Autoclave Synthesis Innovations in High-Performance Thermosetting Polymers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis has been a cornerstone technology in the development of high-performance thermosetting polymers since the mid-20th century. Initially developed for aerospace applications in the 1950s, this processing technique has evolved significantly, enabling the production of composite materials with exceptional mechanical properties, thermal stability, and chemical resistance. The fundamental principle involves the application of heat and pressure in a controlled environment to facilitate polymerization reactions and optimize material properties.

The evolution of autoclave synthesis technology has been marked by several significant milestones. In the 1970s, the introduction of computer-controlled autoclave systems revolutionized process precision. The 1990s witnessed the development of advanced vacuum bagging techniques that substantially reduced void content in composite structures. More recently, the integration of real-time monitoring systems has enabled adaptive processing parameters, further enhancing product quality and consistency.

Current technological trends in autoclave synthesis focus on energy efficiency, cycle time reduction, and the development of more environmentally sustainable processes. The industry is moving toward lower-temperature curing systems that maintain high-performance characteristics while reducing energy consumption. Additionally, there is significant interest in developing autoclave processes compatible with bio-based and recyclable thermosetting resins to address growing sustainability concerns.

The primary objective of innovation in this field is to overcome the inherent limitations of traditional autoclave processing, including high energy consumption, long cycle times, and substantial capital investment requirements. Researchers aim to develop novel catalyst systems that accelerate cure kinetics without compromising the final material properties, thereby reducing processing time and energy requirements.

Another critical objective is the enhancement of process monitoring and control capabilities through the integration of advanced sensors and artificial intelligence. This approach enables real-time optimization of processing parameters based on material behavior during cure, potentially leading to more consistent product quality and reduced scrap rates.

Furthermore, there is a growing focus on developing hybrid processing techniques that combine autoclave synthesis with complementary technologies such as microwave or UV curing to achieve synergistic effects. These hybrid approaches aim to leverage the advantages of multiple processing methods while mitigating their individual limitations.

The ultimate goal of these innovations is to establish autoclave synthesis as a more accessible, efficient, and sustainable manufacturing technology for high-performance thermosetting polymers, expanding its application beyond traditional aerospace and defense sectors into emerging markets such as renewable energy, electric vehicles, and advanced construction materials.

The evolution of autoclave synthesis technology has been marked by several significant milestones. In the 1970s, the introduction of computer-controlled autoclave systems revolutionized process precision. The 1990s witnessed the development of advanced vacuum bagging techniques that substantially reduced void content in composite structures. More recently, the integration of real-time monitoring systems has enabled adaptive processing parameters, further enhancing product quality and consistency.

Current technological trends in autoclave synthesis focus on energy efficiency, cycle time reduction, and the development of more environmentally sustainable processes. The industry is moving toward lower-temperature curing systems that maintain high-performance characteristics while reducing energy consumption. Additionally, there is significant interest in developing autoclave processes compatible with bio-based and recyclable thermosetting resins to address growing sustainability concerns.

The primary objective of innovation in this field is to overcome the inherent limitations of traditional autoclave processing, including high energy consumption, long cycle times, and substantial capital investment requirements. Researchers aim to develop novel catalyst systems that accelerate cure kinetics without compromising the final material properties, thereby reducing processing time and energy requirements.

Another critical objective is the enhancement of process monitoring and control capabilities through the integration of advanced sensors and artificial intelligence. This approach enables real-time optimization of processing parameters based on material behavior during cure, potentially leading to more consistent product quality and reduced scrap rates.

Furthermore, there is a growing focus on developing hybrid processing techniques that combine autoclave synthesis with complementary technologies such as microwave or UV curing to achieve synergistic effects. These hybrid approaches aim to leverage the advantages of multiple processing methods while mitigating their individual limitations.

The ultimate goal of these innovations is to establish autoclave synthesis as a more accessible, efficient, and sustainable manufacturing technology for high-performance thermosetting polymers, expanding its application beyond traditional aerospace and defense sectors into emerging markets such as renewable energy, electric vehicles, and advanced construction materials.

