Autoclave Synthesis and the Development of Sustainable Composite Materials

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the early 20th century, transforming from basic pressure vessels to sophisticated computer-controlled systems essential for high-performance composite manufacturing. Initially developed for industrial sterilization and vulcanization processes, autoclaves found their pivotal application in aerospace manufacturing during the 1960s and 1970s when advanced composite materials began replacing traditional metals in aircraft structures.

The evolution trajectory shows distinct technological phases: early manual systems with limited pressure and temperature controls; semi-automated systems of the 1980s with improved monitoring capabilities; fully computerized systems of the 1990s featuring precise parameter control; and today's smart autoclaves equipped with IoT connectivity, predictive maintenance algorithms, and energy optimization features. This progression reflects the industry's continuous pursuit of process reliability, energy efficiency, and production quality.

Current technological objectives in autoclave synthesis focus on several critical areas. Energy efficiency stands as a primary concern, with research directed toward reducing the substantial power consumption of traditional autoclave cycles through optimized heating protocols, improved insulation materials, and heat recovery systems. Process optimization represents another key objective, with efforts to develop more precise control algorithms that can adapt in real-time to material behavior during curing, potentially reducing cycle times while maintaining or improving part quality.

Sustainability has emerged as a defining objective in modern autoclave technology development. This includes the integration of renewable energy sources to power autoclave operations, designing systems with reduced environmental footprints, and developing processes compatible with recyclable or bio-based composite materials. The industry increasingly recognizes that next-generation autoclave technology must align with global sustainability goals while maintaining the mechanical performance standards required for critical applications.

Size and capacity expansion represents another significant objective, as manufacturers seek to accommodate larger composite structures for aerospace, wind energy, and transportation applications. This drives innovation in autoclave design, heating systems, and pressure management to ensure uniform conditions throughout increasingly voluminous chambers.

The integration of digital technologies constitutes perhaps the most transformative objective, with Industry 4.0 principles being applied to autoclave operations through advanced sensors, digital twins for process simulation, and machine learning algorithms that can predict and prevent quality issues before they occur. These developments aim to transform autoclaves from isolated manufacturing equipment into connected nodes within smart factory ecosystems.

The evolution trajectory shows distinct technological phases: early manual systems with limited pressure and temperature controls; semi-automated systems of the 1980s with improved monitoring capabilities; fully computerized systems of the 1990s featuring precise parameter control; and today's smart autoclaves equipped with IoT connectivity, predictive maintenance algorithms, and energy optimization features. This progression reflects the industry's continuous pursuit of process reliability, energy efficiency, and production quality.

Current technological objectives in autoclave synthesis focus on several critical areas. Energy efficiency stands as a primary concern, with research directed toward reducing the substantial power consumption of traditional autoclave cycles through optimized heating protocols, improved insulation materials, and heat recovery systems. Process optimization represents another key objective, with efforts to develop more precise control algorithms that can adapt in real-time to material behavior during curing, potentially reducing cycle times while maintaining or improving part quality.

Sustainability has emerged as a defining objective in modern autoclave technology development. This includes the integration of renewable energy sources to power autoclave operations, designing systems with reduced environmental footprints, and developing processes compatible with recyclable or bio-based composite materials. The industry increasingly recognizes that next-generation autoclave technology must align with global sustainability goals while maintaining the mechanical performance standards required for critical applications.

Size and capacity expansion represents another significant objective, as manufacturers seek to accommodate larger composite structures for aerospace, wind energy, and transportation applications. This drives innovation in autoclave design, heating systems, and pressure management to ensure uniform conditions throughout increasingly voluminous chambers.

The integration of digital technologies constitutes perhaps the most transformative objective, with Industry 4.0 principles being applied to autoclave operations through advanced sensors, digital twins for process simulation, and machine learning algorithms that can predict and prevent quality issues before they occur. These developments aim to transform autoclaves from isolated manufacturing equipment into connected nodes within smart factory ecosystems.

Market Analysis for Sustainable Composite Materials

The global market for sustainable composite materials is experiencing unprecedented growth, driven by increasing environmental concerns and stringent regulations across industries. Current market valuation stands at approximately $36.1 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 8.2% through 2030. This growth trajectory is particularly evident in sectors such as automotive, aerospace, construction, and renewable energy, where demand for lightweight yet durable materials continues to rise.

The automotive industry represents the largest market segment, accounting for nearly 28% of the total sustainable composites market. This dominance stems from automotive manufacturers' push to reduce vehicle weight to meet fuel efficiency standards and lower carbon emissions. Major automotive companies including BMW, Volkswagen, and Toyota have committed to increasing the percentage of sustainable materials in their vehicles by at least 20% by 2025.

Aerospace applications constitute the fastest-growing segment with a CAGR of 9.7%, driven by the need for fuel-efficient aircraft and the industry's commitment to carbon neutrality by 2050. Boeing and Airbus have both announced initiatives to incorporate sustainable composite materials in their next-generation aircraft designs.

Regional analysis reveals that North America currently leads the market with a 35% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade, primarily due to rapid industrialization in China and India, coupled with government initiatives promoting sustainable manufacturing practices.

