How Autoclave Synthesis Affects Material Hardness in Industrial Alloys

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis has emerged as a pivotal manufacturing technique in the metallurgical industry over the past several decades. This process, which utilizes high pressure and temperature conditions within a sealed vessel, has revolutionized the production of industrial alloys with enhanced material properties, particularly hardness. The evolution of autoclave technology can be traced back to the early 20th century, with significant advancements occurring post-World War II when industrial demands necessitated stronger, more durable materials for aerospace and defense applications.

The technological trajectory of autoclave synthesis has been characterized by continuous refinement in pressure control systems, temperature regulation mechanisms, and vessel design. Modern autoclave systems now operate at pressures exceeding 200 MPa and temperatures above 1000°C, enabling the creation of alloys with previously unattainable microstructural characteristics. This technological progression has been driven by cross-disciplinary collaboration between materials science, mechanical engineering, and chemical engineering fields.

Current trends in autoclave synthesis technology point toward more precise control of processing parameters, integration of real-time monitoring systems, and development of computational models that predict material behavior under extreme conditions. The industry is witnessing a shift toward more energy-efficient designs and environmentally sustainable practices, addressing both economic and ecological concerns in manufacturing processes.

The primary objective of investigating autoclave synthesis effects on material hardness is to establish quantifiable relationships between processing parameters and resultant mechanical properties. This includes understanding how variables such as pressure, temperature, dwell time, cooling rate, and precursor composition interact to influence microstructural development and, consequently, material hardness in industrial alloys.

Secondary objectives encompass the optimization of synthesis protocols for specific alloy systems, development of predictive models for hardness outcomes based on processing inputs, and identification of novel processing windows that may yield exceptional hardness characteristics. Additionally, there is significant interest in exploring how autoclave synthesis can be leveraged to create gradient materials with spatially varied hardness profiles for applications requiring differential wear resistance.

The long-term technological goal is to establish autoclave synthesis as a precisely controllable manufacturing method that can reliably produce alloys with tailored hardness properties, reducing the need for post-processing treatments and minimizing material waste. This aligns with broader industry trends toward more efficient, sustainable manufacturing processes that maximize material performance while minimizing resource consumption.

The technological trajectory of autoclave synthesis has been characterized by continuous refinement in pressure control systems, temperature regulation mechanisms, and vessel design. Modern autoclave systems now operate at pressures exceeding 200 MPa and temperatures above 1000°C, enabling the creation of alloys with previously unattainable microstructural characteristics. This technological progression has been driven by cross-disciplinary collaboration between materials science, mechanical engineering, and chemical engineering fields.

Current trends in autoclave synthesis technology point toward more precise control of processing parameters, integration of real-time monitoring systems, and development of computational models that predict material behavior under extreme conditions. The industry is witnessing a shift toward more energy-efficient designs and environmentally sustainable practices, addressing both economic and ecological concerns in manufacturing processes.

The primary objective of investigating autoclave synthesis effects on material hardness is to establish quantifiable relationships between processing parameters and resultant mechanical properties. This includes understanding how variables such as pressure, temperature, dwell time, cooling rate, and precursor composition interact to influence microstructural development and, consequently, material hardness in industrial alloys.

Secondary objectives encompass the optimization of synthesis protocols for specific alloy systems, development of predictive models for hardness outcomes based on processing inputs, and identification of novel processing windows that may yield exceptional hardness characteristics. Additionally, there is significant interest in exploring how autoclave synthesis can be leveraged to create gradient materials with spatially varied hardness profiles for applications requiring differential wear resistance.

The long-term technological goal is to establish autoclave synthesis as a precisely controllable manufacturing method that can reliably produce alloys with tailored hardness properties, reducing the need for post-processing treatments and minimizing material waste. This aligns with broader industry trends toward more efficient, sustainable manufacturing processes that maximize material performance while minimizing resource consumption.

Industrial Demand for Enhanced Alloy Hardness

The global industrial sector has witnessed a significant surge in demand for enhanced alloy hardness, driven primarily by the evolving requirements across multiple high-performance applications. Aerospace, automotive, defense, and energy sectors are increasingly seeking materials that can withstand extreme operational conditions while maintaining structural integrity over extended periods.

