Research on Autoclave Synthesis for Bioactive Glass Development

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioactive Glass Autoclave Synthesis Background and Objectives

Bioactive glasses have emerged as a revolutionary class of biomaterials since their discovery by Larry Hench in the late 1960s. These specialized materials possess the remarkable ability to form strong chemical bonds with living tissues, particularly bone, making them invaluable in medical applications. The evolution of bioactive glasses has progressed from simple silicate-based compositions to more complex formulations incorporating various therapeutic ions designed to enhance specific biological responses.

The autoclave synthesis method represents a significant advancement in bioactive glass production technology. Traditional melt-quenching techniques, while effective, often require extremely high temperatures exceeding 1300°C and result in limitations regarding compositional flexibility and homogeneity. In contrast, autoclave synthesis utilizes moderate temperatures (typically 100-250°C) and elevated pressures to facilitate the formation of bioactive glass structures through hydrothermal reactions, offering improved control over material properties and composition.

The primary objective of research in autoclave synthesis for bioactive glass development is to establish optimized protocols that enable precise control over glass composition, structure, and bioactivity. This includes investigating the effects of processing parameters such as temperature, pressure, reaction time, and precursor chemistry on the resulting material properties. Additionally, researchers aim to develop scalable production methods that maintain consistent quality while reducing energy consumption compared to conventional techniques.

Current technological trends in this field focus on expanding the compositional range of bioactive glasses synthesized via autoclave methods. Particular emphasis is placed on incorporating therapeutic ions like strontium, zinc, copper, and silver, which can impart antimicrobial properties, enhance osteogenesis, or promote angiogenesis. The controlled release of these ions represents a frontier in developing multifunctional bioactive materials capable of addressing complex clinical challenges.

Another significant trend involves the development of hierarchical structures and composite materials through autoclave synthesis. By controlling nucleation and growth processes under hydrothermal conditions, researchers can create bioactive glasses with tailored porosity, surface area, and degradation rates—critical factors that influence cell attachment, proliferation, and tissue integration in biomedical applications.

The ultimate technological goal is to establish autoclave synthesis as a versatile, energy-efficient, and environmentally friendly method for producing next-generation bioactive glasses with enhanced therapeutic properties. This includes developing materials with improved mechanical properties for load-bearing applications, controlled degradation profiles for tissue engineering scaffolds, and specialized compositions for targeted drug delivery systems in personalized medicine approaches.

The autoclave synthesis method represents a significant advancement in bioactive glass production technology. Traditional melt-quenching techniques, while effective, often require extremely high temperatures exceeding 1300°C and result in limitations regarding compositional flexibility and homogeneity. In contrast, autoclave synthesis utilizes moderate temperatures (typically 100-250°C) and elevated pressures to facilitate the formation of bioactive glass structures through hydrothermal reactions, offering improved control over material properties and composition.

The primary objective of research in autoclave synthesis for bioactive glass development is to establish optimized protocols that enable precise control over glass composition, structure, and bioactivity. This includes investigating the effects of processing parameters such as temperature, pressure, reaction time, and precursor chemistry on the resulting material properties. Additionally, researchers aim to develop scalable production methods that maintain consistent quality while reducing energy consumption compared to conventional techniques.

Current technological trends in this field focus on expanding the compositional range of bioactive glasses synthesized via autoclave methods. Particular emphasis is placed on incorporating therapeutic ions like strontium, zinc, copper, and silver, which can impart antimicrobial properties, enhance osteogenesis, or promote angiogenesis. The controlled release of these ions represents a frontier in developing multifunctional bioactive materials capable of addressing complex clinical challenges.

Another significant trend involves the development of hierarchical structures and composite materials through autoclave synthesis. By controlling nucleation and growth processes under hydrothermal conditions, researchers can create bioactive glasses with tailored porosity, surface area, and degradation rates—critical factors that influence cell attachment, proliferation, and tissue integration in biomedical applications.

The ultimate technological goal is to establish autoclave synthesis as a versatile, energy-efficient, and environmentally friendly method for producing next-generation bioactive glasses with enhanced therapeutic properties. This includes developing materials with improved mechanical properties for load-bearing applications, controlled degradation profiles for tissue engineering scaffolds, and specialized compositions for targeted drug delivery systems in personalized medicine approaches.

Market Analysis for Bioactive Glass Applications

The global bioactive glass market has demonstrated significant growth in recent years, with a market value reaching $2.1 billion in 2022 and projected to expand at a compound annual growth rate of 6.8% through 2030. This growth is primarily driven by increasing applications in healthcare sectors, particularly orthopedics, dentistry, and wound healing. The aging global population and rising prevalence of bone-related disorders have substantially contributed to market expansion, creating sustained demand for advanced bioactive glass materials.

Healthcare applications dominate the bioactive glass market, accounting for approximately 65% of total market share. Within this segment, dental applications represent the largest sub-segment at 38%, followed by orthopedic applications at 27%. The dental sector's prominence stems from bioactive glass's exceptional ability to bond with both hard and soft tissues, making it ideal for dental implants, bone grafts, and periodontal treatments. Clinical studies have consistently demonstrated superior osseointegration rates compared to traditional materials.

