Autoclave Synthesis and Its Enhancement of UV Protective Coatings

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Technology Background and Objectives

Autoclave synthesis technology has evolved significantly over the past several decades, transforming from basic pressure vessel applications to sophisticated controlled-environment processing systems. Originally developed for industrial sterilization in the early 20th century, autoclaves have since become essential tools in materials science, particularly in the synthesis of advanced coatings and composites. The fundamental principle of utilizing elevated pressure and temperature to accelerate chemical reactions and improve material properties remains unchanged, though the precision and control mechanisms have advanced dramatically.

In the context of UV protective coatings, autoclave synthesis represents a critical manufacturing approach that enables the creation of highly durable, transparent, and effective protective layers. The technology leverages hydrothermal or solvothermal conditions to facilitate the formation of nanostructured materials with superior UV absorption or reflection properties. Historical development shows a clear progression from simple oxide-based UV blockers to complex multi-functional coatings that provide both UV protection and additional benefits such as self-cleaning, anti-fogging, or antimicrobial properties.

Recent technological advancements have focused on improving energy efficiency, reducing processing times, and enhancing the uniformity of coating properties across large surface areas. The integration of computer-controlled systems has enabled precise manipulation of temperature ramps, pressure profiles, and atmospheric conditions within the autoclave chamber, resulting in more consistent and predictable coating characteristics. Additionally, innovations in precursor chemistry and post-processing techniques have expanded the range of substrates that can benefit from autoclave-synthesized UV protective coatings.

The primary technical objectives in this field currently center on several key areas. First, researchers aim to develop more environmentally friendly synthesis routes that reduce or eliminate toxic precursors and minimize energy consumption. Second, there is significant interest in extending the spectral range of protection beyond UVA and UVB to include UVC and even portions of the visible spectrum without compromising coating transparency. Third, enhancing the long-term stability of these coatings under extreme environmental conditions remains a critical goal.

Another important objective is the scalability of autoclave synthesis processes for industrial applications. While laboratory-scale demonstrations have shown promising results, translating these achievements to commercial production volumes presents considerable challenges related to reactor design, process control, and quality assurance. Researchers are actively exploring continuous flow autoclave systems and modular designs that could potentially address these scaling issues.

The convergence of autoclave synthesis with other emerging technologies, such as additive manufacturing and smart materials, represents an exciting frontier with potential for revolutionary advances in UV protective coatings. The ultimate goal is to develop customizable, multi-functional coating systems that can be precisely tailored to specific application requirements while maintaining cost-effectiveness and environmental sustainability.

In the context of UV protective coatings, autoclave synthesis represents a critical manufacturing approach that enables the creation of highly durable, transparent, and effective protective layers. The technology leverages hydrothermal or solvothermal conditions to facilitate the formation of nanostructured materials with superior UV absorption or reflection properties. Historical development shows a clear progression from simple oxide-based UV blockers to complex multi-functional coatings that provide both UV protection and additional benefits such as self-cleaning, anti-fogging, or antimicrobial properties.

Recent technological advancements have focused on improving energy efficiency, reducing processing times, and enhancing the uniformity of coating properties across large surface areas. The integration of computer-controlled systems has enabled precise manipulation of temperature ramps, pressure profiles, and atmospheric conditions within the autoclave chamber, resulting in more consistent and predictable coating characteristics. Additionally, innovations in precursor chemistry and post-processing techniques have expanded the range of substrates that can benefit from autoclave-synthesized UV protective coatings.

The primary technical objectives in this field currently center on several key areas. First, researchers aim to develop more environmentally friendly synthesis routes that reduce or eliminate toxic precursors and minimize energy consumption. Second, there is significant interest in extending the spectral range of protection beyond UVA and UVB to include UVC and even portions of the visible spectrum without compromising coating transparency. Third, enhancing the long-term stability of these coatings under extreme environmental conditions remains a critical goal.

Another important objective is the scalability of autoclave synthesis processes for industrial applications. While laboratory-scale demonstrations have shown promising results, translating these achievements to commercial production volumes presents considerable challenges related to reactor design, process control, and quality assurance. Researchers are actively exploring continuous flow autoclave systems and modular designs that could potentially address these scaling issues.

The convergence of autoclave synthesis with other emerging technologies, such as additive manufacturing and smart materials, represents an exciting frontier with potential for revolutionary advances in UV protective coatings. The ultimate goal is to develop customizable, multi-functional coating systems that can be precisely tailored to specific application requirements while maintaining cost-effectiveness and environmental sustainability.

Market Analysis for UV Protective Coating Applications

The global UV protective coatings market has experienced significant growth in recent years, driven by increasing awareness of UV radiation damage and the need for durable protection across multiple industries. Currently valued at approximately 6.5 billion USD, the market is projected to grow at a compound annual growth rate (CAGR) of 7.2% through 2028, reflecting strong demand fundamentals and technological advancements.

Autoclave synthesis methods have created new market opportunities by enabling the development of more effective and durable UV protective coatings. These advanced synthesis techniques allow for better particle dispersion, enhanced cross-linking, and improved adhesion properties, addressing key performance requirements across various applications.