Market analysis indicates that the industrial hard alloys market reached approximately $45.7 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is particularly pronounced in regions with robust manufacturing bases, including East Asia, North America, and Western Europe, where industrial modernization continues to accelerate.

The demand for harder alloys stems from several converging factors. First, the push toward energy efficiency has necessitated lighter yet stronger materials that can reduce overall system weight while maintaining or improving performance characteristics. Second, the extension of maintenance intervals in critical infrastructure requires materials with superior wear resistance and longevity, directly correlating with material hardness properties.

In the automotive sector specifically, the transition toward electric vehicles has created new requirements for specialized alloys with enhanced hardness profiles. These materials must withstand the unique stress patterns associated with electric drivetrains while contributing to overall vehicle efficiency through weight reduction. Similarly, aerospace manufacturers are seeking alloys that can withstand higher operating temperatures while maintaining hardness properties, particularly for next-generation propulsion systems.

The industrial equipment manufacturing segment represents another significant demand driver, with requirements for tools and components that can operate under increasingly demanding conditions. Hard-facing alloys for cutting tools, mining equipment, and industrial machinery constitute a market segment valued at approximately $12.3 billion, growing at 7.2% annually.

Emerging economies are becoming increasingly important markets for enhanced hardness alloys, with countries like China, India, and Brazil investing heavily in infrastructure development and industrial capacity expansion. These markets are projected to account for over 40% of global demand growth in the coming decade.

The premium pricing structure for high-hardness alloys reflects their critical importance in industrial applications, with manufacturers demonstrating willingness to invest in materials that offer demonstrable improvements in operational lifespan and performance. This economic incentive continues to drive research into novel autoclave synthesis methods that can deliver cost-effective hardness enhancements.

Market analysis indicates that the industrial hard alloys market reached approximately $45.7 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is particularly pronounced in regions with robust manufacturing bases, including East Asia, North America, and Western Europe, where industrial modernization continues to accelerate.

The demand for harder alloys stems from several converging factors. First, the push toward energy efficiency has necessitated lighter yet stronger materials that can reduce overall system weight while maintaining or improving performance characteristics. Second, the extension of maintenance intervals in critical infrastructure requires materials with superior wear resistance and longevity, directly correlating with material hardness properties.

In the automotive sector specifically, the transition toward electric vehicles has created new requirements for specialized alloys with enhanced hardness profiles. These materials must withstand the unique stress patterns associated with electric drivetrains while contributing to overall vehicle efficiency through weight reduction. Similarly, aerospace manufacturers are seeking alloys that can withstand higher operating temperatures while maintaining hardness properties, particularly for next-generation propulsion systems.

The industrial equipment manufacturing segment represents another significant demand driver, with requirements for tools and components that can operate under increasingly demanding conditions. Hard-facing alloys for cutting tools, mining equipment, and industrial machinery constitute a market segment valued at approximately $12.3 billion, growing at 7.2% annually.

Emerging economies are becoming increasingly important markets for enhanced hardness alloys, with countries like China, India, and Brazil investing heavily in infrastructure development and industrial capacity expansion. These markets are projected to account for over 40% of global demand growth in the coming decade.

The premium pricing structure for high-hardness alloys reflects their critical importance in industrial applications, with manufacturers demonstrating willingness to invest in materials that offer demonstrable improvements in operational lifespan and performance. This economic incentive continues to drive research into novel autoclave synthesis methods that can deliver cost-effective hardness enhancements.

Current Challenges in Autoclave Synthesis Technology

Despite significant advancements in autoclave synthesis technology for industrial alloys, several critical challenges continue to impede optimal material hardness achievement. The primary obstacle remains precise pressure-temperature control throughout the synthesis process. Even minor fluctuations can lead to inconsistent crystalline structures, directly affecting the final hardness properties of the alloy. Current pressure regulation systems struggle to maintain stability during rapid temperature transitions, particularly in large-scale industrial applications.

Material homogeneity presents another significant challenge. The autoclave environment often creates thermal gradients that result in non-uniform hardness distribution across the synthesized alloy. This heterogeneity becomes particularly problematic in applications requiring consistent mechanical properties throughout the material, such as aerospace components and high-stress industrial machinery parts.