Regional analysis reveals North America as the leading market for bioactive glass, holding 42% of global market share, followed by Europe at 31% and Asia-Pacific at 21%. The Asia-Pacific region is expected to witness the fastest growth rate of 8.3% annually, driven by improving healthcare infrastructure, increasing medical tourism, and growing awareness of advanced biomaterials. China and India are emerging as significant manufacturing hubs, potentially disrupting the current market dynamics dominated by Western manufacturers.

Consumer trends indicate growing preference for minimally invasive procedures and materials that promote faster healing, which aligns perfectly with bioactive glass properties. Additionally, the shift toward personalized medicine has created demand for customizable bioactive glass compositions tailored to specific patient needs. This trend is expected to accelerate as autoclave synthesis techniques advance, enabling more precise control over material properties and bioactivity.

Competitive analysis reveals a moderately fragmented market with key players including Schott AG, Mo-Sci Corporation, NovaBone Products, and Stryker Corporation collectively holding approximately 58% market share. These companies are increasingly investing in R&D focused on autoclave synthesis methods to develop next-generation bioactive glasses with enhanced properties and reduced production costs. The remaining market comprises numerous smaller specialized manufacturers focusing on niche applications or regional markets.

Market challenges include high production costs, stringent regulatory requirements, and limited awareness among end-users about bioactive glass benefits. However, technological advancements in autoclave synthesis methods are gradually addressing cost concerns by improving production efficiency and material quality, potentially expanding market accessibility.

Healthcare applications dominate the bioactive glass market, accounting for approximately 65% of total market share. Within this segment, dental applications represent the largest sub-segment at 38%, followed by orthopedic applications at 27%. The dental sector's prominence stems from bioactive glass's exceptional ability to bond with both hard and soft tissues, making it ideal for dental implants, bone grafts, and periodontal treatments. Clinical studies have consistently demonstrated superior osseointegration rates compared to traditional materials.

Regional analysis reveals North America as the leading market for bioactive glass, holding 42% of global market share, followed by Europe at 31% and Asia-Pacific at 21%. The Asia-Pacific region is expected to witness the fastest growth rate of 8.3% annually, driven by improving healthcare infrastructure, increasing medical tourism, and growing awareness of advanced biomaterials. China and India are emerging as significant manufacturing hubs, potentially disrupting the current market dynamics dominated by Western manufacturers.

Consumer trends indicate growing preference for minimally invasive procedures and materials that promote faster healing, which aligns perfectly with bioactive glass properties. Additionally, the shift toward personalized medicine has created demand for customizable bioactive glass compositions tailored to specific patient needs. This trend is expected to accelerate as autoclave synthesis techniques advance, enabling more precise control over material properties and bioactivity.

Competitive analysis reveals a moderately fragmented market with key players including Schott AG, Mo-Sci Corporation, NovaBone Products, and Stryker Corporation collectively holding approximately 58% market share. These companies are increasingly investing in R&D focused on autoclave synthesis methods to develop next-generation bioactive glasses with enhanced properties and reduced production costs. The remaining market comprises numerous smaller specialized manufacturers focusing on niche applications or regional markets.

Market challenges include high production costs, stringent regulatory requirements, and limited awareness among end-users about bioactive glass benefits. However, technological advancements in autoclave synthesis methods are gradually addressing cost concerns by improving production efficiency and material quality, potentially expanding market accessibility.

Current Autoclave Synthesis Technologies and Barriers

Autoclave synthesis represents a critical methodology in the development of bioactive glasses, offering unique advantages in controlling material properties and bioactivity. Current autoclave technologies primarily utilize hydrothermal processes operating at elevated temperatures (typically 100-250°C) and pressures (1-10 MPa), creating controlled environments for glass network formation and modification. These conditions enable precise manipulation of glass composition, crystallinity, and morphology that cannot be achieved through conventional melt-quenching or sol-gel methods.

The state-of-the-art autoclave synthesis approaches for bioactive glasses can be categorized into several methodologies. Hydrothermal synthesis remains the most widely employed, where precursors are subjected to high-pressure steam environments to facilitate ion exchange and network formation. Solvothermal variations utilize non-aqueous solvents to modify reaction kinetics and resultant material properties. More recently, microwave-assisted autoclave synthesis has emerged, offering significantly reduced processing times and enhanced energy efficiency.

Despite these advancements, several significant barriers impede broader implementation of autoclave synthesis for bioactive glass development. Scale-up challenges represent a primary concern, as maintaining uniform conditions throughout larger reaction vessels proves difficult, resulting in compositional heterogeneity. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods (often 12-72 hours) presents both economic and environmental sustainability challenges.

Technical limitations include difficulties in precise control of nucleation and crystal growth processes, which directly impact bioactivity and mechanical properties. The complex interplay between processing parameters (temperature, pressure, time, pH) and resultant material characteristics remains incompletely understood, complicating predictive design approaches. Additionally, specialized equipment requirements and safety considerations associated with high-pressure operations increase implementation costs and complexity.