The construction sector represents the largest application segment, accounting for roughly 35% of the total market share. UV protective coatings in this sector are primarily used for exterior surfaces, windows, and roofing materials to prevent degradation from prolonged sun exposure. The automotive industry follows as the second-largest consumer, utilizing these coatings for maintaining vehicle appearance and extending the lifespan of exterior components.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, driven by rapid industrialization, construction activities, and automotive manufacturing in China, Japan, and India. North America and Europe collectively account for about 45% of the market, with demand primarily stemming from renovation activities and stringent environmental regulations promoting low-VOC coating solutions.

Consumer preferences are increasingly shifting toward multifunctional coatings that offer UV protection alongside other benefits such as anti-microbial properties, self-cleaning capabilities, and enhanced durability. This trend has created premium market segments with higher profit margins for manufacturers who can deliver these advanced formulations.

The autoclave synthesis method has particularly strengthened market positioning for coatings in high-performance applications where extreme weather resistance is required. Marine, aerospace, and outdoor recreational equipment segments have shown willingness to pay premium prices for coatings synthesized using autoclave technology, with price points 15-20% higher than conventional alternatives.

Supply chain analysis indicates that raw material costs represent a significant challenge, particularly for titanium dioxide and specialized UV absorbers. Manufacturers employing autoclave synthesis techniques have demonstrated better optimization of raw material usage, potentially offering cost advantages despite the higher initial investment in production equipment.

Autoclave synthesis methods have created new market opportunities by enabling the development of more effective and durable UV protective coatings. These advanced synthesis techniques allow for better particle dispersion, enhanced cross-linking, and improved adhesion properties, addressing key performance requirements across various applications.

The construction sector represents the largest application segment, accounting for roughly 35% of the total market share. UV protective coatings in this sector are primarily used for exterior surfaces, windows, and roofing materials to prevent degradation from prolonged sun exposure. The automotive industry follows as the second-largest consumer, utilizing these coatings for maintaining vehicle appearance and extending the lifespan of exterior components.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, driven by rapid industrialization, construction activities, and automotive manufacturing in China, Japan, and India. North America and Europe collectively account for about 45% of the market, with demand primarily stemming from renovation activities and stringent environmental regulations promoting low-VOC coating solutions.

Consumer preferences are increasingly shifting toward multifunctional coatings that offer UV protection alongside other benefits such as anti-microbial properties, self-cleaning capabilities, and enhanced durability. This trend has created premium market segments with higher profit margins for manufacturers who can deliver these advanced formulations.

The autoclave synthesis method has particularly strengthened market positioning for coatings in high-performance applications where extreme weather resistance is required. Marine, aerospace, and outdoor recreational equipment segments have shown willingness to pay premium prices for coatings synthesized using autoclave technology, with price points 15-20% higher than conventional alternatives.

Supply chain analysis indicates that raw material costs represent a significant challenge, particularly for titanium dioxide and specialized UV absorbers. Manufacturers employing autoclave synthesis techniques have demonstrated better optimization of raw material usage, potentially offering cost advantages despite the higher initial investment in production equipment.

Current Challenges in Autoclave Synthesis Technology

Despite significant advancements in autoclave synthesis technology for UV protective coatings, several critical challenges continue to impede optimal performance and widespread industrial adoption. The high-pressure and high-temperature conditions required for autoclave processing create substantial operational complexities and safety concerns. Industrial autoclaves typically operate at pressures exceeding 100 bar and temperatures above 200°C, necessitating specialized equipment and rigorous safety protocols that significantly increase production costs and limit scalability.

Energy consumption represents another major challenge, as maintaining elevated temperatures and pressures for extended periods demands considerable power input. This energy-intensive process not only increases manufacturing expenses but also raises environmental sustainability concerns, particularly as industries face growing pressure to reduce carbon footprints and meet stringent emissions regulations.

Process consistency and quality control present persistent technical hurdles. The complex thermodynamic and chemical reactions occurring within the autoclave environment are difficult to monitor in real-time, resulting in batch-to-batch variations that compromise coating performance uniformity. The opacity of the autoclave chamber further complicates in-situ monitoring, forcing manufacturers to rely on post-production testing rather than real-time process adjustments.

Material compatibility issues also constrain innovation in UV protective coating formulations. Many promising UV-absorbing compounds and nanoparticles exhibit thermal degradation or undesirable phase transformations under autoclave conditions, limiting the palette of available materials. Additionally, the high-pressure environment can induce unwanted morphological changes in coating precursors, affecting the final product's protective capabilities and durability.

Processing time represents a significant bottleneck in production efficiency. Current autoclave synthesis methods for UV protective coatings typically require cycle times of 6-12 hours, including heating, dwelling, and cooling phases. These extended processing periods restrict production throughput and increase manufacturing costs, making it challenging to meet growing market demand for high-performance UV protective solutions.

The integration of advanced nanomaterials into autoclave-processed coatings presents unique dispersion and agglomeration challenges. Achieving uniform distribution of nanoparticles throughout the coating matrix under autoclave conditions remains problematic, often resulting in performance-limiting aggregation that diminishes UV protection efficacy and coating transparency.

Energy consumption represents another major challenge, as maintaining elevated temperatures and pressures for extended periods demands considerable power input. This energy-intensive process not only increases manufacturing expenses but also raises environmental sustainability concerns, particularly as industries face growing pressure to reduce carbon footprints and meet stringent emissions regulations.

