Autoclave Synthesis and Its Role in the Evolution of Electrochromic Devices

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochromic Technology Background and Objectives

Electrochromic technology has evolved significantly since its inception in the 1960s, with the first observations of color changes in tungsten oxide films upon application of electric potential. This phenomenon, known as electrochromism, involves reversible color changes in materials through electrochemical redox reactions. The field has progressed from basic research to commercial applications, with significant advancements in materials science, device architecture, and manufacturing techniques.

The evolution of electrochromic technology has been marked by several key milestones. In the 1980s, researchers developed the first practical electrochromic devices using transition metal oxides. The 1990s saw improvements in device stability and switching speeds, while the 2000s brought innovations in nanomaterials and hybrid systems that enhanced performance metrics. Recent years have witnessed the integration of electrochromic technology with smart systems and IoT platforms, expanding potential applications.

Autoclave synthesis represents a critical manufacturing technique in this technological progression. This high-pressure, high-temperature method enables the creation of specialized electrochromic materials with enhanced properties that are difficult to achieve through conventional synthesis routes. The controlled environment of an autoclave allows for precise crystallization, morphology control, and improved electrochemical properties of electrochromic materials.

The current technological trajectory aims to overcome persistent challenges in electrochromic devices, including switching speed, durability, optical memory, and energy efficiency. Autoclave synthesis offers promising pathways to address these limitations by enabling the creation of novel nanostructured materials with optimized electrochromic properties. The technique allows for fine-tuning of particle size, crystallinity, and composition, which directly influence device performance.

The primary objectives of current research in this field include developing electrochromic materials with faster switching speeds (under 30 seconds for large-area applications), improved cycling stability (exceeding 100,000 cycles), enhanced optical contrast (transmittance difference >70%), and reduced energy consumption. Additionally, researchers aim to create more environmentally sustainable synthesis methods and materials that reduce dependence on rare or toxic elements.

Looking forward, the field is moving toward multifunctional electrochromic devices that combine color-changing capabilities with other functionalities such as energy harvesting, self-cleaning properties, and adaptive thermal management. The integration of autoclave-synthesized materials into these next-generation devices represents a promising frontier for technological innovation, with potential applications spanning architecture, automotive, consumer electronics, and wearable technology sectors.

The evolution of electrochromic technology has been marked by several key milestones. In the 1980s, researchers developed the first practical electrochromic devices using transition metal oxides. The 1990s saw improvements in device stability and switching speeds, while the 2000s brought innovations in nanomaterials and hybrid systems that enhanced performance metrics. Recent years have witnessed the integration of electrochromic technology with smart systems and IoT platforms, expanding potential applications.

Autoclave synthesis represents a critical manufacturing technique in this technological progression. This high-pressure, high-temperature method enables the creation of specialized electrochromic materials with enhanced properties that are difficult to achieve through conventional synthesis routes. The controlled environment of an autoclave allows for precise crystallization, morphology control, and improved electrochemical properties of electrochromic materials.

The current technological trajectory aims to overcome persistent challenges in electrochromic devices, including switching speed, durability, optical memory, and energy efficiency. Autoclave synthesis offers promising pathways to address these limitations by enabling the creation of novel nanostructured materials with optimized electrochromic properties. The technique allows for fine-tuning of particle size, crystallinity, and composition, which directly influence device performance.

The primary objectives of current research in this field include developing electrochromic materials with faster switching speeds (under 30 seconds for large-area applications), improved cycling stability (exceeding 100,000 cycles), enhanced optical contrast (transmittance difference >70%), and reduced energy consumption. Additionally, researchers aim to create more environmentally sustainable synthesis methods and materials that reduce dependence on rare or toxic elements.

Looking forward, the field is moving toward multifunctional electrochromic devices that combine color-changing capabilities with other functionalities such as energy harvesting, self-cleaning properties, and adaptive thermal management. The integration of autoclave-synthesized materials into these next-generation devices represents a promising frontier for technological innovation, with potential applications spanning architecture, automotive, consumer electronics, and wearable technology sectors.

Market Applications and Demand Analysis for Electrochromic Devices

The electrochromic devices market has witnessed significant growth in recent years, driven by increasing demand for energy-efficient solutions across various industries. The global market for electrochromic devices was valued at approximately 3.5 billion USD in 2022 and is projected to reach 7.2 billion USD by 2028, representing a compound annual growth rate of 12.8%. This growth trajectory underscores the expanding applications and market penetration of these technologies.

