Why Autoclave Synthesis Reinforces Structural Integrity in Aerospace Composites

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the aerospace industry during the mid-20th century. Initially developed as an adaptation from industrial pressure vessel technology, autoclaves became essential tools for composite manufacturing when advanced carbon fiber materials emerged in the 1960s and 1970s. The fundamental principle—applying simultaneous heat and pressure in a controlled environment—has remained consistent, though the sophistication of control systems, size capabilities, and energy efficiency have dramatically improved.

The 1980s marked a pivotal transition as aerospace manufacturers standardized autoclave processes for critical structural components. During this period, maximum operating temperatures increased from approximately 180°C to over 400°C, while pressure capabilities expanded from 5 bar to 20+ bar, enabling the processing of increasingly advanced composite materials with higher performance characteristics.

The 1990s and early 2000s saw significant advancements in automation and process control, with the integration of computerized monitoring systems that allowed for precise temperature ramping, pressure application, and vacuum control. These improvements directly correlated with enhanced composite part quality and consistency, critical factors for aerospace applications where structural integrity cannot be compromised.

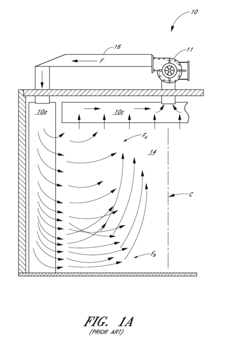

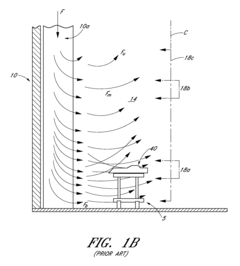

Recent technological developments have focused on energy efficiency and process optimization. Modern autoclaves incorporate advanced thermal insulation, heat recovery systems, and more efficient heating elements, reducing energy consumption by up to 30% compared to earlier generations. Additionally, computational fluid dynamics modeling has enabled optimized airflow designs that ensure temperature uniformity throughout the chamber, addressing one of the historical challenges in autoclave processing.

The primary technical objective of autoclave synthesis in aerospace composites is to achieve maximum consolidation while minimizing void content. Research indicates that pressure application during cure cycles reduces void content to below 1%, compared to 3-5% in non-autoclave processes. This void reduction directly correlates with improved interlaminar shear strength and fatigue resistance—critical properties for aerospace structures subjected to cyclic loading conditions.

Secondary objectives include ensuring complete matrix polymerization, optimizing fiber-matrix interfacial bonding, and maintaining dimensional stability during cure. These factors collectively contribute to the superior mechanical properties and long-term durability that make autoclave-cured composites the gold standard for critical aerospace applications where structural integrity is paramount.

Looking forward, the industry aims to develop more energy-efficient autoclave technologies, reduce cycle times without compromising quality, and enhance process monitoring capabilities through advanced sensor integration and machine learning algorithms for real-time cure optimization.

The 1980s marked a pivotal transition as aerospace manufacturers standardized autoclave processes for critical structural components. During this period, maximum operating temperatures increased from approximately 180°C to over 400°C, while pressure capabilities expanded from 5 bar to 20+ bar, enabling the processing of increasingly advanced composite materials with higher performance characteristics.

The 1990s and early 2000s saw significant advancements in automation and process control, with the integration of computerized monitoring systems that allowed for precise temperature ramping, pressure application, and vacuum control. These improvements directly correlated with enhanced composite part quality and consistency, critical factors for aerospace applications where structural integrity cannot be compromised.

Recent technological developments have focused on energy efficiency and process optimization. Modern autoclaves incorporate advanced thermal insulation, heat recovery systems, and more efficient heating elements, reducing energy consumption by up to 30% compared to earlier generations. Additionally, computational fluid dynamics modeling has enabled optimized airflow designs that ensure temperature uniformity throughout the chamber, addressing one of the historical challenges in autoclave processing.

The primary technical objective of autoclave synthesis in aerospace composites is to achieve maximum consolidation while minimizing void content. Research indicates that pressure application during cure cycles reduces void content to below 1%, compared to 3-5% in non-autoclave processes. This void reduction directly correlates with improved interlaminar shear strength and fatigue resistance—critical properties for aerospace structures subjected to cyclic loading conditions.