Market Demand Analysis for High-Performance Thermosetting Polymers

The global market for high-performance thermosetting polymers has been experiencing robust growth, driven primarily by increasing demand from aerospace, automotive, electronics, and industrial sectors. These advanced materials offer exceptional thermal stability, chemical resistance, and mechanical properties that make them indispensable in extreme operating environments.

The aerospace industry represents the largest market segment, accounting for approximately 35% of the total demand. This sector requires materials capable of withstanding extreme temperatures, pressures, and mechanical stresses while maintaining dimensional stability. The push toward more fuel-efficient aircraft has accelerated the adoption of lightweight composite materials based on high-performance thermosetting polymers.

Automotive applications constitute the fastest-growing segment, with a compound annual growth rate exceeding 7%. The transition toward electric vehicles has created new requirements for battery enclosures and thermal management systems where these polymers excel. Additionally, the pursuit of fuel efficiency through weight reduction continues to drive demand for composite components in conventional vehicles.

The electronics industry demands these materials for circuit boards, semiconductor packaging, and encapsulation applications. The miniaturization trend in electronics has intensified requirements for materials with superior thermal management capabilities and dimensional stability at high temperatures.

Regional analysis reveals that North America and Europe currently dominate the market, though Asia-Pacific is projected to witness the highest growth rate. China's expanding aerospace and electronics manufacturing sectors are significant contributors to this regional growth trend.

Market research indicates that customers increasingly prioritize sustainability alongside performance characteristics. This has created a growing demand for bio-based or recyclable high-performance thermosetting polymers, despite the inherent challenges in developing such materials without compromising their performance attributes.

Price sensitivity varies significantly across application segments. While aerospace and defense applications can absorb premium pricing for materials with exceptional performance, consumer electronics and automotive applications face more stringent cost constraints, creating market opportunities for materials that balance performance and affordability.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, but the market has shown resilience and returned to growth trajectories. Long-term market forecasts remain positive, with projected expansion at a compound annual growth rate of 6.5% through 2028.

Emerging applications in renewable energy, particularly wind turbine blades and hydrogen storage systems, represent significant growth opportunities. These applications leverage the exceptional mechanical properties and chemical resistance of high-performance thermosetting polymers in increasingly demanding environments.

The aerospace industry represents the largest market segment, accounting for approximately 35% of the total demand. This sector requires materials capable of withstanding extreme temperatures, pressures, and mechanical stresses while maintaining dimensional stability. The push toward more fuel-efficient aircraft has accelerated the adoption of lightweight composite materials based on high-performance thermosetting polymers.

Automotive applications constitute the fastest-growing segment, with a compound annual growth rate exceeding 7%. The transition toward electric vehicles has created new requirements for battery enclosures and thermal management systems where these polymers excel. Additionally, the pursuit of fuel efficiency through weight reduction continues to drive demand for composite components in conventional vehicles.

The electronics industry demands these materials for circuit boards, semiconductor packaging, and encapsulation applications. The miniaturization trend in electronics has intensified requirements for materials with superior thermal management capabilities and dimensional stability at high temperatures.

Regional analysis reveals that North America and Europe currently dominate the market, though Asia-Pacific is projected to witness the highest growth rate. China's expanding aerospace and electronics manufacturing sectors are significant contributors to this regional growth trend.

Market research indicates that customers increasingly prioritize sustainability alongside performance characteristics. This has created a growing demand for bio-based or recyclable high-performance thermosetting polymers, despite the inherent challenges in developing such materials without compromising their performance attributes.

Price sensitivity varies significantly across application segments. While aerospace and defense applications can absorb premium pricing for materials with exceptional performance, consumer electronics and automotive applications face more stringent cost constraints, creating market opportunities for materials that balance performance and affordability.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, but the market has shown resilience and returned to growth trajectories. Long-term market forecasts remain positive, with projected expansion at a compound annual growth rate of 6.5% through 2028.

Emerging applications in renewable energy, particularly wind turbine blades and hydrogen storage systems, represent significant growth opportunities. These applications leverage the exceptional mechanical properties and chemical resistance of high-performance thermosetting polymers in increasingly demanding environments.