The construction and architectural sector represents the largest application segment, accounting for nearly 45% of the total market share. Smart windows utilizing electrochromic technology have gained substantial traction in commercial buildings and high-end residential constructions due to their ability to regulate light transmission and heat, thereby reducing energy consumption for heating, ventilation, and air conditioning systems by up to 30%. The growing emphasis on green building certifications such as LEED has further accelerated adoption in this sector.

The automotive industry constitutes the second-largest market segment, with electrochromic mirrors and sunroofs becoming standard features in premium vehicle models. Major automotive manufacturers have integrated these technologies to enhance user comfort and vehicle energy efficiency. Market penetration in mid-range vehicles is gradually increasing, suggesting a broadening consumer base and decreasing cost barriers.

Consumer electronics represents an emerging application area with significant growth potential. Electrochromic displays offer advantages in terms of power consumption and visibility in bright environments compared to conventional display technologies. Wearable devices, e-readers, and specialized mobile devices are increasingly incorporating electrochromic elements, driving innovation in low-power display solutions.

Aerospace applications, though smaller in market volume, demonstrate high value integration of electrochromic technologies in cockpit windows and cabin systems. The premium pricing in this sector contributes disproportionately to market value relative to unit sales.

Regional analysis reveals North America and Europe as the dominant markets, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 15.3% annually, driven by rapid urbanization, automotive sector expansion, and government initiatives promoting energy-efficient technologies.

Market challenges include high initial production costs, durability concerns in extreme environments, and competition from alternative technologies such as thermochromic and photochromic materials. The role of autoclave synthesis in addressing these challenges is particularly significant, as it enables the production of more stable and uniform electrochromic materials with enhanced cycling stability and response times.

The construction and architectural sector represents the largest application segment, accounting for nearly 45% of the total market share. Smart windows utilizing electrochromic technology have gained substantial traction in commercial buildings and high-end residential constructions due to their ability to regulate light transmission and heat, thereby reducing energy consumption for heating, ventilation, and air conditioning systems by up to 30%. The growing emphasis on green building certifications such as LEED has further accelerated adoption in this sector.

The automotive industry constitutes the second-largest market segment, with electrochromic mirrors and sunroofs becoming standard features in premium vehicle models. Major automotive manufacturers have integrated these technologies to enhance user comfort and vehicle energy efficiency. Market penetration in mid-range vehicles is gradually increasing, suggesting a broadening consumer base and decreasing cost barriers.

Consumer electronics represents an emerging application area with significant growth potential. Electrochromic displays offer advantages in terms of power consumption and visibility in bright environments compared to conventional display technologies. Wearable devices, e-readers, and specialized mobile devices are increasingly incorporating electrochromic elements, driving innovation in low-power display solutions.

Aerospace applications, though smaller in market volume, demonstrate high value integration of electrochromic technologies in cockpit windows and cabin systems. The premium pricing in this sector contributes disproportionately to market value relative to unit sales.

Regional analysis reveals North America and Europe as the dominant markets, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 15.3% annually, driven by rapid urbanization, automotive sector expansion, and government initiatives promoting energy-efficient technologies.

Market challenges include high initial production costs, durability concerns in extreme environments, and competition from alternative technologies such as thermochromic and photochromic materials. The role of autoclave synthesis in addressing these challenges is particularly significant, as it enables the production of more stable and uniform electrochromic materials with enhanced cycling stability and response times.

Autoclave Synthesis: Current Status and Technical Challenges

Autoclave synthesis has emerged as a pivotal technique in the development of electrochromic devices, offering unique advantages in material processing under controlled high-pressure and high-temperature conditions. Currently, this synthesis method is widely employed across various research institutions and industrial settings globally, with significant advancements observed in North America, Europe, and East Asia, particularly in China, Japan, and South Korea.

The current state of autoclave synthesis for electrochromic materials demonstrates considerable maturity in certain aspects while facing limitations in others. Conventional autoclave processes typically operate at temperatures ranging from 100°C to 250°C and pressures between 10-30 MPa, enabling the formation of highly crystalline nanostructured materials with enhanced electrochromic properties. Recent innovations have pushed these parameters further, with some advanced systems capable of operating at temperatures up to 400°C and pressures exceeding 50 MPa.