Process consistency and quality control present persistent technical hurdles. The complex thermodynamic and chemical reactions occurring within the autoclave environment are difficult to monitor in real-time, resulting in batch-to-batch variations that compromise coating performance uniformity. The opacity of the autoclave chamber further complicates in-situ monitoring, forcing manufacturers to rely on post-production testing rather than real-time process adjustments.

Material compatibility issues also constrain innovation in UV protective coating formulations. Many promising UV-absorbing compounds and nanoparticles exhibit thermal degradation or undesirable phase transformations under autoclave conditions, limiting the palette of available materials. Additionally, the high-pressure environment can induce unwanted morphological changes in coating precursors, affecting the final product's protective capabilities and durability.

Processing time represents a significant bottleneck in production efficiency. Current autoclave synthesis methods for UV protective coatings typically require cycle times of 6-12 hours, including heating, dwelling, and cooling phases. These extended processing periods restrict production throughput and increase manufacturing costs, making it challenging to meet growing market demand for high-performance UV protective solutions.

The integration of advanced nanomaterials into autoclave-processed coatings presents unique dispersion and agglomeration challenges. Achieving uniform distribution of nanoparticles throughout the coating matrix under autoclave conditions remains problematic, often resulting in performance-limiting aggregation that diminishes UV protection efficacy and coating transparency.

Current Autoclave Synthesis Solutions for UV Protection

01 Hydrothermal synthesis of UV protective materials

Autoclave-based hydrothermal synthesis methods can be used to create nanoparticles and compounds with UV protective properties. This process typically involves heating precursor materials in an autoclave under controlled temperature and pressure conditions, resulting in the formation of metal oxides like zinc oxide and titanium dioxide that effectively absorb or scatter UV radiation. The hydrothermal synthesis approach allows for precise control over particle size, morphology, and crystallinity, which directly impacts the UV protection efficiency.- Hydrothermal synthesis of UV protective nanoparticles: Autoclave-based hydrothermal synthesis methods can be used to produce metal oxide nanoparticles such as zinc oxide, titanium dioxide, and cerium oxide that provide effective UV protection. These nanoparticles can be synthesized under controlled temperature and pressure conditions in an autoclave, resulting in uniform particle size and enhanced UV blocking properties. The synthesized nanoparticles can be incorporated into various formulations including sunscreens, coatings, and textiles.

- Autoclave treatment of natural materials for UV protection: Natural materials such as plant extracts, fibers, and biopolymers can be processed in autoclaves to enhance their UV protective properties. The high temperature and pressure conditions in an autoclave can modify the chemical structure of these materials, increasing their ability to absorb or reflect UV radiation. This approach provides environmentally friendly alternatives to synthetic UV filters and can be applied in cosmetics, textiles, and packaging materials.

- Polymer-based UV protective coatings via autoclave processing: Autoclave processing can be used to develop polymer-based coatings with enhanced UV protection properties. The high-pressure and high-temperature environment in an autoclave facilitates the polymerization process and improves the cross-linking of UV-absorbing compounds within the polymer matrix. These coatings can be applied to various surfaces to provide long-lasting protection against UV radiation damage, including applications in automotive, construction, and electronic industries.

- Autoclave sterilization of UV protective formulations: Autoclave sterilization processes can be applied to UV protective formulations to ensure product safety while maintaining the efficacy of UV protective ingredients. The sterilization parameters need to be carefully controlled to prevent degradation of heat-sensitive UV filters. This approach is particularly important for medical-grade sunscreens, pharmaceutical formulations, and cosmetic products that require both UV protection and sterility.

- Composite materials with UV protection synthesized via autoclave methods: Composite materials with enhanced UV protection can be synthesized using autoclave methods that combine inorganic UV blockers with organic matrices. The autoclave process enables better dispersion of UV protective agents within the composite structure and improves the interfacial bonding between different components. These composite materials offer advantages such as improved durability, transparency, and broader spectrum UV protection for applications in aerospace, marine, and outdoor equipment industries.

02 Autoclave treatment of organic UV absorbers

Organic compounds with UV absorption properties can be synthesized or modified using autoclave treatments. The high-pressure and high-temperature environment in an autoclave facilitates chemical reactions that produce or enhance UV-absorbing characteristics in organic molecules. These compounds can include benzophenones, cinnamates, and triazines, which are commonly used in sunscreen formulations and protective coatings. The autoclave process helps improve stability, purity, and efficacy of these organic UV absorbers.Expand Specific Solutions03 Nanoparticle synthesis for enhanced UV protection

Autoclave-based methods are effective for synthesizing nanoparticles with superior UV protection capabilities. The controlled environment of an autoclave allows for the creation of nanoparticles with specific size distributions, surface properties, and crystal structures that optimize UV absorption or reflection. These nanoparticles can be incorporated into various matrices including cosmetics, textiles, and coatings to provide enhanced protection against harmful UV radiation. The autoclave synthesis approach often results in more uniform and stable nanoparticles compared to other synthesis methods.Expand Specific Solutions04 Autoclave processing of UV-protective coatings and films

