Comparative Study of Autoclave Synthesis Techniques in Nanomaterial Fabrication

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanomaterial Autoclave Synthesis Background and Objectives

Autoclave synthesis techniques have emerged as a cornerstone methodology in nanomaterial fabrication since the early 1990s, evolving from traditional hydrothermal processes first developed for mineral synthesis in the mid-20th century. This evolution represents a significant advancement in controlled nanomaterial production, offering precise parameter management for crystallization processes. The technique has progressively refined from basic pressure vessel applications to sophisticated computer-controlled systems capable of nanoscale precision in material development.

The technological trajectory of autoclave synthesis has been characterized by several distinct phases. Initially focused on simple metal oxide nanoparticles, the field expanded to encompass complex composite nanomaterials, hierarchical structures, and most recently, quantum-confined nanomaterials with tailored electronic properties. This progression reflects broader nanotechnology trends toward increasingly sophisticated control over material properties at the atomic and molecular levels.

Current research in autoclave synthesis techniques is primarily driven by demands for sustainable manufacturing processes, energy-efficient materials, and advanced functional nanomaterials for emerging technologies. The convergence of computational modeling with experimental approaches has accelerated innovation, enabling predictive synthesis protocols that significantly reduce development cycles for new nanomaterials.

The primary objective of this comparative study is to systematically evaluate various autoclave synthesis methodologies across multiple dimensions: energy efficiency, scalability potential, reproducibility, and material quality metrics. By establishing standardized comparison frameworks, we aim to identify optimal synthesis pathways for specific nanomaterial classes and application requirements. This analysis will provide critical insights for both research and industrial implementation decisions.

Secondary objectives include mapping the relationship between synthesis parameters and resultant nanomaterial properties, identifying critical control variables that most significantly impact material outcomes, and developing predictive models to streamline future synthesis protocol development. These objectives align with the broader industry goal of transitioning from empirical to rational design approaches in nanomaterial fabrication.

The study also aims to address existing knowledge gaps regarding the fundamental mechanisms governing nanomaterial formation under autoclave conditions. Despite widespread application, many aspects of nucleation, growth kinetics, and morphology control remain incompletely understood, particularly for complex multi-component systems. By elucidating these mechanisms, we anticipate enabling more precise control over nanomaterial architecture and properties.

Finally, this investigation seeks to establish a comprehensive technical foundation for next-generation autoclave synthesis approaches that integrate emerging technologies such as microfluidic control systems, in-situ characterization capabilities, and AI-assisted parameter optimization. These advancements promise to transform autoclave synthesis from a batch-oriented technique to a more continuous, precisely controlled manufacturing methodology suitable for industrial-scale production of high-performance nanomaterials.

The technological trajectory of autoclave synthesis has been characterized by several distinct phases. Initially focused on simple metal oxide nanoparticles, the field expanded to encompass complex composite nanomaterials, hierarchical structures, and most recently, quantum-confined nanomaterials with tailored electronic properties. This progression reflects broader nanotechnology trends toward increasingly sophisticated control over material properties at the atomic and molecular levels.

Current research in autoclave synthesis techniques is primarily driven by demands for sustainable manufacturing processes, energy-efficient materials, and advanced functional nanomaterials for emerging technologies. The convergence of computational modeling with experimental approaches has accelerated innovation, enabling predictive synthesis protocols that significantly reduce development cycles for new nanomaterials.

The primary objective of this comparative study is to systematically evaluate various autoclave synthesis methodologies across multiple dimensions: energy efficiency, scalability potential, reproducibility, and material quality metrics. By establishing standardized comparison frameworks, we aim to identify optimal synthesis pathways for specific nanomaterial classes and application requirements. This analysis will provide critical insights for both research and industrial implementation decisions.

Secondary objectives include mapping the relationship between synthesis parameters and resultant nanomaterial properties, identifying critical control variables that most significantly impact material outcomes, and developing predictive models to streamline future synthesis protocol development. These objectives align with the broader industry goal of transitioning from empirical to rational design approaches in nanomaterial fabrication.

