Autoclave Synthesis and Its Contribution to Biodegradable Polymer Development

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis represents a pivotal manufacturing technique that has evolved significantly over the past several decades, transforming from a basic pressure vessel process to a sophisticated method for polymer synthesis. This high-pressure, high-temperature reaction environment creates unique conditions that enable the formation of complex polymer structures with controlled properties. The historical development of autoclave technology traces back to industrial applications in the early 20th century, with significant advancements occurring post-1950s when the potential for polymer synthesis became more apparent.

The evolution of autoclave synthesis has been characterized by continuous improvements in pressure control, temperature regulation, and reaction monitoring capabilities. Modern autoclave systems incorporate advanced features such as precise digital controls, real-time analytics, and automated safety protocols that have expanded their application scope considerably. These technological improvements have directly contributed to the advancement of biodegradable polymer research by enabling more precise control over polymerization reactions.

In the context of biodegradable polymers, autoclave synthesis offers distinct advantages over conventional methods. The controlled environment facilitates the creation of polymers with specific degradation profiles, mechanical properties, and biocompatibility characteristics. This technical capability has become increasingly important as global sustainability initiatives drive demand for environmentally responsible materials across multiple industries.

The primary objective of current autoclave synthesis research in biodegradable polymer development is to optimize reaction parameters for producing materials with predictable degradation rates while maintaining functional performance. This includes investigating catalyst systems, monomer combinations, and processing conditions that yield polymers with tailored properties for specific applications in medical devices, packaging, and agricultural products.

Another critical goal is to improve the energy efficiency and scalability of autoclave processes, addressing the industrial challenges of transitioning laboratory successes to commercial production. This involves developing more efficient heating and cooling systems, reducing cycle times, and minimizing waste generation during polymer synthesis.

Research also aims to expand the range of biodegradable polymers that can be effectively synthesized using autoclave technology. This includes exploring novel monomer combinations, investigating copolymerization strategies, and developing techniques for incorporating functional additives that enhance material performance while maintaining biodegradability.

The technological trajectory suggests that autoclave synthesis will continue to play a crucial role in advancing biodegradable polymer science, particularly as researchers seek to develop next-generation materials with enhanced functionality, improved environmental profiles, and competitive production economics. The convergence of computational modeling, materials science, and process engineering is expected to further refine autoclave synthesis methods in the coming decade.

The evolution of autoclave synthesis has been characterized by continuous improvements in pressure control, temperature regulation, and reaction monitoring capabilities. Modern autoclave systems incorporate advanced features such as precise digital controls, real-time analytics, and automated safety protocols that have expanded their application scope considerably. These technological improvements have directly contributed to the advancement of biodegradable polymer research by enabling more precise control over polymerization reactions.

In the context of biodegradable polymers, autoclave synthesis offers distinct advantages over conventional methods. The controlled environment facilitates the creation of polymers with specific degradation profiles, mechanical properties, and biocompatibility characteristics. This technical capability has become increasingly important as global sustainability initiatives drive demand for environmentally responsible materials across multiple industries.

The primary objective of current autoclave synthesis research in biodegradable polymer development is to optimize reaction parameters for producing materials with predictable degradation rates while maintaining functional performance. This includes investigating catalyst systems, monomer combinations, and processing conditions that yield polymers with tailored properties for specific applications in medical devices, packaging, and agricultural products.

Another critical goal is to improve the energy efficiency and scalability of autoclave processes, addressing the industrial challenges of transitioning laboratory successes to commercial production. This involves developing more efficient heating and cooling systems, reducing cycle times, and minimizing waste generation during polymer synthesis.

Research also aims to expand the range of biodegradable polymers that can be effectively synthesized using autoclave technology. This includes exploring novel monomer combinations, investigating copolymerization strategies, and developing techniques for incorporating functional additives that enhance material performance while maintaining biodegradability.

The technological trajectory suggests that autoclave synthesis will continue to play a crucial role in advancing biodegradable polymer science, particularly as researchers seek to develop next-generation materials with enhanced functionality, improved environmental profiles, and competitive production economics. The convergence of computational modeling, materials science, and process engineering is expected to further refine autoclave synthesis methods in the coming decade.

