How Autoclave Synthesis Reduces Defects in Synthetic Diamond Growth

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Diamond Synthesis Background and Objectives

Synthetic diamond production has evolved significantly since its inception in the 1950s, with autoclave synthesis emerging as a pivotal technique for high-quality diamond creation. This high-pressure high-temperature (HPHT) method utilizes specialized pressure vessels to create controlled environments mimicking the extreme conditions under which natural diamonds form. The evolution of autoclave technology has been marked by continuous refinements in pressure control, temperature stability, and growth medium composition, all aimed at reducing defect formation during crystal growth.

The fundamental principle behind autoclave synthesis involves dissolving carbon source material in a metal solvent/catalyst under extreme pressure (typically 5-6 GPa) and temperature (around 1300-1600°C). This creates a supersaturated solution from which carbon precipitates as diamond on seed crystals. Historical developments show a progression from basic belt apparatus designs to more sophisticated cubic and split-sphere systems, each iteration improving control over growth parameters.

Current technological objectives in autoclave diamond synthesis primarily focus on defect reduction through several mechanisms: precise control of temperature gradients, elimination of impurity incorporation, management of growth sector boundaries, and minimization of internal strain. These objectives align with market demands for higher quality synthetic diamonds with fewer structural and point defects that compromise optical, electronic, and mechanical properties.

The scientific understanding of defect formation mechanisms has advanced considerably, revealing how factors such as growth rate fluctuations, impurity segregation, and dislocation propagation contribute to defect generation. Modern autoclave systems incorporate innovations such as multi-zone heating, advanced pressure regulation systems, and computer-controlled growth cycles to address these challenges.

Research objectives in this field now extend beyond mere defect reduction to include targeted defect engineering for specific applications. For instance, controlled nitrogen-vacancy centers are valuable for quantum computing applications, while phosphorus doping enables semiconductor functionality. The ability to selectively introduce or eliminate specific defects represents the frontier of autoclave synthesis technology.

The trajectory of autoclave synthesis development points toward increasingly precise control over growth conditions, with real-time monitoring and feedback systems enabling dynamic adjustments during the growth process. This technological evolution aims to bridge the quality gap between synthetic and natural diamonds while expanding the range of possible applications in electronics, optics, quantum technologies, and industrial tooling.

The fundamental principle behind autoclave synthesis involves dissolving carbon source material in a metal solvent/catalyst under extreme pressure (typically 5-6 GPa) and temperature (around 1300-1600°C). This creates a supersaturated solution from which carbon precipitates as diamond on seed crystals. Historical developments show a progression from basic belt apparatus designs to more sophisticated cubic and split-sphere systems, each iteration improving control over growth parameters.

Current technological objectives in autoclave diamond synthesis primarily focus on defect reduction through several mechanisms: precise control of temperature gradients, elimination of impurity incorporation, management of growth sector boundaries, and minimization of internal strain. These objectives align with market demands for higher quality synthetic diamonds with fewer structural and point defects that compromise optical, electronic, and mechanical properties.

The scientific understanding of defect formation mechanisms has advanced considerably, revealing how factors such as growth rate fluctuations, impurity segregation, and dislocation propagation contribute to defect generation. Modern autoclave systems incorporate innovations such as multi-zone heating, advanced pressure regulation systems, and computer-controlled growth cycles to address these challenges.

Research objectives in this field now extend beyond mere defect reduction to include targeted defect engineering for specific applications. For instance, controlled nitrogen-vacancy centers are valuable for quantum computing applications, while phosphorus doping enables semiconductor functionality. The ability to selectively introduce or eliminate specific defects represents the frontier of autoclave synthesis technology.

The trajectory of autoclave synthesis development points toward increasingly precise control over growth conditions, with real-time monitoring and feedback systems enabling dynamic adjustments during the growth process. This technological evolution aims to bridge the quality gap between synthetic and natural diamonds while expanding the range of possible applications in electronics, optics, quantum technologies, and industrial tooling.

Market Analysis for High-Quality Synthetic Diamonds

The global market for high-quality synthetic diamonds continues to experience robust growth, driven by increasing demand across multiple sectors including jewelry, industrial applications, and emerging technologies. Current market valuations place the synthetic diamond industry at approximately $20 billion, with projections indicating a compound annual growth rate of 7.5% through 2028. This growth trajectory significantly outpaces that of natural diamonds, reflecting shifting consumer preferences and expanding industrial applications.