The study also aims to address existing knowledge gaps regarding the fundamental mechanisms governing nanomaterial formation under autoclave conditions. Despite widespread application, many aspects of nucleation, growth kinetics, and morphology control remain incompletely understood, particularly for complex multi-component systems. By elucidating these mechanisms, we anticipate enabling more precise control over nanomaterial architecture and properties.

Finally, this investigation seeks to establish a comprehensive technical foundation for next-generation autoclave synthesis approaches that integrate emerging technologies such as microfluidic control systems, in-situ characterization capabilities, and AI-assisted parameter optimization. These advancements promise to transform autoclave synthesis from a batch-oriented technique to a more continuous, precisely controlled manufacturing methodology suitable for industrial-scale production of high-performance nanomaterials.

Market Applications and Demand Analysis for Autoclave-Synthesized Nanomaterials

The global market for nanomaterials synthesized via autoclave techniques has experienced significant growth, with the market value reaching approximately 5.3 billion USD in 2022 and projected to expand at a compound annual growth rate of 14.2% through 2030. This robust growth is primarily driven by increasing applications across multiple industries including electronics, healthcare, energy storage, and advanced materials manufacturing.

In the electronics sector, autoclave-synthesized nanomaterials are increasingly sought after for the development of high-performance semiconductors, conductive inks, and flexible electronics. The miniaturization trend in consumer electronics has created substantial demand for nanomaterials with precisely controlled properties that autoclave synthesis can deliver. Industry reports indicate that electronics applications account for nearly 28% of the total market share for these materials.

The healthcare and pharmaceutical industries represent another significant market segment, with applications spanning drug delivery systems, diagnostic tools, and antimicrobial coatings. Hydrothermal autoclave synthesis enables the production of biocompatible nanomaterials with controlled morphology and surface chemistry, critical for medical applications. Market analysis shows this sector growing at 16.8% annually, faster than the overall market average.

Energy storage and conversion technologies constitute a rapidly expanding application area. Autoclave-synthesized nanomaterials are integral to next-generation batteries, supercapacitors, and photovoltaic cells. The superior electrochemical properties achieved through controlled autoclave synthesis directly translate to enhanced device performance. The renewable energy transition has accelerated demand in this segment, with industry forecasts predicting a market size of 2.1 billion USD by 2028 for energy-related nanomaterials.

The automotive industry has emerged as a promising growth market, incorporating nanomaterials into lightweight composites, catalytic converters, and advanced coatings. Autoclave synthesis techniques enable the production of nanomaterials that contribute to fuel efficiency, emissions reduction, and enhanced durability. This sector currently represents approximately 15% of the market but is expected to reach 22% by 2027.

Regional market analysis reveals that Asia-Pacific dominates the demand landscape, accounting for 42% of global consumption, followed by North America (27%) and Europe (21%). China, Japan, and South Korea lead in both production and consumption, driven by their robust electronics manufacturing sectors. However, North America and Europe maintain technological leadership in high-value applications, particularly in healthcare and aerospace.

Market challenges include high production costs associated with autoclave equipment, scaling limitations, and regulatory hurdles regarding nanomaterial safety. Nevertheless, the continuous improvement in autoclave synthesis techniques and growing recognition of the performance advantages offered by precisely engineered nanomaterials suggest sustained market growth for the foreseeable future.

In the electronics sector, autoclave-synthesized nanomaterials are increasingly sought after for the development of high-performance semiconductors, conductive inks, and flexible electronics. The miniaturization trend in consumer electronics has created substantial demand for nanomaterials with precisely controlled properties that autoclave synthesis can deliver. Industry reports indicate that electronics applications account for nearly 28% of the total market share for these materials.

The healthcare and pharmaceutical industries represent another significant market segment, with applications spanning drug delivery systems, diagnostic tools, and antimicrobial coatings. Hydrothermal autoclave synthesis enables the production of biocompatible nanomaterials with controlled morphology and surface chemistry, critical for medical applications. Market analysis shows this sector growing at 16.8% annually, faster than the overall market average.