Secondary objectives include ensuring complete matrix polymerization, optimizing fiber-matrix interfacial bonding, and maintaining dimensional stability during cure. These factors collectively contribute to the superior mechanical properties and long-term durability that make autoclave-cured composites the gold standard for critical aerospace applications where structural integrity is paramount.

Looking forward, the industry aims to develop more energy-efficient autoclave technologies, reduce cycle times without compromising quality, and enhance process monitoring capabilities through advanced sensor integration and machine learning algorithms for real-time cure optimization.

Aerospace Industry Demand for High-Performance Composites

The aerospace industry's demand for high-performance composites has experienced exponential growth over the past two decades, driven primarily by the need for materials that offer superior strength-to-weight ratios, enhanced durability, and improved fuel efficiency. Commercial aircraft manufacturers like Boeing and Airbus have increased composite usage from approximately 10% in earlier models to over 50% in modern aircraft such as the Boeing 787 Dreamliner and Airbus A350 XWB.

This surge in demand stems from several critical industry requirements. Weight reduction remains paramount, as each kilogram saved in structural weight translates to significant fuel savings over an aircraft's operational lifetime. Modern commercial aircraft operate under increasingly demanding economic conditions, where fuel efficiency directly impacts operational profitability. High-performance composites, particularly those reinforced through autoclave synthesis, deliver weight reductions of 20-30% compared to traditional aluminum structures while maintaining or improving structural integrity.

Durability requirements have similarly intensified as airlines seek to extend service intervals and overall aircraft lifespan. Autoclave-processed composites demonstrate superior fatigue resistance and corrosion immunity compared to metal alternatives, addressing the industry's push toward maintenance cost reduction and extended service life. These materials typically exhibit fatigue life improvements of 2-3 times that of conventional aerospace alloys.

Safety certification standards have become increasingly stringent, requiring materials that maintain structural integrity under extreme conditions. The aerospace industry specifically demands composites that can withstand high-impact events, pressure differentials, and thermal cycling without catastrophic failure. Autoclave-synthesized composites meet these requirements through their enhanced interlaminar strength and reduced void content.

Environmental factors are also driving demand, with regulatory pressures pushing manufacturers toward more fuel-efficient designs. The European Union's Clean Sky initiative and similar programs worldwide have established aggressive emissions reduction targets that can only be achieved through advanced materials implementation. High-performance composites directly support these goals through structural weight optimization.

Military and defense applications represent another significant market segment, with requirements for stealth capabilities, extreme performance envelopes, and resistance to hostile environments. Advanced fighter aircraft like the F-35 utilize autoclave-cured composites for critical structural components, benefiting from their radar-absorbing properties and structural performance under high g-force conditions.

The space sector has emerged as a rapidly growing market for high-performance composites, with private companies and government agencies seeking materials capable of withstanding the extreme conditions of launch, orbit, and re-entry. Satellite structures, launch vehicle components, and habitat modules increasingly rely on autoclave-processed composites for their exceptional strength-to-weight characteristics and thermal stability.

This surge in demand stems from several critical industry requirements. Weight reduction remains paramount, as each kilogram saved in structural weight translates to significant fuel savings over an aircraft's operational lifetime. Modern commercial aircraft operate under increasingly demanding economic conditions, where fuel efficiency directly impacts operational profitability. High-performance composites, particularly those reinforced through autoclave synthesis, deliver weight reductions of 20-30% compared to traditional aluminum structures while maintaining or improving structural integrity.

Durability requirements have similarly intensified as airlines seek to extend service intervals and overall aircraft lifespan. Autoclave-processed composites demonstrate superior fatigue resistance and corrosion immunity compared to metal alternatives, addressing the industry's push toward maintenance cost reduction and extended service life. These materials typically exhibit fatigue life improvements of 2-3 times that of conventional aerospace alloys.

Safety certification standards have become increasingly stringent, requiring materials that maintain structural integrity under extreme conditions. The aerospace industry specifically demands composites that can withstand high-impact events, pressure differentials, and thermal cycling without catastrophic failure. Autoclave-synthesized composites meet these requirements through their enhanced interlaminar strength and reduced void content.

Environmental factors are also driving demand, with regulatory pressures pushing manufacturers toward more fuel-efficient designs. The European Union's Clean Sky initiative and similar programs worldwide have established aggressive emissions reduction targets that can only be achieved through advanced materials implementation. High-performance composites directly support these goals through structural weight optimization.