Current Challenges in Autoclave Synthesis Technology

Despite significant advancements in autoclave synthesis technology for high-performance thermosetting polymers, several critical challenges continue to impede further innovation and industrial application. The most prominent issue remains the high energy consumption associated with traditional autoclave processes. Current systems typically operate at temperatures between 120-180°C and pressures of 6-10 bar, resulting in substantial energy requirements and corresponding carbon footprints that contradict modern sustainability objectives.

Process scalability presents another significant hurdle, as the transition from laboratory-scale synthesis to industrial production often encounters inconsistencies in polymer properties. These variations primarily stem from non-uniform temperature and pressure distributions within larger autoclaves, leading to heterogeneous curing profiles and compromised mechanical performance in the final products.

Cycle time optimization continues to challenge manufacturers, with conventional autoclave cycles for high-performance thermosetting polymers requiring 2-8 hours depending on component thickness and complexity. This extended processing duration significantly impacts production efficiency and increases manufacturing costs, particularly for aerospace and automotive applications where production volume demands are escalating.

Quality control and process monitoring capabilities remain inadequate in many existing autoclave systems. Real-time monitoring of cure progression, particularly in complex geometries and thick laminates, is limited by current sensor technology and data integration frameworks. This deficiency often necessitates conservative processing parameters to ensure complete curing, further extending cycle times and energy consumption.

Material compatibility issues persist when processing next-generation thermosetting polymers with specialized additives, nanofillers, or hybrid compositions. Current autoclave designs and control systems struggle to accommodate the unique processing windows and cure kinetics of these advanced formulations, limiting innovation in material development.

Automation and process control sophistication lags behind other manufacturing technologies. Many autoclave operations still rely on manual intervention and predetermined cure cycles rather than adaptive, AI-driven control systems that could optimize parameters in real-time based on material behavior and environmental conditions.

Cost considerations remain paramount, with capital investment for industrial-scale autoclaves ranging from $500,000 to several million dollars, plus significant operational expenses. This economic barrier restricts adoption, particularly among small to medium enterprises seeking to enter the high-performance polymer market, thereby limiting industry-wide innovation potential.

Process scalability presents another significant hurdle, as the transition from laboratory-scale synthesis to industrial production often encounters inconsistencies in polymer properties. These variations primarily stem from non-uniform temperature and pressure distributions within larger autoclaves, leading to heterogeneous curing profiles and compromised mechanical performance in the final products.

Cycle time optimization continues to challenge manufacturers, with conventional autoclave cycles for high-performance thermosetting polymers requiring 2-8 hours depending on component thickness and complexity. This extended processing duration significantly impacts production efficiency and increases manufacturing costs, particularly for aerospace and automotive applications where production volume demands are escalating.

Quality control and process monitoring capabilities remain inadequate in many existing autoclave systems. Real-time monitoring of cure progression, particularly in complex geometries and thick laminates, is limited by current sensor technology and data integration frameworks. This deficiency often necessitates conservative processing parameters to ensure complete curing, further extending cycle times and energy consumption.

Material compatibility issues persist when processing next-generation thermosetting polymers with specialized additives, nanofillers, or hybrid compositions. Current autoclave designs and control systems struggle to accommodate the unique processing windows and cure kinetics of these advanced formulations, limiting innovation in material development.

Automation and process control sophistication lags behind other manufacturing technologies. Many autoclave operations still rely on manual intervention and predetermined cure cycles rather than adaptive, AI-driven control systems that could optimize parameters in real-time based on material behavior and environmental conditions.

Cost considerations remain paramount, with capital investment for industrial-scale autoclaves ranging from $500,000 to several million dollars, plus significant operational expenses. This economic barrier restricts adoption, particularly among small to medium enterprises seeking to enter the high-performance polymer market, thereby limiting industry-wide innovation potential.