Energy storage and conversion technologies constitute a rapidly expanding application area. Autoclave-synthesized nanomaterials are integral to next-generation batteries, supercapacitors, and photovoltaic cells. The superior electrochemical properties achieved through controlled autoclave synthesis directly translate to enhanced device performance. The renewable energy transition has accelerated demand in this segment, with industry forecasts predicting a market size of 2.1 billion USD by 2028 for energy-related nanomaterials.

The automotive industry has emerged as a promising growth market, incorporating nanomaterials into lightweight composites, catalytic converters, and advanced coatings. Autoclave synthesis techniques enable the production of nanomaterials that contribute to fuel efficiency, emissions reduction, and enhanced durability. This sector currently represents approximately 15% of the market but is expected to reach 22% by 2027.

Regional market analysis reveals that Asia-Pacific dominates the demand landscape, accounting for 42% of global consumption, followed by North America (27%) and Europe (21%). China, Japan, and South Korea lead in both production and consumption, driven by their robust electronics manufacturing sectors. However, North America and Europe maintain technological leadership in high-value applications, particularly in healthcare and aerospace.

Market challenges include high production costs associated with autoclave equipment, scaling limitations, and regulatory hurdles regarding nanomaterial safety. Nevertheless, the continuous improvement in autoclave synthesis techniques and growing recognition of the performance advantages offered by precisely engineered nanomaterials suggest sustained market growth for the foreseeable future.

Current Autoclave Synthesis Techniques and Challenges

Autoclave synthesis represents a cornerstone methodology in nanomaterial fabrication, characterized by its utilization of high-pressure and high-temperature conditions within sealed vessels. Currently, several distinct autoclave synthesis techniques dominate the field, each with specific advantages and limitations that influence their application domains.

Hydrothermal synthesis stands as the most widely employed autoclave technique, operating at temperatures between 100-250°C and pressures up to 100 MPa. This method excels in producing oxide nanomaterials with high crystallinity and controlled morphology. However, it faces challenges in precise control of nucleation and growth kinetics, often resulting in particle size distribution variability that can compromise material performance in sensitive applications.

Solvothermal synthesis, a variation utilizing non-aqueous solvents, offers enhanced solubility for organic precursors and enables synthesis of materials that would hydrolyze in aqueous environments. While this technique provides access to unique nanostructures, it frequently encounters issues with solvent toxicity, higher processing costs, and complex purification procedures that limit industrial scalability.

Microwave-assisted autoclave synthesis has emerged as a rapid alternative, reducing reaction times from hours to minutes through volumetric heating mechanisms. Despite its time efficiency and energy conservation benefits, this approach struggles with temperature gradient formation in larger vessels and exhibits limited penetration depth in certain reaction media, constraining batch sizes and homogeneity.

Supercritical fluid-based autoclave methods leverage the unique properties of supercritical fluids (particularly CO2) to facilitate rapid diffusion and reaction rates. These techniques excel in producing highly monodisperse nanoparticles but require sophisticated equipment capable of withstanding extreme conditions, presenting significant capital investment barriers and safety concerns.

The continuous flow autoclave approach represents the cutting edge of current technology, enabling precise residence time control and improved scalability. However, this method faces substantial engineering challenges related to pressure maintenance, nozzle clogging, and material deposition on reactor walls during extended operation periods.

Cross-cutting challenges across all autoclave synthesis techniques include energy intensity, with high thermal and pressure requirements translating to substantial energy consumption. Additionally, batch-to-batch reproducibility remains problematic, particularly when scaling from laboratory to industrial production volumes. Safety considerations also present significant hurdles, as high-pressure vessels inherently carry risks that necessitate robust containment systems and rigorous operating protocols.

Material-specific challenges further complicate the landscape, with certain nanomaterials requiring precise control over multiple parameters simultaneously—temperature, pressure, pH, and precursor concentration—creating complex process optimization problems that current autoclave technologies struggle to address comprehensively.