Market Demand for Biodegradable Polymers

The global market for biodegradable polymers has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures against conventional plastics. Current market valuations indicate that the biodegradable polymers sector reached approximately 4.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 14-17% through 2030, potentially reaching 12-15 billion USD by the end of the decade.

Consumer awareness regarding plastic pollution has become a major market driver, with surveys indicating that over 70% of consumers across developed markets express willingness to pay premium prices for environmentally friendly packaging alternatives. This shift in consumer behavior has prompted major retail chains and consumer goods companies to commit to biodegradable packaging solutions, creating substantial downstream demand.

Regulatory frameworks have emerged as another critical factor shaping market dynamics. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition toward biodegradable alternatives across multiple industries. Similar legislative measures in North America, Japan, and increasingly in developing economies have created a favorable regulatory environment for biodegradable polymer adoption.

By application segment, packaging represents the largest market share at approximately 45-48% of total biodegradable polymer consumption, followed by agriculture (18-20%), textiles (12-15%), and medical applications (8-10%). The packaging sector's dominance reflects the urgent need to address single-use plastic waste, which constitutes a significant portion of global plastic pollution.

Geographically, Europe leads the market with approximately 35-38% share, followed by North America (28-30%) and Asia-Pacific (25-27%). However, the highest growth rates are observed in emerging economies, particularly in Southeast Asia and Latin America, where rapid industrialization coupled with growing environmental awareness is driving adoption.

The medical and pharmaceutical sectors represent particularly promising growth areas, with demand for biodegradable polymers in controlled drug delivery systems, tissue engineering, and implantable medical devices growing at nearly twice the overall market rate. This specialized application segment values the unique properties achievable through autoclave synthesis methods, including precise degradation profiles and biocompatibility.

Despite positive market indicators, several challenges persist, including cost differentials between conventional and biodegradable polymers (typically 20-30% higher for biodegradable alternatives), performance limitations in certain applications, and inconsistent end-of-life infrastructure for proper composting or biodegradation. These factors highlight the need for continued innovation in synthesis methods, including advanced autoclave techniques, to improve cost-effectiveness and performance characteristics.

Consumer awareness regarding plastic pollution has become a major market driver, with surveys indicating that over 70% of consumers across developed markets express willingness to pay premium prices for environmentally friendly packaging alternatives. This shift in consumer behavior has prompted major retail chains and consumer goods companies to commit to biodegradable packaging solutions, creating substantial downstream demand.

Regulatory frameworks have emerged as another critical factor shaping market dynamics. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition toward biodegradable alternatives across multiple industries. Similar legislative measures in North America, Japan, and increasingly in developing economies have created a favorable regulatory environment for biodegradable polymer adoption.

By application segment, packaging represents the largest market share at approximately 45-48% of total biodegradable polymer consumption, followed by agriculture (18-20%), textiles (12-15%), and medical applications (8-10%). The packaging sector's dominance reflects the urgent need to address single-use plastic waste, which constitutes a significant portion of global plastic pollution.

Geographically, Europe leads the market with approximately 35-38% share, followed by North America (28-30%) and Asia-Pacific (25-27%). However, the highest growth rates are observed in emerging economies, particularly in Southeast Asia and Latin America, where rapid industrialization coupled with growing environmental awareness is driving adoption.

The medical and pharmaceutical sectors represent particularly promising growth areas, with demand for biodegradable polymers in controlled drug delivery systems, tissue engineering, and implantable medical devices growing at nearly twice the overall market rate. This specialized application segment values the unique properties achievable through autoclave synthesis methods, including precise degradation profiles and biocompatibility.

Despite positive market indicators, several challenges persist, including cost differentials between conventional and biodegradable polymers (typically 20-30% higher for biodegradable alternatives), performance limitations in certain applications, and inconsistent end-of-life infrastructure for proper composting or biodegradation. These factors highlight the need for continued innovation in synthesis methods, including advanced autoclave techniques, to improve cost-effectiveness and performance characteristics.

Current State and Challenges in Autoclave Synthesis

Autoclave synthesis has emerged as a critical technology in the development of biodegradable polymers, with significant advancements occurring globally over the past decade. Currently, this synthesis method utilizes high-pressure and high-temperature conditions within sealed vessels to facilitate polymerization reactions that would otherwise be challenging under ambient conditions. The controlled environment of autoclaves enables precise manipulation of reaction parameters, making them particularly valuable for synthesizing complex biodegradable polymers with specific properties.