Current Autoclave Synthesis Solutions for Thermosetting Polymers

01 Novel synthesis methods for high-temperature resistant polymers

Advanced synthesis techniques for developing thermosetting polymers with exceptional thermal stability and resistance to degradation at elevated temperatures. These methods involve specialized catalysts and controlled polymerization conditions to create cross-linked structures that maintain mechanical properties under extreme thermal conditions. The resulting polymers exhibit glass transition temperatures significantly higher than conventional materials, making them suitable for aerospace and other high-temperature applications.- Novel synthesis methods for high-temperature resistant polymers: Advanced synthesis techniques for developing thermosetting polymers with exceptional thermal stability. These methods focus on creating polymer structures that maintain mechanical integrity and performance at elevated temperatures. The innovations include specialized catalytic processes, controlled polymerization techniques, and novel monomer combinations that result in highly cross-linked networks with superior thermal resistance properties.

- Bio-based and sustainable thermosetting polymer innovations: Environmentally friendly approaches to thermosetting polymer synthesis using renewable resources and bio-based feedstocks. These innovations focus on replacing petroleum-based raw materials with sustainable alternatives while maintaining or enhancing performance characteristics. The methods include utilizing plant-derived monomers, enzymatic polymerization processes, and green chemistry principles to create high-performance thermosetting materials with reduced environmental impact.

- Advanced curing mechanisms and cross-linking technologies: Innovative curing and cross-linking methods that enhance the performance properties of thermosetting polymers. These technologies include photo-initiated curing, microwave-assisted processing, controlled radical polymerization, and dual-curing systems. The innovations enable precise control over network formation, resulting in improved mechanical properties, thermal stability, and chemical resistance while potentially reducing curing times and energy requirements.

- Nanocomposite and hybrid thermosetting polymer systems: Integration of nanomaterials and hybrid components into thermosetting polymer matrices to create advanced composite materials with enhanced properties. These innovations involve incorporating nanoparticles, nanofibers, or other nanoscale reinforcements to improve mechanical strength, thermal conductivity, flame retardancy, and other performance characteristics. The synthesis methods focus on achieving uniform dispersion and strong interfacial bonding between the polymer matrix and nano-components.

- Self-healing and smart thermosetting polymer technologies: Development of thermosetting polymers with self-healing capabilities and stimuli-responsive functionalities. These innovations incorporate dynamic covalent bonds, reversible cross-linking mechanisms, or encapsulated healing agents that enable the material to repair damage autonomously. The synthesis approaches focus on creating polymer networks that can respond to external stimuli such as temperature, pH, or mechanical stress while maintaining the high-performance characteristics of traditional thermosetting materials.

02 Bio-based and sustainable thermosetting polymer innovations

Development of environmentally friendly thermosetting polymers derived from renewable resources and bio-based feedstocks. These synthesis approaches focus on replacing petroleum-based components with sustainable alternatives while maintaining or enhancing performance characteristics. The innovations include modified curing processes that reduce energy consumption and the incorporation of natural fibers or bio-derived monomers to create high-performance composites with reduced environmental impact.Expand Specific Solutions03 Advanced curing technologies for improved polymer properties

Innovative curing methodologies that enhance the mechanical, thermal, and chemical properties of thermosetting polymers. These technologies include photo-initiated curing, microwave-assisted processes, and dual-curing systems that allow for precise control over cross-linking density and network formation. The resulting polymers demonstrate superior toughness, impact resistance, and dimensional stability compared to conventionally cured systems, while often reducing processing time and energy requirements.Expand Specific Solutions04 Nanocomposite thermosetting polymer systems

Integration of nanomaterials into thermosetting polymer matrices to create high-performance composite systems with enhanced properties. These synthesis innovations involve the uniform dispersion of nanoparticles, nanofibers, or nanoplatelets within the polymer network to significantly improve mechanical strength, thermal conductivity, flame retardancy, and barrier properties. The controlled interfacial interactions between the nanomaterials and polymer matrix are crucial for achieving optimal performance enhancements.Expand Specific Solutions05 Self-healing and smart thermosetting polymer technologies

Development of advanced thermosetting polymers with self-healing capabilities and stimuli-responsive functionalities. These innovations incorporate dynamic covalent bonds, encapsulated healing agents, or reversible cross-linking mechanisms that enable the material to repair damage autonomously. Additionally, these smart polymer systems can respond to external stimuli such as temperature, pH, or electrical fields, allowing for programmable behavior and adaptive properties in various applications including electronics, coatings, and structural materials.Expand Specific Solutions

