Autoclave Synthesis and the Advancement of High-Temperature Resins

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the early 20th century, transforming from basic pressure vessels to sophisticated systems critical for advanced materials processing. Initially developed for sterilization purposes in medical and food industries, autoclaves found their way into materials science in the 1940s when researchers discovered their potential for creating high-performance composites under controlled temperature and pressure conditions.

The 1960s marked a pivotal era when aerospace industries began utilizing autoclave technology for manufacturing composite components, driving substantial technological advancements. This period saw the introduction of computer-controlled systems that enabled precise manipulation of processing parameters, significantly enhancing the quality and reproducibility of high-temperature resin curing processes.

By the 1980s, autoclave technology had become standardized in advanced manufacturing, with significant improvements in heating systems, pressure control mechanisms, and vacuum capabilities. These advancements facilitated the development of increasingly complex high-temperature resins with superior thermal and mechanical properties, essential for aerospace and defense applications.

The 1990s to early 2000s witnessed the integration of sophisticated monitoring systems into autoclaves, including real-time cure monitoring technologies such as dielectric analysis and fiber optic sensors. These innovations allowed manufacturers to observe and control the polymerization process of high-temperature resins with unprecedented precision, minimizing defects and optimizing material properties.

Current autoclave technology represents a culmination of these evolutionary steps, featuring advanced automation, energy efficiency improvements, and enhanced safety systems. Modern autoclaves operate at temperatures exceeding 400°C and pressures up to 20 bar, creating ideal conditions for synthesizing and processing high-temperature resins such as polyimides, bismaleimides, and advanced epoxy systems.

The primary objective of contemporary autoclave technology in resin advancement is to enable the development of materials with exceptional thermal stability, mechanical strength, and chemical resistance while maintaining processability. Researchers aim to overcome the inherent trade-off between high-temperature performance and ease of processing that has historically limited the application scope of these materials.

Additional objectives include reducing energy consumption and processing times, as traditional autoclave cycles for high-temperature resins can be lengthy and energy-intensive. The industry is also focused on scaling capabilities to accommodate larger structures while maintaining uniform properties throughout the component, addressing a significant challenge in the production of large-scale aerospace and industrial parts using high-temperature resin systems.

The 1960s marked a pivotal era when aerospace industries began utilizing autoclave technology for manufacturing composite components, driving substantial technological advancements. This period saw the introduction of computer-controlled systems that enabled precise manipulation of processing parameters, significantly enhancing the quality and reproducibility of high-temperature resin curing processes.

By the 1980s, autoclave technology had become standardized in advanced manufacturing, with significant improvements in heating systems, pressure control mechanisms, and vacuum capabilities. These advancements facilitated the development of increasingly complex high-temperature resins with superior thermal and mechanical properties, essential for aerospace and defense applications.

The 1990s to early 2000s witnessed the integration of sophisticated monitoring systems into autoclaves, including real-time cure monitoring technologies such as dielectric analysis and fiber optic sensors. These innovations allowed manufacturers to observe and control the polymerization process of high-temperature resins with unprecedented precision, minimizing defects and optimizing material properties.

Current autoclave technology represents a culmination of these evolutionary steps, featuring advanced automation, energy efficiency improvements, and enhanced safety systems. Modern autoclaves operate at temperatures exceeding 400°C and pressures up to 20 bar, creating ideal conditions for synthesizing and processing high-temperature resins such as polyimides, bismaleimides, and advanced epoxy systems.

The primary objective of contemporary autoclave technology in resin advancement is to enable the development of materials with exceptional thermal stability, mechanical strength, and chemical resistance while maintaining processability. Researchers aim to overcome the inherent trade-off between high-temperature performance and ease of processing that has historically limited the application scope of these materials.

Additional objectives include reducing energy consumption and processing times, as traditional autoclave cycles for high-temperature resins can be lengthy and energy-intensive. The industry is also focused on scaling capabilities to accommodate larger structures while maintaining uniform properties throughout the component, addressing a significant challenge in the production of large-scale aerospace and industrial parts using high-temperature resin systems.

Market Analysis for High-Temperature Resin Applications

The high-temperature resin market has experienced significant growth in recent years, driven primarily by increasing demand from aerospace, automotive, and electronics industries. The global market for high-temperature resins was valued at approximately $1.5 billion in 2022 and is projected to reach $2.3 billion by 2028, representing a compound annual growth rate (CAGR) of 7.4% during the forecast period.

Aerospace applications constitute the largest segment of the high-temperature resin market, accounting for roughly 35% of the total market share. This dominance is attributed to the critical need for materials that can withstand extreme temperatures in aircraft engines, structural components, and interior parts. The automotive sector follows closely, representing about 28% of the market, with applications in under-hood components, powertrain systems, and increasingly in electric vehicle battery enclosures.

Electronics and electrical applications comprise approximately 20% of the market, with high-temperature resins being essential for printed circuit boards, semiconductor packaging, and other components that operate in thermally demanding environments. The remaining market share is distributed among industrial applications, including oil and gas, chemical processing, and power generation.