Hydrothermal synthesis stands as the most widely employed autoclave technique, operating at temperatures between 100-250°C and pressures up to 100 MPa. This method excels in producing oxide nanomaterials with high crystallinity and controlled morphology. However, it faces challenges in precise control of nucleation and growth kinetics, often resulting in particle size distribution variability that can compromise material performance in sensitive applications.

Solvothermal synthesis, a variation utilizing non-aqueous solvents, offers enhanced solubility for organic precursors and enables synthesis of materials that would hydrolyze in aqueous environments. While this technique provides access to unique nanostructures, it frequently encounters issues with solvent toxicity, higher processing costs, and complex purification procedures that limit industrial scalability.

Microwave-assisted autoclave synthesis has emerged as a rapid alternative, reducing reaction times from hours to minutes through volumetric heating mechanisms. Despite its time efficiency and energy conservation benefits, this approach struggles with temperature gradient formation in larger vessels and exhibits limited penetration depth in certain reaction media, constraining batch sizes and homogeneity.

Supercritical fluid-based autoclave methods leverage the unique properties of supercritical fluids (particularly CO2) to facilitate rapid diffusion and reaction rates. These techniques excel in producing highly monodisperse nanoparticles but require sophisticated equipment capable of withstanding extreme conditions, presenting significant capital investment barriers and safety concerns.

The continuous flow autoclave approach represents the cutting edge of current technology, enabling precise residence time control and improved scalability. However, this method faces substantial engineering challenges related to pressure maintenance, nozzle clogging, and material deposition on reactor walls during extended operation periods.

Cross-cutting challenges across all autoclave synthesis techniques include energy intensity, with high thermal and pressure requirements translating to substantial energy consumption. Additionally, batch-to-batch reproducibility remains problematic, particularly when scaling from laboratory to industrial production volumes. Safety considerations also present significant hurdles, as high-pressure vessels inherently carry risks that necessitate robust containment systems and rigorous operating protocols.

Material-specific challenges further complicate the landscape, with certain nanomaterials requiring precise control over multiple parameters simultaneously—temperature, pressure, pH, and precursor concentration—creating complex process optimization problems that current autoclave technologies struggle to address comprehensively.

Comparative Analysis of Current Autoclave Synthesis Approaches

01 Hydrothermal synthesis in autoclaves

Hydrothermal synthesis techniques involve using autoclaves to create high-pressure and high-temperature environments for material synthesis. This method is particularly effective for crystalline materials where water acts as both a pressure transmitting medium and sometimes as a reactant. The controlled conditions within the autoclave allow for precise crystal growth and formation of materials that would be difficult to synthesize under normal conditions.- Hydrothermal synthesis in autoclaves: Hydrothermal synthesis techniques involve using autoclaves to create high-pressure and high-temperature environments for material synthesis. This method is particularly effective for creating crystalline materials, ceramics, and nanomaterials. The controlled environment within the autoclave allows for precise manipulation of reaction conditions, resulting in materials with specific properties and structures.

- Autoclave design and equipment optimization: Innovations in autoclave design focus on improving safety, efficiency, and process control. These developments include specialized sealing mechanisms, temperature and pressure monitoring systems, and materials that can withstand extreme conditions. Advanced autoclave equipment may incorporate automated control systems, specialized heating elements, and corrosion-resistant components to enhance synthesis capabilities.

- Nanoparticle and nanomaterial synthesis: Autoclave techniques are widely used for synthesizing nanoparticles and nanomaterials with controlled size, shape, and composition. The high-pressure environment in autoclaves facilitates the formation of unique nanostructures that cannot be achieved through conventional synthesis methods. These techniques are particularly valuable for creating quantum dots, metal oxide nanoparticles, and carbon-based nanomaterials with applications in electronics, catalysis, and medicine.