Military and defense applications represent another significant market segment, with requirements for stealth capabilities, extreme performance envelopes, and resistance to hostile environments. Advanced fighter aircraft like the F-35 utilize autoclave-cured composites for critical structural components, benefiting from their radar-absorbing properties and structural performance under high g-force conditions.

The space sector has emerged as a rapidly growing market for high-performance composites, with private companies and government agencies seeking materials capable of withstanding the extreme conditions of launch, orbit, and re-entry. Satellite structures, launch vehicle components, and habitat modules increasingly rely on autoclave-processed composites for their exceptional strength-to-weight characteristics and thermal stability.

Current Autoclave Synthesis Challenges and Limitations

Despite its proven effectiveness in aerospace composite manufacturing, autoclave synthesis faces several significant challenges and limitations that impact production efficiency, cost-effectiveness, and environmental sustainability. The primary constraint remains the substantial capital investment required for autoclave equipment, with industrial-grade systems costing between $2-10 million depending on size and specifications. This high initial investment creates a significant barrier to entry for smaller manufacturers and limits production capacity expansion.

Energy consumption presents another critical challenge, as autoclaves require enormous amounts of electricity to maintain precise temperature and pressure conditions, typically consuming 100-300 kWh per processing cycle. This energy intensity not only increases operational costs but also contributes to a considerable carbon footprint, raising sustainability concerns in an increasingly environmentally conscious industry.

The physical limitations of autoclave chambers restrict the maximum dimensions of producible composite parts, typically to lengths under 30 meters. This constraint becomes particularly problematic for manufacturing large aerospace structures such as complete wing sections or fuselage components, often necessitating complex joining processes that can introduce potential structural weaknesses.

Processing time inefficiency represents another significant limitation, with typical autoclave cycles lasting 6-12 hours. This extended duration creates production bottlenecks and reduces manufacturing throughput, directly impacting delivery schedules and production capacity. The slow thermal transfer within large autoclaves further exacerbates this issue, sometimes resulting in thermal gradients that can compromise composite quality.

Quality control challenges persist despite technological advancements. The enclosed nature of autoclaves makes real-time monitoring difficult, often requiring manufacturers to rely on pre-programmed cycles without the ability to make dynamic adjustments based on actual curing conditions. This limitation can lead to inconsistencies in composite quality, particularly when processing novel material systems.

Maintenance requirements present ongoing operational challenges, with autoclaves requiring regular specialized servicing to maintain vacuum integrity, pressure systems, and heating elements. These maintenance procedures often necessitate production downtime, further reducing overall manufacturing efficiency.

Recent research has identified specific technical limitations in current autoclave technology, including difficulties in achieving uniform pressure distribution across complex geometries, challenges in controlling resin flow during curing, and limitations in accommodating advanced composite materials with specialized curing requirements. These technical constraints can result in microstructural variations that potentially compromise the structural integrity of finished components.

Energy consumption presents another critical challenge, as autoclaves require enormous amounts of electricity to maintain precise temperature and pressure conditions, typically consuming 100-300 kWh per processing cycle. This energy intensity not only increases operational costs but also contributes to a considerable carbon footprint, raising sustainability concerns in an increasingly environmentally conscious industry.

The physical limitations of autoclave chambers restrict the maximum dimensions of producible composite parts, typically to lengths under 30 meters. This constraint becomes particularly problematic for manufacturing large aerospace structures such as complete wing sections or fuselage components, often necessitating complex joining processes that can introduce potential structural weaknesses.

Processing time inefficiency represents another significant limitation, with typical autoclave cycles lasting 6-12 hours. This extended duration creates production bottlenecks and reduces manufacturing throughput, directly impacting delivery schedules and production capacity. The slow thermal transfer within large autoclaves further exacerbates this issue, sometimes resulting in thermal gradients that can compromise composite quality.

Quality control challenges persist despite technological advancements. The enclosed nature of autoclaves makes real-time monitoring difficult, often requiring manufacturers to rely on pre-programmed cycles without the ability to make dynamic adjustments based on actual curing conditions. This limitation can lead to inconsistencies in composite quality, particularly when processing novel material systems.

Maintenance requirements present ongoing operational challenges, with autoclaves requiring regular specialized servicing to maintain vacuum integrity, pressure systems, and heating elements. These maintenance procedures often necessitate production downtime, further reducing overall manufacturing efficiency.