Scalability issues continue to plague industrial implementation. While laboratory-scale autoclave synthesis can achieve remarkable hardness results, translating these outcomes to industrial production volumes introduces variables that compromise quality consistency. The geometric scaling factors affect heat transfer dynamics and pressure distribution, creating discrepancies between small-batch and large-batch hardness profiles.

Energy efficiency remains a substantial concern. Current autoclave synthesis methods for enhancing material hardness are energy-intensive processes, requiring sustained high temperatures and pressures over extended periods. This energy consumption significantly impacts production costs and environmental footprint, making hardness optimization an economically challenging proposition for many manufacturers.

Corrosion and contamination within the autoclave chamber represent persistent technical hurdles. The extreme conditions necessary for hardness enhancement accelerate degradation of autoclave components, potentially introducing contaminants that compromise alloy purity and subsequently affect hardness properties. Current materials used in autoclave construction often require frequent replacement, creating production downtime and consistency issues.

Monitoring limitations further complicate the synthesis process. Real-time assessment of material hardness development during autoclave processing remains largely inferential rather than direct. The sealed, high-pressure environment makes in-situ hardness testing nearly impossible with current technology, forcing manufacturers to rely on predictive models that may not account for all process variables.

Lastly, the relationship between cooling rates and final hardness properties presents ongoing challenges. Post-synthesis cooling protocols significantly impact microstructure development, yet precise control of cooling gradients within large industrial autoclaves remains difficult to achieve consistently across different alloy compositions and batch sizes.

Material homogeneity presents another significant challenge. The autoclave environment often creates thermal gradients that result in non-uniform hardness distribution across the synthesized alloy. This heterogeneity becomes particularly problematic in applications requiring consistent mechanical properties throughout the material, such as aerospace components and high-stress industrial machinery parts.

Scalability issues continue to plague industrial implementation. While laboratory-scale autoclave synthesis can achieve remarkable hardness results, translating these outcomes to industrial production volumes introduces variables that compromise quality consistency. The geometric scaling factors affect heat transfer dynamics and pressure distribution, creating discrepancies between small-batch and large-batch hardness profiles.

Energy efficiency remains a substantial concern. Current autoclave synthesis methods for enhancing material hardness are energy-intensive processes, requiring sustained high temperatures and pressures over extended periods. This energy consumption significantly impacts production costs and environmental footprint, making hardness optimization an economically challenging proposition for many manufacturers.

Corrosion and contamination within the autoclave chamber represent persistent technical hurdles. The extreme conditions necessary for hardness enhancement accelerate degradation of autoclave components, potentially introducing contaminants that compromise alloy purity and subsequently affect hardness properties. Current materials used in autoclave construction often require frequent replacement, creating production downtime and consistency issues.

Monitoring limitations further complicate the synthesis process. Real-time assessment of material hardness development during autoclave processing remains largely inferential rather than direct. The sealed, high-pressure environment makes in-situ hardness testing nearly impossible with current technology, forcing manufacturers to rely on predictive models that may not account for all process variables.

Lastly, the relationship between cooling rates and final hardness properties presents ongoing challenges. Post-synthesis cooling protocols significantly impact microstructure development, yet precise control of cooling gradients within large industrial autoclaves remains difficult to achieve consistently across different alloy compositions and batch sizes.

Contemporary Autoclave Synthesis Approaches

01 Autoclave synthesis parameters for alloy hardness enhancement

Specific autoclave parameters such as temperature, pressure, and duration significantly influence the hardness properties of synthesized industrial alloys. Controlled autoclave environments enable precise crystallization and phase formation, resulting in improved microstructural characteristics that directly enhance material hardness. Optimization of these parameters allows for tailored hardness profiles suitable for various industrial applications.- Autoclave synthesis parameters for enhanced alloy hardness: Specific autoclave synthesis parameters including temperature, pressure, and time can significantly influence the hardness properties of industrial alloys. Optimizing these parameters allows for controlled crystallization and grain structure formation, resulting in alloys with superior hardness characteristics. The process typically involves precise control of heating rates and cooling cycles to achieve desired microstructural properties that directly impact material hardness.

- Composition modifications for hardness improvement in autoclave-synthesized alloys: The addition of specific alloying elements during autoclave synthesis can significantly enhance the hardness properties of industrial alloys. Elements such as chromium, tungsten, and various rare earth metals can form complex intermetallic compounds or precipitates that strengthen the alloy matrix. These compositional modifications, when combined with appropriate autoclave processing conditions, create alloys with optimized hardness for specific industrial applications.