In the United States and Europe, autoclave synthesis has reached a relatively mature stage, with sophisticated equipment featuring advanced monitoring systems and precise control mechanisms. These regions lead in developing autoclave technologies that incorporate real-time analytics and automated parameter adjustments. Conversely, in developing economies, adoption remains limited primarily due to high equipment costs and technical expertise requirements, creating a notable technological divide in global distribution.

The primary technical challenges facing autoclave synthesis for biodegradable polymers include energy efficiency concerns, scaling limitations, and process consistency issues. Conventional autoclave operations demand substantial energy inputs to maintain elevated temperatures and pressures, conflicting with sustainability goals inherent to biodegradable polymer production. This contradiction represents a significant hurdle that researchers are actively addressing through alternative heating methods and catalytic innovations.

Scaling production from laboratory to industrial levels presents another formidable challenge. While small-scale autoclaves demonstrate excellent control over reaction conditions, maintaining this precision in larger vessels introduces complexities in heat distribution, pressure regulation, and mixing efficiency. These factors can lead to product inconsistency and quality variations across batches, hampering commercial viability.

Material constraints further complicate advancement in this field. Autoclave vessels must withstand extreme conditions while remaining inert to reactive components, necessitating specialized construction materials that add to production costs. Additionally, the corrosive nature of some monomers and catalysts used in biodegradable polymer synthesis accelerates equipment degradation, requiring frequent maintenance and replacement.

Recent research has identified catalyst poisoning and unwanted side reactions as significant impediments to achieving high molecular weight biodegradable polymers through autoclave synthesis. These issues often result in premature chain termination and reduced polymer performance. Scientists are exploring novel catalyst systems and protective strategies to overcome these limitations, though comprehensive solutions remain elusive.

Safety considerations also pose substantial challenges, as high-pressure operations inherently carry risks. Modern autoclave systems incorporate multiple redundant safety features, but these add complexity and cost to the equipment, further limiting widespread adoption, particularly in smaller manufacturing facilities and research institutions with limited resources.

In the United States and Europe, autoclave synthesis has reached a relatively mature stage, with sophisticated equipment featuring advanced monitoring systems and precise control mechanisms. These regions lead in developing autoclave technologies that incorporate real-time analytics and automated parameter adjustments. Conversely, in developing economies, adoption remains limited primarily due to high equipment costs and technical expertise requirements, creating a notable technological divide in global distribution.

The primary technical challenges facing autoclave synthesis for biodegradable polymers include energy efficiency concerns, scaling limitations, and process consistency issues. Conventional autoclave operations demand substantial energy inputs to maintain elevated temperatures and pressures, conflicting with sustainability goals inherent to biodegradable polymer production. This contradiction represents a significant hurdle that researchers are actively addressing through alternative heating methods and catalytic innovations.

Scaling production from laboratory to industrial levels presents another formidable challenge. While small-scale autoclaves demonstrate excellent control over reaction conditions, maintaining this precision in larger vessels introduces complexities in heat distribution, pressure regulation, and mixing efficiency. These factors can lead to product inconsistency and quality variations across batches, hampering commercial viability.

Material constraints further complicate advancement in this field. Autoclave vessels must withstand extreme conditions while remaining inert to reactive components, necessitating specialized construction materials that add to production costs. Additionally, the corrosive nature of some monomers and catalysts used in biodegradable polymer synthesis accelerates equipment degradation, requiring frequent maintenance and replacement.

Recent research has identified catalyst poisoning and unwanted side reactions as significant impediments to achieving high molecular weight biodegradable polymers through autoclave synthesis. These issues often result in premature chain termination and reduced polymer performance. Scientists are exploring novel catalyst systems and protective strategies to overcome these limitations, though comprehensive solutions remain elusive.

Safety considerations also pose substantial challenges, as high-pressure operations inherently carry risks. Modern autoclave systems incorporate multiple redundant safety features, but these add complexity and cost to the equipment, further limiting widespread adoption, particularly in smaller manufacturing facilities and research institutions with limited resources.