Material-specific barriers also exist, particularly regarding incorporation of temperature-sensitive bioactive components such as growth factors or antibacterial agents. The harsh processing conditions often degrade these elements, limiting functional versatility. Furthermore, achieving consistent porosity and pore interconnectivity—critical for cell infiltration and vascularization—remains challenging under autoclave conditions.

Regulatory hurdles present additional obstacles, as variability in autoclave-synthesized materials can complicate validation processes required for medical applications. The lack of standardized protocols for characterizing these materials further impedes regulatory approval pathways. These combined factors have limited widespread industrial adoption despite the promising properties of autoclave-synthesized bioactive glasses.

The state-of-the-art autoclave synthesis approaches for bioactive glasses can be categorized into several methodologies. Hydrothermal synthesis remains the most widely employed, where precursors are subjected to high-pressure steam environments to facilitate ion exchange and network formation. Solvothermal variations utilize non-aqueous solvents to modify reaction kinetics and resultant material properties. More recently, microwave-assisted autoclave synthesis has emerged, offering significantly reduced processing times and enhanced energy efficiency.

Despite these advancements, several significant barriers impede broader implementation of autoclave synthesis for bioactive glass development. Scale-up challenges represent a primary concern, as maintaining uniform conditions throughout larger reaction vessels proves difficult, resulting in compositional heterogeneity. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods (often 12-72 hours) presents both economic and environmental sustainability challenges.

Technical limitations include difficulties in precise control of nucleation and crystal growth processes, which directly impact bioactivity and mechanical properties. The complex interplay between processing parameters (temperature, pressure, time, pH) and resultant material characteristics remains incompletely understood, complicating predictive design approaches. Additionally, specialized equipment requirements and safety considerations associated with high-pressure operations increase implementation costs and complexity.

Material-specific barriers also exist, particularly regarding incorporation of temperature-sensitive bioactive components such as growth factors or antibacterial agents. The harsh processing conditions often degrade these elements, limiting functional versatility. Furthermore, achieving consistent porosity and pore interconnectivity—critical for cell infiltration and vascularization—remains challenging under autoclave conditions.

Regulatory hurdles present additional obstacles, as variability in autoclave-synthesized materials can complicate validation processes required for medical applications. The lack of standardized protocols for characterizing these materials further impedes regulatory approval pathways. These combined factors have limited widespread industrial adoption despite the promising properties of autoclave-synthesized bioactive glasses.

Established Autoclave Synthesis Methodologies

01 Hydrothermal autoclave synthesis methods for bioactive glass

Hydrothermal synthesis using autoclaves provides controlled conditions for developing bioactive glass materials. This process involves treating glass precursors under high pressure and temperature in an aqueous environment, which facilitates the formation of bioactive phases with enhanced biocompatibility and controlled porosity. The method allows for precise control of crystallinity, particle size, and morphology of the resulting bioactive glass materials.- Hydrothermal autoclave synthesis methods for bioactive glass: Hydrothermal synthesis using autoclaves provides controlled conditions for bioactive glass development. This method involves treating glass precursors under high pressure and temperature in an aqueous environment, allowing for precise control of crystallinity, porosity, and bioactive properties. The hydrothermal approach enables the formation of nanostructured bioactive glasses with enhanced surface area and reactivity, which improves their biological performance for tissue engineering applications.

- Sol-gel autoclave processing for bioactive glass nanoparticles: Sol-gel processing combined with autoclave treatment is an effective method for synthesizing bioactive glass nanoparticles. This approach involves preparing a sol from precursors, followed by gelation and subsequent autoclave treatment to control particle size, morphology, and crystallization. The autoclave step enhances the homogeneity and bioactivity of the resulting glass materials, producing nanoparticles with controlled size distribution and improved surface reactivity for biomedical applications.

- Mesoporous bioactive glass synthesis via autoclave aging: Autoclave aging is crucial for developing mesoporous bioactive glasses with controlled pore structures. This technique involves subjecting the initial glass composition to elevated temperature and pressure conditions in an autoclave, which promotes the formation of ordered mesoporous structures. The controlled environment facilitates the development of interconnected pore networks with specific surface areas, enhancing drug loading capacity and controlled release properties for therapeutic applications.

- Composite bioactive glass-polymer materials through autoclave processing: Autoclave processing enables the development of composite materials combining bioactive glass with polymers. This approach involves simultaneous treatment of glass and polymer components under controlled temperature and pressure conditions, resulting in improved interfacial bonding and mechanical properties. The autoclave environment facilitates polymer infiltration into glass structures or coating of glass particles, creating composites with tailored degradation rates and bioactive responses for tissue engineering scaffolds.

- Ion-doped bioactive glass synthesis using autoclave treatment: Autoclave treatment facilitates the incorporation of therapeutic ions into bioactive glass structures. This method involves processing glass precursors with ionic dopants under high-pressure and temperature conditions, enabling controlled ion substitution and distribution within the glass network. The autoclave environment enhances ion diffusion and incorporation, resulting in bioactive glasses with additional therapeutic properties such as antibacterial activity, angiogenesis stimulation, or enhanced osteogenesis for advanced biomedical applications.