Regionally, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China, India, and Japan.

The market for autoclave-processed high-temperature resins specifically is witnessing robust growth due to their superior mechanical properties and thermal stability. These resins command premium pricing, with margins typically 15-20% higher than conventionally processed alternatives. The autoclave synthesis method, while capital-intensive, delivers resins with lower void content and higher crosslinking density, which translates to enhanced performance in critical applications.

Customer requirements are increasingly focused on resins that can withstand temperatures above 300°C while maintaining mechanical integrity and chemical resistance. There is also growing demand for resins with improved processability, reduced cure times, and lower energy consumption during manufacturing. Additionally, sustainability concerns are driving interest in bio-based high-temperature resins, though these currently represent less than 5% of the market.

Market barriers include high capital costs for autoclave equipment, energy-intensive processing, and complex quality control requirements. Despite these challenges, the market outlook remains positive, supported by ongoing technological advancements and expanding application areas in emerging industries such as renewable energy and advanced transportation systems.

Aerospace applications constitute the largest segment of the high-temperature resin market, accounting for roughly 35% of the total market share. This dominance is attributed to the critical need for materials that can withstand extreme temperatures in aircraft engines, structural components, and interior parts. The automotive sector follows closely, representing about 28% of the market, with applications in under-hood components, powertrain systems, and increasingly in electric vehicle battery enclosures.

Electronics and electrical applications comprise approximately 20% of the market, with high-temperature resins being essential for printed circuit boards, semiconductor packaging, and other components that operate in thermally demanding environments. The remaining market share is distributed among industrial applications, including oil and gas, chemical processing, and power generation.

Regionally, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China, India, and Japan.

The market for autoclave-processed high-temperature resins specifically is witnessing robust growth due to their superior mechanical properties and thermal stability. These resins command premium pricing, with margins typically 15-20% higher than conventionally processed alternatives. The autoclave synthesis method, while capital-intensive, delivers resins with lower void content and higher crosslinking density, which translates to enhanced performance in critical applications.

Customer requirements are increasingly focused on resins that can withstand temperatures above 300°C while maintaining mechanical integrity and chemical resistance. There is also growing demand for resins with improved processability, reduced cure times, and lower energy consumption during manufacturing. Additionally, sustainability concerns are driving interest in bio-based high-temperature resins, though these currently represent less than 5% of the market.

Market barriers include high capital costs for autoclave equipment, energy-intensive processing, and complex quality control requirements. Despite these challenges, the market outlook remains positive, supported by ongoing technological advancements and expanding application areas in emerging industries such as renewable energy and advanced transportation systems.

Current Challenges in Autoclave Synthesis of Advanced Resins

Despite significant advancements in autoclave synthesis of high-temperature resins, several critical challenges continue to impede further progress in this field. One of the most persistent issues is the energy-intensive nature of autoclave processing, which requires substantial power consumption to maintain high temperatures (often exceeding 350°C) and pressures (typically 5-20 bar) for extended periods. This energy demand translates to high operational costs and considerable carbon footprint, making the process increasingly unsustainable in the context of growing environmental concerns.

Process control represents another significant challenge, as achieving uniform temperature distribution throughout large composite structures remains problematic. Temperature gradients within the autoclave can lead to inconsistent curing, resulting in residual stresses, warpage, and potential delamination in the final products. These quality issues become particularly critical when manufacturing components for aerospace applications, where structural integrity is paramount.

The time-consuming nature of autoclave cycles presents a substantial bottleneck in production efficiency. Current high-temperature resin systems typically require cure cycles ranging from 2 to 8 hours, with additional time needed for heating and cooling phases. This extended processing time limits production throughput and increases manufacturing costs, creating a significant barrier to widespread industrial adoption.

Material compatibility issues further complicate autoclave synthesis. Advanced high-temperature resins often exhibit poor interfacial adhesion with reinforcement materials, leading to compromised mechanical properties in the resulting composites. Additionally, many high-performance resins demonstrate limited shelf life and challenging handling characteristics, requiring specialized storage conditions and careful processing protocols.

Scalability remains a persistent concern, particularly for large-scale industrial applications. As component dimensions increase, ensuring uniform pressure distribution becomes increasingly difficult, often resulting in void formation and porosity in thicker sections. These defects significantly compromise the mechanical properties and thermal stability of the final products.

The development of suitable monitoring and quality control methodologies presents another technical hurdle. Current in-situ monitoring techniques often lack the precision required to detect subtle variations in the curing process of high-temperature resins, making it difficult to implement real-time process adjustments and quality assurance protocols.

Regulatory and safety considerations add another layer of complexity, as many high-temperature resin systems contain potentially hazardous components that require careful handling and disposal. Compliance with increasingly stringent environmental regulations necessitates the development of more environmentally friendly formulations without compromising performance characteristics.

