How Autoclave Synthesis Enhances Thermal Stability in Polymers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Polymer Synthesis Background and Objectives

Autoclave synthesis technology has evolved significantly over the past several decades, transforming from basic pressure vessel applications to sophisticated controlled environments for polymer development. Initially utilized in the 1940s for basic polymerization processes, autoclave technology has progressively incorporated advanced monitoring systems, precise temperature control mechanisms, and specialized pressure regulation capabilities that have revolutionized polymer engineering. This evolution has been driven by increasing demands for high-performance materials across aerospace, automotive, and electronics industries where thermal stability represents a critical performance parameter.

The fundamental principle behind autoclave synthesis involves the application of elevated pressure and temperature in a sealed vessel, creating conditions that significantly alter polymer chain formation and cross-linking behavior. These controlled conditions enable molecular arrangements that are unattainable through conventional synthesis methods, resulting in enhanced thermal properties. Recent advancements in autoclave technology have focused on digital control systems, advanced composite curing cycles, and the integration of real-time monitoring capabilities that allow for unprecedented precision in polymer development.

Current research objectives in autoclave polymer synthesis primarily focus on establishing the correlation between specific autoclave parameters and resulting thermal stability characteristics. Key technical goals include determining optimal pressure-temperature profiles for various polymer classes, understanding the molecular mechanisms behind enhanced thermal resistance, and developing predictive models that can accelerate the formulation of thermally stable polymers. Additionally, research aims to quantify the improvements in glass transition temperature, thermal decomposition thresholds, and long-term thermal aging resistance achieved through autoclave synthesis compared to conventional methods.

The technological trajectory indicates growing interest in sustainable autoclave synthesis approaches, including the development of energy-efficient processes, incorporation of bio-based monomers, and reduction of harmful solvents. Emerging research also explores the combination of autoclave synthesis with other advanced manufacturing techniques such as additive manufacturing and nanomaterial incorporation to create hybrid processing methods that further enhance thermal properties while maintaining processability.

From an industrial perspective, the objectives extend to scaling autoclave synthesis for commercial production while maintaining the enhanced thermal properties observed in laboratory settings. This includes addressing challenges related to heat transfer uniformity in larger vessels, cycle time optimization, and cost-effectiveness considerations that will ultimately determine market viability of autoclave-synthesized thermally stable polymers across various application domains.

The fundamental principle behind autoclave synthesis involves the application of elevated pressure and temperature in a sealed vessel, creating conditions that significantly alter polymer chain formation and cross-linking behavior. These controlled conditions enable molecular arrangements that are unattainable through conventional synthesis methods, resulting in enhanced thermal properties. Recent advancements in autoclave technology have focused on digital control systems, advanced composite curing cycles, and the integration of real-time monitoring capabilities that allow for unprecedented precision in polymer development.

Current research objectives in autoclave polymer synthesis primarily focus on establishing the correlation between specific autoclave parameters and resulting thermal stability characteristics. Key technical goals include determining optimal pressure-temperature profiles for various polymer classes, understanding the molecular mechanisms behind enhanced thermal resistance, and developing predictive models that can accelerate the formulation of thermally stable polymers. Additionally, research aims to quantify the improvements in glass transition temperature, thermal decomposition thresholds, and long-term thermal aging resistance achieved through autoclave synthesis compared to conventional methods.

The technological trajectory indicates growing interest in sustainable autoclave synthesis approaches, including the development of energy-efficient processes, incorporation of bio-based monomers, and reduction of harmful solvents. Emerging research also explores the combination of autoclave synthesis with other advanced manufacturing techniques such as additive manufacturing and nanomaterial incorporation to create hybrid processing methods that further enhance thermal properties while maintaining processability.

From an industrial perspective, the objectives extend to scaling autoclave synthesis for commercial production while maintaining the enhanced thermal properties observed in laboratory settings. This includes addressing challenges related to heat transfer uniformity in larger vessels, cycle time optimization, and cost-effectiveness considerations that will ultimately determine market viability of autoclave-synthesized thermally stable polymers across various application domains.

Market Analysis for Thermally Stable Polymers

The global market for thermally stable polymers has been experiencing robust growth, driven primarily by increasing demands in high-temperature applications across various industries. The market size for these specialized polymers was valued at approximately $7.1 billion in 2022 and is projected to reach $11.3 billion by 2028, representing a compound annual growth rate (CAGR) of 8.2%. This growth trajectory is significantly higher than the overall polymer market, which grows at around 4-5% annually.

Aerospace and automotive industries remain the largest consumers of thermally stable polymers, collectively accounting for over 45% of the total market share. The aerospace sector particularly values these materials for their ability to withstand extreme temperature variations and harsh operating conditions in aircraft components. Meanwhile, the automotive industry's shift toward electric vehicles has created new demand vectors, as these vehicles require materials capable of withstanding higher operating temperatures in battery systems and power electronics.