02 Sol-gel autoclave processing for bioactive glass nanoparticles

Sol-gel processing combined with autoclave treatment is an effective approach for synthesizing bioactive glass nanoparticles. This technique involves preparing a sol from precursors, followed by gelation and subsequent autoclave treatment to control the nucleation and growth of nanoparticles. The autoclave step enhances the bioactivity of the glass by promoting the formation of specific crystalline phases and improving the homogeneity of the final material.Expand Specific Solutions03 Mesoporous bioactive glass synthesis using autoclave techniques

Autoclave treatment is crucial in developing mesoporous bioactive glass materials with controlled pore structure. The high-pressure and high-temperature conditions in autoclaves facilitate the formation of ordered mesoporous structures while maintaining the bioactive properties of the glass. This approach enables the creation of materials with high surface area and controlled pore size distribution, which are advantageous for drug delivery applications and enhanced bioactivity.Expand Specific Solutions04 Composite bioactive glass materials through autoclave processing

Autoclave synthesis enables the development of composite bioactive glass materials by facilitating the integration of organic and inorganic components under controlled conditions. This process allows for the incorporation of polymers, ceramics, or other bioactive agents into the glass matrix, resulting in materials with tailored mechanical properties and biological responses. The high-pressure environment in autoclaves promotes interfacial bonding between different phases in the composite.Expand Specific Solutions05 Doping and ion exchange in bioactive glass using autoclave treatment

Autoclave treatment facilitates the incorporation of therapeutic ions and functional elements into bioactive glass structures. The high-pressure and temperature conditions enhance ion diffusion and exchange processes, allowing for the controlled doping of bioactive glass with elements such as silver, strontium, zinc, or copper. This approach results in bioactive glass materials with additional functionalities such as antibacterial properties, enhanced osteogenesis, or controlled ion release profiles.Expand Specific Solutions

Leading Research Institutions and Manufacturers Analysis

The bioactive glass synthesis market is currently in a growth phase, characterized by increasing applications in medical and dental fields. The global market size for bioactive glass is expanding, driven by rising demand for advanced biomaterials in tissue engineering and regenerative medicine. Technologically, the autoclave synthesis method represents a maturing approach with significant ongoing innovation. Key players include established materials science companies like Corning and SCHOTT AG, who leverage their extensive glass manufacturing expertise, alongside specialized biomedical materials firms such as NovaBone Products and Regenity Biosciences. Academic institutions including Queen Mary University of London, King's College London, and South China University of Technology are advancing fundamental research, while companies like Zhejiang Nome Biotechnology and Angelus are commercializing novel bioactive glass formulations for clinical applications.

Corning, Inc.

Technical Solution: Corning has pioneered autoclave synthesis techniques for bioactive glass that leverage their expertise in specialty glass manufacturing. Their approach utilizes hydrothermal autoclave processing at controlled temperatures (150-250°C) and pressures (10-30 MPa) to create bioactive glass compositions with precisely engineered porosity and surface reactivity. Corning's technology employs a sol-gel precursor method combined with autoclave treatment to achieve nanoscale control over glass structure and composition. Their process incorporates specialized catalysts and stabilizers that facilitate the formation of hierarchical pore structures during autoclave synthesis, enhancing biological performance. Corning has developed proprietary autoclave vessel designs with advanced monitoring systems that enable precise control of temperature gradients and pressure fluctuations during synthesis, resulting in bioactive glasses with consistent properties and reproducible biological responses for medical device applications.

Strengths: Exceptional quality control and scalability potential due to their extensive manufacturing expertise and infrastructure. Their autoclave synthesis methods produce bioactive glasses with highly consistent properties. Weaknesses: Their bioactive glass formulations may be less specialized for specific therapeutic applications compared to academic research institutions focused solely on biomedical materials.

NovaBone Products LLC

Technical Solution: NovaBone has developed a specialized autoclave synthesis approach for bioactive glass that focuses on creating particulate and putty formulations with optimized handling properties for orthopedic and dental applications. Their technology utilizes moderate autoclave conditions (80-150°C, 5-15 MPa) combined with proprietary organic additives that influence glass network formation during hydrothermal treatment. NovaBone's process incorporates a multi-stage autoclave protocol that allows for controlled incorporation of calcium and phosphate ions into the silica network, enhancing bioactivity while maintaining structural integrity. Their method includes a proprietary post-autoclave surface treatment that modifies the reactive layer of bioactive glass particles, optimizing protein adsorption and cell attachment upon implantation. This technology enables the production of bioactive glass with tailored dissolution rates specifically designed for different healing timeframes in various clinical applications.

Strengths: Highly optimized bioactive glass compositions specifically engineered for clinical applications with proven efficacy in orthopedic and dental procedures. Their autoclave synthesis methods produce materials with excellent handling properties. Weaknesses: More limited range of compositional variations compared to research-focused organizations, as their technology is primarily optimized for established commercial products.