The jewelry segment represents the largest market share for high-quality synthetic diamonds, accounting for roughly 45% of total demand. This sector has witnessed remarkable transformation as consumer perception evolves from viewing synthetic diamonds as mere substitutes to recognizing them as ethically superior alternatives. Price points for gem-quality synthetic diamonds typically range from 30-40% lower than comparable natural diamonds, creating a compelling value proposition for price-conscious consumers.

Industrial applications constitute the second-largest market segment, representing approximately 35% of demand. High-purity synthetic diamonds with minimal defects are essential for cutting tools, abrasives, and thermal management solutions in electronics. The semiconductor industry in particular has emerged as a critical growth driver, with demand for diamond substrates and heat spreaders increasing by over 15% annually due to their superior thermal conductivity properties.

Geographically, North America and Europe currently dominate market consumption, collectively accounting for over 60% of global demand for high-quality synthetic diamonds. However, the Asia-Pacific region, led by China, Japan, and India, represents the fastest-growing market with annual growth rates exceeding 10%. This regional shift reflects both expanding manufacturing capabilities and increasing consumer acceptance in emerging economies.

The market demonstrates clear price sensitivity to defect levels, with premium pricing directly correlated to diamond purity. Autoclave synthesis methods that reduce defects command price premiums of 50-200% compared to diamonds with visible inclusions or color imperfections. This price differential underscores the significant market incentive for technological advancements in defect reduction during synthesis.

Competitive dynamics within the market reveal consolidation among major producers, with the top five manufacturers controlling approximately 65% of global production capacity. However, technological innovations in defect reduction are enabling smaller specialized producers to establish defensible market positions through quality differentiation rather than volume production.

The jewelry segment represents the largest market share for high-quality synthetic diamonds, accounting for roughly 45% of total demand. This sector has witnessed remarkable transformation as consumer perception evolves from viewing synthetic diamonds as mere substitutes to recognizing them as ethically superior alternatives. Price points for gem-quality synthetic diamonds typically range from 30-40% lower than comparable natural diamonds, creating a compelling value proposition for price-conscious consumers.

Industrial applications constitute the second-largest market segment, representing approximately 35% of demand. High-purity synthetic diamonds with minimal defects are essential for cutting tools, abrasives, and thermal management solutions in electronics. The semiconductor industry in particular has emerged as a critical growth driver, with demand for diamond substrates and heat spreaders increasing by over 15% annually due to their superior thermal conductivity properties.

Geographically, North America and Europe currently dominate market consumption, collectively accounting for over 60% of global demand for high-quality synthetic diamonds. However, the Asia-Pacific region, led by China, Japan, and India, represents the fastest-growing market with annual growth rates exceeding 10%. This regional shift reflects both expanding manufacturing capabilities and increasing consumer acceptance in emerging economies.

The market demonstrates clear price sensitivity to defect levels, with premium pricing directly correlated to diamond purity. Autoclave synthesis methods that reduce defects command price premiums of 50-200% compared to diamonds with visible inclusions or color imperfections. This price differential underscores the significant market incentive for technological advancements in defect reduction during synthesis.

Competitive dynamics within the market reveal consolidation among major producers, with the top five manufacturers controlling approximately 65% of global production capacity. However, technological innovations in defect reduction are enabling smaller specialized producers to establish defensible market positions through quality differentiation rather than volume production.

Current Challenges in Defect Reduction Technologies

Despite significant advancements in synthetic diamond production, several critical challenges persist in defect reduction technologies within autoclave synthesis methods. The primary obstacle remains the precise control of growth conditions at extreme pressures (5-6 GPa) and temperatures (1300-1600°C). Even minor fluctuations in these parameters can lead to the formation of unwanted defects, including nitrogen impurities, dislocations, and inclusions that compromise the diamond's structural integrity and optical properties.

Temperature gradient management presents another significant challenge, as uneven heat distribution across the growth chamber creates inconsistent crystallization environments. This results in sector-dependent defect incorporation, where different crystal faces accumulate varying types and concentrations of impurities. Current heating technologies struggle to maintain the required precision across the entire growth volume throughout the extended synthesis period.

Carbon source purity remains problematic despite advances in materials science. Trace contaminants in graphite or other carbon precursors inevitably become incorporated into the diamond lattice. While ultra-purification techniques exist, they significantly increase production costs, creating a challenging economic trade-off between diamond quality and commercial viability.