Process control represents another significant challenge, as achieving uniform temperature distribution throughout large composite structures remains problematic. Temperature gradients within the autoclave can lead to inconsistent curing, resulting in residual stresses, warpage, and potential delamination in the final products. These quality issues become particularly critical when manufacturing components for aerospace applications, where structural integrity is paramount.

The time-consuming nature of autoclave cycles presents a substantial bottleneck in production efficiency. Current high-temperature resin systems typically require cure cycles ranging from 2 to 8 hours, with additional time needed for heating and cooling phases. This extended processing time limits production throughput and increases manufacturing costs, creating a significant barrier to widespread industrial adoption.

Material compatibility issues further complicate autoclave synthesis. Advanced high-temperature resins often exhibit poor interfacial adhesion with reinforcement materials, leading to compromised mechanical properties in the resulting composites. Additionally, many high-performance resins demonstrate limited shelf life and challenging handling characteristics, requiring specialized storage conditions and careful processing protocols.

Scalability remains a persistent concern, particularly for large-scale industrial applications. As component dimensions increase, ensuring uniform pressure distribution becomes increasingly difficult, often resulting in void formation and porosity in thicker sections. These defects significantly compromise the mechanical properties and thermal stability of the final products.

The development of suitable monitoring and quality control methodologies presents another technical hurdle. Current in-situ monitoring techniques often lack the precision required to detect subtle variations in the curing process of high-temperature resins, making it difficult to implement real-time process adjustments and quality assurance protocols.

Regulatory and safety considerations add another layer of complexity, as many high-temperature resin systems contain potentially hazardous components that require careful handling and disposal. Compliance with increasingly stringent environmental regulations necessitates the development of more environmentally friendly formulations without compromising performance characteristics.

Contemporary Autoclave Synthesis Methodologies

01 Autoclave synthesis methods for high-temperature resins

Various autoclave synthesis methods can be employed to produce high-temperature resistant resins. These methods typically involve controlled temperature and pressure conditions to facilitate polymerization reactions. The autoclave environment allows for precise control of reaction parameters, resulting in resins with enhanced thermal stability and mechanical properties suitable for high-temperature applications.- Autoclave synthesis methods for high-temperature resins: Various autoclave synthesis methods are employed for producing high-temperature resistant resins. These methods typically involve controlled temperature and pressure conditions to facilitate polymerization reactions. The autoclave environment allows for precise control of reaction parameters, resulting in resins with enhanced thermal stability and mechanical properties suitable for high-temperature applications.

- High-temperature resin formulations and compositions: Specialized formulations of high-temperature resins incorporate various monomers, additives, and curing agents to achieve desired thermal and mechanical properties. These compositions often include aromatic components, heterocyclic structures, or silicon-based compounds that contribute to thermal stability. The formulations are designed to withstand extreme temperatures while maintaining structural integrity and performance characteristics.

- Equipment and apparatus for autoclave synthesis of resins: Specialized equipment and apparatus are designed for the autoclave synthesis of high-temperature resins. These systems include pressure vessels, temperature control mechanisms, mixing devices, and monitoring instruments that ensure optimal reaction conditions. The equipment is engineered to withstand high pressures and temperatures while providing uniform heating and efficient mixing during the polymerization process.

- Applications of autoclave-synthesized high-temperature resins: High-temperature resins produced through autoclave synthesis find applications in various industries including aerospace, electronics, automotive, and energy sectors. These resins are used in composite materials, adhesives, coatings, and structural components that must withstand extreme thermal conditions. Their excellent thermal stability, chemical resistance, and mechanical strength make them suitable for demanding environments.

- Post-processing and modification of high-temperature resins: After autoclave synthesis, high-temperature resins often undergo post-processing treatments to enhance their properties. These treatments may include additional curing steps, surface modifications, or incorporation of reinforcing materials. Post-processing techniques can improve the resin's heat resistance, dimensional stability, and mechanical properties, tailoring them for specific high-temperature applications.

02 High-temperature resin formulations and compositions

Specific formulations and compositions have been developed for high-temperature resins synthesized in autoclaves. These formulations may include various monomers, catalysts, and additives that contribute to the thermal stability of the resulting polymer. The composition of these resins is carefully designed to achieve desired properties such as heat resistance, chemical resistance, and mechanical strength at elevated temperatures.Expand Specific Solutions03 Equipment and apparatus for autoclave synthesis of resins

Specialized equipment and apparatus have been developed for the autoclave synthesis of high-temperature resins. These systems include pressure vessels, heating elements, monitoring devices, and control systems that enable precise regulation of synthesis conditions. The design of these autoclave systems is critical for achieving consistent quality in high-temperature resin production and ensuring safety during high-pressure polymerization processes.Expand Specific Solutions04 Applications of autoclave-synthesized high-temperature resins

High-temperature resins produced through autoclave synthesis find applications in various industries due to their exceptional thermal stability. These applications include aerospace components, electronic materials, automotive parts, and industrial coatings. The resins' ability to maintain structural integrity and performance at elevated temperatures makes them valuable in environments where conventional polymers would degrade or fail.Expand Specific Solutions05 Process optimization for autoclave synthesis of high-temperature resins