Electronics and semiconductor manufacturing represent the fastest-growing application segment, with a CAGR exceeding 10%. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for polymers that can maintain structural integrity at elevated temperatures. Additionally, the deployment of 5G infrastructure has further accelerated this demand due to higher power densities and operating temperatures in telecommunications equipment.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 58%, primarily due to their advanced aerospace, defense, and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the highest growth rate at 9.7% annually, driven by rapid industrialization in China, India, and South Korea, alongside expanding electronics manufacturing capabilities.

From a product perspective, polyimides, polysulfones, and high-performance polyamides collectively represent about 65% of the market value. Notably, autoclave-synthesized variants of these polymers command premium pricing, typically 30-40% higher than conventionally produced alternatives, due to their superior thermal stability profiles and enhanced mechanical properties at elevated temperatures.

Customer willingness to pay this premium is strongly correlated with application criticality – industries where material failure could result in catastrophic consequences (aerospace, medical, defense) show minimal price sensitivity. Conversely, consumer electronics and general industrial applications demonstrate moderate to high price sensitivity, creating distinct market segments with different value propositions and competitive dynamics.

Aerospace and automotive industries remain the largest consumers of thermally stable polymers, collectively accounting for over 45% of the total market share. The aerospace sector particularly values these materials for their ability to withstand extreme temperature variations and harsh operating conditions in aircraft components. Meanwhile, the automotive industry's shift toward electric vehicles has created new demand vectors, as these vehicles require materials capable of withstanding higher operating temperatures in battery systems and power electronics.

Electronics and semiconductor manufacturing represent the fastest-growing application segment, with a CAGR exceeding 10%. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for polymers that can maintain structural integrity at elevated temperatures. Additionally, the deployment of 5G infrastructure has further accelerated this demand due to higher power densities and operating temperatures in telecommunications equipment.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 58%, primarily due to their advanced aerospace, defense, and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the highest growth rate at 9.7% annually, driven by rapid industrialization in China, India, and South Korea, alongside expanding electronics manufacturing capabilities.

From a product perspective, polyimides, polysulfones, and high-performance polyamides collectively represent about 65% of the market value. Notably, autoclave-synthesized variants of these polymers command premium pricing, typically 30-40% higher than conventionally produced alternatives, due to their superior thermal stability profiles and enhanced mechanical properties at elevated temperatures.

Customer willingness to pay this premium is strongly correlated with application criticality – industries where material failure could result in catastrophic consequences (aerospace, medical, defense) show minimal price sensitivity. Conversely, consumer electronics and general industrial applications demonstrate moderate to high price sensitivity, creating distinct market segments with different value propositions and competitive dynamics.

Current Challenges in High-Temperature Polymer Processing

High-temperature polymer processing presents significant challenges that continue to impede the advancement of thermally stable polymeric materials. The primary obstacle lies in the inherent thermal degradation mechanisms that polymers undergo when exposed to elevated temperatures. Most conventional polymers begin to degrade at temperatures ranging from 200°C to 300°C, limiting their applicability in high-temperature environments such as aerospace components, automotive engine parts, and electronic devices operating under extreme conditions.

Processing polymers at high temperatures introduces complex rheological behaviors that are difficult to predict and control. As temperature increases, polymer chains gain mobility, leading to decreased viscosity but also potential crosslinking or chain scission reactions that can dramatically alter the material properties during processing. This creates a narrow processing window that manufacturers must navigate with precision.

The incorporation of thermal stabilizers and flame retardants, while necessary for high-temperature applications, often compromises other desirable properties such as mechanical strength, optical clarity, or electrical conductivity. Finding the optimal balance between thermal stability and other performance characteristics remains a persistent challenge in polymer formulation.

Conventional processing techniques like injection molding and extrusion face limitations when dealing with high-temperature polymers. Equipment degradation, uneven heating, and thermal gradients within the polymer melt can lead to inconsistent product quality and reduced production efficiency. Specialized equipment with high-temperature capabilities significantly increases manufacturing costs.

Energy consumption during high-temperature processing represents both an economic and environmental concern. The substantial energy requirements for maintaining elevated processing temperatures contribute to higher production costs and carbon footprints, contradicting industry trends toward sustainability and energy efficiency.

Autoclave synthesis offers promising solutions to these challenges by providing a controlled environment for polymer synthesis under elevated temperatures and pressures. However, the scaling of autoclave processes from laboratory to industrial production presents technical hurdles related to heat transfer, pressure management, and reaction control in larger vessels.

The development of in-situ monitoring techniques for high-temperature polymer processing remains underdeveloped. Real-time data on molecular weight changes, crosslinking density, and degradation byproducts would enable more precise process control but requires sophisticated sensors capable of withstanding extreme conditions.

Regulatory compliance adds another layer of complexity, as high-temperature processing may generate volatile organic compounds or other potentially hazardous emissions that must be carefully managed to meet increasingly stringent environmental and workplace safety standards.