Autoclave treatment can be used to cure, densify, or modify UV-protective coatings and films. The high-pressure environment promotes better adhesion, crosslinking, and elimination of defects in protective layers. This process is particularly valuable for creating transparent UV-protective coatings for various substrates including glass, plastics, and textiles. The autoclave treatment often results in coatings with improved durability, weather resistance, and long-term UV protection performance compared to those processed under ambient conditions.Expand Specific Solutions05 Sterilization and UV protection for medical and pharmaceutical applications

Autoclave processes are used for both sterilization and the development of UV-protective packaging or formulations for medical and pharmaceutical products. The high-temperature steam sterilization in autoclaves ensures product safety while maintaining the integrity of UV-protective components. This dual functionality is particularly important for light-sensitive pharmaceuticals, biologics, and medical devices that require protection from UV degradation. The autoclave process can be optimized to preserve or enhance the UV-protective properties of materials while achieving complete sterilization.Expand Specific Solutions

Leading Companies in Autoclave Synthesis Industry

The autoclave synthesis for UV protective coatings market is currently in a growth phase, with increasing demand driven by rising awareness of UV protection across industries. The global market size for UV protective coatings is estimated to exceed $5 billion, expanding at a CAGR of approximately 7-8%. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include DuPont de Nemours and Eastman Chemical, who have established robust R&D capabilities, while L'Oréal and BASF Coatings demonstrate strong commercial applications. Academic institutions like Shandong University and Zhejiang University contribute significant research advancements. Chinese companies such as Guangdong Leary and Jiangsu Sidike are rapidly gaining market share through cost-effective manufacturing and incremental innovations, particularly in autoclave-enhanced UV coating technologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced autoclave synthesis methods for UV protective coatings that incorporate their proprietary titanium dioxide nanoparticles. Their process involves high-pressure hydrothermal treatment in autoclaves at temperatures between 200-300°C, which creates uniform, highly crystalline TiO2 particles with enhanced UV absorption properties. The company has further refined this technology by incorporating organic surface modifications during the autoclave process, resulting in better dispersion of nanoparticles in polymer matrices. Their latest innovation includes a dual-layer coating system where the autoclave-synthesized UV absorbers are concentrated in the top layer, providing maximum protection while minimizing material usage. DuPont's coatings demonstrate superior weatherability with less than 5% degradation after 5000 hours of accelerated weathering tests.

Strengths: Superior particle uniformity and crystallinity leading to enhanced UV absorption; excellent dispersion in various polymer systems; proven long-term durability. Weaknesses: Higher production costs due to energy-intensive autoclave processes; longer production cycles compared to conventional methods; requires specialized high-pressure equipment.

L'Oréal SA

Technical Solution: L'Oréal has developed a sophisticated autoclave synthesis approach for UV protective coatings specifically designed for cosmetic and personal care applications. Their technology utilizes moderate-temperature (150-180°C) autoclave processing to create core-shell nanostructures where UV-absorbing compounds are encapsulated within biocompatible matrices. The company's proprietary "Mexoryl" UV filters are synthesized under controlled autoclave conditions to enhance both UVA and UVB protection capabilities. L'Oréal's innovation includes a continuous-flow autoclave system that allows for scaled production while maintaining precise control over particle morphology and size distribution. Their latest enhancement incorporates natural polyphenols during the autoclave synthesis, which act as both reducing agents in the process and additional UV protectants in the final coating. The resulting materials show exceptional photostability with less than 10% degradation after 24 hours of continuous UV exposure, significantly outperforming conventional UV filters.

Strengths: Specialized formulations for skin compatibility; excellent photostability of UV protective compounds; innovative continuous processing technology. Weaknesses: Relatively narrow application focus on cosmetic/personal care products; higher cost compared to conventional UV filters; more complex regulatory approval process.