Optimization techniques have been developed for the autoclave synthesis of high-temperature resins to enhance efficiency and product quality. These techniques include precise control of reaction parameters, innovative heating and cooling strategies, and advanced monitoring systems. Process optimization aims to reduce cycle times, minimize energy consumption, and improve the consistency of resin properties while maintaining the high-temperature performance characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions in High-Temperature Resins

The autoclave synthesis and high-temperature resin market is currently in a growth phase, with increasing demand driven by aerospace, automotive, and electronics applications. The global high-temperature resin market is projected to reach approximately $5-6 billion by 2025, growing at a CAGR of 6-8%. Technology maturity varies across different resin types, with companies like Hexcel Corp. and DuPont leading in aerospace-grade materials, while Boeing and Airbus drive application requirements. Asian manufacturers including LG Chem, Kingfa, and Toray are rapidly advancing capabilities, particularly in electronics applications. European players such as Arkema and Wacker Chemie focus on specialty high-performance formulations. Recent innovations from Cubicure and Surface Generation indicate emerging opportunities in additive manufacturing of high-temperature resins, suggesting the technology continues to evolve toward more specialized applications.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced autoclave synthesis methods for high-temperature silicone and epoxy-based resin systems, with applications spanning electronics, transportation, and industrial sectors. Their proprietary technology utilizes precisely controlled temperature ramps (typically 150-300°C) and pressures up to 8 bar to achieve optimal molecular weight distribution and cross-linking density. Dow's autoclave synthesis incorporates specialized catalysts that enable lower processing temperatures while maintaining high-temperature performance in the final product. Their recent innovations include the development of hybrid silicone-organic resin systems that combine the thermal stability of silicones with the mechanical properties of organic polymers. The company has also pioneered the use of supercritical CO2 as a processing aid during autoclave synthesis, which enhances molecular mobility during cure and results in more homogeneous network formation. Dow's autoclave technology enables the production of high-temperature resins with exceptional thermal conductivity and electrical insulation properties, critical for advanced electronics applications. Their process optimization has focused on reducing cycle times while maintaining the exceptional thermal and chemical resistance properties required for demanding industrial applications.

Strengths: Excellent balance of thermal stability and processability; superior electrical properties maintained at elevated temperatures; exceptional resistance to thermal cycling; proprietary additives that enhance thermal conductivity without compromising mechanical properties. Weaknesses: Some formulations require specialized handling due to moisture sensitivity; higher cost compared to conventional resin systems; complex cure schedules may require sophisticated process control systems.

Hexcel Corp.

Technical Solution: Hexcel has pioneered advanced autoclave synthesis methods for aerospace-grade high-temperature resins, particularly focusing on bismaleimides (BMIs) and cyanate esters. Their HexPly® technology utilizes precisely controlled autoclave cycles with multi-stage temperature profiles (typically ranging from 180°C to 230°C) and pressures up to 7 bar to achieve optimal cross-linking density and void-free composites. Hexcel's proprietary autoclave synthesis incorporates vacuum-assisted processing to remove volatile components and ensure consistent mechanical properties. Their recent innovations include the development of toughened BMI systems with improved damage tolerance while maintaining high-temperature performance up to 260°C. The company has also developed specialized cure monitoring systems that track the degree of polymerization in real-time during autoclave processing, allowing for adaptive cure cycles that optimize both processing efficiency and final material properties. Hexcel's autoclave synthesis technology enables the production of composite materials with exceptional fiber-to-resin interfacial strength, critical for aerospace structural applications.

Strengths: Exceptional thermal-oxidative stability; superior mechanical property retention at elevated temperatures; excellent hot/wet performance critical for aerospace applications; proprietary toughening mechanisms that maintain high glass transition temperatures. Weaknesses: Relatively high processing costs due to extended autoclave cycles; requires specialized equipment for optimal results; some formulations have limited out-time before processing.