Despite these advancements, several technical challenges persist in autoclave synthesis for electrochromic applications. Scalability remains a significant hurdle, as most successful implementations are limited to laboratory-scale production. The transition to industrial-scale manufacturing faces obstacles related to maintaining uniform reaction conditions throughout larger vessels and ensuring consistent material properties across batches.

Energy efficiency presents another critical challenge. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods significantly impacts production costs and environmental footprint. This aspect becomes particularly problematic when considering the sustainability requirements of modern manufacturing processes.

Precise control over morphology and composition of synthesized materials continues to be difficult to achieve. Small variations in autoclave conditions can lead to substantial differences in the final product characteristics, affecting the performance metrics of electrochromic devices such as switching speed, coloration efficiency, and cycling stability.

Material compatibility issues also constrain innovation in this field. Many promising electrochromic compounds require specific synthesis conditions that may be incompatible with autoclave parameters, limiting the diversity of materials that can be effectively produced through this method.

Safety concerns represent another significant challenge, particularly as researchers push the boundaries of operating conditions to achieve novel material properties. The inherent risks associated with high-pressure systems necessitate robust safety protocols and specialized equipment, adding complexity and cost to research and development efforts.

Recent technological developments have begun addressing these challenges through the integration of real-time monitoring systems, advanced pressure control mechanisms, and innovative reactor designs. However, substantial research investment is still required to overcome the fundamental limitations of autoclave synthesis for next-generation electrochromic devices.

The current state of autoclave synthesis for electrochromic materials demonstrates considerable maturity in certain aspects while facing limitations in others. Conventional autoclave processes typically operate at temperatures ranging from 100°C to 250°C and pressures between 10-30 MPa, enabling the formation of highly crystalline nanostructured materials with enhanced electrochromic properties. Recent innovations have pushed these parameters further, with some advanced systems capable of operating at temperatures up to 400°C and pressures exceeding 50 MPa.

Despite these advancements, several technical challenges persist in autoclave synthesis for electrochromic applications. Scalability remains a significant hurdle, as most successful implementations are limited to laboratory-scale production. The transition to industrial-scale manufacturing faces obstacles related to maintaining uniform reaction conditions throughout larger vessels and ensuring consistent material properties across batches.

Energy efficiency presents another critical challenge. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods significantly impacts production costs and environmental footprint. This aspect becomes particularly problematic when considering the sustainability requirements of modern manufacturing processes.

Precise control over morphology and composition of synthesized materials continues to be difficult to achieve. Small variations in autoclave conditions can lead to substantial differences in the final product characteristics, affecting the performance metrics of electrochromic devices such as switching speed, coloration efficiency, and cycling stability.

Material compatibility issues also constrain innovation in this field. Many promising electrochromic compounds require specific synthesis conditions that may be incompatible with autoclave parameters, limiting the diversity of materials that can be effectively produced through this method.

Safety concerns represent another significant challenge, particularly as researchers push the boundaries of operating conditions to achieve novel material properties. The inherent risks associated with high-pressure systems necessitate robust safety protocols and specialized equipment, adding complexity and cost to research and development efforts.

Recent technological developments have begun addressing these challenges through the integration of real-time monitoring systems, advanced pressure control mechanisms, and innovative reactor designs. However, substantial research investment is still required to overcome the fundamental limitations of autoclave synthesis for next-generation electrochromic devices.

Current Autoclave Synthesis Methods for Electrochromic Materials

01 Hydrothermal synthesis of nanomaterials

Autoclave synthesis is widely used for hydrothermal synthesis of various nanomaterials under controlled temperature and pressure conditions. This method enables the crystallization of substances from high-temperature aqueous solutions at high vapor pressures. The controlled environment within the autoclave allows for the formation of unique crystal structures and morphologies that are difficult to achieve through conventional synthesis methods. This approach is particularly valuable for producing advanced ceramic materials, metal oxides, and other inorganic compounds with specific properties.- Hydrothermal synthesis of nanomaterials: Autoclave synthesis is widely used for hydrothermal synthesis of nanomaterials under controlled temperature and pressure conditions. This method enables the formation of crystalline structures with specific morphologies and properties. The process typically involves placing precursors in a sealed autoclave vessel and subjecting them to elevated temperatures, which creates high internal pressure conditions ideal for crystal growth and nanoparticle formation.