Key Industry Players in Polymer Synthesis Equipment

The autoclave synthesis market for high-performance thermosetting polymers is currently in a growth phase, characterized by increasing demand across aerospace, automotive, and industrial applications. The global market size is estimated to exceed $3 billion, with projected annual growth of 6-8%. Technical innovation is concentrated among three key player categories: academic institutions (Shandong University, Zhejiang University, Beijing University of Chemical Technology), aerospace leaders (Airbus, Boeing), and chemical corporations (Hexcel, ExxonMobil, SABIC, Kuraray). Industry maturity varies by application, with aerospace applications being most advanced. Recent breakthroughs in process optimization and sustainable formulations from Hexcel, Airbus, and Chinese research institutions indicate accelerating technical maturity, though commercialization challenges remain for novel synthesis methods.

Dow Global Technologies LLC

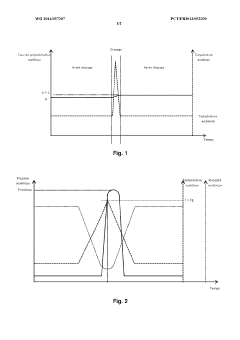

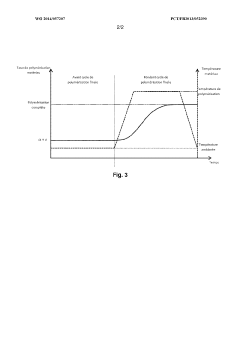

Technical Solution: Dow has pioneered advanced autoclave synthesis techniques for high-performance thermosetting polymers through their proprietary VORAFUSE™ technology. This system combines epoxy resins with thermoplastic materials in a controlled autoclave environment, enabling precise temperature and pressure control during polymerization. Their innovation focuses on prepreg materials that can be rapidly processed at temperatures between 180-200°C and pressures of 6-8 bar in autoclaves, significantly reducing cycle times while maintaining structural integrity. Dow's approach incorporates specialized catalysts and curing agents that activate at specific temperature thresholds, allowing for better control of crosslinking density and reaction kinetics. The company has also developed novel monitoring systems that track the degree of cure in real-time during autoclave processing, enabling adaptive process control to optimize mechanical properties and minimize residual stresses in the final composite parts.

Strengths: Superior control over crosslinking density and reaction kinetics; reduced cycle times while maintaining structural integrity; real-time monitoring capabilities. Weaknesses: Higher initial investment costs for specialized equipment; requires precise temperature and pressure control that may be challenging in large-scale production environments.

Hexcel Corp.

Technical Solution: Hexcel has developed innovative autoclave synthesis methods for their HexPly® high-performance thermosetting prepreg systems, specifically designed for aerospace applications. Their technology utilizes precisely controlled autoclave environments with temperatures ranging from 120-180°C and pressures of 6-7 bar to achieve optimal curing of advanced epoxy and bismaleimide (BMI) resin systems. Hexcel's innovation lies in their proprietary resin formulations that incorporate latent curing agents and toughening modifiers, enabling extended out-of-autoclave shelf life while delivering exceptional mechanical properties after autoclave processing. Their autoclave synthesis approach includes multi-stage cure cycles with programmed temperature ramps and dwells that optimize crosslinking while minimizing internal stresses. Additionally, Hexcel has pioneered the integration of nano-reinforcements into their resin systems that are specifically designed to enhance performance under autoclave processing conditions, resulting in composites with improved interlaminar properties and damage tolerance.

Strengths: Exceptional mechanical properties tailored for aerospace applications; extended out-of-autoclave shelf life; optimized multi-stage cure cycles. Weaknesses: Higher energy consumption during processing; relatively long cure cycles compared to some emerging technologies; specialized equipment requirements.

Core Patents in High-Performance Polymer Autoclave Processing

Method for producing thermosetting composite parts by drape-forming of preimpregnated material

PatentActiveEP2911863A2

Innovation

- A process involving partially polymerized pre-impregnated material with a resin polymerization rate between 10% and 60%, allowing draping without intermediate compactions and potentially eliminating the need for autoclave polymerization, by heating and pressing the material to control porosity and viscosity.