Recent research has identified specific technical limitations in current autoclave technology, including difficulties in achieving uniform pressure distribution across complex geometries, challenges in controlling resin flow during curing, and limitations in accommodating advanced composite materials with specialized curing requirements. These technical constraints can result in microstructural variations that potentially compromise the structural integrity of finished components.

State-of-the-Art Autoclave Processing Methodologies

01 Monitoring and testing autoclave structural integrity

Various methods and systems for monitoring and testing the structural integrity of autoclaves during synthesis processes. These include non-destructive testing techniques, real-time monitoring systems, and pressure vessel inspection methods that ensure the autoclave maintains its structural integrity under high-pressure and high-temperature conditions. These monitoring systems can detect potential failures before they occur, enhancing safety and reliability of autoclave operations.- Monitoring and testing structural integrity during autoclave synthesis: Various methods and systems for monitoring and testing the structural integrity of materials during autoclave synthesis processes. These include non-destructive testing techniques, real-time monitoring systems, and sensors that can detect potential structural failures or weaknesses. These monitoring systems help ensure the quality and safety of materials synthesized under high-pressure and high-temperature conditions in autoclaves.

- Materials and compositions for enhanced structural integrity in autoclave conditions: Specialized materials and compositions designed to maintain structural integrity under extreme autoclave conditions. These include advanced composites, ceramics, and metal alloys that resist degradation when exposed to high temperatures and pressures. The formulations are specifically engineered to prevent deformation, cracking, or other structural failures during the synthesis process, resulting in more reliable and durable end products.

- Process optimization for maintaining structural integrity: Methodologies and techniques for optimizing autoclave synthesis processes to maintain structural integrity. These include precise control of temperature gradients, pressure cycles, and curing profiles to minimize stress on materials. Advanced process control algorithms and predictive models help determine optimal processing parameters that prevent structural defects while ensuring complete synthesis reactions.

- Structural analysis and simulation for autoclave synthesis: Computational methods and simulation techniques for predicting and analyzing structural behavior during autoclave synthesis. These include finite element analysis, molecular dynamics simulations, and digital twins that model how materials will respond to autoclave conditions. These analytical tools help identify potential weak points and optimize structural designs before physical manufacturing, reducing the risk of integrity failures.

- Post-synthesis evaluation of structural integrity: Methods and systems for evaluating the structural integrity of materials after autoclave synthesis. These include various testing protocols, quality control procedures, and inspection techniques that assess whether the synthesized materials meet required structural specifications. Advanced imaging technologies, mechanical testing, and microstructural analysis help identify any defects or weaknesses that may have developed during the synthesis process.

02 Materials and coatings for enhanced autoclave durability

Advanced materials and protective coatings that improve the structural integrity of autoclaves used in synthesis processes. These materials are designed to withstand extreme conditions including high temperatures, pressures, and corrosive environments typically encountered during autoclave synthesis. Specialized alloys, composite materials, and surface treatments help extend the operational life of autoclaves while maintaining structural integrity throughout repeated synthesis cycles.Expand Specific Solutions03 Design optimization for autoclave structural integrity

Engineering approaches to optimize autoclave design for improved structural integrity during synthesis processes. These include computational modeling, stress analysis, and innovative geometric configurations that distribute pressure more evenly throughout the vessel. Design optimizations focus on critical components such as seals, closures, and support structures to ensure the autoclave can withstand the demanding conditions of synthesis reactions while maintaining safety and efficiency.Expand Specific Solutions04 Process control systems for maintaining autoclave integrity

Automated control systems and methodologies that regulate synthesis conditions within autoclaves to preserve structural integrity. These systems monitor and adjust parameters such as temperature, pressure, heating/cooling rates, and reaction kinetics to prevent conditions that could compromise the autoclave structure. Advanced process control technologies include predictive algorithms, safety interlocks, and emergency response protocols that protect both the synthesis process and the autoclave vessel.Expand Specific Solutions05 Post-synthesis evaluation of autoclave structural integrity

Methods for assessing the structural integrity of autoclaves after synthesis operations to determine maintenance needs and remaining service life. These techniques include ultrasonic testing, radiographic inspection, pressure testing, and material analysis to identify potential degradation, fatigue, or damage caused by synthesis conditions. Regular post-synthesis evaluations help maintain safety standards and optimize maintenance schedules for autoclave equipment.Expand Specific Solutions