- Post-autoclave treatment methods for hardness enhancement: Various post-autoclave treatments can be applied to further enhance the hardness of synthesized industrial alloys. These treatments include controlled heat treatment processes, quenching techniques, and surface modification methods. The application of these secondary processes after autoclave synthesis allows for additional microstructural refinement and precipitation hardening, resulting in alloys with significantly improved hardness properties suitable for demanding industrial applications.

- Nanostructured alloys via autoclave synthesis for superior hardness: Autoclave synthesis techniques can be specifically tailored to produce nanostructured industrial alloys with exceptional hardness properties. By controlling nucleation and growth kinetics during the autoclave process, nanoscale grains or precipitates can be formed within the alloy matrix. These nanostructures create numerous grain boundaries and interfaces that effectively impede dislocation movement, resulting in alloys with significantly enhanced hardness compared to their conventional counterparts.

- Composite and reinforced alloys through autoclave processing: Autoclave synthesis enables the production of composite and reinforced industrial alloys with superior hardness characteristics. By incorporating reinforcing phases such as ceramic particles, fibers, or other hard materials during the autoclave process, the resulting composite alloys exhibit enhanced hardness and wear resistance. The high-pressure environment of the autoclave facilitates better integration of the reinforcing components within the alloy matrix, creating materials with optimized hardness for specialized industrial applications.

02 Composition control for hardness optimization in autoclave synthesis

The careful selection and precise control of alloy compositions during autoclave synthesis significantly impacts the resulting material hardness. By adjusting elemental ratios and incorporating specific additives, manufacturers can achieve targeted hardness properties. This approach enables the development of alloys with enhanced wear resistance and structural integrity through controlled precipitation hardening and solid solution strengthening mechanisms.Expand Specific Solutions03 Post-autoclave treatment techniques for hardness modification

Various post-synthesis treatments applied after autoclave processing can further modify and enhance the hardness of industrial alloys. These techniques include controlled cooling protocols, heat treatments, aging processes, and surface modifications. By implementing specific post-autoclave treatments, manufacturers can achieve significant improvements in material hardness through microstructural refinement and phase transformation control.Expand Specific Solutions04 Reinforcement additives for enhanced alloy hardness in autoclave synthesis

The incorporation of specific reinforcement additives during autoclave synthesis can substantially improve the hardness properties of industrial alloys. These additives include ceramic particles, carbon-based materials, and other hard phases that create composite structures. When properly dispersed throughout the alloy matrix during autoclave processing, these reinforcements create effective barriers to dislocation movement, resulting in significantly enhanced material hardness and wear resistance.Expand Specific Solutions05 Microstructural control techniques for optimized hardness in autoclave-synthesized alloys

Advanced techniques for controlling microstructural development during autoclave synthesis enable precise manipulation of material hardness. These methods include grain size refinement, controlled precipitation, phase transformation management, and texture development. By implementing specific microstructural control strategies during the autoclave process, manufacturers can achieve optimized hardness properties through mechanisms such as grain boundary strengthening and dispersion hardening.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The autoclave synthesis market for industrial alloys is in a growth phase, with increasing demand for high-hardness materials across aerospace and manufacturing sectors. The market is expanding as companies develop proprietary techniques to enhance material properties. Leading players include Boeing and MTU Aero Engines focusing on aerospace applications, while Kobe Steel and voestalpine BÖHLER Edelstahl are advancing industrial implementations. Chinese companies like Zigong Cemented Carbide and Zhuzhou Cemented Carbides Group are rapidly developing capabilities in hard alloy production. Research institutions such as Sichuan University and Korea Institute of Ceramic Engineering & Technology are driving innovation through collaborative industry partnerships, pushing the technology toward greater commercial maturity.

Zhuzhou Cemented Carbides Group Corp. Ltd.