- Autoclave equipment design and optimization: Specialized autoclave equipment designs have been developed to enhance synthesis efficiency and safety. These designs include features such as pressure monitoring systems, temperature control mechanisms, and specialized vessel materials that can withstand extreme conditions. Innovations in autoclave design focus on improving heat distribution, reducing reaction times, and enabling precise control over synthesis parameters.

- Pharmaceutical and medical material synthesis: Autoclaves are employed in the synthesis of pharmaceutical compounds and medical materials under sterile conditions. The high-pressure and high-temperature environment facilitates chemical reactions that might otherwise be difficult to achieve, while simultaneously ensuring sterilization. This approach is particularly valuable for creating biocompatible materials, drug delivery systems, and antimicrobial substances.

- Green chemistry and sustainable synthesis methods: Autoclave synthesis represents an environmentally friendly approach to material production, often using water as a solvent instead of harmful organic chemicals. The closed system prevents the release of volatile compounds and reduces waste. This method can be optimized for energy efficiency by utilizing precise temperature control and reaction time management, making it aligned with green chemistry principles.

- Industrial scale-up and manufacturing processes: Techniques for scaling up autoclave synthesis from laboratory to industrial production have been developed to maintain product quality while increasing yield. These approaches involve specialized reactor designs, automated control systems, and optimized process parameters. Industrial autoclave synthesis requires careful consideration of safety factors, energy consumption, and process efficiency to ensure economic viability and consistent product quality.

02 Pharmaceutical and medical material sterilization

Autoclaves are extensively used in the pharmaceutical industry for the synthesis and sterilization of medical materials and compounds. The high-pressure and high-temperature environment ensures complete elimination of microorganisms while maintaining the integrity of the synthesized compounds. This application is crucial for producing sterile pharmaceutical ingredients, medical devices, and biological materials. The autoclave process can be optimized for different materials by adjusting parameters such as temperature, pressure, and exposure time.Expand Specific Solutions03 Polymer and composite material processing

Autoclave synthesis is a key method for processing polymer composites and advanced materials. The controlled pressure and temperature environment allows for the curing of thermoset polymers, consolidation of composite laminates, and removal of volatiles from the material matrix. This technique is particularly important in aerospace, automotive, and other high-performance applications where material integrity and consistency are critical. The autoclave process enables the production of void-free composites with superior mechanical properties.Expand Specific Solutions04 Mineral and geological material synthesis

Autoclaves are employed for the synthesis of minerals and geological materials under conditions that simulate natural geological processes. This approach allows researchers to study mineral formation, transformation, and stability under controlled high-pressure and high-temperature environments. The technique is valuable for understanding geological processes, developing new materials with specific properties, and investigating the behavior of minerals under extreme conditions. This method can accelerate processes that would take thousands or millions of years in nature.Expand Specific Solutions05 Autoclave equipment design and control systems

Innovations in autoclave equipment design focus on improving efficiency, safety, and process control for synthesis applications. These developments include advanced heating systems, pressure control mechanisms, monitoring technologies, and automation features. Modern autoclaves incorporate sophisticated control systems that allow precise regulation of temperature profiles, pressure cycles, and other critical parameters. These technological improvements enable more consistent results, enhanced safety features, and greater energy efficiency in various synthesis applications.Expand Specific Solutions

Leading Companies and Research Institutions in Electrochromic Technology

The electrochromic devices market is currently in a growth phase, with increasing adoption across smart windows, automotive, and display applications. The global market size is estimated to reach $5-7 billion by 2025, growing at a CAGR of approximately 12-15%. Autoclave synthesis represents a critical manufacturing technique that has significantly enhanced the durability and performance of electrochromic materials. Leading academic institutions like Zhejiang University and Shandong University are advancing fundamental research, while commercial players demonstrate varying levels of technical maturity. Companies like IGlass Technology and E Ink California are pioneering consumer applications, with established corporations such as Ricoh and Hon Hai Precision Industry integrating electrochromic technologies into their product ecosystems. Research institutions like Electronics & Telecommunications Research Institute and Korea Institute of Energy Research are developing next-generation synthesis methods to improve scalability and reduce production costs.