Current Autoclave Synthesis Methods for Biodegradable Polymers

01 Hydrothermal synthesis of nanomaterials

Autoclave synthesis is widely used for hydrothermal synthesis of nanomaterials under high temperature and pressure conditions. This method enables the controlled growth of crystalline structures by dissolving precursors in water and subjecting them to elevated temperatures and pressures in a sealed vessel. The technique is particularly effective for producing high-quality nanoparticles, nanowires, and other nanostructures with specific morphologies and properties.- Hydrothermal synthesis of nanomaterials: Autoclave synthesis is widely used for hydrothermal synthesis of various nanomaterials under high temperature and pressure conditions. This method enables controlled growth of crystalline structures by utilizing water as a reaction medium above its critical point. The process typically involves placing precursors in a sealed autoclave vessel and heating it to create the necessary pressure for crystal formation. This technique is particularly effective for producing high-quality nanoparticles with specific morphologies and properties.

- Autoclave sterilization and medical applications: Autoclaves are extensively used for sterilization in medical and laboratory settings. The high-pressure steam environment effectively eliminates microorganisms and pathogens. Advanced autoclave systems incorporate precise temperature and pressure controls, monitoring systems, and specialized cycles for different types of medical devices and materials. These systems ensure complete sterilization while maintaining the integrity of heat-sensitive instruments and materials through carefully controlled synthesis conditions.

- Solvothermal synthesis techniques: Solvothermal synthesis in autoclaves uses non-aqueous solvents under high temperature and pressure conditions. This approach offers advantages over traditional hydrothermal methods for certain materials, allowing for synthesis of compounds that are difficult to obtain through water-based reactions. The technique enables precise control over particle size, morphology, and composition by adjusting parameters such as solvent type, temperature, pressure, and reaction time. This method is particularly valuable for producing advanced functional materials with tailored properties.

- Industrial-scale autoclave processes: Industrial autoclave processes are designed for large-scale synthesis and manufacturing operations. These systems feature enhanced safety mechanisms, automated controls, and optimized energy efficiency. Advanced industrial autoclaves incorporate sophisticated pressure and temperature regulation systems, specialized agitation mechanisms, and continuous monitoring capabilities. These features enable consistent production of materials with uniform properties while maintaining strict quality control standards across batches, making them essential for commercial manufacturing of various materials and compounds.

- Novel autoclave reactor designs: Innovative autoclave reactor designs incorporate advanced features for improved synthesis control and efficiency. These include specialized liners for corrosion resistance, enhanced heating and cooling systems, and integrated monitoring technologies. Modern autoclave reactors may feature rotating or oscillating mechanisms to improve mixing, microwave-assisted heating for faster reactions, and modular designs for versatility across different synthesis applications. These technological advancements enable more precise control over reaction conditions, resulting in higher quality products and more efficient synthesis processes.

02 Autoclave equipment design and safety features

Specialized autoclave equipment designs incorporate safety features to manage the high pressures and temperatures required for synthesis reactions. These designs include pressure relief valves, temperature control systems, corrosion-resistant materials, and monitoring devices to ensure safe operation during synthesis processes. Advanced autoclaves may also feature automated control systems, specialized sealing mechanisms, and customized reaction chambers for specific synthesis applications.Expand Specific Solutions03 Pharmaceutical and medical material synthesis

Autoclave synthesis is employed in the pharmaceutical industry for the production of active pharmaceutical ingredients and medical materials. The controlled environment of an autoclave allows for sterile conditions and precise reaction parameters, which are crucial for pharmaceutical synthesis. This method is particularly valuable for creating specialized medical materials, drug delivery systems, and biocompatible compounds that require high purity and specific structural characteristics.Expand Specific Solutions04 Advanced ceramic and composite material synthesis

Autoclave synthesis enables the production of advanced ceramic materials and composites through processes that require high temperature and pressure. This technique allows for the creation of materials with enhanced mechanical, thermal, and electrical properties by facilitating reactions that would not occur under ambient conditions. The method is particularly effective for synthesizing complex oxide ceramics, carbides, nitrides, and multi-component composite materials with controlled microstructures.Expand Specific Solutions05 Green chemistry and sustainable synthesis methods