Technical Solution: Zhuzhou Cemented Carbides Group has developed a sophisticated autoclave synthesis technology specifically for tungsten carbide-cobalt (WC-Co) cemented carbides that significantly enhances material hardness. Their process employs a proprietary high-pressure (150-250 MPa) and high-temperature (400-600°C) autoclave environment with precisely controlled oxygen partial pressure to optimize the carbide grain growth and cobalt binder phase distribution. The company's research has shown that their autoclave synthesis method produces ultra-fine WC grains (0.2-0.5 μm) with minimal size variation, resulting in hardness values exceeding 92 HRA (Rockwell A). Their technology incorporates a specialized cooling protocol that prevents detrimental phase transformations and maintains the optimized microstructure. Additionally, Zhuzhou has pioneered the addition of chromium and vanadium carbide inhibitors during the autoclave process, which further refines grain structure and enhances hardness by up to 15% compared to conventional sintering methods.

Strengths: Produces exceptionally uniform carbide grain size distribution; achieves superior hardness-to-toughness ratio; enables production of gradient materials with tailored properties. Weaknesses: Requires significant energy input; process control complexity increases production costs; limited to certain alloy compositions that respond well to autoclave conditions.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed an advanced autoclave synthesis process for high-performance alloys that combines precise pressure and temperature control with specialized heat treatment protocols. Their proprietary method utilizes a multi-stage autoclave process where pressure is gradually increased to 200-300 MPa while maintaining temperatures between 600-800°C, creating optimal conditions for precipitate formation and grain refinement. This controlled environment enables the formation of nano-scale carbides and intermetallic compounds that significantly enhance material hardness. Kobe's research has demonstrated that autoclave-synthesized nickel-based superalloys exhibit up to 30% higher hardness values compared to conventional processing methods, with improved uniformity across the material matrix. The company has also pioneered the use of specialized catalysts during autoclave synthesis to accelerate phase transformations and promote beneficial microstructural development that contributes to superior mechanical properties.

Strengths: Achieves exceptional hardness uniformity across complex geometries; enables production of alloys with superior high-temperature performance; reduces internal stresses compared to conventional methods. Weaknesses: Higher production costs due to specialized equipment requirements; longer processing times compared to conventional methods; limited batch sizes due to autoclave capacity constraints.

Critical Patents and Research in Alloy Hardening

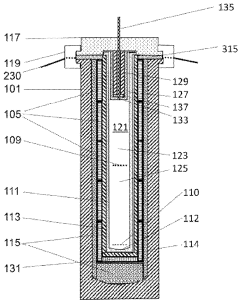

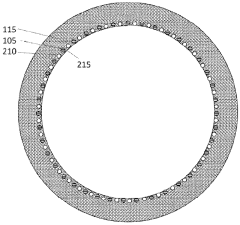

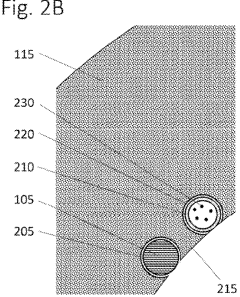

Compound internally-heated high-pressure apparatus for solvothermal crystal growth

PatentWO2024020513A1

Innovation

- A compound internally-heated high-pressure apparatus with a cylindrical enclosure, a primary liner, load-bearing annular insulating members, and heating elements, allowing for radial and axial support, enabling pressures up to 500 MPa and temperatures between 200 and 900 degrees Celsius, while reducing costs and improving scalability.

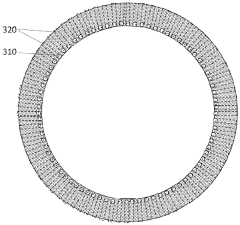

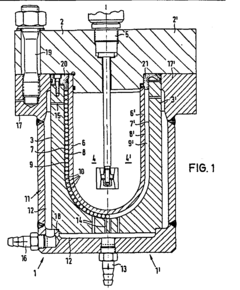

High pressure autoclave

PatentInactiveEP0099443A3

Innovation

- The pressure vessel is equipped with a spaced skirt and spacer elements, such as spherical steel balls, between its inner and outer walls, allowing for optimized material selection and reducing the wall thickness needed to withstand internal pressure, while the outer shell absorbs tensile forces and chemical influences, and a heat transfer medium is used to manage temperature exposure through a connected passage space.

Pressure-Temperature Relationship Effects on Microstructure

The relationship between pressure and temperature during autoclave synthesis represents a critical factor in determining the microstructural development of industrial alloys. When materials are subjected to autoclave conditions, the simultaneous application of elevated pressure and temperature creates unique thermodynamic environments that significantly influence atomic diffusion rates, phase transformations, and grain boundary dynamics.