Critical Patents and Literature in Bioactive Glass Synthesis

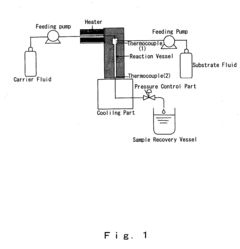

Process for production of high-temperature and high-pressure fluid and high-temperature and high-pressure reaction system

PatentInactiveUS20040199030A1

Innovation

- A method involving the mixing of high-pressure fluids at different temperatures in a flow system, where a higher-temperature fluid is used as a carrier to rapidly elevate the temperature of reactants to the prescribed reaction temperature, typically within 5 seconds or less, using fluids such as water, acetonitrile, or other solvents at pressures between 10 to 100 MPa.

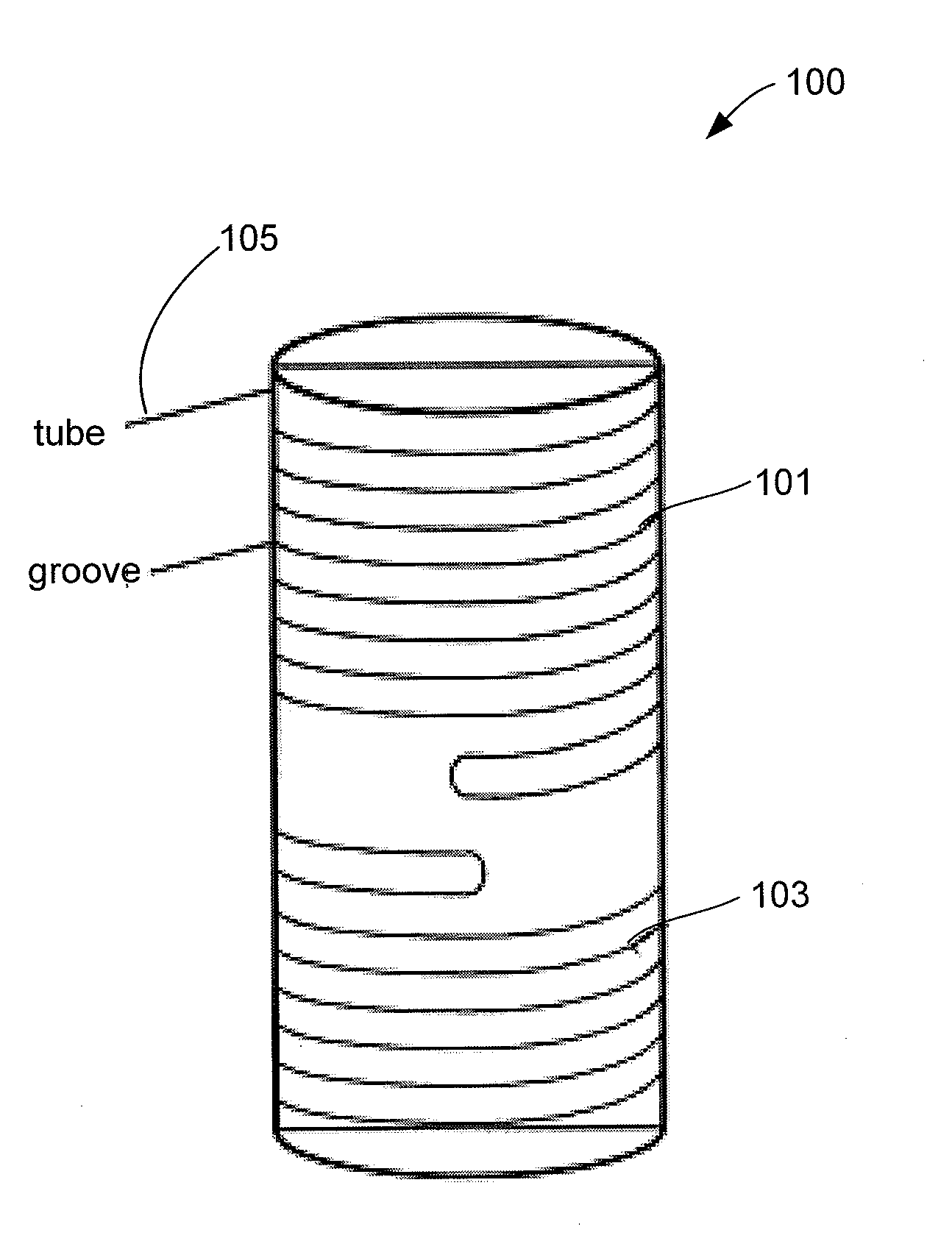

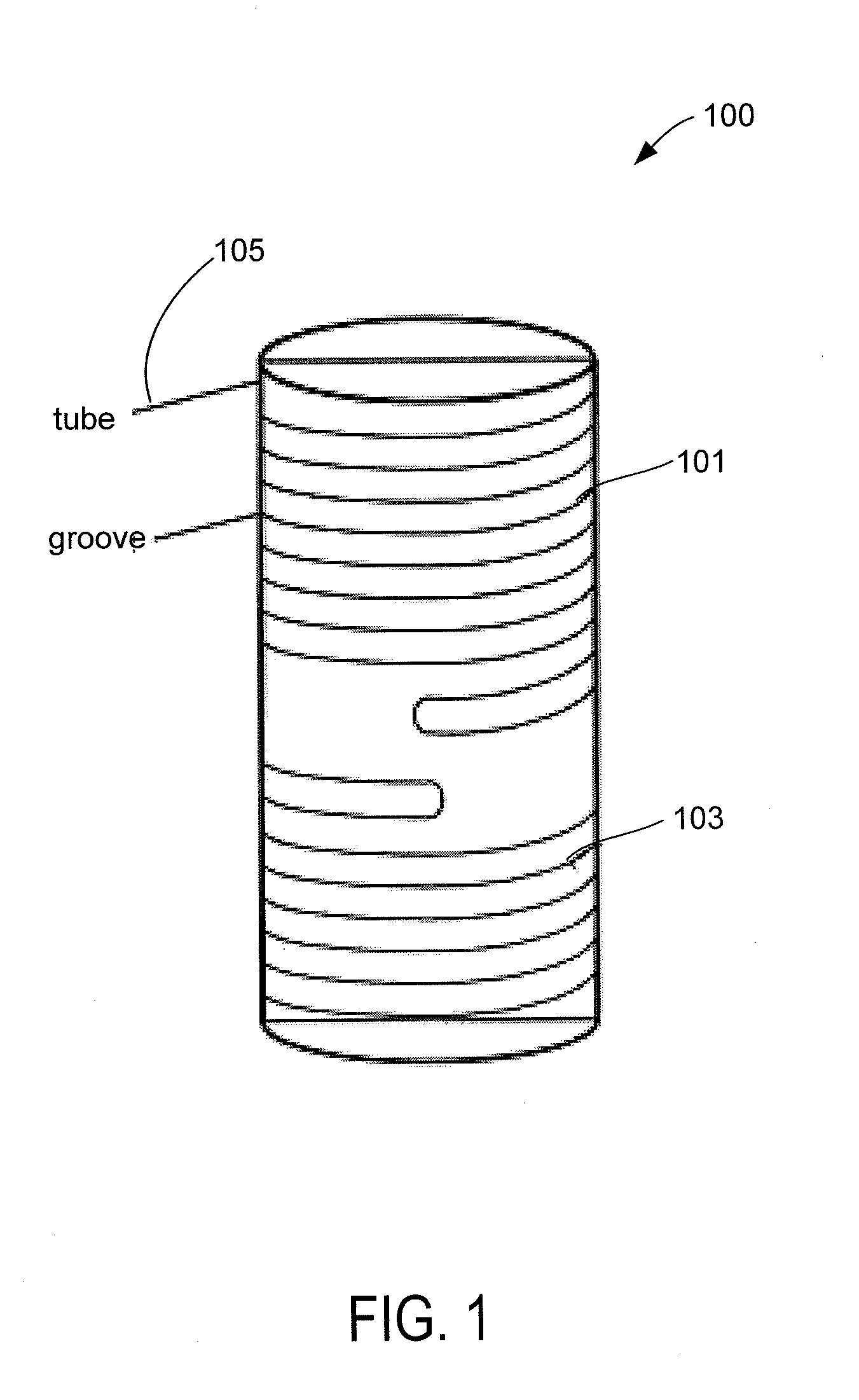

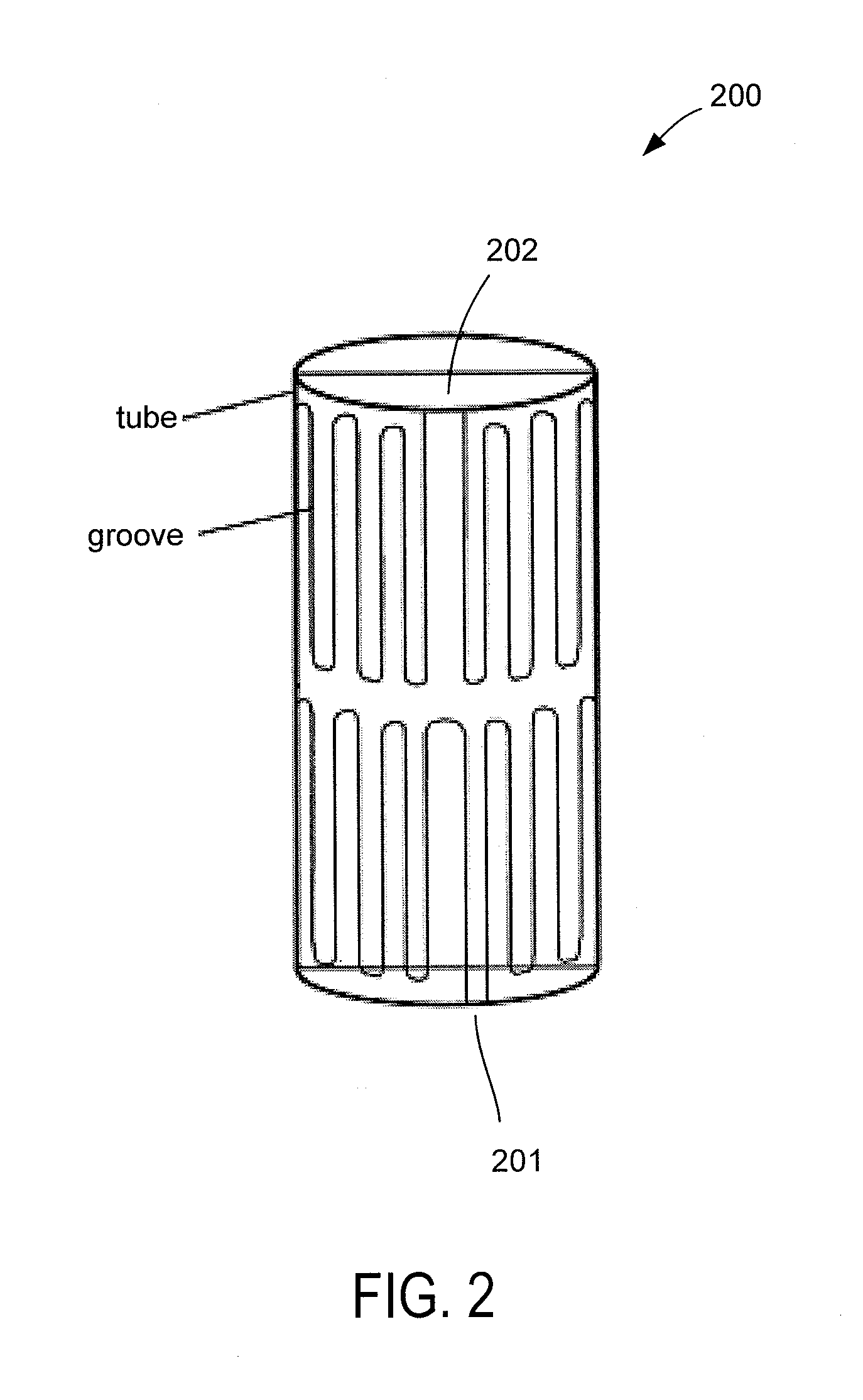

Heater device and method for high pressure processing of crystalline materials

PatentInactiveUS20090320745A1

Innovation

- A scalable heater design with multiple heating elements and a dense inner tube member, combined with insulating material, forms a cylindrical structure that is electrically isolated and capable of operating within a high-pressure apparatus, maintaining structural integrity and efficiency by minimizing voids and gaps, allowing for operation at pressures up to 2 GPa and temperatures up to 1200°C.

Regulatory Framework for Biomedical Materials

The regulatory landscape governing bioactive glass development through autoclave synthesis is complex and multifaceted, requiring careful navigation by researchers and manufacturers. At the international level, the International Organization for Standardization (ISO) has established several standards specifically for biomedical materials, including