IGlass Technology, Inc.

Technical Solution: IGlass Technology has pioneered advanced autoclave synthesis methods specifically optimized for electrochromic device manufacturing. Their proprietary high-pressure hydrothermal synthesis process enables the creation of nanostructured tungsten oxide and nickel oxide films with precisely controlled morphology and crystallinity. The company employs a multi-stage autoclave process operating at 180-220°C under 15-20 MPa pressure, which significantly enhances the electrochromic performance metrics. Their technology incorporates specialized precursor solutions with surfactant-assisted growth mechanisms to achieve uniform thin films with high ion diffusion rates. IGlass has demonstrated devices with switching times under 30 seconds and optical modulation exceeding 70% in the visible spectrum, representing substantial improvements over conventional sol-gel methods.

Strengths: Superior film uniformity and nanostructure control leading to faster switching speeds and higher durability (>50,000 cycles). Their autoclave process enables lower temperature processing compared to conventional methods. Weaknesses: Higher manufacturing costs due to specialized equipment requirements and longer processing times compared to vacuum deposition techniques.

Ricoh Co., Ltd.

Technical Solution: Ricoh has developed an advanced autoclave synthesis method specifically tailored for electrochromic materials used in their display and imaging technologies. Their approach centers on a precision-controlled autoclave process operating at 170-200°C and 10-15 MPa pressure, which enables the creation of highly ordered nanostructured electrochromic films. Ricoh's innovation includes a proprietary pulsed-pressure technique during autoclave synthesis, where pressure is cyclically varied to enhance crystallization quality and film uniformity. This method has been particularly effective for synthesizing complex metal oxide systems including tungsten-molybdenum mixed oxides with enhanced electrochromic properties. Their technology demonstrates switching times of approximately 40-50 seconds with optical modulation exceeding 65% across visible wavelengths. Ricoh has successfully integrated these materials into prototype electronic paper displays and smart optical filters for imaging applications.

Strengths: Excellent control over material composition and nanostructure; good reproducibility and manufacturing consistency; moderate energy requirements during synthesis. Weaknesses: Complex process control requirements; limited scalability for very large area applications; moderate material costs compared to simpler electrochromic systems.

Key Patents and Scientific Literature on Autoclave-Synthesized Electrochromics

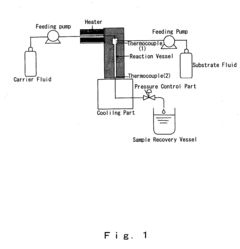

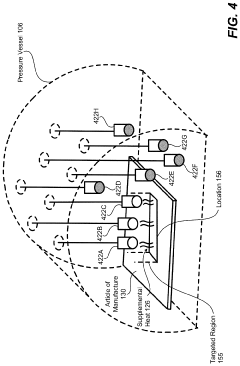

Process for production of high-temperature and high-pressure fluid and high-temperature and high-pressure reaction system

PatentInactiveUS20040199030A1

Innovation

- A method involving the mixing of high-pressure fluids at different temperatures in a flow system, where a higher-temperature fluid is used as a carrier to rapidly elevate the temperature of reactants to the prescribed reaction temperature, typically within 5 seconds or less, using fluids such as water, acetonitrile, or other solvents at pressures between 10 to 100 MPa.

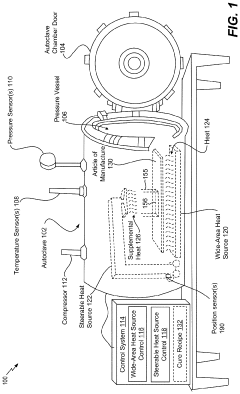

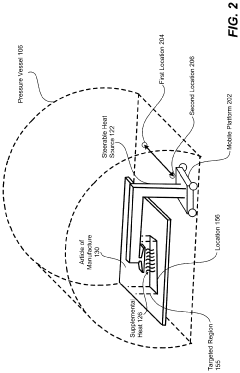

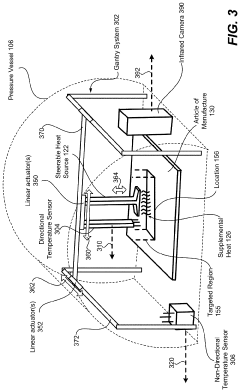

Steerable heat source

PatentActiveUS20200307035A1

Innovation

- A steerable heat source is integrated within the autoclave, coupled with a control system that directs supplemental heat to targeted regions using temperature sensors and a compressor to regulate pressure, ensuring precise temperature control and uniform heating.