Nitrogen management continues to be particularly troublesome in HPHT synthesis. As the most common impurity in synthetic diamonds, nitrogen atoms readily substitute for carbon in the diamond lattice, creating color centers and affecting electronic properties. Current nitrogen getters (typically titanium or aluminum) have limited efficiency, especially during long growth runs where getter saturation occurs.

Seed crystal quality substantially impacts defect propagation. Imperfections in seed crystals tend to extend into newly grown material through epitaxial replication. The industry faces challenges in consistently producing defect-free seed crystals at scale, creating a problematic cycle where defects perpetuate across generations of synthetic diamonds.

Growth rate optimization presents a fundamental dilemma. Faster growth rates improve economic efficiency but typically increase defect density. Conversely, slower, more controlled growth reduces defects but extends production time and raises costs. Finding the optimal balance remains elusive, particularly when scaling production.

Monitoring and control systems for real-time defect detection during synthesis represent another technological gap. Current processes rely heavily on post-growth characterization rather than in-situ monitoring, limiting the ability to make dynamic adjustments during the growth process to minimize defect formation.

Temperature gradient management presents another significant challenge, as uneven heat distribution across the growth chamber creates inconsistent crystallization environments. This results in sector-dependent defect incorporation, where different crystal faces accumulate varying types and concentrations of impurities. Current heating technologies struggle to maintain the required precision across the entire growth volume throughout the extended synthesis period.

Carbon source purity remains problematic despite advances in materials science. Trace contaminants in graphite or other carbon precursors inevitably become incorporated into the diamond lattice. While ultra-purification techniques exist, they significantly increase production costs, creating a challenging economic trade-off between diamond quality and commercial viability.

Nitrogen management continues to be particularly troublesome in HPHT synthesis. As the most common impurity in synthetic diamonds, nitrogen atoms readily substitute for carbon in the diamond lattice, creating color centers and affecting electronic properties. Current nitrogen getters (typically titanium or aluminum) have limited efficiency, especially during long growth runs where getter saturation occurs.

Seed crystal quality substantially impacts defect propagation. Imperfections in seed crystals tend to extend into newly grown material through epitaxial replication. The industry faces challenges in consistently producing defect-free seed crystals at scale, creating a problematic cycle where defects perpetuate across generations of synthetic diamonds.

Growth rate optimization presents a fundamental dilemma. Faster growth rates improve economic efficiency but typically increase defect density. Conversely, slower, more controlled growth reduces defects but extends production time and raises costs. Finding the optimal balance remains elusive, particularly when scaling production.

Monitoring and control systems for real-time defect detection during synthesis represent another technological gap. Current processes rely heavily on post-growth characterization rather than in-situ monitoring, limiting the ability to make dynamic adjustments during the growth process to minimize defect formation.

Current Autoclave Techniques for Defect Minimization

01 High-pressure high-temperature (HPHT) autoclave methods for diamond synthesis

High-pressure high-temperature (HPHT) autoclave methods are used for synthetic diamond growth, where specific pressure and temperature conditions are maintained to convert carbon source materials into diamond. These methods typically involve specialized autoclave designs that can withstand extreme conditions while minimizing defect formation. The process parameters must be carefully controlled to reduce structural defects and impurities in the resulting diamond crystals.- High-pressure high-temperature (HPHT) autoclave methods for diamond synthesis: High-pressure high-temperature (HPHT) autoclave methods are used for synthetic diamond growth, where specific pressure and temperature conditions are maintained to convert carbon source materials into diamond. These methods typically involve specialized autoclave designs that can withstand extreme conditions while minimizing defects in the resulting diamond crystals. The process parameters must be carefully controlled to reduce impurities and structural defects that can affect diamond quality.

- Defect control and reduction techniques in autoclave diamond synthesis: Various techniques are employed to control and reduce defects during autoclave synthesis of diamonds. These include precise control of temperature gradients, pressure regulation, and the use of specific catalysts or growth modifiers. Methods for minimizing nitrogen incorporation, dislocations, and other structural imperfections are critical for producing high-quality synthetic diamonds. Post-growth treatments may also be applied to reduce certain types of defects in the final diamond product.