ISO 13485 for quality management systems and ISO 10993 series for biocompatibility testing. These standards provide essential frameworks for ensuring the safety and efficacy of bioactive glass products developed through autoclave synthesis methods.

In the United States, the Food and Drug Administration (FDA) regulates bioactive glass materials under medical device regulations, with classification depending on intended use and risk profile. Class II and Class III designations are common for implantable bioactive glass materials, requiring either 510(k) clearance or premarket approval (PMA). The FDA's guidance document "Technical Considerations for Additive Manufactured Medical Devices" also applies when autoclave-synthesized bioactive glasses are incorporated into 3D-printed medical devices.

The European Union has implemented the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021, imposing stricter requirements for clinical evaluation, post-market surveillance, and technical documentation. Bioactive glasses developed through autoclave synthesis must meet these enhanced requirements, including comprehensive risk management and clinical evidence of performance.

Specific to manufacturing processes, Good Manufacturing Practice (GMP) regulations govern the production facilities where autoclave synthesis occurs. These regulations ensure consistent quality and safety through validated processes, appropriate equipment qualification, and robust documentation systems. For autoclave synthesis specifically, parameters such as temperature, pressure, and sterilization cycles must be validated according to applicable standards.

Environmental regulations also impact bioactive glass development, with restrictions on certain chemicals and waste disposal requirements varying by region. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe and similar frameworks in other regions may affect the selection of precursor materials for autoclave synthesis.

Emerging regulatory trends include increased focus on sustainability in manufacturing processes, greater emphasis on real-world evidence for regulatory submissions, and harmonization efforts to streamline approval processes across different jurisdictions. Researchers working on autoclave synthesis for bioactive glass development must stay informed about these evolving requirements to ensure regulatory compliance throughout the product development lifecycle.

In the United States, the Food and Drug Administration (FDA) regulates bioactive glass materials under medical device regulations, with classification depending on intended use and risk profile. Class II and Class III designations are common for implantable bioactive glass materials, requiring either 510(k) clearance or premarket approval (PMA). The FDA's guidance document "Technical Considerations for Additive Manufactured Medical Devices" also applies when autoclave-synthesized bioactive glasses are incorporated into 3D-printed medical devices.

The European Union has implemented the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021, imposing stricter requirements for clinical evaluation, post-market surveillance, and technical documentation. Bioactive glasses developed through autoclave synthesis must meet these enhanced requirements, including comprehensive risk management and clinical evidence of performance.