- Green chemistry and sustainable synthesis approaches: Environmentally friendly autoclave synthesis techniques focus on reducing energy consumption, using non-toxic reagents, and minimizing waste. These approaches often utilize water as a solvent and incorporate renewable resources as starting materials. The controlled conditions in autoclaves allow for efficient reactions with higher yields and fewer byproducts, contributing to more sustainable chemical manufacturing processes.

- Process monitoring and quality control: Advanced monitoring systems for autoclave synthesis enable real-time tracking of reaction parameters such as temperature, pressure, and pH. These technologies improve reproducibility and product quality by allowing precise control over synthesis conditions. Innovations in this area include in-situ spectroscopic techniques, automated sampling systems, and predictive modeling approaches that optimize reaction conditions based on desired product characteristics.

02 Autoclave process control and monitoring systems

Advanced control and monitoring systems are essential for autoclave synthesis to ensure precise temperature, pressure, and time parameters. These systems include computerized controls, sensors for real-time data collection, and automated safety mechanisms. Modern autoclave synthesis techniques incorporate sophisticated monitoring equipment that allows for reproducible results and enhanced safety during high-pressure operations.Expand Specific Solutions03 Novel materials synthesis using autoclave methods

Autoclave synthesis enables the creation of novel materials with unique properties that cannot be achieved through conventional synthesis methods. This includes nanomaterials, advanced ceramics, and composite materials with specialized applications. The controlled environment of an autoclave allows for precise manipulation of reaction conditions, resulting in materials with tailored characteristics for specific industrial or research applications.Expand Specific Solutions04 Autoclave design innovations for synthesis applications

Innovations in autoclave design have significantly improved synthesis capabilities, including specialized liners, enhanced sealing mechanisms, and materials that withstand extreme conditions. Modern autoclaves feature improved heat distribution systems, corrosion-resistant components, and modular designs that can be adapted for different synthesis requirements. These design innovations have expanded the range of materials that can be synthesized and improved process efficiency.Expand Specific Solutions05 Green chemistry approaches in autoclave synthesis

Environmentally friendly approaches to autoclave synthesis focus on reducing energy consumption, using sustainable reactants, and minimizing waste production. These techniques often employ lower temperatures, catalysts to improve efficiency, and solvent-free or water-based reaction media. Green autoclave synthesis methods aim to maintain high product quality while reducing the environmental impact of manufacturing processes.Expand Specific Solutions

Leading Research Institutions and Commercial Manufacturers

The autoclave synthesis techniques in nanomaterial fabrication market is currently in a growth phase, with increasing adoption across research institutions and industrial applications. The global market size for advanced nanomaterial synthesis is projected to expand significantly, driven by applications in electronics, medicine, and energy storage. Technologically, academic institutions like MIT, Cornell University, and Shandong University are leading fundamental research, while companies such as Samsung Electronics, Apple, and Hon Hai Precision are focusing on commercial applications. The technology demonstrates varying maturity levels across different nanomaterial types, with metal oxide nanoparticles showing higher maturity compared to newer carbon-based nanomaterials. Research collaborations between universities and industrial players like Nanocomp Technologies are accelerating the development of scalable autoclave synthesis methods.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced autoclave synthesis techniques for nanomaterial fabrication focusing on hydrothermal and solvothermal processes. Their approach employs precisely controlled temperature gradients within specialized autoclave reactors to enable selective crystallization and growth of nanomaterials. MIT researchers have developed innovative autoclave liners made from novel composite materials that resist corrosion while enhancing heat distribution. Their techniques incorporate programmable pressure cycling protocols that significantly improve morphological control of synthesized nanostructures. MIT's autoclave systems feature integrated in-situ characterization capabilities, allowing researchers to monitor crystallization processes in real-time using spectroscopic methods. This enables unprecedented control over nucleation and growth phases, resulting in nanomaterials with highly uniform properties. The institute has also developed computational models that predict optimal autoclave synthesis parameters based on thermodynamic principles, reducing experimental iterations required for new material development.

Strengths: Exceptional precision in controlling synthesis parameters; advanced in-situ monitoring capabilities; strong theoretical foundation through computational modeling. Weaknesses: Complex equipment setup requires specialized expertise; higher initial investment costs; some techniques remain challenging to scale beyond laboratory settings.