Key Patents in Enhanced UV Protective Coating Technology

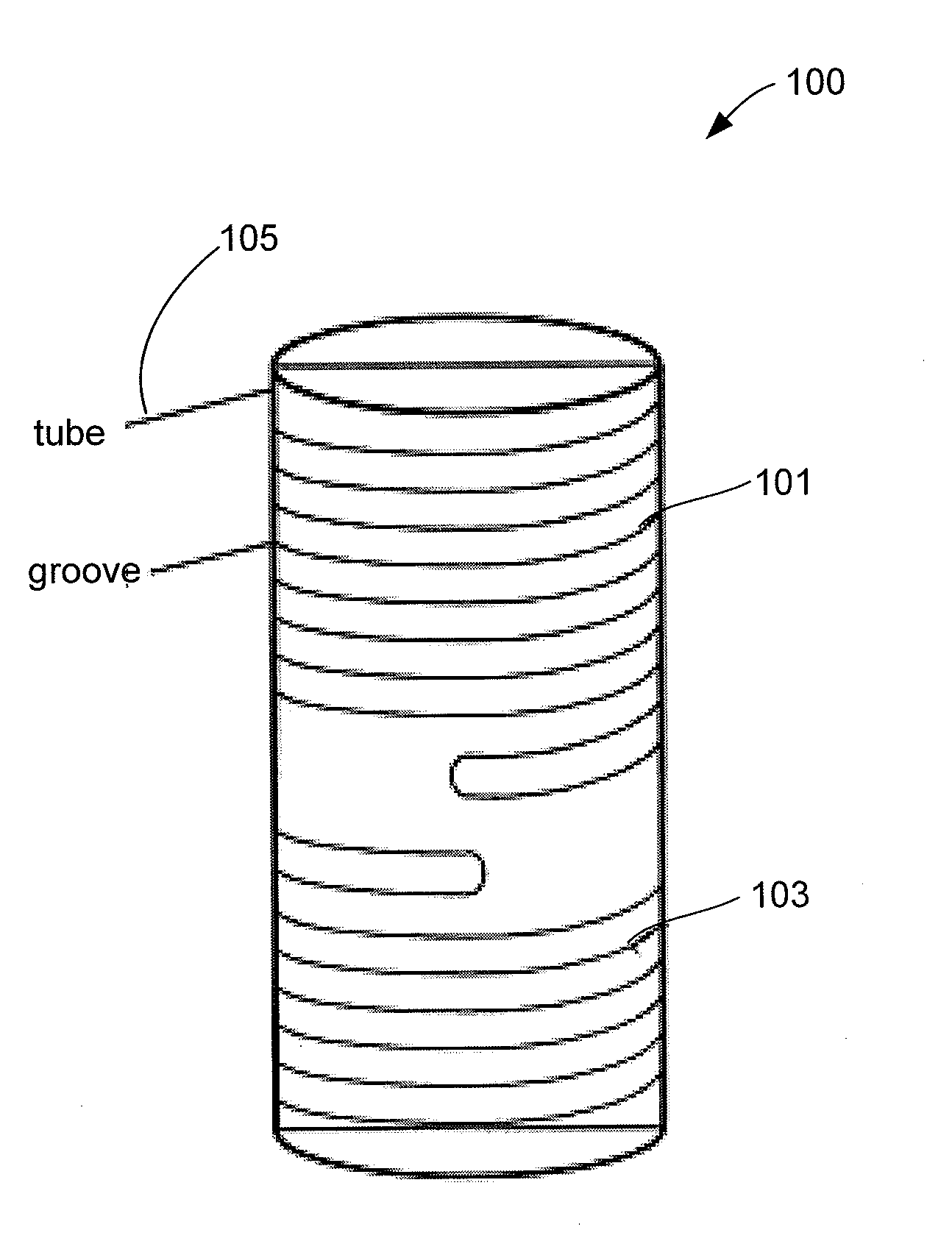

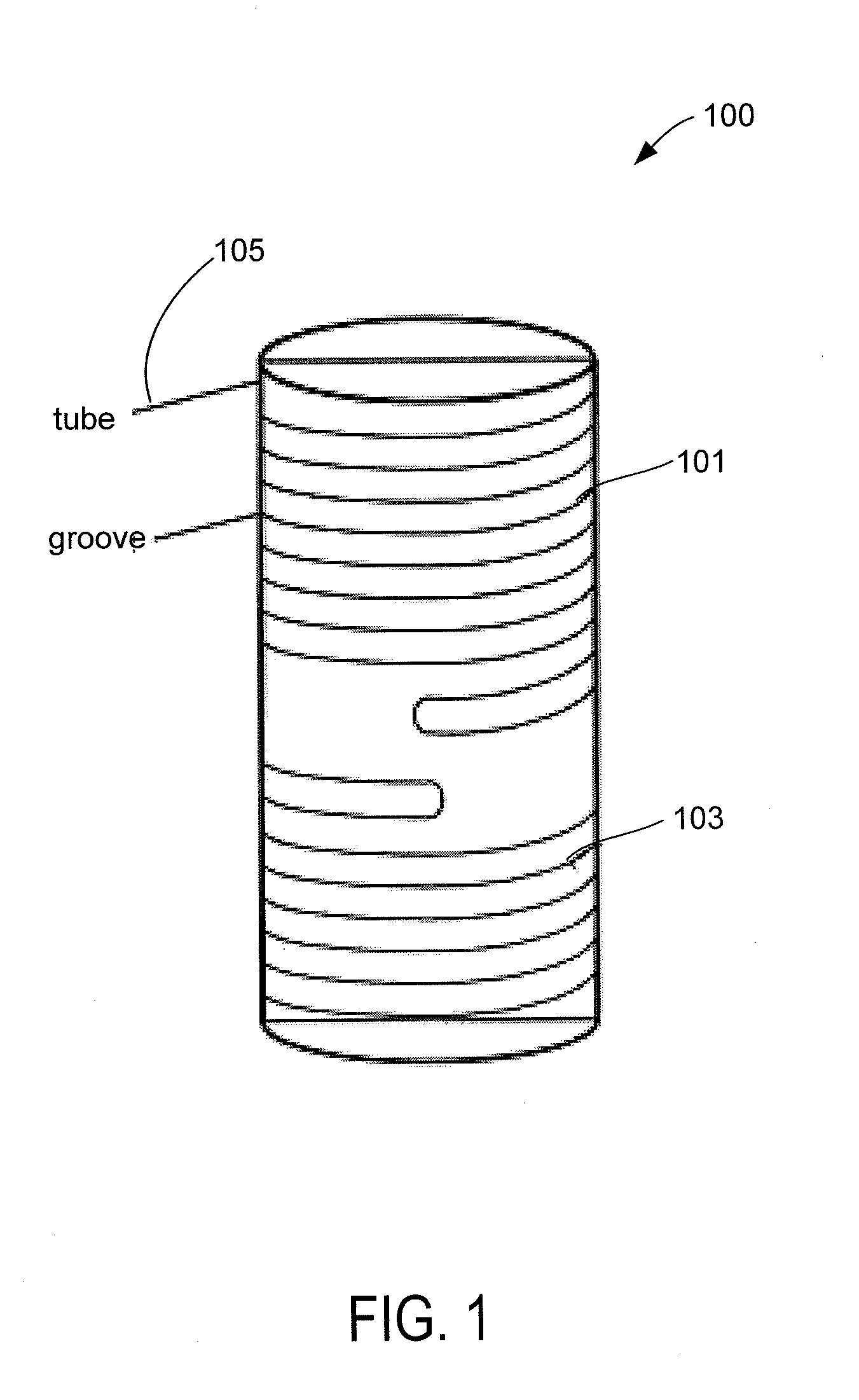

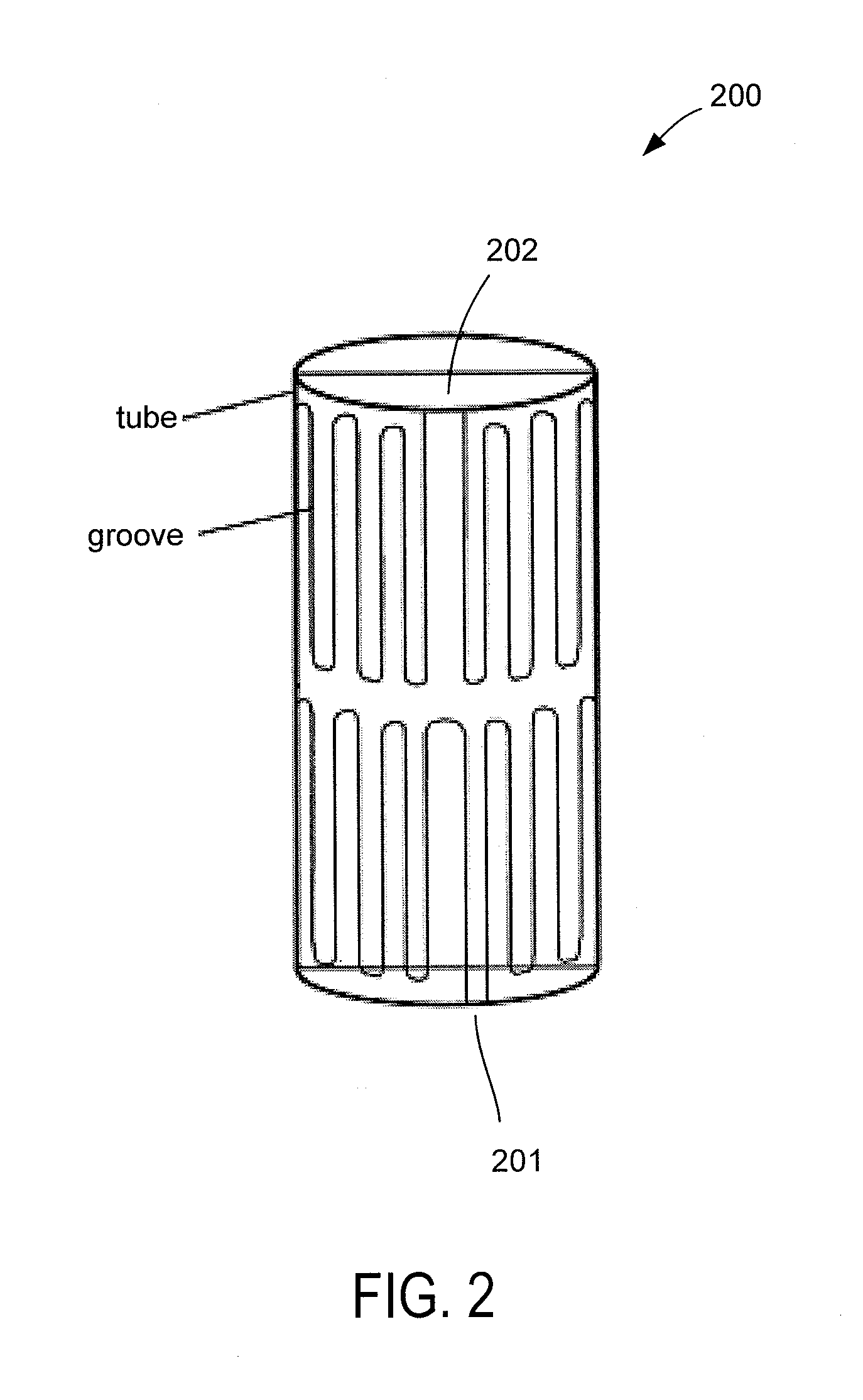

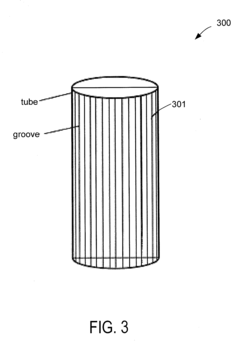

Heater device and method for high pressure processing of crystalline materials

PatentInactiveUS20090320745A1

Innovation

- A scalable heater design with multiple heating elements and a dense inner tube member, combined with insulating material, forms a cylindrical structure that is electrically isolated and capable of operating within a high-pressure apparatus, maintaining structural integrity and efficiency by minimizing voids and gaps, allowing for operation at pressures up to 2 GPa and temperatures up to 1200°C.