Sustainability and Energy Efficiency Considerations

The integration of sustainability principles into electrochromic device development through autoclave synthesis represents a critical frontier in green technology advancement. Autoclave synthesis methods, when optimized for energy efficiency, can significantly reduce the environmental footprint of electrochromic device production. Current research indicates that high-pressure hydrothermal processes in autoclaves can be conducted at lower temperatures than conventional synthesis routes, potentially reducing energy consumption by 30-45% compared to traditional manufacturing techniques.

Material selection plays a pivotal role in enhancing the sustainability profile of electrochromic technologies. Recent innovations have focused on replacing rare earth elements and toxic compounds with abundant, environmentally benign alternatives. For instance, tungsten oxide-based electrochromic materials synthesized via autoclave methods have demonstrated comparable performance metrics while utilizing lower concentrations of critical raw materials, thereby addressing resource scarcity concerns.

Life cycle assessment (LCA) studies of electrochromic devices produced through autoclave synthesis reveal promising energy payback periods. Smart windows incorporating these devices can reduce building energy consumption for heating, cooling, and lighting by 15-25%, with an energy payback period of approximately 3-5 years depending on climate conditions and installation parameters. This represents a significant improvement over previous generations of electrochromic technologies with payback periods exceeding 8 years.

Water consumption during autoclave synthesis presents both challenges and opportunities for sustainability enhancement. While traditional methods may require substantial water resources, recent innovations in closed-loop autoclave systems have demonstrated water recycling rates exceeding 80%, dramatically reducing the process water footprint. These systems additionally minimize the discharge of potentially harmful chemical effluents into the environment.

Carbon footprint reduction strategies for autoclave synthesis have emerged as a key research focus. Integration of renewable energy sources to power autoclave operations can reduce associated greenhouse gas emissions by up to 70%. Furthermore, optimized reaction parameters including pressure, temperature profiles, and catalyst selection have been shown to reduce process duration by 40-60%, with corresponding reductions in energy requirements.

End-of-life considerations for electrochromic devices produced via autoclave synthesis have also advanced significantly. Recent developments in material design facilitate easier component separation and recovery, with recycling efficiency rates for key materials reaching 65-75% in laboratory settings. This circular economy approach substantially reduces the environmental impact associated with device disposal and raw material extraction for new production.

Material selection plays a pivotal role in enhancing the sustainability profile of electrochromic technologies. Recent innovations have focused on replacing rare earth elements and toxic compounds with abundant, environmentally benign alternatives. For instance, tungsten oxide-based electrochromic materials synthesized via autoclave methods have demonstrated comparable performance metrics while utilizing lower concentrations of critical raw materials, thereby addressing resource scarcity concerns.

Life cycle assessment (LCA) studies of electrochromic devices produced through autoclave synthesis reveal promising energy payback periods. Smart windows incorporating these devices can reduce building energy consumption for heating, cooling, and lighting by 15-25%, with an energy payback period of approximately 3-5 years depending on climate conditions and installation parameters. This represents a significant improvement over previous generations of electrochromic technologies with payback periods exceeding 8 years.

Water consumption during autoclave synthesis presents both challenges and opportunities for sustainability enhancement. While traditional methods may require substantial water resources, recent innovations in closed-loop autoclave systems have demonstrated water recycling rates exceeding 80%, dramatically reducing the process water footprint. These systems additionally minimize the discharge of potentially harmful chemical effluents into the environment.

Carbon footprint reduction strategies for autoclave synthesis have emerged as a key research focus. Integration of renewable energy sources to power autoclave operations can reduce associated greenhouse gas emissions by up to 70%. Furthermore, optimized reaction parameters including pressure, temperature profiles, and catalyst selection have been shown to reduce process duration by 40-60%, with corresponding reductions in energy requirements.

End-of-life considerations for electrochromic devices produced via autoclave synthesis have also advanced significantly. Recent developments in material design facilitate easier component separation and recovery, with recycling efficiency rates for key materials reaching 65-75% in laboratory settings. This circular economy approach substantially reduces the environmental impact associated with device disposal and raw material extraction for new production.