California Institute of Technology

Technical Solution: Caltech has developed sophisticated autoclave synthesis methodologies focusing on quantum dot and metal oxide nanoparticle fabrication. Their approach utilizes microfluidic-assisted autoclave systems that enable precise control over reaction kinetics through controlled mixing of precursors under high-pressure conditions. Caltech's innovation includes the development of specialized autoclave reactors with zoned heating capabilities, allowing for the creation of controlled temperature gradients that facilitate directional crystal growth. Their techniques incorporate advanced precursor delivery systems that enable the sequential introduction of reactants at precisely timed intervals during the synthesis process. This temporal control over reaction chemistry has proven particularly valuable for creating core-shell nanostructures with atomically sharp interfaces. Caltech researchers have also pioneered the use of ultrasonic agitation within autoclave environments to enhance precursor dispersion and prevent agglomeration during nanomaterial growth, resulting in improved size distribution and morphological uniformity.

Strengths: Exceptional control over nanoparticle composition and structure; ability to create complex multi-component nanomaterials; excellent reproducibility. Weaknesses: Equipment complexity limits widespread adoption; higher operational costs; requires specialized training for effective implementation.

Key Patents and Scientific Breakthroughs in Autoclave Synthesis

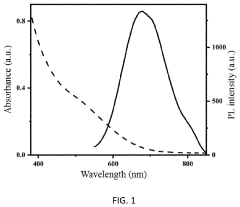

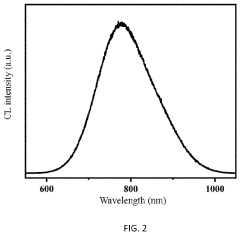

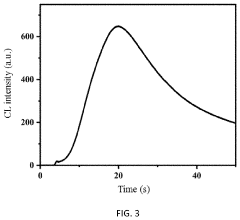

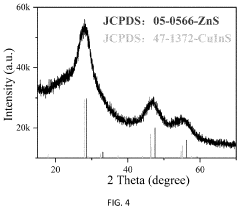

Flash-type chemiluminescence system based on cuins2@zns nanomaterial

PatentActiveUS20230067974A1

Innovation

- A flash-type CL liquid composition utilizing CuInS2/ZnS nanomaterials excited by Tris-N2H4.H2O—H2O2, which simplifies synthesis, enhances CL intensity, and provides photostability, with CL times ranging from 1-10 seconds and emission in the near-infrared region.

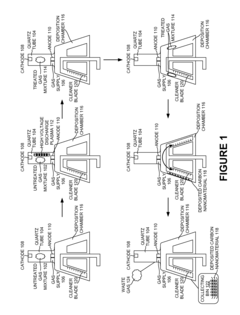

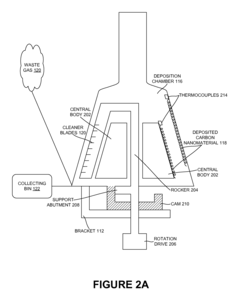

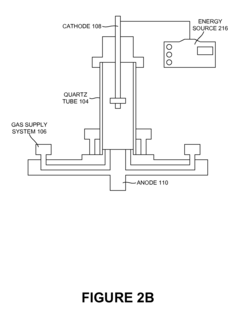

Increased efficiency in the synthesis of carbon nanomaterial

PatentInactiveUS8920739B2

Innovation

- An automated system with cleaner blades fixed on a rocker coupled to a rotation drive, translating rotational motion into linear motion to scrape and collect deposited carbon nanomaterial from the deposition chamber and central body, eliminating the need for chamber disassembly and allowing continuous synthesis.

Environmental Impact and Sustainability Considerations

The environmental impact of autoclave synthesis techniques in nanomaterial fabrication represents a critical consideration as these processes gain wider industrial adoption. Traditional autoclave methods often involve high energy consumption due to the elevated temperatures and pressures required for extended periods, typically ranging from 12 to 72 hours. This energy-intensive nature contributes significantly to the carbon footprint of nanomaterial production, with some studies indicating that energy consumption can account for up to 60% of the environmental impact in certain hydrothermal synthesis processes.