- Catalyst-solvent systems for controlling diamond growth and defects: Specific catalyst-solvent systems are utilized in autoclave diamond synthesis to control growth rates and minimize defects. These systems typically involve metal catalysts (such as Fe, Ni, Co, or their alloys) that facilitate carbon dissolution and recrystallization as diamond. The composition and purity of these catalyst-solvent systems significantly impact the type and concentration of defects in the resulting synthetic diamonds. Innovations in catalyst formulations aim to produce diamonds with fewer metallic inclusions and structural imperfections.

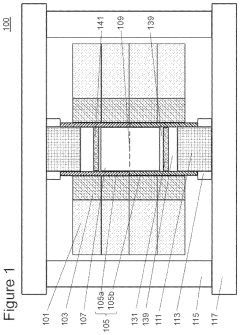

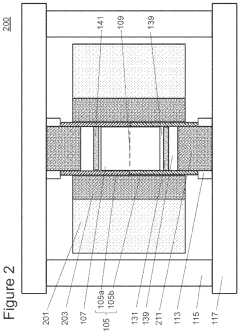

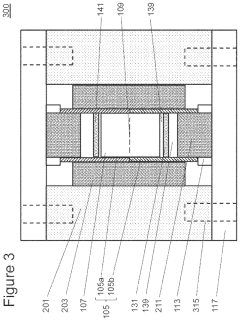

- Equipment design and modifications for improved diamond synthesis: Specialized autoclave equipment designs and modifications are implemented to improve synthetic diamond growth and reduce defects. These include innovations in pressure vessel construction, heating element configurations, and temperature monitoring systems. Advanced autoclave designs incorporate features to maintain more uniform growth conditions, prevent contamination, and allow for better control of the synthesis process. Equipment modifications also focus on safety features to manage the extreme conditions required for diamond synthesis.

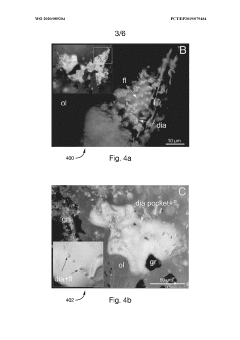

- Novel approaches to defect characterization and quality control in synthetic diamonds: Advanced methods for characterizing and controlling defects in autoclave-synthesized diamonds have been developed. These include spectroscopic techniques, microscopy, and other analytical methods to identify and quantify various types of defects. Quality control processes are implemented throughout the synthesis workflow to monitor and adjust growth parameters based on defect formation. Post-growth analysis helps categorize diamonds according to their defect profiles and suitability for different applications, from industrial uses to gemstone production.

02 Defect control and reduction techniques in autoclave diamond synthesis

Various techniques have been developed to control and reduce defects during autoclave synthesis of diamonds. These include precise control of temperature gradients, pressure cycling, and the use of specific catalysts or growth modifiers. Methods for minimizing nitrogen incorporation, dislocations, and other structural imperfections focus on optimizing growth conditions and using getter materials to trap unwanted impurities. Post-growth treatments may also be applied to reduce certain types of defects.Expand Specific Solutions03 Catalyst-solvent systems for controlling diamond growth and defects

Specific catalyst-solvent systems are employed in autoclave diamond synthesis to control growth rates and minimize defects. These systems typically involve metal catalysts (such as Fe, Ni, Co, or their alloys) that facilitate carbon dissolution and recrystallization as diamond. The composition and purity of these catalyst systems significantly impact the type and concentration of defects in the resulting diamonds. Innovations in catalyst design focus on reducing metal inclusions and improving crystal quality.Expand Specific Solutions04 Autoclave equipment design for defect minimization

Specialized autoclave equipment designs are crucial for minimizing defects in synthetic diamond growth. These designs incorporate features such as precise temperature control systems, uniform pressure distribution mechanisms, and specialized growth chambers. Advanced monitoring systems allow for real-time adjustment of growth parameters to prevent defect formation. Innovations in autoclave materials and construction techniques help maintain stable growth conditions over extended periods, resulting in higher quality diamonds with fewer defects.Expand Specific Solutions05 Characterization and analysis of defects in autoclave-synthesized diamonds

Various analytical techniques are employed to characterize and understand defects in autoclave-synthesized diamonds. These include spectroscopic methods (such as infrared, Raman, and photoluminescence), electron microscopy, X-ray diffraction, and cathodoluminescence. These techniques help identify specific defect types, their distribution, and their impact on diamond properties. Understanding defect formation mechanisms enables the development of improved synthesis protocols and post-growth treatments to enhance diamond quality for specific applications.Expand Specific Solutions