Method for producing parts made of thermosetting composite by laying of fibres of preimpregnated material

PatentWO2014057207A2

Innovation

- A process involving partially polymerized pre-impregnated materials with a resin polymerization rate between 10% and 60%, allowing for air reduction during draping without speed degradation, eliminating intermediate compactions, and enabling final polymerization outside the autoclave by controlling temperature and pressure to achieve a porosity rate of less than 4%.

Environmental Impact and Sustainability Considerations

The autoclave synthesis of high-performance thermosetting polymers presents significant environmental challenges that must be addressed for sustainable industrial practices. Traditional autoclave processes consume substantial energy due to high temperature and pressure requirements, often operating at 120-180°C and 6-7 bar pressure for extended periods. This energy intensity contributes considerably to carbon emissions, with estimates suggesting that autoclave curing accounts for approximately 17-25% of the total carbon footprint in advanced composite manufacturing.

Water consumption represents another critical environmental concern, as autoclave systems typically require cooling systems that utilize large volumes of water. Recent industry analyses indicate that a standard industrial autoclave operation can consume between 2,000-5,000 gallons of water per production cycle, depending on size and specifications. Additionally, the release of volatile organic compounds (VOCs) during the curing process poses air quality concerns and potential health risks to workers.

Waste generation from failed batches and material trimming constitutes a significant sustainability challenge. Unlike thermoplastics, cured thermoset polymers cannot be easily recycled through conventional melting and reforming processes, resulting in disposal challenges. Current estimates suggest that material waste rates in autoclave processing can reach 15-30% in some applications, representing both economic and environmental inefficiencies.

Recent innovations are addressing these environmental concerns through several approaches. Bio-based feedstocks derived from renewable resources are being developed as alternatives to petroleum-based raw materials, with some commercial formulations achieving 30-60% bio-content while maintaining performance specifications. Energy-efficient autoclave designs incorporating improved insulation, heat recovery systems, and optimized cure cycles have demonstrated energy savings of 15-25% compared to conventional systems.

Catalyst innovations enabling lower temperature curing represent another promising direction, with new catalytic systems allowing complete curing at temperatures 20-40°C lower than traditional formulations. This temperature reduction translates directly to energy savings and reduced carbon emissions. Additionally, solvent-free formulations and water-based systems are gaining traction, significantly reducing VOC emissions during processing.

The industry is also exploring end-of-life considerations through the development of thermosetting polymers with designed degradation pathways or reversible crosslinking mechanisms. These innovations could potentially enable the recovery and reuse of valuable components from thermoset waste, addressing one of the fundamental sustainability challenges in this field.

Water consumption represents another critical environmental concern, as autoclave systems typically require cooling systems that utilize large volumes of water. Recent industry analyses indicate that a standard industrial autoclave operation can consume between 2,000-5,000 gallons of water per production cycle, depending on size and specifications. Additionally, the release of volatile organic compounds (VOCs) during the curing process poses air quality concerns and potential health risks to workers.

Waste generation from failed batches and material trimming constitutes a significant sustainability challenge. Unlike thermoplastics, cured thermoset polymers cannot be easily recycled through conventional melting and reforming processes, resulting in disposal challenges. Current estimates suggest that material waste rates in autoclave processing can reach 15-30% in some applications, representing both economic and environmental inefficiencies.

Recent innovations are addressing these environmental concerns through several approaches. Bio-based feedstocks derived from renewable resources are being developed as alternatives to petroleum-based raw materials, with some commercial formulations achieving 30-60% bio-content while maintaining performance specifications. Energy-efficient autoclave designs incorporating improved insulation, heat recovery systems, and optimized cure cycles have demonstrated energy savings of 15-25% compared to conventional systems.

Catalyst innovations enabling lower temperature curing represent another promising direction, with new catalytic systems allowing complete curing at temperatures 20-40°C lower than traditional formulations. This temperature reduction translates directly to energy savings and reduced carbon emissions. Additionally, solvent-free formulations and water-based systems are gaining traction, significantly reducing VOC emissions during processing.