Consumer demand patterns show increasing willingness to pay premium prices for products manufactured using sustainable materials. A recent industry survey indicated that 67% of consumers across major markets consider sustainability as an important factor in their purchasing decisions, with 41% willing to pay up to 15% more for products with proven environmental benefits.

Supply chain challenges remain significant, with raw material availability and processing capabilities being the primary constraints. The autoclave synthesis process, while effective for producing high-quality composites, faces criticism for its energy intensity. This has spurred research into alternative, more energy-efficient manufacturing methods such as out-of-autoclave (OOA) processing and additive manufacturing techniques.

Market barriers include high initial investment costs, technical limitations in certain applications, and the need for industry-wide standards for sustainability certification. Despite these challenges, the market outlook remains highly positive, with venture capital investments in sustainable composite startups exceeding $1.2 billion in 2022 alone, signaling strong confidence in the sector's future growth potential.

The automotive industry represents the largest market segment, accounting for nearly 28% of the total sustainable composites market. This dominance stems from automotive manufacturers' push to reduce vehicle weight to meet fuel efficiency standards and lower carbon emissions. Major automotive companies including BMW, Volkswagen, and Toyota have committed to increasing the percentage of sustainable materials in their vehicles by at least 20% by 2025.

Aerospace applications constitute the fastest-growing segment with a CAGR of 9.7%, driven by the need for fuel-efficient aircraft and the industry's commitment to carbon neutrality by 2050. Boeing and Airbus have both announced initiatives to incorporate sustainable composite materials in their next-generation aircraft designs.

Regional analysis reveals that North America currently leads the market with a 35% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade, primarily due to rapid industrialization in China and India, coupled with government initiatives promoting sustainable manufacturing practices.

Consumer demand patterns show increasing willingness to pay premium prices for products manufactured using sustainable materials. A recent industry survey indicated that 67% of consumers across major markets consider sustainability as an important factor in their purchasing decisions, with 41% willing to pay up to 15% more for products with proven environmental benefits.

Supply chain challenges remain significant, with raw material availability and processing capabilities being the primary constraints. The autoclave synthesis process, while effective for producing high-quality composites, faces criticism for its energy intensity. This has spurred research into alternative, more energy-efficient manufacturing methods such as out-of-autoclave (OOA) processing and additive manufacturing techniques.

Market barriers include high initial investment costs, technical limitations in certain applications, and the need for industry-wide standards for sustainability certification. Despite these challenges, the market outlook remains highly positive, with venture capital investments in sustainable composite startups exceeding $1.2 billion in 2022 alone, signaling strong confidence in the sector's future growth potential.

Current Challenges in Autoclave Synthesis Methods

Despite significant advancements in autoclave synthesis technology, several critical challenges continue to impede the efficient and sustainable development of composite materials. The high energy consumption of autoclave processes remains a primary concern, with typical cure cycles requiring temperatures between 120-180°C and pressures of 6-7 bar maintained for several hours. This energy-intensive operation contributes substantially to the carbon footprint of composite manufacturing and increases production costs by approximately 30-40% compared to out-of-autoclave alternatives.

Scale limitations present another significant barrier, as traditional autoclaves are restricted by their physical dimensions. Large-scale components for aerospace or wind energy applications often require specialized facilities with autoclaves exceeding 30 meters in length, representing substantial capital investments exceeding $10-15 million and limiting production flexibility.

Process control inconsistencies during autoclave curing cycles frequently lead to quality variations in the final composite products. Temperature gradients within large autoclaves can reach 5-10°C differences across the chamber, resulting in uneven curing, residual stresses, and potential structural weaknesses. These inconsistencies necessitate extensive quality control measures, increasing production time and costs.

The environmental impact of autoclave processes extends beyond energy consumption to include significant water usage for cooling systems and the generation of volatile organic compounds (VOCs) during the curing of certain resin systems. Recent studies indicate that conventional autoclave processes can release 2-5% of resin mass as VOCs, contributing to workplace hazards and environmental pollution.

Material compatibility issues further complicate autoclave synthesis, particularly when incorporating sustainable or bio-based components. Many eco-friendly alternatives to traditional carbon fibers and petroleum-based resins demonstrate thermal degradation or property alterations at standard autoclave processing conditions, limiting their integration into high-performance applications.

Cycle time inefficiencies represent another challenge, with typical autoclave cycles requiring 4-8 hours for complete curing. This extended processing time creates production bottlenecks and reduces manufacturing throughput, particularly problematic for industries facing increasing demand for composite components.

The integration of real-time monitoring and quality control systems within the high-pressure, high-temperature autoclave environment presents technical difficulties that hinder process optimization. Current sensor technologies often struggle to provide accurate, continuous data throughout the cure cycle, complicating efforts to implement Industry 4.0 principles in autoclave manufacturing.

Scale limitations present another significant barrier, as traditional autoclaves are restricted by their physical dimensions. Large-scale components for aerospace or wind energy applications often require specialized facilities with autoclaves exceeding 30 meters in length, representing substantial capital investments exceeding $10-15 million and limiting production flexibility.