At the microscopic level, pressure-temperature combinations directly affect the nucleation and growth mechanisms of crystalline structures. Higher pressures typically suppress the formation of voids and porosity, leading to more densely packed microstructures with enhanced hardness properties. This compression effect forces atoms into more ordered arrangements, reducing interatomic distances and strengthening atomic bonds throughout the material matrix.

Temperature gradients within the autoclave chamber interact with applied pressure to control grain size development. The synergistic effect creates conditions where recrystallization processes can be precisely managed. Research indicates that specific pressure-temperature profiles can produce ultra-fine grain structures with dimensions below 100 nanometers, contributing to exceptional hardness improvements through the Hall-Petch strengthening mechanism.

Phase stability boundaries shift significantly under autoclave conditions compared to ambient processing. The pressure-temperature relationship can stabilize metastable phases that would otherwise not form during conventional synthesis routes. These metastable phases often exhibit unique hardness characteristics due to their non-equilibrium crystal structures and distinctive bonding arrangements. Industrial applications have leveraged this phenomenon to develop specialized alloys with hardness values exceeding those achievable through traditional heat treatment alone.

Precipitation kinetics are dramatically altered by the pressure-temperature relationship during autoclave synthesis. The nucleation energy barriers for precipitate formation decrease under elevated pressures, while diffusion rates increase with temperature. This combination accelerates the formation of fine, dispersed precipitates that serve as effective obstacles to dislocation movement, thereby enhancing material hardness through precipitation hardening mechanisms.

Pressure-induced phase transformations represent another critical microstructural effect. Certain alloy systems undergo martensitic or bainitic transformations at specific pressure-temperature combinations that would not occur under atmospheric conditions. These transformations generate high-dislocation-density microstructures characterized by exceptional hardness and wear resistance properties, making them particularly valuable for industrial applications requiring superior surface durability.

The pressure-temperature relationship also influences solute segregation patterns at grain boundaries, which can either strengthen or embrittle the material depending on the specific elements involved. Controlling these segregation behaviors through precise autoclave parameters enables manufacturers to optimize grain boundary cohesion while maintaining the desired hardness characteristics across the bulk material.

At the microscopic level, pressure-temperature combinations directly affect the nucleation and growth mechanisms of crystalline structures. Higher pressures typically suppress the formation of voids and porosity, leading to more densely packed microstructures with enhanced hardness properties. This compression effect forces atoms into more ordered arrangements, reducing interatomic distances and strengthening atomic bonds throughout the material matrix.

Temperature gradients within the autoclave chamber interact with applied pressure to control grain size development. The synergistic effect creates conditions where recrystallization processes can be precisely managed. Research indicates that specific pressure-temperature profiles can produce ultra-fine grain structures with dimensions below 100 nanometers, contributing to exceptional hardness improvements through the Hall-Petch strengthening mechanism.

Phase stability boundaries shift significantly under autoclave conditions compared to ambient processing. The pressure-temperature relationship can stabilize metastable phases that would otherwise not form during conventional synthesis routes. These metastable phases often exhibit unique hardness characteristics due to their non-equilibrium crystal structures and distinctive bonding arrangements. Industrial applications have leveraged this phenomenon to develop specialized alloys with hardness values exceeding those achievable through traditional heat treatment alone.

Precipitation kinetics are dramatically altered by the pressure-temperature relationship during autoclave synthesis. The nucleation energy barriers for precipitate formation decrease under elevated pressures, while diffusion rates increase with temperature. This combination accelerates the formation of fine, dispersed precipitates that serve as effective obstacles to dislocation movement, thereby enhancing material hardness through precipitation hardening mechanisms.

Pressure-induced phase transformations represent another critical microstructural effect. Certain alloy systems undergo martensitic or bainitic transformations at specific pressure-temperature combinations that would not occur under atmospheric conditions. These transformations generate high-dislocation-density microstructures characterized by exceptional hardness and wear resistance properties, making them particularly valuable for industrial applications requiring superior surface durability.

The pressure-temperature relationship also influences solute segregation patterns at grain boundaries, which can either strengthen or embrittle the material depending on the specific elements involved. Controlling these segregation behaviors through precise autoclave parameters enables manufacturers to optimize grain boundary cohesion while maintaining the desired hardness characteristics across the bulk material.