Leading Companies in Synthetic Diamond Production

The autoclave synthesis market for synthetic diamonds is in a growth phase, with increasing demand for high-quality, defect-reduced diamonds across industrial and gemstone applications. The global market is expanding as technology matures, with estimated annual growth of 7-9%. Leading players like Element Six, Sumitomo Electric Industries, and Henan Liliang Diamond have established strong technological positions through proprietary autoclave processes. Research institutions including CNRS, CEA, and Tohoku University are advancing fundamental understanding of defect reduction mechanisms. The competitive landscape features both established industrial giants with vertically integrated operations and specialized technology providers like Plasmability LLC and M7D Corp. focusing on CVD equipment optimization. The technology is approaching maturity but continues to evolve with innovations in pressure control, temperature management, and catalyst systems.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed a sophisticated temperature-gradient controlled autoclave synthesis method for diamond growth that significantly reduces common defects. Their process operates at pressures of 5-6 GPa and temperatures of 1300-1600°C, utilizing a proprietary metal catalyst system that minimizes nitrogen incorporation during crystal formation. The company's technology features precise control of carbon supersaturation through carefully engineered temperature gradients within the growth cell, allowing carbon atoms to deposit in a more ordered manner on the seed crystal. Sumitomo's autoclave systems incorporate advanced monitoring capabilities that detect and correct growth anomalies in real-time, reducing the formation of inclusions and dislocations. Their method includes a specialized cooling protocol that prevents thermal stress-induced defects during the post-growth phase. This comprehensive approach has enabled Sumitomo to produce synthetic diamonds with defect concentrations below 10 ppb for certain applications, particularly for their electronic and optical grade materials.

Strengths: Exceptional control over nitrogen and other impurity incorporation; ability to produce large single crystals with consistent quality; advanced automation systems that ensure reproducibility across production runs. Weaknesses: Relatively slow growth rates compared to some competing technologies; high capital investment requirements for equipment; limited scalability for mass production of larger stones.

Element Six Ltd.

Technical Solution: Element Six has pioneered advanced autoclave synthesis techniques for diamond growth, utilizing High Pressure High Temperature (HPHT) processes operating at approximately 5-6 GPa and temperatures exceeding 1400°C. Their proprietary technology employs carefully controlled metal catalysts (typically Fe, Ni, Co alloys) within sealed autoclave chambers to create an environment where carbon dissolves and precipitates as diamond. Element Six's process incorporates precise temperature gradient control systems that maintain optimal supersaturation conditions, significantly reducing common defects such as nitrogen inclusions and dislocations. Their advanced monitoring systems allow real-time adjustments to growth parameters, resulting in diamonds with fewer than 1 ppm nitrogen impurities in their highest grade synthetic diamonds. The company has also developed specialized post-growth treatments that can further reduce defects through controlled annealing processes in the autoclave environment.

Strengths: Superior control over growth parameters allowing production of ultra-high purity diamonds with minimal defects; proprietary catalyst formulations that enhance growth rates while maintaining quality; extensive intellectual property portfolio protecting their techniques. Weaknesses: Higher production costs compared to conventional methods; longer growth cycles required for larger stones; energy-intensive process with significant environmental footprint.

Key Patents in Autoclave Diamond Synthesis

High-pressure synthesis of diamond

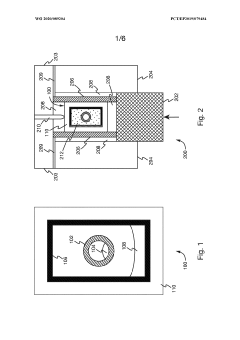

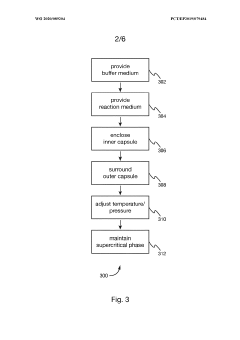

PatentWO2020089204A1

Innovation

- A device comprising an inner hydrogen-permeable capsule with a buffer medium to stabilize hydrogen fugacity, an outer capsule with a reaction medium, and a pressure medium that inhibits hydrogen exchange, allowing for diamond synthesis at lower pressures and temperatures without diamond seed crystals.