Process control inconsistencies during autoclave curing cycles frequently lead to quality variations in the final composite products. Temperature gradients within large autoclaves can reach 5-10°C differences across the chamber, resulting in uneven curing, residual stresses, and potential structural weaknesses. These inconsistencies necessitate extensive quality control measures, increasing production time and costs.

The environmental impact of autoclave processes extends beyond energy consumption to include significant water usage for cooling systems and the generation of volatile organic compounds (VOCs) during the curing of certain resin systems. Recent studies indicate that conventional autoclave processes can release 2-5% of resin mass as VOCs, contributing to workplace hazards and environmental pollution.

Material compatibility issues further complicate autoclave synthesis, particularly when incorporating sustainable or bio-based components. Many eco-friendly alternatives to traditional carbon fibers and petroleum-based resins demonstrate thermal degradation or property alterations at standard autoclave processing conditions, limiting their integration into high-performance applications.

Cycle time inefficiencies represent another challenge, with typical autoclave cycles requiring 4-8 hours for complete curing. This extended processing time creates production bottlenecks and reduces manufacturing throughput, particularly problematic for industries facing increasing demand for composite components.

The integration of real-time monitoring and quality control systems within the high-pressure, high-temperature autoclave environment presents technical difficulties that hinder process optimization. Current sensor technologies often struggle to provide accurate, continuous data throughout the cure cycle, complicating efforts to implement Industry 4.0 principles in autoclave manufacturing.

State-of-the-Art Autoclave Synthesis Solutions

01 Autoclave processing of bio-based composite materials

Autoclave processing techniques are used to synthesize sustainable composite materials from bio-based resources. This approach involves applying controlled heat and pressure to consolidate natural fibers with eco-friendly resins, resulting in high-performance composites with reduced environmental impact. The process optimizes curing conditions to enhance mechanical properties while maintaining the sustainability benefits of renewable raw materials.- Autoclave processing of bio-based composite materials: Autoclave processing techniques are used to synthesize sustainable composite materials from bio-based resources. This approach involves applying heat and pressure in a controlled environment to create high-performance composites with reduced environmental impact. The process enables the incorporation of natural fibers, biopolymers, and other renewable resources into composite structures that can replace conventional petroleum-based materials while maintaining comparable mechanical properties.

- Waste material valorization for sustainable composites: Autoclave synthesis methods are employed to transform industrial and agricultural waste materials into valuable composite components. This approach focuses on converting waste streams such as agricultural residues, plastic waste, and industrial byproducts into functional composite materials through controlled temperature and pressure conditions. The process contributes to circular economy principles by reducing landfill waste while creating materials with commercial applications in construction, automotive, and consumer goods sectors.

- Energy-efficient autoclave processes for composite manufacturing: Innovations in autoclave technology focus on reducing energy consumption during the synthesis of sustainable composite materials. These advancements include optimized heating cycles, improved insulation systems, and precise control mechanisms that minimize energy requirements while maintaining product quality. The development of low-temperature curing systems and rapid processing techniques further enhances the sustainability profile of autoclave-based composite manufacturing by reducing the carbon footprint associated with energy-intensive traditional methods.

- Multifunctional sustainable composites through autoclave synthesis: Autoclave synthesis enables the creation of multifunctional sustainable composite materials with enhanced properties beyond mechanical strength. These advanced materials incorporate features such as self-healing capabilities, thermal management properties, electromagnetic shielding, and improved fire resistance. The controlled environment of the autoclave process allows for the precise integration of functional additives and nanofillers into the composite structure, resulting in materials that can serve multiple purposes while maintaining their sustainability credentials.

- Scalable autoclave methods for industrial production of sustainable composites: Scalable autoclave synthesis methods have been developed to enable industrial-scale production of sustainable composite materials. These approaches focus on process optimization, quality control systems, and equipment design that can accommodate large-volume manufacturing while maintaining material performance and sustainability benefits. Innovations include continuous processing techniques, modular autoclave systems, and integrated production lines that reduce cycle times and increase throughput, making sustainable composites more economically viable for widespread commercial adoption.

02 Waste material utilization in autoclave-processed composites

Sustainable composite materials can be synthesized in autoclaves using recycled or waste materials as feedstock. This approach transforms industrial by-products, agricultural waste, or post-consumer materials into valuable composite components, reducing landfill waste while creating functional materials. The autoclave process enables proper consolidation and bonding of these heterogeneous materials, resulting in composites with competitive mechanical and thermal properties.Expand Specific Solutions03 Energy-efficient autoclave cycles for sustainable manufacturing

Optimized autoclave processing cycles have been developed to reduce energy consumption during the synthesis of sustainable composite materials. These improved cycles feature precise temperature and pressure profiles, reduced curing times, and enhanced heat transfer mechanisms. By minimizing energy requirements while maintaining product quality, these approaches significantly improve the overall sustainability of the manufacturing process.Expand Specific Solutions04 Advanced monitoring and control systems for autoclave synthesis

Smart monitoring and control systems have been integrated into autoclave processes for sustainable composite manufacturing. These systems utilize sensors, real-time data analysis, and predictive modeling to optimize processing parameters dynamically. By ensuring precise control over temperature, pressure, and curing conditions, these technologies minimize material waste, reduce energy consumption, and improve the consistency and quality of sustainable composite materials.Expand Specific Solutions05 Multi-functional sustainable composites through autoclave processing