Water usage presents another environmental concern, as autoclave synthesis frequently requires substantial amounts of water both as a reaction medium and for cooling systems. The post-synthesis treatment of this water is particularly problematic as it may contain residual nanomaterials, precursors, and other potentially harmful chemicals that require specialized treatment before discharge.

Chemical waste generation during autoclave synthesis varies significantly depending on the specific technique employed. Hydrothermal methods typically produce less hazardous waste compared to solvothermal approaches, which often utilize organic solvents with inherent toxicity concerns. Recent comparative analyses have shown that microwave-assisted autoclave techniques can reduce solvent usage by 30-45% compared to conventional methods, offering a more environmentally friendly alternative.

Sustainability improvements in autoclave synthesis have emerged through several innovative approaches. The integration of continuous flow systems has demonstrated potential for reducing both energy consumption and waste generation by enabling precise control over reaction parameters and minimizing the need for batch processing. Additionally, the development of low-temperature autoclave techniques utilizing catalysts or pressure-modulation strategies has shown promise in decreasing energy requirements while maintaining product quality.

Life cycle assessments of various autoclave synthesis methods reveal significant differences in environmental impact. For instance, supercritical fluid-assisted autoclave techniques demonstrate approximately 25% lower global warming potential compared to conventional hydrothermal methods when producing equivalent quantities of metal oxide nanoparticles. These assessments also highlight the importance of raw material selection, as the environmental footprint of precursors can sometimes exceed that of the synthesis process itself.

The recyclability of reaction media represents another frontier in sustainable autoclave synthesis. Closed-loop systems that enable the recovery and reuse of solvents and unreacted precursors have been implemented in some advanced facilities, reducing waste generation by up to 70% in continuous production settings. Such approaches align with circular economy principles and offer pathways toward more sustainable nanomaterial manufacturing paradigms.

Water usage presents another environmental concern, as autoclave synthesis frequently requires substantial amounts of water both as a reaction medium and for cooling systems. The post-synthesis treatment of this water is particularly problematic as it may contain residual nanomaterials, precursors, and other potentially harmful chemicals that require specialized treatment before discharge.

Chemical waste generation during autoclave synthesis varies significantly depending on the specific technique employed. Hydrothermal methods typically produce less hazardous waste compared to solvothermal approaches, which often utilize organic solvents with inherent toxicity concerns. Recent comparative analyses have shown that microwave-assisted autoclave techniques can reduce solvent usage by 30-45% compared to conventional methods, offering a more environmentally friendly alternative.

Sustainability improvements in autoclave synthesis have emerged through several innovative approaches. The integration of continuous flow systems has demonstrated potential for reducing both energy consumption and waste generation by enabling precise control over reaction parameters and minimizing the need for batch processing. Additionally, the development of low-temperature autoclave techniques utilizing catalysts or pressure-modulation strategies has shown promise in decreasing energy requirements while maintaining product quality.

Life cycle assessments of various autoclave synthesis methods reveal significant differences in environmental impact. For instance, supercritical fluid-assisted autoclave techniques demonstrate approximately 25% lower global warming potential compared to conventional hydrothermal methods when producing equivalent quantities of metal oxide nanoparticles. These assessments also highlight the importance of raw material selection, as the environmental footprint of precursors can sometimes exceed that of the synthesis process itself.

The recyclability of reaction media represents another frontier in sustainable autoclave synthesis. Closed-loop systems that enable the recovery and reuse of solvents and unreacted precursors have been implemented in some advanced facilities, reducing waste generation by up to 70% in continuous production settings. Such approaches align with circular economy principles and offer pathways toward more sustainable nanomaterial manufacturing paradigms.