Key Patents and Breakthroughs in High-Temperature Resin Development

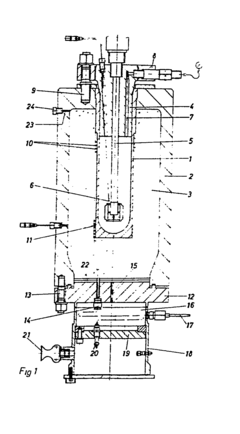

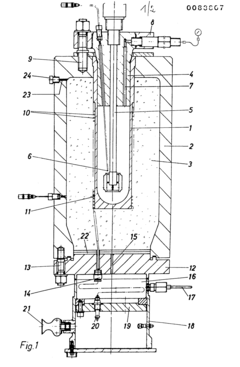

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

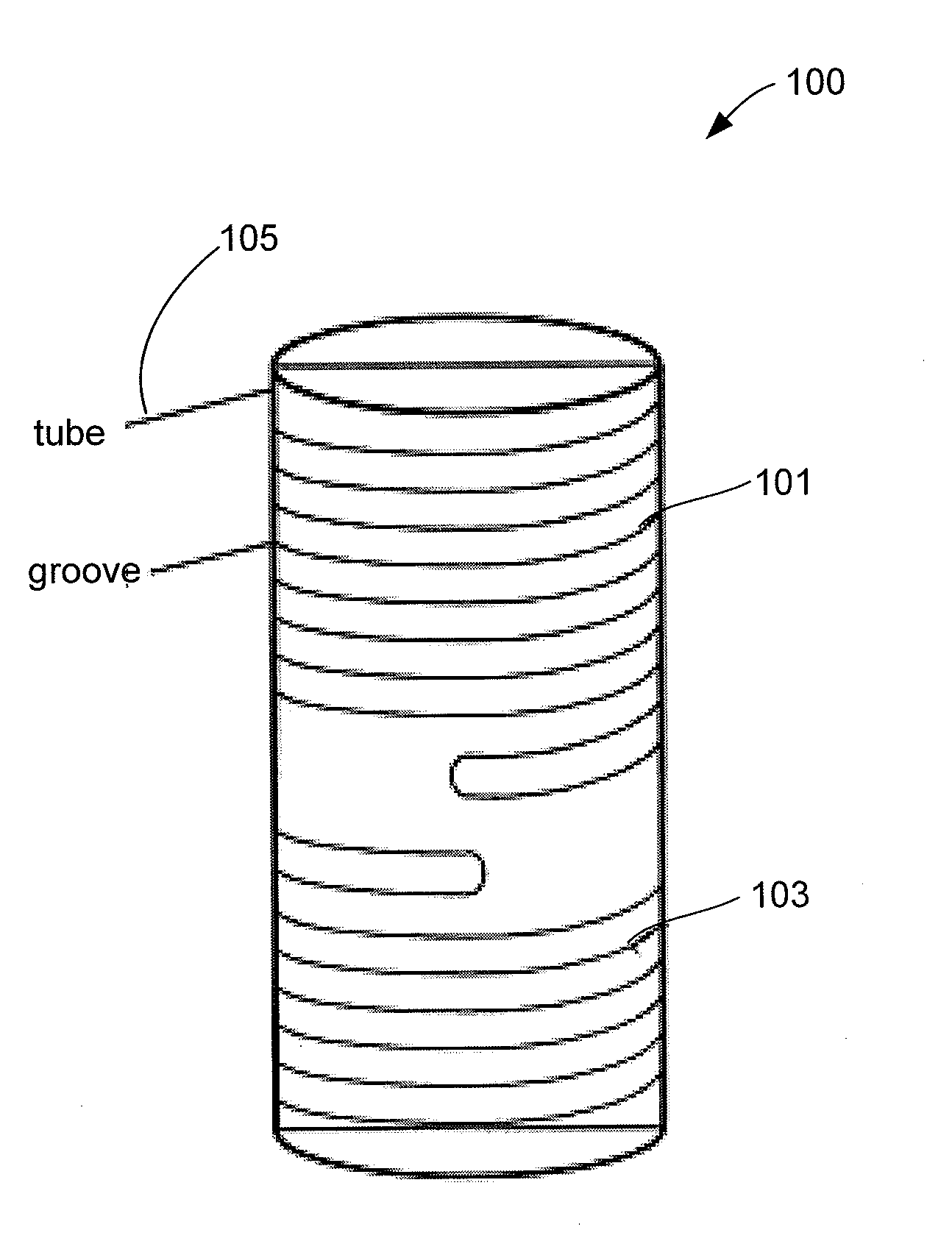

Heater device and method for high pressure processing of crystalline materials

PatentInactiveUS20090320745A1

Innovation

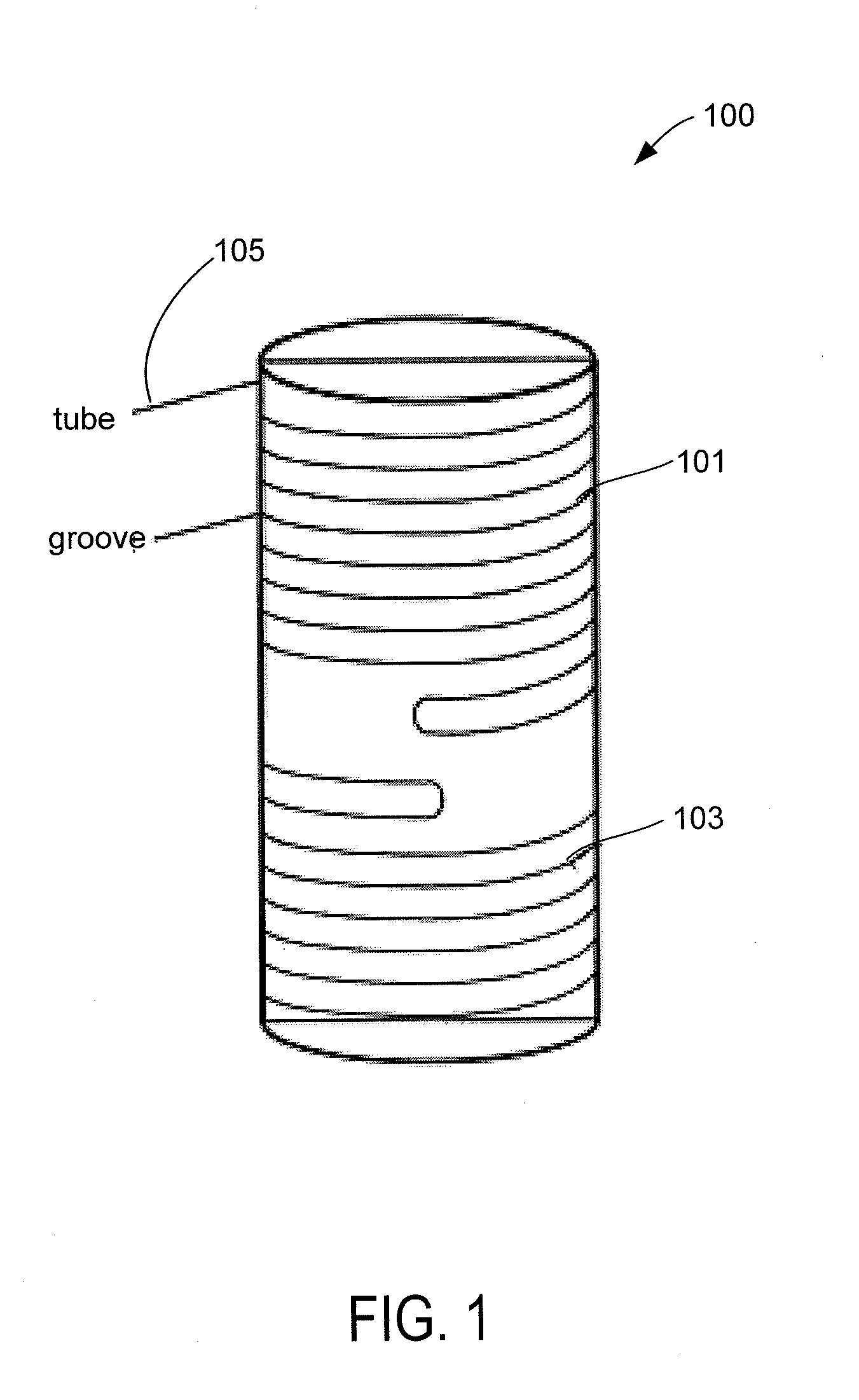

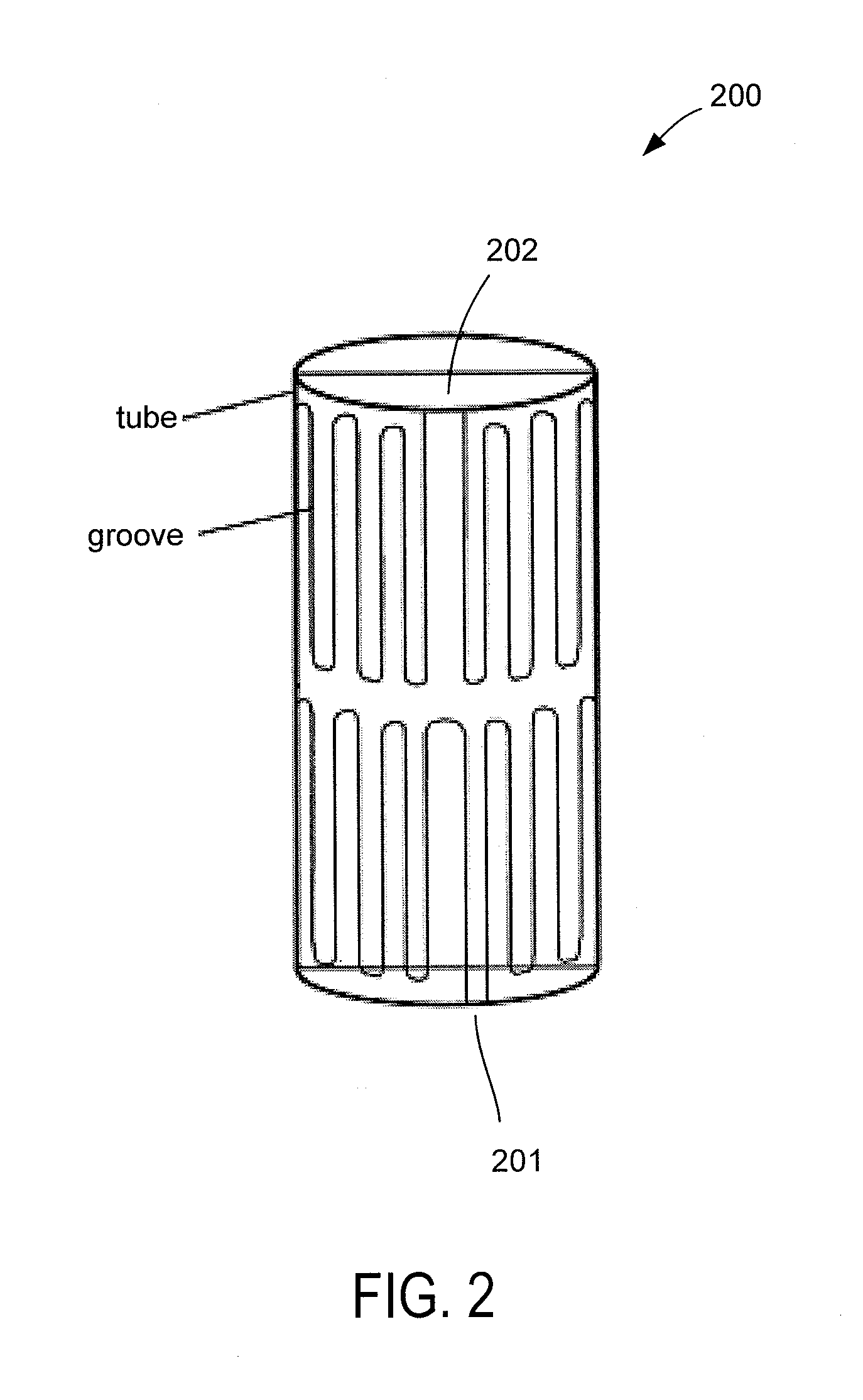

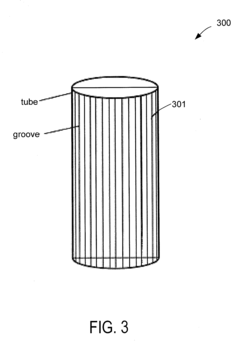

- A scalable heater design with multiple heating elements and a dense inner tube member, combined with insulating material, forms a cylindrical structure that is electrically isolated and capable of operating within a high-pressure apparatus, maintaining structural integrity and efficiency by minimizing voids and gaps, allowing for operation at pressures up to 2 GPa and temperatures up to 1200°C.

Environmental Impact and Sustainability Considerations

The environmental impact of autoclave synthesis processes for high-temperature resins represents a critical consideration in modern materials science. Traditional autoclave manufacturing methods consume substantial energy due to the high temperatures (often exceeding 350°C) and pressures required for proper resin curing. This energy-intensive process contributes significantly to carbon emissions, particularly when power sources are not renewable, creating a considerable carbon footprint for aerospace and advanced manufacturing industries.