Autoclave synthesis enables the development of multi-functional sustainable composite materials with enhanced properties beyond mechanical strength. These advanced composites incorporate features such as self-healing capabilities, thermal management properties, electromagnetic shielding, or biodegradability. The controlled environment of autoclave processing allows for the precise integration of functional additives while maintaining the sustainability aspects of the base materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The autoclave synthesis market for sustainable composite materials is in a growth phase, characterized by increasing demand for lightweight, high-performance materials across aerospace, automotive, and renewable energy sectors. The global market is expanding rapidly, driven by sustainability initiatives and performance requirements. Technologically, the field shows varying maturity levels, with established aerospace players like Boeing and Airbus leading commercial applications, while research institutions such as MIT and Shandong University advance fundamental innovations. Companies like Hexcel and Spirit AeroSystems have developed specialized expertise in carbon fiber composites, while chemical giants including INEOS Styrolution and China Petroleum & Chemical Corporation are investing in sustainable resin systems. The competitive landscape features strategic collaborations between material suppliers, manufacturers, and research institutions to overcome processing challenges and reduce environmental impact.

The Boeing Co.

Technical Solution: Boeing has developed advanced autoclave synthesis processes for aerospace composite materials, focusing on out-of-autoclave (OOA) manufacturing technologies while maintaining high-performance standards. Their CFRP (Carbon Fiber Reinforced Polymer) autoclave curing processes operate at temperatures of 180°C and pressures of 7 bar, enabling the production of large-scale composite structures with minimal void content (<1%)[1]. Boeing's sustainable composite development includes incorporating bio-based resins derived from plant oils that reduce carbon footprint by up to 30% compared to traditional petroleum-based systems[2]. Their proprietary TPMC (Thermoplastic Matrix Composite) autoclave process allows for recyclable composite components that maintain 85-90% of original mechanical properties after reprocessing[3].

Strengths: Boeing's autoclave processes deliver exceptional structural integrity and reliability for critical aerospace applications, with proven flight certification. Their integration of sustainable materials maintains high performance while reducing environmental impact. Weaknesses: High energy consumption during autoclave curing (approximately 2-3 times more energy than OOA methods), significant capital investment requirements, and longer processing cycles limiting production throughput.

Airbus Espana SL

Technical Solution: Airbus España has pioneered autoclave synthesis techniques for large composite aerostructures, developing specialized high-temperature (up to 200°C) and high-pressure (up to 10 bar) autoclave systems for manufacturing primary aircraft components. Their AFDX (Advanced Fiber Deposition and Xlink) process combines automated fiber placement with optimized autoclave curing cycles, reducing cure times by approximately 25% while maintaining structural integrity[1]. For sustainable composites, Airbus España has implemented a hybrid approach incorporating recycled carbon fibers (rCF) that can constitute up to 30% of the fiber content without compromising mechanical properties[2]. Their CLEAN (Composite Lifecycle Environmental Assessment Network) program has developed bio-based epoxy systems that reduce VOC emissions during curing by up to 40% compared to conventional systems[3].

Strengths: Airbus España's autoclave processes enable production of extremely large, complex composite structures with excellent dimensional stability and void-free laminates. Their integration of recycled materials maintains certification-level performance while reducing virgin material consumption. Weaknesses: The massive autoclaves required for aircraft components have high operational costs, significant energy consumption (approximately 1.5 MWh per cure cycle for large parts), and limited production capacity due to long cycle times.

Key Patents and Innovations in Composite Curing

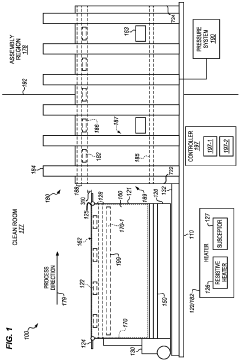

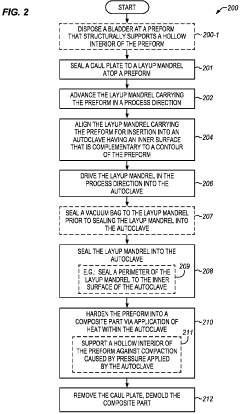

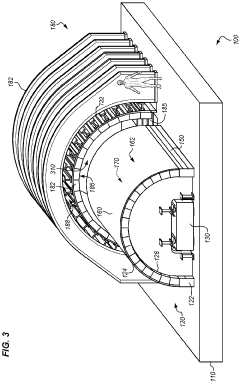

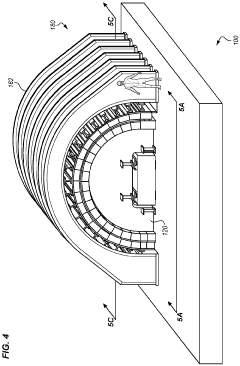

Method and system for sealing an autoclave

PatentActiveEP4000898A1

Innovation

- The development of autoclaves with inner surfaces that match the contours of specific preforms, allowing for a smaller volume to be heated, combined with the use of layup mandrels and caul plates to form a pressure chamber, reducing thermal mass and gas usage, and enabling efficient heating and cooling cycles.