Scale-up Strategies and Industrial Implementation

The transition from laboratory-scale autoclave synthesis to industrial production represents a significant challenge in nanomaterial fabrication. Successful scale-up requires careful consideration of multiple factors including reactor design, process parameters, quality control, and economic feasibility. Current industrial implementations typically employ continuous flow reactors or batch processing systems with volumes ranging from 50 to 500 liters, significantly larger than the 25-100 ml laboratory autoclaves commonly used in research settings.

Key scale-up strategies include the development of multi-zone temperature control systems that maintain precise thermal gradients across larger reaction vessels. Companies like BASF and Evonik have pioneered such systems, achieving production capacities of 5-10 tons annually for specialized nanomaterials while maintaining particle size distributions comparable to laboratory samples (±5% deviation).

Process intensification techniques have emerged as critical enablers for industrial implementation. These include the integration of in-situ monitoring tools such as Raman spectroscopy and dynamic light scattering, allowing real-time quality assessment during production. Such approaches have reduced batch-to-batch variations by approximately 30% compared to traditional scale-up methods.

Economic considerations drive the adoption of continuous hydrothermal synthesis (CHS) systems, which demonstrate superior energy efficiency (40-60% reduction) compared to batch autoclave processes at industrial scales. Notable implementations include Promethean Particles' patented reactor design, capable of producing up to 1000 tons of nanomaterials annually while reducing solvent usage by 25-35%.

Safety and environmental concerns have led to the development of specialized pressure relief systems and containment protocols for large-scale autoclave operations. Recent innovations include automated sampling systems that minimize operator exposure to high-pressure environments and potentially hazardous nanomaterials.

Modular scale-up approaches have gained traction, where multiple medium-sized autoclaves operate in parallel rather than scaling to a single large unit. This strategy, employed by companies like Nanomaterials Technology Pte Ltd, offers flexibility in production volumes while minimizing the engineering challenges associated with extreme scale-up. Production efficiency improvements of 15-20% have been reported using this distributed approach.

The integration of computational fluid dynamics (CFD) modeling has become standard practice for predicting mixing patterns, temperature distributions, and reaction kinetics in scaled-up autoclave systems. These simulation tools have reduced development cycles by approximately 40% and decreased the number of pilot-scale experiments required before full industrial implementation.

Key scale-up strategies include the development of multi-zone temperature control systems that maintain precise thermal gradients across larger reaction vessels. Companies like BASF and Evonik have pioneered such systems, achieving production capacities of 5-10 tons annually for specialized nanomaterials while maintaining particle size distributions comparable to laboratory samples (±5% deviation).

Process intensification techniques have emerged as critical enablers for industrial implementation. These include the integration of in-situ monitoring tools such as Raman spectroscopy and dynamic light scattering, allowing real-time quality assessment during production. Such approaches have reduced batch-to-batch variations by approximately 30% compared to traditional scale-up methods.

Economic considerations drive the adoption of continuous hydrothermal synthesis (CHS) systems, which demonstrate superior energy efficiency (40-60% reduction) compared to batch autoclave processes at industrial scales. Notable implementations include Promethean Particles' patented reactor design, capable of producing up to 1000 tons of nanomaterials annually while reducing solvent usage by 25-35%.

Safety and environmental concerns have led to the development of specialized pressure relief systems and containment protocols for large-scale autoclave operations. Recent innovations include automated sampling systems that minimize operator exposure to high-pressure environments and potentially hazardous nanomaterials.

Modular scale-up approaches have gained traction, where multiple medium-sized autoclaves operate in parallel rather than scaling to a single large unit. This strategy, employed by companies like Nanomaterials Technology Pte Ltd, offers flexibility in production volumes while minimizing the engineering challenges associated with extreme scale-up. Production efficiency improvements of 15-20% have been reported using this distributed approach.

The integration of computational fluid dynamics (CFD) modeling has become standard practice for predicting mixing patterns, temperature distributions, and reaction kinetics in scaled-up autoclave systems. These simulation tools have reduced development cycles by approximately 40% and decreased the number of pilot-scale experiments required before full industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!