Chemical emissions present another environmental challenge. During autoclave processing, volatile organic compounds (VOCs) and other potentially harmful substances may be released from resin systems. These emissions can contribute to air quality degradation and pose occupational health risks if not properly managed through effective ventilation and filtration systems.

Water usage in autoclave operations also raises sustainability concerns. Cooling systems and cleaning processes associated with autoclave manufacturing can consume substantial water resources. Additionally, chemical runoff from these processes may contain resin residues and solvents that require specialized treatment before discharge to prevent water contamination.

Recent advancements in sustainable autoclave technologies demonstrate promising developments. Energy recovery systems that capture and repurpose heat from autoclave operations have shown potential to reduce energy consumption by 15-30%. Similarly, closed-loop water systems have emerged as effective solutions for minimizing water usage and preventing contamination, though implementation costs remain high.

Bio-based high-temperature resins represent a significant innovation pathway. Research into plant-derived precursors for high-performance resins has accelerated, with some bio-based alternatives demonstrating comparable thermal stability to petroleum-derived counterparts while reducing reliance on fossil resources. However, challenges in scalability and consistent performance properties persist.

Life cycle assessment (LCA) studies indicate that despite the energy-intensive nature of autoclave processing, the extended service life and lightweight properties of high-temperature resin composites may offset initial environmental impacts through operational efficiencies, particularly in transportation applications. These studies suggest that a comprehensive sustainability evaluation must consider the entire product lifecycle rather than focusing solely on manufacturing impacts.

Regulatory frameworks worldwide are increasingly addressing environmental aspects of advanced materials manufacturing. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener chemistry approaches and more sustainable processing methods for high-temperature resins, creating both compliance challenges and innovation opportunities in autoclave synthesis technologies.

Chemical emissions present another environmental challenge. During autoclave processing, volatile organic compounds (VOCs) and other potentially harmful substances may be released from resin systems. These emissions can contribute to air quality degradation and pose occupational health risks if not properly managed through effective ventilation and filtration systems.

Water usage in autoclave operations also raises sustainability concerns. Cooling systems and cleaning processes associated with autoclave manufacturing can consume substantial water resources. Additionally, chemical runoff from these processes may contain resin residues and solvents that require specialized treatment before discharge to prevent water contamination.