Composite pressure tank and process for its manufacture

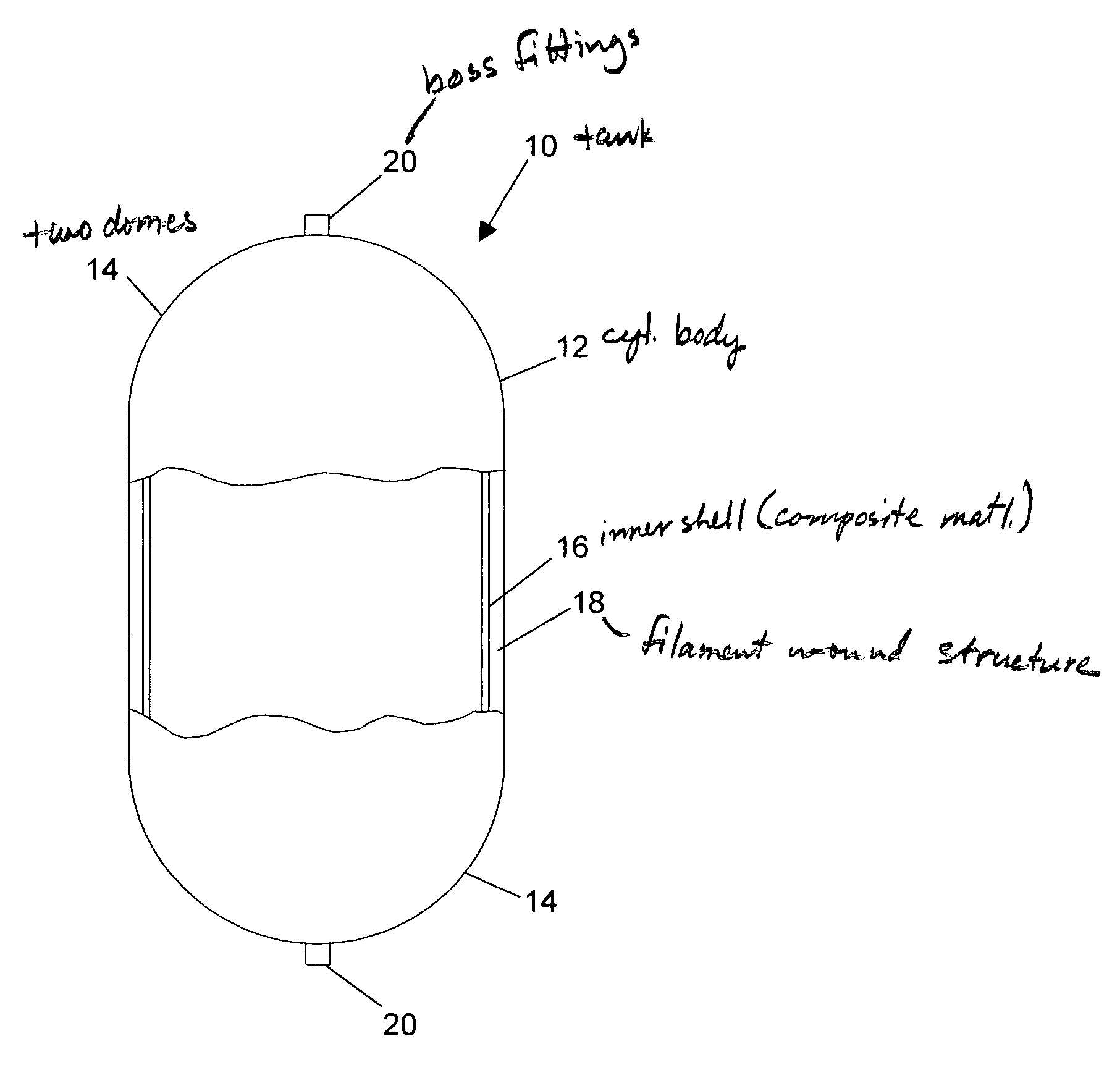

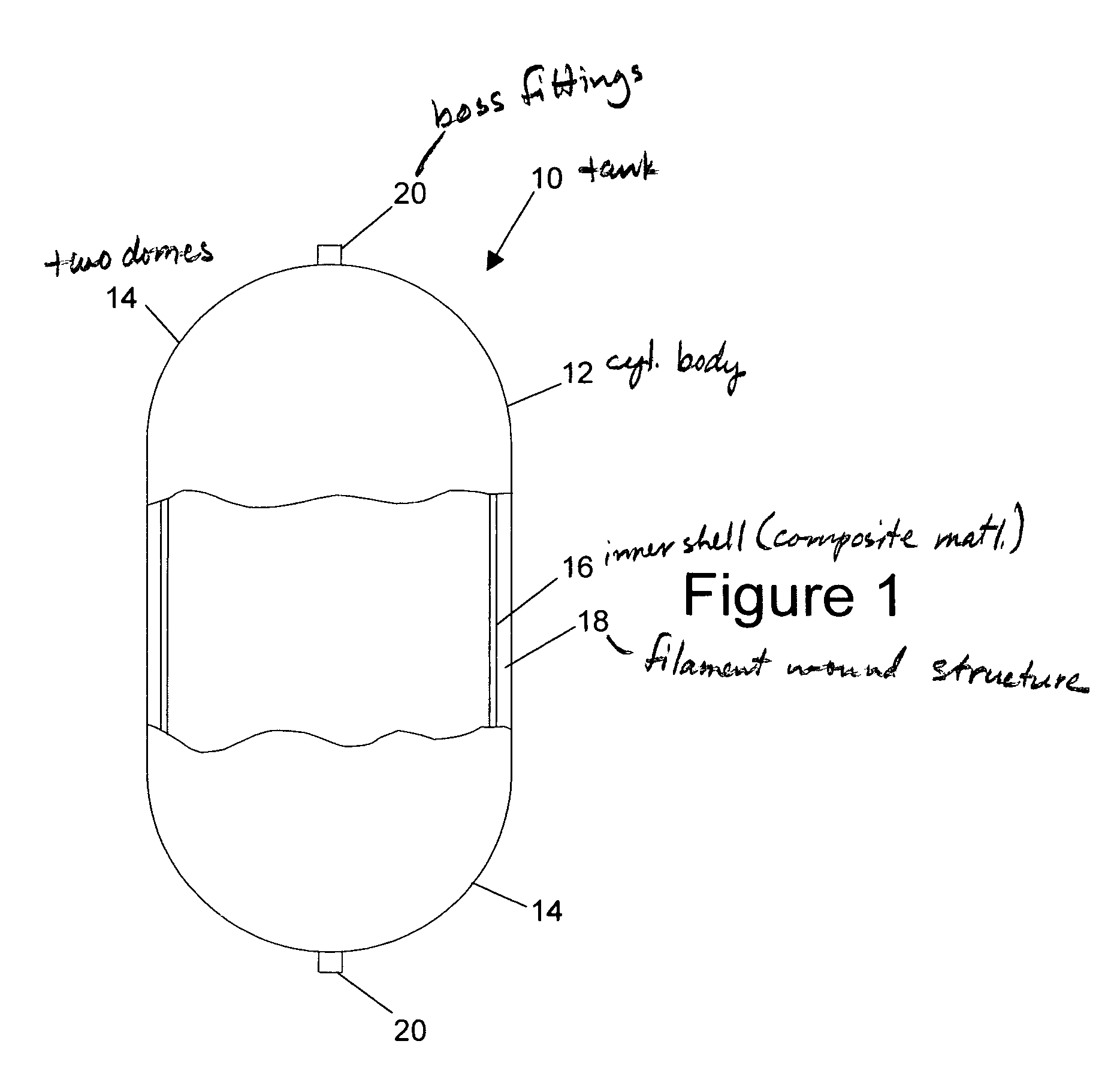

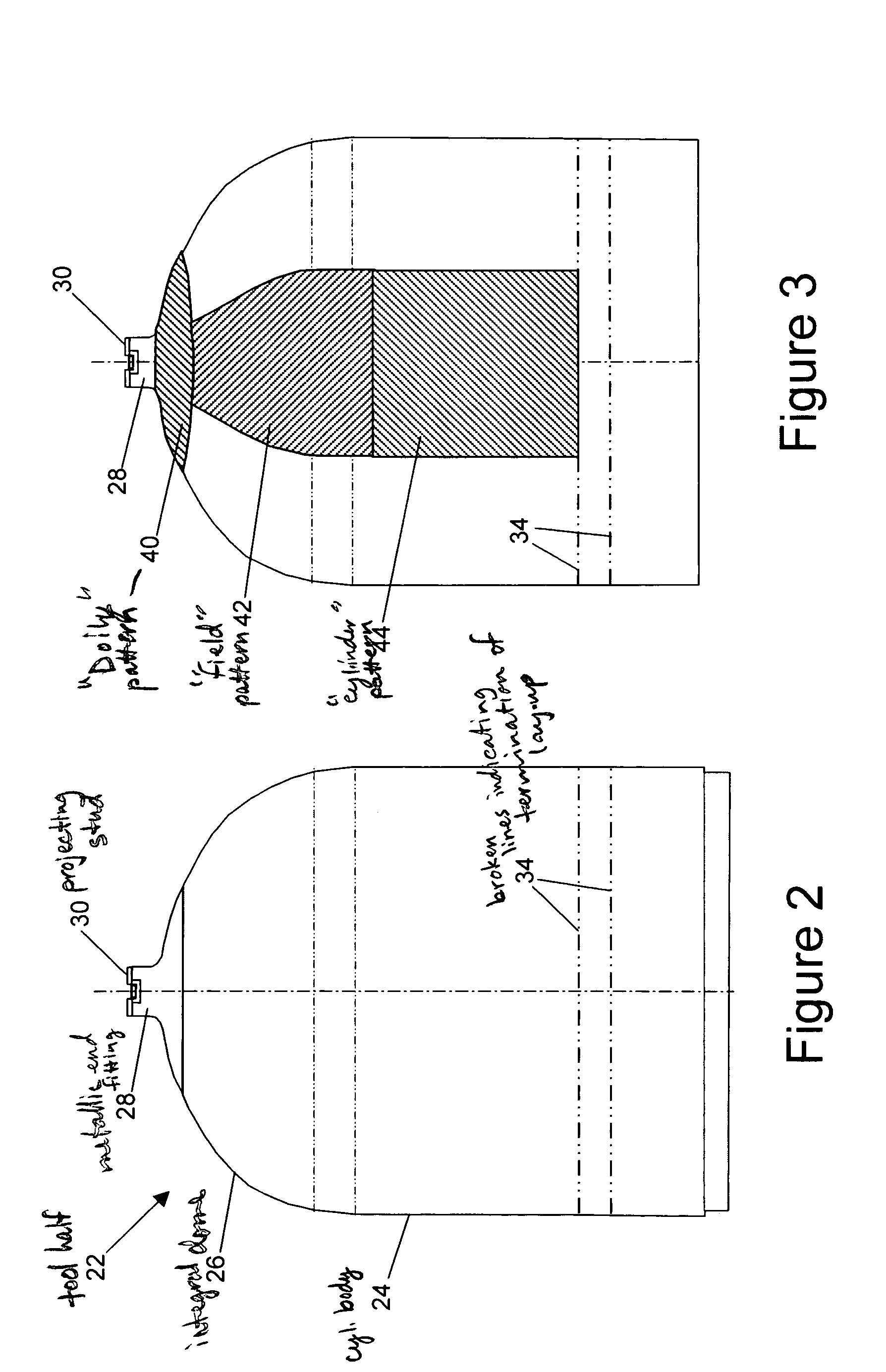

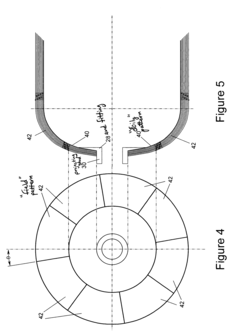

PatentInactiveUS7195133B1

Innovation

- A pressure vessel with an inner composite shell filament wound with an outer composite structure, cured out-of-autoclave, eliminating the need for metallic liners and autoclaving, using cryogenically compliant adhesives to reduce stress peaking and micro-cracking, and featuring geodesic iso-tensoid dome contours for enhanced structural integrity.

Life Cycle Assessment of Autoclave-Produced Materials

Life Cycle Assessment (LCA) of autoclave-produced composite materials reveals significant environmental impacts across their entire lifecycle. The energy-intensive nature of autoclave processing, typically requiring high temperatures (120-180°C) and pressures (6-7 bar), contributes substantially to the carbon footprint of these materials. Research indicates that the curing phase alone can account for 15-25% of the total environmental impact of composite part production.

When examining raw material extraction and processing, conventional carbon fiber production demonstrates particularly high environmental costs. The precursor manufacturing and subsequent carbonization processes consume approximately 200-300 MJ of energy per kilogram of carbon fiber produced, resulting in 20-30 kg CO2 equivalent emissions. Similarly, epoxy resin systems commonly used with autoclave processing carry their own environmental burdens through petroleum-based feedstocks.