Autoclave synthesis contributes to green chemistry initiatives by enabling more efficient and environmentally friendly synthesis routes. The closed system of an autoclave allows for better containment of reagents, reduced solvent usage, and improved energy efficiency compared to conventional synthesis methods. This approach can reduce waste generation, minimize the use of hazardous substances, and enable the use of water as a reaction medium instead of organic solvents, aligning with sustainable chemistry principles.Expand Specific Solutions

Key Industry Players in Biodegradable Polymer Manufacturing

The autoclave synthesis field for biodegradable polymers is currently in a growth phase, with market size expanding rapidly due to increasing environmental regulations and consumer demand for sustainable materials. The technology has reached moderate maturity, with established players like Novamont SpA and Plantic Technologies leading commercial applications, while academic institutions such as Zhejiang University and Shandong University drive fundamental research innovations. Major chemical corporations including LG Chem, DuPont, and Cargill are investing significantly in scaling production capabilities, while specialized firms like PHAXTEC focus on niche applications in food packaging and agriculture. The competitive landscape shows a blend of established petrochemical companies pivoting toward bio-based solutions and emerging startups with proprietary biodegradable polymer technologies.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced autoclave synthesis platform for biodegradable polymers, with particular focus on poly(butylene succinate) (PBS) and its copolymers. Their technology utilizes specialized high-pressure autoclave reactors operating at precisely controlled temperatures (180-230°C) and pressures to facilitate two-stage polymerization processes. The first stage involves direct esterification of bio-based succinic acid with 1,4-butanediol, followed by a high-vacuum polycondensation phase to achieve high molecular weights. LG Chem's proprietary titanium-based catalyst systems enable efficient polymerization while minimizing side reactions and catalyst residues. Their autoclave design incorporates sophisticated agitation systems that ensure uniform heat distribution and efficient removal of condensation byproducts, resulting in polymers with narrow molecular weight distribution. The company's BIOICE® product line is manufactured using this technology and features controlled biodegradation rates in various environments. LG Chem has also developed specialized autoclave processes for incorporating comonomers such as adipic acid and terephthalic acid at precise reaction stages, allowing fine-tuning of material properties including crystallinity, flexibility, and degradation rates. Their autoclave systems feature advanced process control technology that monitors and adjusts reaction parameters in real-time, ensuring consistent product quality across production batches.

Strengths: Large-scale commercial production capacity; vertically integrated production from monomer synthesis to polymer processing; ability to produce high-performance biodegradable materials with consistent quality. Weaknesses: Energy-intensive autoclave processes requiring significant capital investment; challenges in achieving ultra-high molecular weights without gel formation; sensitivity to monomer purity variations.

Novamont SpA

Technical Solution: Novamont has developed an innovative autoclave synthesis process for biodegradable polymers, particularly focusing on starch-based bioplastics under their MATER-BI® product line. Their technology utilizes high-pressure autoclave systems operating at controlled temperatures (typically 120-180°C) and pressures (up to 15 bar) to facilitate the complexation between starch and biodegradable polyesters. The process involves destructurization of native starch followed by complexation with synthetic biodegradable polymers in the presence of specific plasticizers. This autoclave-based approach enables precise control over reaction conditions, resulting in materials with tailored biodegradability profiles and mechanical properties comparable to conventional plastics. Novamont's technology incorporates renewable raw materials and employs catalysts that minimize environmental impact during synthesis. Their autoclave systems are designed with energy recovery mechanisms, reducing the overall carbon footprint of the manufacturing process while maintaining high product quality and consistency.

Strengths: Proprietary technology allowing production of fully biodegradable materials with controlled degradation rates; vertical integration from agricultural feedstocks to final products; scalable industrial production capabilities. Weaknesses: Higher production costs compared to conventional plastics; energy-intensive autoclave processes requiring significant capital investment; limited high-temperature applications for some product grades.

Core Patents and Innovations in Autoclave Polymer Synthesis

A process for the preparation of biopolymers

PatentActiveIN1271KOL2014A

Innovation

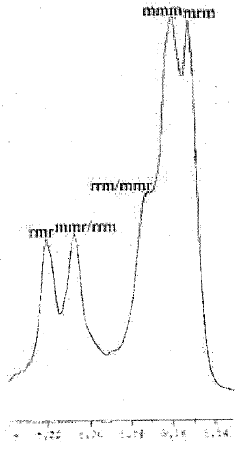

- The use of Bismuth Oxide (Bi2O3) as a catalyst for controlled ring-opening polymerization (ROP) of lactides and ε-caprolactone, allowing for the production of biopolymers with controlled molecular weights and distributions without requiring elaborate ligands, enabling bulk production and reducing costs.