Leading Aerospace Manufacturers and Material Suppliers

The autoclave synthesis market for aerospace composites is in a growth phase, characterized by increasing demand for high-performance materials with enhanced structural integrity. The global market is expanding rapidly, driven by the aerospace industry's need for lightweight yet durable components. Boeing, Airbus Operations GmbH, and Spirit AeroSystems lead technological innovation in this field, with significant contributions from Leonardo SpA and Mitsubishi Heavy Industries. Academic institutions like Central South University and MIT collaborate with industry players to advance autoclave processing techniques. The technology has reached moderate maturity but continues to evolve, with companies like Hexcel Composites and Toray Industries developing specialized materials optimized for autoclave conditions, focusing on improving composite performance while reducing processing time and energy consumption.

The Boeing Co.

Technical Solution: Boeing has developed proprietary autoclave synthesis processes for aerospace composites that operate at precisely controlled temperatures (typically 350°F/177°C) and pressures (up to 100 psi) to ensure optimal resin flow and cure cycles. Their approach incorporates vacuum bagging techniques with computerized cure cycle management to minimize void content below 1% in critical structural components. Boeing's autoclave technology enables the production of large-scale composite structures like the 787 Dreamliner's one-piece fuselage sections, which measure up to 33 feet in diameter. Their process utilizes pre-impregnated carbon fiber materials with toughened epoxy systems specifically formulated to withstand the extreme thermal cycling and mechanical stresses encountered in aerospace applications.

Strengths: Industry-leading capability to produce massive one-piece composite structures, reducing weight and eliminating thousands of fasteners. Proprietary cure cycle algorithms optimize material properties. Weaknesses: High energy consumption during autoclave operation and significant capital investment requirements for large autoclaves limit production flexibility.

Airbus Operations GmbH

Technical Solution: Airbus Operations has pioneered advanced autoclave synthesis techniques for aerospace composites featuring multi-zone temperature control systems that maintain temperature uniformity within ±3°C across large composite structures. Their process incorporates specialized pressure application sequences that gradually increase to 7 bar (101.5 psi) to optimize resin flow and minimize fiber distortion. Airbus utilizes proprietary vacuum bagging configurations with breather and bleeder systems designed to extract volatiles while maintaining precise pressure distribution. Their autoclave synthesis approach includes automated real-time monitoring with embedded sensors that track cure progression, allowing for dynamic adjustments to cure parameters. This technology enables Airbus to manufacture complex geometries like the A350 XWB's curved wing components with exceptional dimensional stability and void content below 0.5%.

Strengths: Superior temperature uniformity control across large structures, resulting in consistent material properties. Advanced sensor integration provides real-time cure monitoring. Weaknesses: Complex multi-zone systems require sophisticated control algorithms and experienced operators, increasing operational complexity and training requirements.

Critical Patents in Autoclave Composite Reinforcement

Industrial oven for curing composite material structures

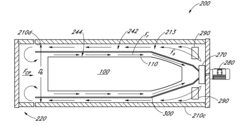

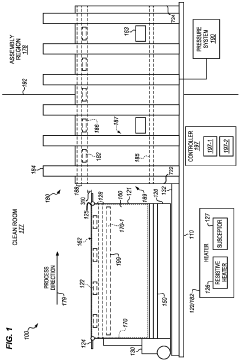

PatentActiveUS20120003597A1

Innovation

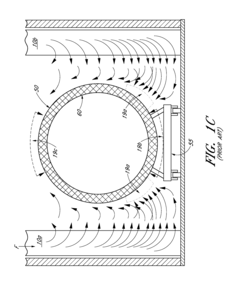

- An industrial oven system with a contoured shroud that directs heated airflow through annular channels to maintain uniform temperature along the length of the composite material structure, using computational fluid dynamics to optimize heat transfer and prevent warping.