Manufacturing phase assessments show that autoclave operations typically consume between 10-15 kWh of electricity per kilogram of processed composite material. This energy intensity is primarily attributed to the extended heating cycles and vacuum systems required to maintain precise processing conditions. Studies comparing autoclave processing with out-of-autoclave alternatives demonstrate potential energy savings of 30-50% when utilizing alternative manufacturing methods.

The use phase of autoclave-produced composites presents a more favorable environmental profile, particularly in transportation applications. The lightweight nature of these materials contributes to fuel efficiency improvements, with studies indicating that each 10% reduction in vehicle weight can improve fuel economy by 6-8%. This weight advantage creates a complex environmental trade-off between production impacts and use-phase benefits.

End-of-life considerations remain particularly challenging for autoclave-cured thermoset composites. Current recycling technologies achieve only 30-40% material recovery rates, with significant quality degradation in recovered fibers. Mechanical recycling processes reduce fiber length by 60-80%, while pyrolysis and solvolysis methods, though preserving fiber integrity, require substantial energy inputs that partially offset their environmental benefits.

Recent LCA studies have begun incorporating social and economic dimensions alongside environmental metrics, revealing that autoclave-produced materials often score lower on sustainability indices despite their technical performance advantages. This comprehensive assessment approach is driving industry innovation toward more sustainable autoclave cycles and alternative processing technologies that maintain material performance while reducing environmental impact.

When examining raw material extraction and processing, conventional carbon fiber production demonstrates particularly high environmental costs. The precursor manufacturing and subsequent carbonization processes consume approximately 200-300 MJ of energy per kilogram of carbon fiber produced, resulting in 20-30 kg CO2 equivalent emissions. Similarly, epoxy resin systems commonly used with autoclave processing carry their own environmental burdens through petroleum-based feedstocks.

Manufacturing phase assessments show that autoclave operations typically consume between 10-15 kWh of electricity per kilogram of processed composite material. This energy intensity is primarily attributed to the extended heating cycles and vacuum systems required to maintain precise processing conditions. Studies comparing autoclave processing with out-of-autoclave alternatives demonstrate potential energy savings of 30-50% when utilizing alternative manufacturing methods.