Method for producing expanded thermoplastic polymers

PatentWO2018104009A1

Innovation

- A method involving placing non-expanded thermoplastic polymer in an autoclave partly filled with liquid, increasing pressure with environmentally friendly gaseous fluids below the melting temperature, allowing saturation, and then submerging the material into the liquid to expand, thereby improving thermal control and reducing sticking and anisotropy.

Environmental Impact Assessment of Synthesis Processes

The environmental impact of autoclave synthesis processes in biodegradable polymer development represents a critical consideration for sustainable manufacturing practices. Life cycle assessment (LCA) studies indicate that autoclave synthesis typically consumes significant energy—approximately 25-40 kWh per kilogram of polymer produced—primarily due to the high temperatures and pressures maintained during operation. This energy intensity translates to substantial carbon emissions, with estimates suggesting 2-5 kg CO2 equivalent per kilogram of polymer, depending on energy sources and process efficiency.

Water consumption presents another environmental concern, as autoclave processes require substantial amounts for cooling systems and polymer purification stages. Typical industrial operations consume 10-15 liters of water per kilogram of biodegradable polymer synthesized, with additional environmental impacts arising from wastewater treatment requirements.

Chemical inputs and emissions from autoclave synthesis vary significantly based on catalyst systems and reaction parameters. Traditional metal-based catalysts, while effective, often introduce toxicity concerns and disposal challenges. Recent innovations have focused on developing bio-based catalysts and environmentally benign initiator systems that reduce hazardous waste generation by up to 40% compared to conventional approaches.

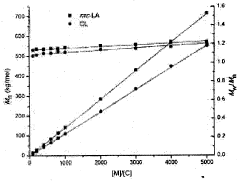

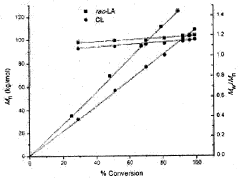

Comparative analyses between autoclave synthesis and alternative methods reveal important sustainability trade-offs. While ring-opening polymerization in autoclaves offers precise control over molecular weight distribution and polymer properties, enzymatic polymerization techniques operate at lower temperatures and pressures, reducing energy requirements by 30-50%. However, these alternative approaches often yield lower production rates and may require more extensive downstream processing.

Waste generation from autoclave synthesis primarily consists of unreacted monomers, solvents, and catalyst residues. Implementation of closed-loop solvent recovery systems has demonstrated potential to recapture and reuse up to 85% of process solvents, significantly reducing environmental footprint. Additionally, advances in catalyst immobilization technologies allow for catalyst recovery and reuse across multiple production cycles.

Recent regulatory frameworks, including the European Union's Sustainable Chemistry Initiative and similar programs in North America and Asia, have established increasingly stringent environmental performance standards for polymer synthesis. These regulations are driving industry adoption of cleaner production technologies, including modified autoclave processes with enhanced energy efficiency and reduced emissions profiles.

Water consumption presents another environmental concern, as autoclave processes require substantial amounts for cooling systems and polymer purification stages. Typical industrial operations consume 10-15 liters of water per kilogram of biodegradable polymer synthesized, with additional environmental impacts arising from wastewater treatment requirements.

Chemical inputs and emissions from autoclave synthesis vary significantly based on catalyst systems and reaction parameters. Traditional metal-based catalysts, while effective, often introduce toxicity concerns and disposal challenges. Recent innovations have focused on developing bio-based catalysts and environmentally benign initiator systems that reduce hazardous waste generation by up to 40% compared to conventional approaches.

Comparative analyses between autoclave synthesis and alternative methods reveal important sustainability trade-offs. While ring-opening polymerization in autoclaves offers precise control over molecular weight distribution and polymer properties, enzymatic polymerization techniques operate at lower temperatures and pressures, reducing energy requirements by 30-50%. However, these alternative approaches often yield lower production rates and may require more extensive downstream processing.