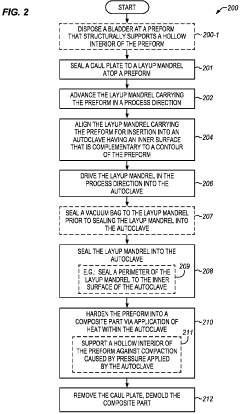

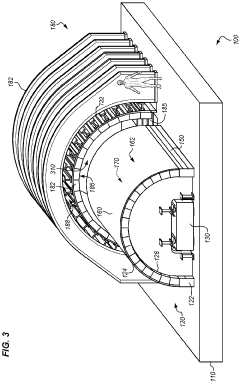

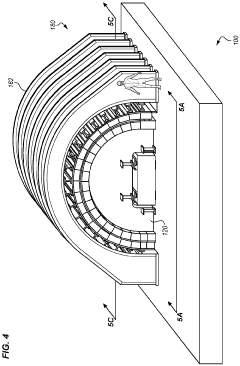

Method and system for sealing an autoclave

PatentActiveEP4000898A1

Innovation

- The development of autoclaves with inner surfaces that match the contours of specific preforms, allowing for a smaller volume to be heated, combined with the use of layup mandrels and caul plates to form a pressure chamber, reducing thermal mass and gas usage, and enabling efficient heating and cooling cycles.

Material Science Advancements for Aerospace Applications

Material science has undergone remarkable evolution in aerospace applications, particularly with the advent of advanced composite materials. These composites, primarily carbon fiber reinforced polymers (CFRPs), have revolutionized aircraft design by offering superior strength-to-weight ratios compared to traditional aluminum alloys. The integration of these materials has enabled significant weight reduction in modern aircraft, with the Boeing 787 Dreamliner and Airbus A350 XWB incorporating approximately 50% composite materials by weight.

The autoclave synthesis process represents a critical advancement in this domain, providing aerospace engineers with a method to create composites with exceptional structural integrity. This process involves placing composite layups in a pressurized vessel where controlled temperature and pressure conditions facilitate optimal curing of the polymer matrix. Typically operating at pressures of 6-7 atmospheres and temperatures ranging from 120°C to 180°C, autoclaves create an environment that minimizes void formation and ensures thorough resin impregnation.

Recent developments in autoclave technology have focused on enhancing process efficiency while maintaining or improving material properties. Digital twin modeling of autoclave processes has emerged as a powerful tool for predicting cure cycles and optimizing parameters for specific composite formulations. These computational approaches have reduced development time by approximately 30% while improving final part quality.

Nanomaterial integration represents another frontier in aerospace composites. Carbon nanotubes and graphene, when properly dispersed within the polymer matrix during autoclave processing, can enhance interlaminar shear strength by up to 40%. These nanomaterials create multiscale reinforcement mechanisms that address traditional weakness points in composite structures.

The aerospace industry has also witnessed significant progress in out-of-autoclave (OOA) processing technologies. While traditional autoclave methods remain superior for critical structural components, OOA techniques have advanced considerably for secondary structures. This dual-track development allows manufacturers to optimize production costs while maintaining stringent performance requirements for primary load-bearing components.

Thermoplastic composites processed through autoclave synthesis have gained attention for their potential recyclability and improved impact resistance. Unlike thermoset composites, these materials can be remelted and reformed, offering sustainability advantages while maintaining the structural benefits of autoclave processing. Boeing's research indicates potential weight savings of 15-20% when using these advanced thermoplastic systems in specific applications.

The autoclave synthesis process represents a critical advancement in this domain, providing aerospace engineers with a method to create composites with exceptional structural integrity. This process involves placing composite layups in a pressurized vessel where controlled temperature and pressure conditions facilitate optimal curing of the polymer matrix. Typically operating at pressures of 6-7 atmospheres and temperatures ranging from 120°C to 180°C, autoclaves create an environment that minimizes void formation and ensures thorough resin impregnation.

Recent developments in autoclave technology have focused on enhancing process efficiency while maintaining or improving material properties. Digital twin modeling of autoclave processes has emerged as a powerful tool for predicting cure cycles and optimizing parameters for specific composite formulations. These computational approaches have reduced development time by approximately 30% while improving final part quality.

Nanomaterial integration represents another frontier in aerospace composites. Carbon nanotubes and graphene, when properly dispersed within the polymer matrix during autoclave processing, can enhance interlaminar shear strength by up to 40%. These nanomaterials create multiscale reinforcement mechanisms that address traditional weakness points in composite structures.

The aerospace industry has also witnessed significant progress in out-of-autoclave (OOA) processing technologies. While traditional autoclave methods remain superior for critical structural components, OOA techniques have advanced considerably for secondary structures. This dual-track development allows manufacturers to optimize production costs while maintaining stringent performance requirements for primary load-bearing components.