The industry is also exploring end-of-life considerations through the development of thermosetting polymers with designed degradation pathways or reversible crosslinking mechanisms. These innovations could potentially enable the recovery and reuse of valuable components from thermoset waste, addressing one of the fundamental sustainability challenges in this field.

Cost-Benefit Analysis of Advanced Autoclave Systems

The implementation of advanced autoclave systems for thermosetting polymer synthesis represents a significant capital investment that must be carefully evaluated against potential returns. Initial acquisition costs for state-of-the-art autoclave systems range from $500,000 to over $2 million, depending on size, pressure capabilities, temperature range, and control sophistication. However, these systems offer substantial long-term economic benefits that may justify the investment.

Energy efficiency improvements in modern autoclave systems can reduce operational costs by 15-30% compared to conventional equipment. Advanced thermal management systems, including precise temperature control and improved insulation, minimize heat loss during curing cycles. Additionally, newer systems incorporate energy recovery mechanisms that capture and reuse thermal energy, further reducing utility expenses over the equipment's lifecycle.

Production throughput enhancements represent another significant economic advantage. Advanced autoclaves with optimized heating/cooling rates can reduce cycle times by up to 40%, increasing annual production capacity without expanding physical infrastructure. Automated loading/unloading systems and improved pressure control further contribute to operational efficiency, reducing labor costs and minimizing downtime between production runs.

Quality improvements delivered by advanced autoclave systems translate directly to financial benefits through reduced scrap rates and warranty claims. Enhanced pressure uniformity and temperature homogeneity across the curing chamber result in more consistent material properties and fewer defects. Studies indicate that scrap reduction alone can save manufacturers 5-12% in material costs annually, particularly for high-value aerospace and automotive components.

Maintenance requirements present a mixed cost profile. While advanced systems incorporate sophisticated monitoring capabilities that enable predictive maintenance and reduce catastrophic failures, they also contain more complex components that may require specialized service. Manufacturers typically report 20-30% lower unplanned downtime with modern systems, though annual maintenance costs may be 10-15% higher than legacy equipment.

Return on investment calculations indicate that most advanced autoclave implementations achieve payback periods of 3-5 years in high-volume production environments. This timeline shortens considerably for applications involving high-value materials where quality improvements and scrap reduction deliver outsized financial benefits. Organizations must also consider less quantifiable benefits, including improved workplace safety, reduced environmental impact, and enhanced manufacturing flexibility.

Energy efficiency improvements in modern autoclave systems can reduce operational costs by 15-30% compared to conventional equipment. Advanced thermal management systems, including precise temperature control and improved insulation, minimize heat loss during curing cycles. Additionally, newer systems incorporate energy recovery mechanisms that capture and reuse thermal energy, further reducing utility expenses over the equipment's lifecycle.

Production throughput enhancements represent another significant economic advantage. Advanced autoclaves with optimized heating/cooling rates can reduce cycle times by up to 40%, increasing annual production capacity without expanding physical infrastructure. Automated loading/unloading systems and improved pressure control further contribute to operational efficiency, reducing labor costs and minimizing downtime between production runs.

Quality improvements delivered by advanced autoclave systems translate directly to financial benefits through reduced scrap rates and warranty claims. Enhanced pressure uniformity and temperature homogeneity across the curing chamber result in more consistent material properties and fewer defects. Studies indicate that scrap reduction alone can save manufacturers 5-12% in material costs annually, particularly for high-value aerospace and automotive components.

Maintenance requirements present a mixed cost profile. While advanced systems incorporate sophisticated monitoring capabilities that enable predictive maintenance and reduce catastrophic failures, they also contain more complex components that may require specialized service. Manufacturers typically report 20-30% lower unplanned downtime with modern systems, though annual maintenance costs may be 10-15% higher than legacy equipment.

Return on investment calculations indicate that most advanced autoclave implementations achieve payback periods of 3-5 years in high-volume production environments. This timeline shortens considerably for applications involving high-value materials where quality improvements and scrap reduction deliver outsized financial benefits. Organizations must also consider less quantifiable benefits, including improved workplace safety, reduced environmental impact, and enhanced manufacturing flexibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!