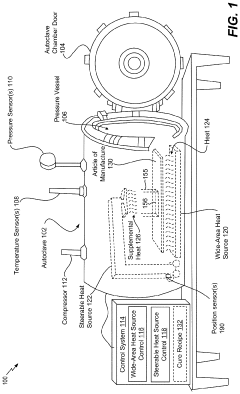

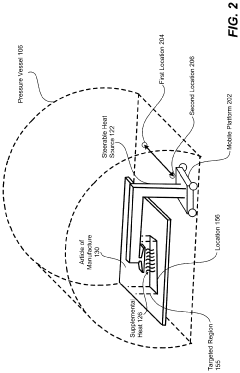

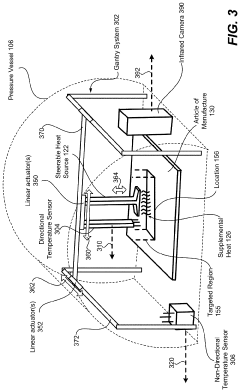

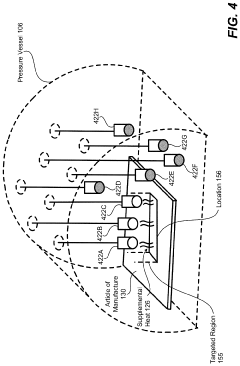

Steerable heat source

PatentActiveUS20200307035A1

Innovation

- A steerable heat source is integrated within the autoclave, coupled with a control system that directs supplemental heat to targeted regions using temperature sensors and a compressor to regulate pressure, ensuring precise temperature control and uniform heating.

Environmental Impact Assessment of Synthesis Methods

The environmental impact of autoclave synthesis methods for UV protective coatings represents a critical consideration in the sustainable development of advanced materials. Traditional autoclave processes typically involve high energy consumption due to the elevated temperatures and pressures required for optimal reaction conditions. These energy-intensive operations contribute significantly to carbon emissions, particularly when power sources are derived from fossil fuels rather than renewable alternatives.

Water usage presents another environmental concern in autoclave synthesis. The process often requires substantial volumes of water for cooling systems and post-synthesis cleaning procedures. In regions facing water scarcity, this consumption pattern raises sustainability questions that merit careful evaluation and potential optimization through water recycling systems or alternative cooling technologies.

Chemical waste generation during autoclave synthesis poses additional environmental challenges. The process frequently utilizes solvents, catalysts, and precursors that may contain hazardous components. Proper waste management protocols are essential to prevent soil contamination and water pollution. Recent advancements have focused on developing greener chemistry approaches that substitute harmful chemicals with environmentally benign alternatives, thereby reducing the ecological footprint of the synthesis process.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative methods reveal varying environmental impacts across different stages of production. While autoclave processes may consume more energy during synthesis, they often yield coatings with superior durability and performance characteristics. This enhanced longevity potentially offsets initial environmental costs through reduced replacement frequency and associated resource consumption over the product lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for industrial processes. Manufacturers employing autoclave synthesis must navigate evolving standards regarding emissions, waste disposal, and chemical usage. This regulatory landscape has stimulated innovation in cleaner production technologies, including closed-loop systems that capture and reuse process materials.

Recent technological innovations have demonstrated promising approaches to mitigating the environmental impact of autoclave synthesis. These include microwave-assisted autoclave processes that reduce energy consumption, solvent-free reaction systems that minimize chemical waste, and catalytic methods that operate at lower temperatures while maintaining product quality. Such advancements represent significant progress toward more sustainable manufacturing practices for UV protective coatings.

The environmental considerations of autoclave synthesis ultimately require balanced assessment against performance requirements and alternative production methods. As sustainability becomes increasingly central to materials development strategies, optimization of autoclave processes continues to evolve toward greener practices while maintaining the exceptional performance characteristics that make these UV protective coatings valuable in various applications.

Water usage presents another environmental concern in autoclave synthesis. The process often requires substantial volumes of water for cooling systems and post-synthesis cleaning procedures. In regions facing water scarcity, this consumption pattern raises sustainability questions that merit careful evaluation and potential optimization through water recycling systems or alternative cooling technologies.

Chemical waste generation during autoclave synthesis poses additional environmental challenges. The process frequently utilizes solvents, catalysts, and precursors that may contain hazardous components. Proper waste management protocols are essential to prevent soil contamination and water pollution. Recent advancements have focused on developing greener chemistry approaches that substitute harmful chemicals with environmentally benign alternatives, thereby reducing the ecological footprint of the synthesis process.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative methods reveal varying environmental impacts across different stages of production. While autoclave processes may consume more energy during synthesis, they often yield coatings with superior durability and performance characteristics. This enhanced longevity potentially offsets initial environmental costs through reduced replacement frequency and associated resource consumption over the product lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for industrial processes. Manufacturers employing autoclave synthesis must navigate evolving standards regarding emissions, waste disposal, and chemical usage. This regulatory landscape has stimulated innovation in cleaner production technologies, including closed-loop systems that capture and reuse process materials.