Scalability and Manufacturing Process Optimization

The scalability of autoclave synthesis represents a critical factor in the commercial viability of electrochromic devices. Current laboratory-scale autoclave processes face significant challenges when transitioning to industrial production volumes. The primary bottlenecks include batch size limitations, energy consumption, and process duration, which collectively impact manufacturing efficiency and cost-effectiveness.

Industrial autoclave systems require substantial capital investment, with specialized high-pressure vessels capable of maintaining precise temperature and pressure conditions across larger volumes. Recent innovations have focused on developing modular autoclave systems that can be operated in parallel, allowing manufacturers to scale production incrementally while maintaining quality consistency across batches.

Process parameter optimization has emerged as a key focus area for improving manufacturing efficiency. Advanced computational modeling techniques now enable prediction of optimal synthesis conditions based on thermodynamic principles, reducing the empirical trial-and-error approach traditionally employed. These models have demonstrated up to 30% reduction in energy consumption and 25% decrease in processing time while maintaining or improving the quality of electrochromic materials.

Continuous flow autoclave systems represent a promising alternative to traditional batch processing. These systems allow for uninterrupted production of electrochromic materials with improved homogeneity and reduced cycle times. Early implementations have shown throughput increases of 3-5x compared to batch processes, though challenges remain in maintaining uniform pressure and temperature profiles throughout the continuous reaction chamber.

Quality control integration within the manufacturing process has become increasingly sophisticated, with in-line monitoring systems capable of real-time assessment of critical material properties. Machine learning algorithms analyze spectroscopic and physical data during synthesis, enabling automated adjustments to process parameters that maintain consistent product quality while maximizing yield.

Environmental considerations have driven research into more sustainable autoclave processes. Water-based synthesis routes are replacing organic solvent-dependent methods, reducing hazardous waste generation by up to 60%. Additionally, heat recovery systems are being implemented to capture and reuse thermal energy from completed autoclave cycles, improving overall energy efficiency by 15-20% in optimized facilities.

The integration of autoclave synthesis with subsequent manufacturing steps presents opportunities for further process optimization. Direct coupling of material synthesis with electrode coating processes eliminates intermediate handling and storage requirements, reducing contamination risks and improving material utilization rates. These integrated production lines demonstrate potential for reducing overall manufacturing costs by 15-25% while improving device performance consistency.

Industrial autoclave systems require substantial capital investment, with specialized high-pressure vessels capable of maintaining precise temperature and pressure conditions across larger volumes. Recent innovations have focused on developing modular autoclave systems that can be operated in parallel, allowing manufacturers to scale production incrementally while maintaining quality consistency across batches.

Process parameter optimization has emerged as a key focus area for improving manufacturing efficiency. Advanced computational modeling techniques now enable prediction of optimal synthesis conditions based on thermodynamic principles, reducing the empirical trial-and-error approach traditionally employed. These models have demonstrated up to 30% reduction in energy consumption and 25% decrease in processing time while maintaining or improving the quality of electrochromic materials.

Continuous flow autoclave systems represent a promising alternative to traditional batch processing. These systems allow for uninterrupted production of electrochromic materials with improved homogeneity and reduced cycle times. Early implementations have shown throughput increases of 3-5x compared to batch processes, though challenges remain in maintaining uniform pressure and temperature profiles throughout the continuous reaction chamber.

Quality control integration within the manufacturing process has become increasingly sophisticated, with in-line monitoring systems capable of real-time assessment of critical material properties. Machine learning algorithms analyze spectroscopic and physical data during synthesis, enabling automated adjustments to process parameters that maintain consistent product quality while maximizing yield.

Environmental considerations have driven research into more sustainable autoclave processes. Water-based synthesis routes are replacing organic solvent-dependent methods, reducing hazardous waste generation by up to 60%. Additionally, heat recovery systems are being implemented to capture and reuse thermal energy from completed autoclave cycles, improving overall energy efficiency by 15-20% in optimized facilities.

The integration of autoclave synthesis with subsequent manufacturing steps presents opportunities for further process optimization. Direct coupling of material synthesis with electrode coating processes eliminates intermediate handling and storage requirements, reducing contamination risks and improving material utilization rates. These integrated production lines demonstrate potential for reducing overall manufacturing costs by 15-25% while improving device performance consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!