harmonization efforts are underway to establish consistent regulatory approaches across jurisdictions. The International Council for Harmonisation (ICH) has initiated discussions on adapting existing guidelines to accommodate organoid technologies, with particular attention to thermal validation parameters that ensure consistent performance across different laboratory environments and clinical settings.

Looking forward, regulatory evolution will likely include the development of specialized pathways for organoid-based products, with thermal dynamics protocols forming a cornerstone of validation requirements. Industry stakeholders are actively engaging with regulatory authorities to shape these frameworks, advocating for risk-based approaches that recognize the transformative potential of organoid technologies while ensuring appropriate safeguards for patient safety and product efficacy.

Scalability Considerations for Clinical Translation

The scalability of organoid culture systems represents a critical challenge for their successful translation into clinical applications. Current laboratory-scale organoid cultures typically involve small batches that are sufficient for research purposes but fall short of the volumes required for widespread therapeutic use. Scaling up these systems necessitates addressing several interconnected thermal management challenges that become increasingly complex with larger culture volumes.

Temperature uniformity emerges as a primary concern in scaled organoid systems. As culture vessels increase in size, maintaining consistent temperature throughout the growth medium becomes technically challenging. Thermal gradients can develop within larger bioreactors, potentially leading to heterogeneous organoid development and compromising therapeutic efficacy. Advanced thermal modeling and novel bioreactor designs incorporating distributed temperature sensors and multiple heating elements are being explored to mitigate these issues.

Energy efficiency considerations also gain prominence at clinical scales. The energy requirements for maintaining precise temperature control in large-scale organoid production facilities can be substantial, impacting operational costs and environmental sustainability. Innovations in insulation materials and heat recovery systems are being integrated into next-generation culture platforms to address these concerns while maintaining the exacting thermal conditions required for organoid development.

Automation of thermal management becomes essential when transitioning from manual laboratory processes to industrial-scale production. Sophisticated control systems capable of real-time temperature monitoring and adjustment are being developed, incorporating machine learning algorithms that can predict and preemptively respond to thermal fluctuations. These systems must be validated to meet stringent regulatory requirements for clinical-grade biological products.

Infrastructure requirements present another significant hurdle for clinical translation. Healthcare facilities implementing organoid-based therapies will need specialized equipment and trained personnel to maintain appropriate thermal conditions throughout the organoid lifecycle—from production through storage and delivery to patients. This necessitates substantial investment in both physical infrastructure and human resources.

Regulatory considerations further complicate scalability efforts. Thermal management protocols must demonstrate consistency and reliability across production scales to satisfy regulatory agencies. Documentation of thermal validation studies, including stress testing under various conditions, will be required to establish the robustness of scaled production systems and ensure patient safety.

Temperature uniformity emerges as a primary concern in scaled organoid systems. As culture vessels increase in size, maintaining consistent temperature throughout the growth medium becomes technically challenging. Thermal gradients can develop within larger bioreactors, potentially leading to heterogeneous organoid development and compromising therapeutic efficacy. Advanced thermal modeling and novel bioreactor designs incorporating distributed temperature sensors and multiple heating elements are being explored to mitigate these issues.

Energy efficiency considerations also gain prominence at clinical scales. The energy requirements for maintaining precise temperature control in large-scale organoid production facilities can be substantial, impacting operational costs and environmental sustainability. Innovations in insulation materials and heat recovery systems are being integrated into next-generation culture platforms to address these concerns while maintaining the exacting thermal conditions required for organoid development.

Automation of thermal management becomes essential when transitioning from manual laboratory processes to industrial-scale production. Sophisticated control systems capable of real-time temperature monitoring and adjustment are being developed, incorporating machine learning algorithms that can predict and preemptively respond to thermal fluctuations. These systems must be validated to meet stringent regulatory requirements for clinical-grade biological products.

Infrastructure requirements present another significant hurdle for clinical translation. Healthcare facilities implementing organoid-based therapies will need specialized equipment and trained personnel to maintain appropriate thermal conditions throughout the organoid lifecycle—from production through storage and delivery to patients. This necessitates substantial investment in both physical infrastructure and human resources.

Regulatory considerations further complicate scalability efforts. Thermal management protocols must demonstrate consistency and reliability across production scales to satisfy regulatory agencies. Documentation of thermal validation studies, including stress testing under various conditions, will be required to establish the robustness of scaled production systems and ensure patient safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!