Recent technological innovations have demonstrated promising approaches to mitigating the environmental impact of autoclave synthesis. These include microwave-assisted autoclave processes that reduce energy consumption, solvent-free reaction systems that minimize chemical waste, and catalytic methods that operate at lower temperatures while maintaining product quality. Such advancements represent significant progress toward more sustainable manufacturing practices for UV protective coatings.

The environmental considerations of autoclave synthesis ultimately require balanced assessment against performance requirements and alternative production methods. As sustainability becomes increasingly central to materials development strategies, optimization of autoclave processes continues to evolve toward greener practices while maintaining the exceptional performance characteristics that make these UV protective coatings valuable in various applications.

Quality Control Standards for UV Protective Coatings

Quality control standards for UV protective coatings derived from autoclave synthesis processes require rigorous testing protocols to ensure consistent performance and durability. These standards typically encompass physical, chemical, and optical properties that directly impact the coating's ability to block harmful ultraviolet radiation while maintaining structural integrity under various environmental conditions.

The primary quality control parameters include UV blocking efficiency, measured through spectrophotometric analysis across the UVA (320-400nm) and UVB (280-320nm) ranges. Industry standards typically require a minimum of 95% blockage in the UVB range and 85% in the UVA range for premium protective coatings. Autoclave-synthesized coatings often demonstrate superior performance in these metrics due to their enhanced molecular structure and density.

Adhesion testing represents another critical quality control measure, typically conducted through cross-hatch tests (ASTM D3359) and pull-off adhesion tests (ASTM D4541). Autoclave-synthesized coatings must demonstrate adhesion values exceeding 4B on the ASTM scale to ensure long-term durability when applied to various substrates.

Weathering resistance standards involve accelerated testing protocols such as QUV exposure (ASTM G154) and xenon arc testing (ASTM G155), simulating years of outdoor exposure in compressed timeframes. Quality autoclave-synthesized UV coatings should maintain at least 90% of their initial protective properties after 2000 hours of accelerated weathering, with minimal color change (ΔE < 2.0) and no visible surface defects.

Chemical resistance testing follows ASTM D1308 protocols, requiring coatings to withstand exposure to common chemicals including acids, bases, solvents, and cleaning agents without degradation. Autoclave synthesis typically enhances this property through improved cross-linking and molecular arrangement.

Thickness uniformity represents a particular challenge for quality control of autoclave-synthesized coatings. Standards typically permit no more than ±5% variation across the coated surface, measured using non-destructive methods such as ultrasonic or magnetic thickness gauges. This parameter directly impacts both protective performance and aesthetic qualities.

Recent advancements in quality control standards have incorporated sustainability metrics, including VOC content (EPA Method 24), heavy metal analysis (ICP-MS), and leachability testing (TCLP). These standards ensure that high-performance UV protective coatings also meet increasingly stringent environmental regulations while maintaining their protective capabilities.

Implementation of these quality control standards requires sophisticated testing equipment and trained personnel capable of interpreting results within the context of application requirements. Manufacturers utilizing autoclave synthesis must establish comprehensive quality management systems that incorporate these standards at multiple production stages to ensure consistent product performance.

The primary quality control parameters include UV blocking efficiency, measured through spectrophotometric analysis across the UVA (320-400nm) and UVB (280-320nm) ranges. Industry standards typically require a minimum of 95% blockage in the UVB range and 85% in the UVA range for premium protective coatings. Autoclave-synthesized coatings often demonstrate superior performance in these metrics due to their enhanced molecular structure and density.

Adhesion testing represents another critical quality control measure, typically conducted through cross-hatch tests (ASTM D3359) and pull-off adhesion tests (ASTM D4541). Autoclave-synthesized coatings must demonstrate adhesion values exceeding 4B on the ASTM scale to ensure long-term durability when applied to various substrates.

Weathering resistance standards involve accelerated testing protocols such as QUV exposure (ASTM G154) and xenon arc testing (ASTM G155), simulating years of outdoor exposure in compressed timeframes. Quality autoclave-synthesized UV coatings should maintain at least 90% of their initial protective properties after 2000 hours of accelerated weathering, with minimal color change (ΔE < 2.0) and no visible surface defects.

Chemical resistance testing follows ASTM D1308 protocols, requiring coatings to withstand exposure to common chemicals including acids, bases, solvents, and cleaning agents without degradation. Autoclave synthesis typically enhances this property through improved cross-linking and molecular arrangement.

Thickness uniformity represents a particular challenge for quality control of autoclave-synthesized coatings. Standards typically permit no more than ±5% variation across the coated surface, measured using non-destructive methods such as ultrasonic or magnetic thickness gauges. This parameter directly impacts both protective performance and aesthetic qualities.

Recent advancements in quality control standards have incorporated sustainability metrics, including VOC content (EPA Method 24), heavy metal analysis (ICP-MS), and leachability testing (TCLP). These standards ensure that high-performance UV protective coatings also meet increasingly stringent environmental regulations while maintaining their protective capabilities.

Implementation of these quality control standards requires sophisticated testing equipment and trained personnel capable of interpreting results within the context of application requirements. Manufacturers utilizing autoclave synthesis must establish comprehensive quality management systems that incorporate these standards at multiple production stages to ensure consistent product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!