Waste generation from autoclave synthesis primarily consists of unreacted monomers, solvents, and catalyst residues. Implementation of closed-loop solvent recovery systems has demonstrated potential to recapture and reuse up to 85% of process solvents, significantly reducing environmental footprint. Additionally, advances in catalyst immobilization technologies allow for catalyst recovery and reuse across multiple production cycles.

Recent regulatory frameworks, including the European Union's Sustainable Chemistry Initiative and similar programs in North America and Asia, have established increasingly stringent environmental performance standards for polymer synthesis. These regulations are driving industry adoption of cleaner production technologies, including modified autoclave processes with enhanced energy efficiency and reduced emissions profiles.

Scalability and Industrial Implementation Considerations

The scaling of autoclave synthesis processes from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability of biodegradable polymer production. Current industrial implementation typically employs batch reactors ranging from 500L to 10,000L capacity, requiring substantial capital investment and specialized engineering expertise. The transition from lab-scale to industrial production necessitates careful consideration of heat transfer dynamics, as the surface-to-volume ratio decreases dramatically at larger scales, potentially leading to temperature gradients that affect polymer quality.

Process control systems for industrial autoclaves must maintain precise temperature profiles (typically ±1°C) and pressure conditions (±0.5 bar) throughout the polymerization cycle, which may extend from 8 to 48 hours depending on the specific biodegradable polymer being synthesized. Modern facilities increasingly incorporate real-time monitoring technologies, including in-situ spectroscopic methods and advanced sensors, to track reaction progress and polymer molecular weight development.

Energy efficiency represents another critical consideration, with industrial autoclave operations consuming between 0.8-2.5 kWh per kilogram of biodegradable polymer produced. Recent innovations in heat recovery systems have demonstrated potential energy savings of 15-30%, significantly improving the economic and environmental sustainability of these processes. Additionally, solvent recovery and recycling systems have become standard in most commercial operations, with recovery rates exceeding 95% in optimized facilities.

Safety protocols for industrial autoclave operations must address the high-pressure environments (typically 5-30 bar) and potential hazards associated with catalyst handling. Regulatory compliance frameworks, including FDA approval for medical-grade biodegradable polymers, necessitate rigorous validation protocols and documentation of manufacturing processes. The implementation of continuous manufacturing approaches, rather than traditional batch processing, has shown promise in reducing production costs by 20-35% while improving product consistency.

Supply chain considerations for raw materials represent another crucial aspect of industrial implementation. The availability of high-purity monomers, often derived from renewable resources, can fluctuate significantly based on agricultural yields and competing applications. Establishing reliable supplier networks and potentially developing vertical integration strategies may be necessary to ensure consistent production capabilities and manage cost volatility in the biodegradable polymer market.

Process control systems for industrial autoclaves must maintain precise temperature profiles (typically ±1°C) and pressure conditions (±0.5 bar) throughout the polymerization cycle, which may extend from 8 to 48 hours depending on the specific biodegradable polymer being synthesized. Modern facilities increasingly incorporate real-time monitoring technologies, including in-situ spectroscopic methods and advanced sensors, to track reaction progress and polymer molecular weight development.

Energy efficiency represents another critical consideration, with industrial autoclave operations consuming between 0.8-2.5 kWh per kilogram of biodegradable polymer produced. Recent innovations in heat recovery systems have demonstrated potential energy savings of 15-30%, significantly improving the economic and environmental sustainability of these processes. Additionally, solvent recovery and recycling systems have become standard in most commercial operations, with recovery rates exceeding 95% in optimized facilities.

Safety protocols for industrial autoclave operations must address the high-pressure environments (typically 5-30 bar) and potential hazards associated with catalyst handling. Regulatory compliance frameworks, including FDA approval for medical-grade biodegradable polymers, necessitate rigorous validation protocols and documentation of manufacturing processes. The implementation of continuous manufacturing approaches, rather than traditional batch processing, has shown promise in reducing production costs by 20-35% while improving product consistency.

Supply chain considerations for raw materials represent another crucial aspect of industrial implementation. The availability of high-purity monomers, often derived from renewable resources, can fluctuate significantly based on agricultural yields and competing applications. Establishing reliable supplier networks and potentially developing vertical integration strategies may be necessary to ensure consistent production capabilities and manage cost volatility in the biodegradable polymer market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!