Specific to manufacturing processes, Good Manufacturing Practice (GMP) regulations govern the production facilities where autoclave synthesis occurs. These regulations ensure consistent quality and safety through validated processes, appropriate equipment qualification, and robust documentation systems. For autoclave synthesis specifically, parameters such as temperature, pressure, and sterilization cycles must be validated according to applicable standards.

Environmental regulations also impact bioactive glass development, with restrictions on certain chemicals and waste disposal requirements varying by region. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe and similar frameworks in other regions may affect the selection of precursor materials for autoclave synthesis.

Emerging regulatory trends include increased focus on sustainability in manufacturing processes, greater emphasis on real-world evidence for regulatory submissions, and harmonization efforts to streamline approval processes across different jurisdictions. Researchers working on autoclave synthesis for bioactive glass development must stay informed about these evolving requirements to ensure regulatory compliance throughout the product development lifecycle.

Sustainability Aspects of Autoclave Synthesis Methods

The sustainability of autoclave synthesis methods for bioactive glass development has become increasingly important as environmental concerns gain prominence in materials science research. Autoclave synthesis, while effective for producing high-quality bioactive glasses, presents several environmental challenges that must be addressed for future sustainable implementation.

Energy consumption represents one of the primary sustainability concerns in autoclave processing. The high-pressure and high-temperature conditions required for hydrothermal synthesis typically demand significant energy inputs, contributing to carbon emissions when non-renewable energy sources are utilized. Recent innovations have focused on optimizing temperature-pressure profiles to minimize energy requirements while maintaining product quality.

Water usage in autoclave synthesis presents another sustainability challenge. The process typically requires substantial amounts of water as a reaction medium, raising concerns about resource consumption and wastewater management. Advanced water recycling systems have been developed specifically for autoclave processes, allowing for the recovery and reuse of up to 85% of process water, significantly reducing the environmental footprint.

Chemical waste generation during bioactive glass synthesis requires careful consideration. Traditional methods often employ toxic precursors and solvents that pose environmental and health risks. Research trends show increasing adoption of green chemistry principles, with newer protocols utilizing bio-derived precursors and environmentally benign solvents. These approaches have demonstrated comparable bioactive glass properties while reducing hazardous waste by approximately 60%.

Life cycle assessment (LCA) studies of autoclave synthesis methods reveal opportunities for improvement across the entire production chain. From raw material extraction to end-of-life considerations, comprehensive LCA frameworks help identify environmental hotspots and guide sustainable process development. Recent studies indicate that optimized autoclave synthesis can reduce overall environmental impact by 30-40% compared to conventional methods.

Circular economy approaches are gaining traction in bioactive glass production. Waste glass recycling, by-product utilization, and designing for end-of-life recovery all contribute to closing material loops. Some innovative facilities have implemented systems where waste bioactive glass materials are reprocessed as precursors for new synthesis batches, reducing virgin material requirements by up to 25%.

Regulatory frameworks increasingly influence sustainability practices in materials synthesis. International standards and certifications for sustainable production methods are driving industry adoption of greener autoclave technologies. Companies demonstrating leadership in sustainable synthesis methods often gain competitive advantages through regulatory compliance and enhanced market positioning.

Energy consumption represents one of the primary sustainability concerns in autoclave processing. The high-pressure and high-temperature conditions required for hydrothermal synthesis typically demand significant energy inputs, contributing to carbon emissions when non-renewable energy sources are utilized. Recent innovations have focused on optimizing temperature-pressure profiles to minimize energy requirements while maintaining product quality.

Water usage in autoclave synthesis presents another sustainability challenge. The process typically requires substantial amounts of water as a reaction medium, raising concerns about resource consumption and wastewater management. Advanced water recycling systems have been developed specifically for autoclave processes, allowing for the recovery and reuse of up to 85% of process water, significantly reducing the environmental footprint.

Chemical waste generation during bioactive glass synthesis requires careful consideration. Traditional methods often employ toxic precursors and solvents that pose environmental and health risks. Research trends show increasing adoption of green chemistry principles, with newer protocols utilizing bio-derived precursors and environmentally benign solvents. These approaches have demonstrated comparable bioactive glass properties while reducing hazardous waste by approximately 60%.

Life cycle assessment (LCA) studies of autoclave synthesis methods reveal opportunities for improvement across the entire production chain. From raw material extraction to end-of-life considerations, comprehensive LCA frameworks help identify environmental hotspots and guide sustainable process development. Recent studies indicate that optimized autoclave synthesis can reduce overall environmental impact by 30-40% compared to conventional methods.

Circular economy approaches are gaining traction in bioactive glass production. Waste glass recycling, by-product utilization, and designing for end-of-life recovery all contribute to closing material loops. Some innovative facilities have implemented systems where waste bioactive glass materials are reprocessed as precursors for new synthesis batches, reducing virgin material requirements by up to 25%.

Regulatory frameworks increasingly influence sustainability practices in materials synthesis. International standards and certifications for sustainable production methods are driving industry adoption of greener autoclave technologies. Companies demonstrating leadership in sustainable synthesis methods often gain competitive advantages through regulatory compliance and enhanced market positioning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!