The use phase of autoclave-produced composites presents a more favorable environmental profile, particularly in transportation applications. The lightweight nature of these materials contributes to fuel efficiency improvements, with studies indicating that each 10% reduction in vehicle weight can improve fuel economy by 6-8%. This weight advantage creates a complex environmental trade-off between production impacts and use-phase benefits.

End-of-life considerations remain particularly challenging for autoclave-cured thermoset composites. Current recycling technologies achieve only 30-40% material recovery rates, with significant quality degradation in recovered fibers. Mechanical recycling processes reduce fiber length by 60-80%, while pyrolysis and solvolysis methods, though preserving fiber integrity, require substantial energy inputs that partially offset their environmental benefits.

Recent LCA studies have begun incorporating social and economic dimensions alongside environmental metrics, revealing that autoclave-produced materials often score lower on sustainability indices despite their technical performance advantages. This comprehensive assessment approach is driving industry innovation toward more sustainable autoclave cycles and alternative processing technologies that maintain material performance while reducing environmental impact.

Energy Efficiency Optimization Strategies

Energy efficiency in autoclave synthesis represents a critical frontier for sustainable composite material development. Current autoclave operations typically consume between 6-10 kWh per kilogram of processed composite material, presenting significant opportunities for optimization. Advanced thermal insulation technologies, including aerogel-based solutions and multi-layer ceramic composites, have demonstrated potential to reduce heat loss by 25-35% during processing cycles. These innovations maintain temperature uniformity while minimizing energy transfer to the external environment.

Process parameter optimization offers another promising avenue for energy conservation. Research indicates that modified cure cycles with optimized temperature ramp rates and dwell times can reduce energy consumption by 15-20% without compromising material properties. Computational fluid dynamics modeling has enabled precise prediction of thermal gradients within autoclaves, allowing for more efficient heating strategies tailored to specific composite geometries and resin systems.

Heat recovery systems represent a transformative approach to autoclave efficiency. Implementation of regenerative heat exchangers can capture and repurpose up to 40% of waste heat from exhaust gases, significantly reducing the energy required for subsequent processing cycles. These systems have demonstrated payback periods of 2-3 years in industrial settings, making them economically viable for large-scale manufacturing operations.

Smart control systems utilizing machine learning algorithms have emerged as powerful tools for real-time energy management. These systems continuously monitor and adjust processing parameters based on material state and energy consumption patterns. Field tests have shown that AI-driven control systems can achieve energy savings of 18-22% compared to conventional PID controllers while simultaneously improving composite quality consistency through more precise cure management.

Hybrid heating technologies combining conventional resistive elements with microwave or infrared systems have demonstrated potential for targeted energy delivery. This approach reduces overall energy requirements by focusing heat generation directly within the composite material rather than heating the entire autoclave chamber. Laboratory-scale implementations have achieved energy reductions of 30-45% for certain composite formulations, though challenges remain in scaling these technologies to industrial production volumes.

Alternative pressure generation mechanisms, such as mechanical pressure intensifiers and hydraulic systems with energy recovery capabilities, offer additional efficiency gains by reducing the compressed air requirements that typically account for 25-30% of autoclave energy consumption. These innovations, when combined with thermal optimization strategies, present a comprehensive approach to transforming autoclave synthesis into a more sustainable manufacturing process for next-generation composite materials.

Process parameter optimization offers another promising avenue for energy conservation. Research indicates that modified cure cycles with optimized temperature ramp rates and dwell times can reduce energy consumption by 15-20% without compromising material properties. Computational fluid dynamics modeling has enabled precise prediction of thermal gradients within autoclaves, allowing for more efficient heating strategies tailored to specific composite geometries and resin systems.

Heat recovery systems represent a transformative approach to autoclave efficiency. Implementation of regenerative heat exchangers can capture and repurpose up to 40% of waste heat from exhaust gases, significantly reducing the energy required for subsequent processing cycles. These systems have demonstrated payback periods of 2-3 years in industrial settings, making them economically viable for large-scale manufacturing operations.

Smart control systems utilizing machine learning algorithms have emerged as powerful tools for real-time energy management. These systems continuously monitor and adjust processing parameters based on material state and energy consumption patterns. Field tests have shown that AI-driven control systems can achieve energy savings of 18-22% compared to conventional PID controllers while simultaneously improving composite quality consistency through more precise cure management.

Hybrid heating technologies combining conventional resistive elements with microwave or infrared systems have demonstrated potential for targeted energy delivery. This approach reduces overall energy requirements by focusing heat generation directly within the composite material rather than heating the entire autoclave chamber. Laboratory-scale implementations have achieved energy reductions of 30-45% for certain composite formulations, though challenges remain in scaling these technologies to industrial production volumes.

Alternative pressure generation mechanisms, such as mechanical pressure intensifiers and hydraulic systems with energy recovery capabilities, offer additional efficiency gains by reducing the compressed air requirements that typically account for 25-30% of autoclave energy consumption. These innovations, when combined with thermal optimization strategies, present a comprehensive approach to transforming autoclave synthesis into a more sustainable manufacturing process for next-generation composite materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!