Thermoplastic composites processed through autoclave synthesis have gained attention for their potential recyclability and improved impact resistance. Unlike thermoset composites, these materials can be remelted and reformed, offering sustainability advantages while maintaining the structural benefits of autoclave processing. Boeing's research indicates potential weight savings of 15-20% when using these advanced thermoplastic systems in specific applications.

Environmental Impact and Sustainability Considerations

The autoclave synthesis process for aerospace composites presents significant environmental considerations that must be addressed in the context of increasing sustainability demands across industries. The energy-intensive nature of autoclave operations, typically requiring temperatures between 120-180°C and pressures of 6-7 bar for extended periods, results in substantial carbon footprints. A single autoclave cycle for large aerospace components can consume electricity equivalent to powering dozens of households for a month.

Material waste represents another critical environmental concern. The precision required in aerospace applications means that up to 30% of prepreg materials may become scrap during the manufacturing process. These specialized materials contain epoxy resins and other chemicals that present disposal challenges and often cannot be easily recycled using conventional methods.

Volatile organic compounds (VOCs) released during the curing process contribute to air quality concerns. Although modern autoclave facilities implement sophisticated filtration systems, the complete elimination of these emissions remains challenging. Recent regulatory frameworks in Europe and North America have established increasingly stringent limits on permissible VOC emissions from composite manufacturing facilities.

Water usage for cooling systems in autoclave operations presents additional sustainability challenges, particularly in water-stressed regions. A typical aerospace manufacturing facility may consume millions of gallons annually for temperature regulation in autoclave processes, necessitating comprehensive water management strategies.

Industry leaders have begun implementing sustainability initiatives specifically targeting autoclave processes. These include energy recovery systems that capture and repurpose heat from autoclave operations, reducing overall energy consumption by 15-25%. Advanced material utilization techniques, such as automated cutting and placement systems, have demonstrated potential to reduce waste by up to 40% compared to traditional methods.

Emerging technologies show promise for reducing environmental impacts while maintaining the structural integrity benefits of autoclave processing. These include microwave-assisted curing, which can reduce energy consumption by up to 50%, and bio-based resin systems that decrease reliance on petroleum-derived chemicals. Several major aerospace manufacturers have committed to carbon-neutral production targets by 2040, with autoclave process optimization forming a central component of their sustainability roadmaps.

The industry faces a delicate balance between maintaining the proven structural integrity benefits of autoclave synthesis while addressing growing environmental concerns. This balance will likely shape research priorities and technological development in aerospace composite manufacturing for the coming decade.

Material waste represents another critical environmental concern. The precision required in aerospace applications means that up to 30% of prepreg materials may become scrap during the manufacturing process. These specialized materials contain epoxy resins and other chemicals that present disposal challenges and often cannot be easily recycled using conventional methods.

Volatile organic compounds (VOCs) released during the curing process contribute to air quality concerns. Although modern autoclave facilities implement sophisticated filtration systems, the complete elimination of these emissions remains challenging. Recent regulatory frameworks in Europe and North America have established increasingly stringent limits on permissible VOC emissions from composite manufacturing facilities.

Water usage for cooling systems in autoclave operations presents additional sustainability challenges, particularly in water-stressed regions. A typical aerospace manufacturing facility may consume millions of gallons annually for temperature regulation in autoclave processes, necessitating comprehensive water management strategies.

Industry leaders have begun implementing sustainability initiatives specifically targeting autoclave processes. These include energy recovery systems that capture and repurpose heat from autoclave operations, reducing overall energy consumption by 15-25%. Advanced material utilization techniques, such as automated cutting and placement systems, have demonstrated potential to reduce waste by up to 40% compared to traditional methods.

Emerging technologies show promise for reducing environmental impacts while maintaining the structural integrity benefits of autoclave processing. These include microwave-assisted curing, which can reduce energy consumption by up to 50%, and bio-based resin systems that decrease reliance on petroleum-derived chemicals. Several major aerospace manufacturers have committed to carbon-neutral production targets by 2040, with autoclave process optimization forming a central component of their sustainability roadmaps.

The industry faces a delicate balance between maintaining the proven structural integrity benefits of autoclave synthesis while addressing growing environmental concerns. This balance will likely shape research priorities and technological development in aerospace composite manufacturing for the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!