Internally-heated high-pressure apparatus for solvothermal crystal growth

PatentPendingUS20240026562A1

Innovation

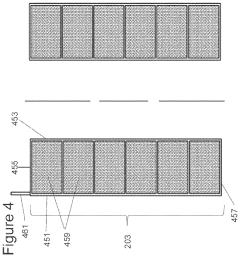

- An improved internally-heated high-pressure apparatus using a packed-bed ceramic composition as a load-bearing thermal insulator, allowing for radial and axial support, operates at pressures between 5-500 MPa and temperatures between 200-900 degrees Celsius, reducing costs and increasing scalability.

Environmental Impact of Autoclave Synthesis Methods

The environmental impact of autoclave synthesis methods for diamond production represents a critical consideration in the broader context of sustainable manufacturing practices. Autoclave synthesis, while primarily valued for its defect reduction capabilities, also offers significant environmental advantages compared to alternative diamond synthesis techniques such as High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD) methods.

Energy efficiency stands as one of the most notable environmental benefits of autoclave synthesis. The controlled pressure and temperature conditions in autoclave systems typically require less energy input than HPHT processes, which demand extreme conditions maintained over extended periods. Studies indicate that optimized autoclave systems can achieve energy reductions of 15-30% compared to traditional HPHT methods, contributing to lower carbon footprints in manufacturing operations.

Water consumption and management represent another environmental dimension where autoclave synthesis demonstrates advantages. Modern autoclave systems implement closed-loop water recycling mechanisms that significantly reduce freshwater requirements. This recycling capability minimizes wastewater discharge and associated treatment needs, addressing growing concerns about industrial water usage in regions facing water scarcity challenges.

Chemical usage efficiency in autoclave synthesis further enhances its environmental profile. The contained environment of autoclaves allows for precise control of catalysts and growth media, reducing waste and preventing the release of potentially harmful substances. Advanced autoclave designs incorporate filtration systems that capture and recycle growth solution components, minimizing the need for continuous chemical replenishment.

Emissions reduction constitutes a significant environmental benefit of autoclave synthesis. The sealed nature of autoclave chambers prevents the escape of process gases and particulates that might otherwise contribute to air pollution. This containment capability is particularly important when working with carbon-based precursors and metallic catalysts that could pose environmental hazards if released.

Life cycle assessment studies comparing diamond synthesis methods have demonstrated that autoclave processes generally produce lower environmental impacts across multiple categories including global warming potential, acidification potential, and resource depletion. These advantages become particularly pronounced when considering the entire production chain from raw material extraction through manufacturing to end-of-life disposal.

The environmental benefits of autoclave synthesis align with growing regulatory pressures and market demands for sustainable production methods in luxury goods and industrial materials sectors. As environmental compliance requirements become more stringent globally, the relative advantages of autoclave synthesis may translate into competitive advantages for manufacturers adopting these technologies.

Energy efficiency stands as one of the most notable environmental benefits of autoclave synthesis. The controlled pressure and temperature conditions in autoclave systems typically require less energy input than HPHT processes, which demand extreme conditions maintained over extended periods. Studies indicate that optimized autoclave systems can achieve energy reductions of 15-30% compared to traditional HPHT methods, contributing to lower carbon footprints in manufacturing operations.

Water consumption and management represent another environmental dimension where autoclave synthesis demonstrates advantages. Modern autoclave systems implement closed-loop water recycling mechanisms that significantly reduce freshwater requirements. This recycling capability minimizes wastewater discharge and associated treatment needs, addressing growing concerns about industrial water usage in regions facing water scarcity challenges.

Chemical usage efficiency in autoclave synthesis further enhances its environmental profile. The contained environment of autoclaves allows for precise control of catalysts and growth media, reducing waste and preventing the release of potentially harmful substances. Advanced autoclave designs incorporate filtration systems that capture and recycle growth solution components, minimizing the need for continuous chemical replenishment.

Emissions reduction constitutes a significant environmental benefit of autoclave synthesis. The sealed nature of autoclave chambers prevents the escape of process gases and particulates that might otherwise contribute to air pollution. This containment capability is particularly important when working with carbon-based precursors and metallic catalysts that could pose environmental hazards if released.

Life cycle assessment studies comparing diamond synthesis methods have demonstrated that autoclave processes generally produce lower environmental impacts across multiple categories including global warming potential, acidification potential, and resource depletion. These advantages become particularly pronounced when considering the entire production chain from raw material extraction through manufacturing to end-of-life disposal.