Environmental and Energy Efficiency Considerations

Autoclave synthesis processes in industrial alloy production present significant environmental and energy efficiency considerations that must be addressed in modern manufacturing contexts. The high-pressure, high-temperature conditions required for autoclave synthesis typically demand substantial energy inputs, with industrial autoclaves often operating at temperatures exceeding 1000°C and pressures up to 200 MPa. These extreme operating conditions translate to considerable energy consumption, primarily derived from fossil fuel sources in many manufacturing facilities.

The environmental footprint of autoclave synthesis extends beyond energy consumption to include greenhouse gas emissions, with a typical industrial autoclave process generating approximately 2-5 tons of CO2 equivalent per ton of processed alloy. Water usage represents another critical environmental factor, as cooling systems and pressure maintenance mechanisms require substantial water resources, often exceeding 10,000 liters per production cycle in large-scale operations.

Recent advancements in autoclave technology have focused on improving energy efficiency through enhanced insulation materials, heat recovery systems, and process optimization. Studies indicate that implementation of regenerative heat exchangers can reduce energy consumption by 15-30%, while modern control systems that optimize heating cycles based on material-specific requirements can further decrease energy usage by 10-25%. These improvements not only reduce environmental impact but also offer significant cost savings in production.

Waste heat recovery presents a particularly promising avenue for efficiency improvement. Advanced systems can capture and repurpose up to 40% of waste heat from autoclave operations for preheating materials or supporting auxiliary processes. Additionally, the integration of renewable energy sources, particularly for electrical components of autoclave systems, has shown potential to reduce carbon emissions by 20-60% depending on the energy mix available.

Material efficiency considerations also play a crucial role in environmental impact assessment. Optimized autoclave synthesis parameters can reduce material waste through more precise control of alloy formation, potentially decreasing raw material requirements by 5-15%. Furthermore, the enhanced material properties achieved through optimized autoclave processes—particularly increased hardness and durability—extend product lifecycles, thereby reducing the environmental impact associated with replacement and remanufacturing.

Regulatory frameworks increasingly influence autoclave synthesis operations, with emissions standards and energy efficiency requirements becoming more stringent across major manufacturing regions. Companies implementing best practices in environmental management for autoclave processes report not only compliance benefits but also competitive advantages through reduced operational costs and improved market positioning with environmentally conscious customers and supply chain partners.

The environmental footprint of autoclave synthesis extends beyond energy consumption to include greenhouse gas emissions, with a typical industrial autoclave process generating approximately 2-5 tons of CO2 equivalent per ton of processed alloy. Water usage represents another critical environmental factor, as cooling systems and pressure maintenance mechanisms require substantial water resources, often exceeding 10,000 liters per production cycle in large-scale operations.

Recent advancements in autoclave technology have focused on improving energy efficiency through enhanced insulation materials, heat recovery systems, and process optimization. Studies indicate that implementation of regenerative heat exchangers can reduce energy consumption by 15-30%, while modern control systems that optimize heating cycles based on material-specific requirements can further decrease energy usage by 10-25%. These improvements not only reduce environmental impact but also offer significant cost savings in production.

Waste heat recovery presents a particularly promising avenue for efficiency improvement. Advanced systems can capture and repurpose up to 40% of waste heat from autoclave operations for preheating materials or supporting auxiliary processes. Additionally, the integration of renewable energy sources, particularly for electrical components of autoclave systems, has shown potential to reduce carbon emissions by 20-60% depending on the energy mix available.

Material efficiency considerations also play a crucial role in environmental impact assessment. Optimized autoclave synthesis parameters can reduce material waste through more precise control of alloy formation, potentially decreasing raw material requirements by 5-15%. Furthermore, the enhanced material properties achieved through optimized autoclave processes—particularly increased hardness and durability—extend product lifecycles, thereby reducing the environmental impact associated with replacement and remanufacturing.

Regulatory frameworks increasingly influence autoclave synthesis operations, with emissions standards and energy efficiency requirements becoming more stringent across major manufacturing regions. Companies implementing best practices in environmental management for autoclave processes report not only compliance benefits but also competitive advantages through reduced operational costs and improved market positioning with environmentally conscious customers and supply chain partners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!