Recent advancements in sustainable autoclave technologies demonstrate promising developments. Energy recovery systems that capture and repurpose heat from autoclave operations have shown potential to reduce energy consumption by 15-30%. Similarly, closed-loop water systems have emerged as effective solutions for minimizing water usage and preventing contamination, though implementation costs remain high.

Bio-based high-temperature resins represent a significant innovation pathway. Research into plant-derived precursors for high-performance resins has accelerated, with some bio-based alternatives demonstrating comparable thermal stability to petroleum-derived counterparts while reducing reliance on fossil resources. However, challenges in scalability and consistent performance properties persist.

Life cycle assessment (LCA) studies indicate that despite the energy-intensive nature of autoclave processing, the extended service life and lightweight properties of high-temperature resin composites may offset initial environmental impacts through operational efficiencies, particularly in transportation applications. These studies suggest that a comprehensive sustainability evaluation must consider the entire product lifecycle rather than focusing solely on manufacturing impacts.

Regulatory frameworks worldwide are increasingly addressing environmental aspects of advanced materials manufacturing. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener chemistry approaches and more sustainable processing methods for high-temperature resins, creating both compliance challenges and innovation opportunities in autoclave synthesis technologies.

Quality Control and Standardization in Autoclave Processing

Quality control and standardization are critical components in the autoclave processing of high-temperature resins, ensuring consistent product quality and reliable performance. The autoclave synthesis process involves complex interactions between temperature, pressure, and time parameters, necessitating rigorous control mechanisms to achieve desired material properties. Industry standards such as ASTM D6604 and AMS 3144 provide baseline requirements for autoclave curing processes, while organizations like NADCAP offer certification programs specifically for composite manufacturing.

Temperature uniformity within the autoclave chamber represents one of the most significant quality control challenges. Modern autoclaves incorporate multiple temperature sensors strategically positioned throughout the chamber, connected to sophisticated feedback control systems that maintain temperature variations within ±3°C. Pressure control systems similarly employ redundant sensors and regulators to ensure consistent application of pressure during the curing cycle, critical for void elimination and proper resin flow.

Documentation and traceability form the backbone of quality assurance in autoclave processing. Digital monitoring systems now record complete cure cycle data, including temperature ramps, pressure profiles, and vacuum levels. These records serve both as quality verification documents and valuable process improvement data. Many manufacturers have implemented Statistical Process Control (SPC) methodologies to identify trends and anomalies in autoclave performance before they result in product defects.

Material qualification protocols have evolved significantly, with standardized test methods for evaluating resin flow characteristics, gel times, and degree of cure. Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA) have become standard tools for verifying the glass transition temperature and crosslinking density of processed resins. These analytical techniques provide quantitative measures of cure completion that correlate with mechanical performance.

Non-destructive testing (NDT) methods, including ultrasonic inspection and thermography, have been standardized for post-cure quality verification. These techniques can detect internal defects such as delaminations, voids, and resin-starved areas without compromising part integrity. Industry standards now specify acceptance criteria based on NDT results, establishing clear pass/fail thresholds for critical components.

The emergence of Industry 4.0 technologies has revolutionized quality control in autoclave processing. Real-time monitoring systems with predictive algorithms can anticipate process deviations and automatically adjust parameters to maintain optimal curing conditions. Digital twins of autoclave systems enable virtual process validation and optimization before physical implementation, reducing development costs and accelerating innovation in high-temperature resin applications.

Temperature uniformity within the autoclave chamber represents one of the most significant quality control challenges. Modern autoclaves incorporate multiple temperature sensors strategically positioned throughout the chamber, connected to sophisticated feedback control systems that maintain temperature variations within ±3°C. Pressure control systems similarly employ redundant sensors and regulators to ensure consistent application of pressure during the curing cycle, critical for void elimination and proper resin flow.

Documentation and traceability form the backbone of quality assurance in autoclave processing. Digital monitoring systems now record complete cure cycle data, including temperature ramps, pressure profiles, and vacuum levels. These records serve both as quality verification documents and valuable process improvement data. Many manufacturers have implemented Statistical Process Control (SPC) methodologies to identify trends and anomalies in autoclave performance before they result in product defects.

Material qualification protocols have evolved significantly, with standardized test methods for evaluating resin flow characteristics, gel times, and degree of cure. Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA) have become standard tools for verifying the glass transition temperature and crosslinking density of processed resins. These analytical techniques provide quantitative measures of cure completion that correlate with mechanical performance.

Non-destructive testing (NDT) methods, including ultrasonic inspection and thermography, have been standardized for post-cure quality verification. These techniques can detect internal defects such as delaminations, voids, and resin-starved areas without compromising part integrity. Industry standards now specify acceptance criteria based on NDT results, establishing clear pass/fail thresholds for critical components.

The emergence of Industry 4.0 technologies has revolutionized quality control in autoclave processing. Real-time monitoring systems with predictive algorithms can anticipate process deviations and automatically adjust parameters to maintain optimal curing conditions. Digital twins of autoclave systems enable virtual process validation and optimization before physical implementation, reducing development costs and accelerating innovation in high-temperature resin applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!