The environmental benefits of autoclave synthesis align with growing regulatory pressures and market demands for sustainable production methods in luxury goods and industrial materials sectors. As environmental compliance requirements become more stringent globally, the relative advantages of autoclave synthesis may translate into competitive advantages for manufacturers adopting these technologies.

Quality Control Standards for Synthetic Diamonds

Quality control standards for synthetic diamonds produced through autoclave synthesis have evolved significantly to address the unique defect reduction capabilities of this method. These standards now incorporate specialized parameters that evaluate the effectiveness of high-pressure, high-temperature (HPHT) conditions in minimizing crystal lattice imperfections and impurities.

The industry has established multi-tiered classification systems specifically for autoclave-synthesized diamonds, with particular emphasis on nitrogen content measurement. Type IIa diamonds, containing minimal nitrogen impurities, represent the highest quality standard achievable through controlled autoclave synthesis. Advanced spectroscopic analysis protocols have been standardized to detect and quantify various defect types, including vacancy clusters, dislocations, and metallic inclusions that are uniquely mitigated by autoclave conditions.

Certification bodies have developed specialized grading criteria for autoclave-synthesized diamonds that differ from those applied to other synthetic production methods. These criteria account for the distinctive defect reduction patterns achieved through precise pressure and temperature control during the growth phase. The Gemological Institute of America (GIA) and International Gemological Institute (IGI) have both implemented dedicated sections in their grading reports that specifically address defect characteristics unique to autoclave synthesis.

Optical homogeneity standards have become increasingly stringent, with requirements for less than 5 parts per million of optically detectable defects in premium-grade synthetic diamonds. This standard directly leverages autoclave synthesis's superior ability to create uniform crystal structures through isostatic pressure application. Birefringence measurement protocols have been standardized to detect internal strain patterns that indicate incomplete defect elimination during the growth process.

Industry benchmarks now include quantitative metrics for dislocation density, with high-quality autoclave-synthesized diamonds expected to demonstrate less than 10^3 dislocations per square centimeter—a standard achievable primarily through the controlled cooling phases unique to autoclave synthesis. Electronic grade synthetic diamonds require even more stringent standards, with defect concentrations below detectable limits to ensure proper semiconductor functionality.

Traceability standards have also emerged, requiring detailed documentation of autoclave synthesis parameters throughout the production process. This documentation serves as quality assurance evidence and enables verification that optimal defect-reduction conditions were maintained during crystal growth. These comprehensive quality control frameworks continue to evolve as autoclave technology advances, driving continuous improvement in synthetic diamond purity and performance characteristics.

The industry has established multi-tiered classification systems specifically for autoclave-synthesized diamonds, with particular emphasis on nitrogen content measurement. Type IIa diamonds, containing minimal nitrogen impurities, represent the highest quality standard achievable through controlled autoclave synthesis. Advanced spectroscopic analysis protocols have been standardized to detect and quantify various defect types, including vacancy clusters, dislocations, and metallic inclusions that are uniquely mitigated by autoclave conditions.

Certification bodies have developed specialized grading criteria for autoclave-synthesized diamonds that differ from those applied to other synthetic production methods. These criteria account for the distinctive defect reduction patterns achieved through precise pressure and temperature control during the growth phase. The Gemological Institute of America (GIA) and International Gemological Institute (IGI) have both implemented dedicated sections in their grading reports that specifically address defect characteristics unique to autoclave synthesis.

Optical homogeneity standards have become increasingly stringent, with requirements for less than 5 parts per million of optically detectable defects in premium-grade synthetic diamonds. This standard directly leverages autoclave synthesis's superior ability to create uniform crystal structures through isostatic pressure application. Birefringence measurement protocols have been standardized to detect internal strain patterns that indicate incomplete defect elimination during the growth process.

Industry benchmarks now include quantitative metrics for dislocation density, with high-quality autoclave-synthesized diamonds expected to demonstrate less than 10^3 dislocations per square centimeter—a standard achievable primarily through the controlled cooling phases unique to autoclave synthesis. Electronic grade synthetic diamonds require even more stringent standards, with defect concentrations below detectable limits to ensure proper semiconductor functionality.

Traceability standards have also emerged, requiring detailed documentation of autoclave synthesis parameters throughout the production process. This documentation serves as quality assurance evidence and enables verification that optimal defect-reduction conditions were maintained during crystal growth. These comprehensive quality control frameworks continue to evolve as autoclave technology advances, driving continuous improvement in synthetic diamond purity and performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!