Processing polymers at high temperatures introduces complex rheological behaviors that are difficult to predict and control. As temperature increases, polymer chains gain mobility, leading to decreased viscosity but also potential crosslinking or chain scission reactions that can dramatically alter the material properties during processing. This creates a narrow processing window that manufacturers must navigate with precision.

The incorporation of thermal stabilizers and flame retardants, while necessary for high-temperature applications, often compromises other desirable properties such as mechanical strength, optical clarity, or electrical conductivity. Finding the optimal balance between thermal stability and other performance characteristics remains a persistent challenge in polymer formulation.

Conventional processing techniques like injection molding and extrusion face limitations when dealing with high-temperature polymers. Equipment degradation, uneven heating, and thermal gradients within the polymer melt can lead to inconsistent product quality and reduced production efficiency. Specialized equipment with high-temperature capabilities significantly increases manufacturing costs.

Energy consumption during high-temperature processing represents both an economic and environmental concern. The substantial energy requirements for maintaining elevated processing temperatures contribute to higher production costs and carbon footprints, contradicting industry trends toward sustainability and energy efficiency.

Autoclave synthesis offers promising solutions to these challenges by providing a controlled environment for polymer synthesis under elevated temperatures and pressures. However, the scaling of autoclave processes from laboratory to industrial production presents technical hurdles related to heat transfer, pressure management, and reaction control in larger vessels.

The development of in-situ monitoring techniques for high-temperature polymer processing remains underdeveloped. Real-time data on molecular weight changes, crosslinking density, and degradation byproducts would enable more precise process control but requires sophisticated sensors capable of withstanding extreme conditions.

Regulatory compliance adds another layer of complexity, as high-temperature processing may generate volatile organic compounds or other potentially hazardous emissions that must be carefully managed to meet increasingly stringent environmental and workplace safety standards.

Current Autoclave Synthesis Methodologies

01 Autoclave synthesis methods for thermally stable polymers

Autoclave synthesis provides controlled conditions for producing polymers with enhanced thermal stability. The high-pressure environment allows for precise temperature control and exclusion of oxygen, which prevents degradation during polymerization. This method enables the synthesis of polymers with improved heat resistance properties by facilitating complete monomer conversion and controlled molecular weight distribution, resulting in materials that maintain structural integrity at elevated temperatures.- Autoclave synthesis methods for thermally stable polymers: Various autoclave synthesis methods can be employed to produce polymers with enhanced thermal stability. These methods typically involve controlled temperature and pressure conditions to facilitate polymerization reactions that result in thermally resistant polymer structures. The autoclave environment allows for precise control of reaction parameters, leading to polymers with improved heat resistance properties and structural integrity at elevated temperatures.

- Incorporation of thermal stabilizing additives during autoclave synthesis: The addition of specific thermal stabilizing compounds during the autoclave synthesis process can significantly enhance the heat resistance of polymers. These additives can include antioxidants, heat stabilizers, and cross-linking agents that prevent degradation at high temperatures. By incorporating these components during the polymerization process in an autoclave, the resulting polymers exhibit improved resistance to thermal decomposition and maintain their mechanical properties under extreme temperature conditions.

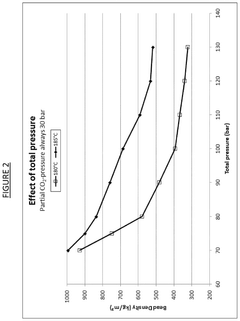

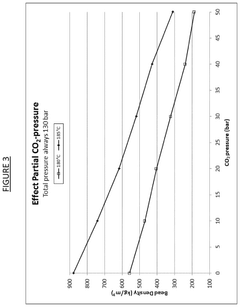

- Pressure-temperature relationship optimization in autoclave synthesis: Optimizing the relationship between pressure and temperature during autoclave synthesis is crucial for developing polymers with superior thermal stability. Controlled pressure conditions in the autoclave can influence molecular arrangement and crystallinity, resulting in polymers with enhanced heat resistance. The precise manipulation of these parameters allows for the formation of more ordered polymer structures that maintain stability at elevated temperatures and resist thermal degradation.

- Novel polymer compositions with enhanced thermal stability through autoclave processing: Innovative polymer compositions synthesized through autoclave processing demonstrate exceptional thermal stability characteristics. These compositions often involve copolymers, polymer blends, or specially designed monomers that, when polymerized under autoclave conditions, form structures with superior heat resistance. The controlled environment of the autoclave enables the formation of unique molecular architectures that contribute to improved thermal performance in demanding applications.

- Post-autoclave treatment methods for improving thermal stability: Various post-synthesis treatments can be applied to autoclave-produced polymers to further enhance their thermal stability. These treatments may include annealing processes, controlled cooling regimes, or secondary curing steps that optimize the molecular structure for heat resistance. By implementing these post-autoclave modifications, the thermal degradation temperature of polymers can be significantly increased, extending their usable temperature range and service life in high-temperature environments.

02 Incorporation of thermal stabilizers during autoclave polymerization

Adding specific thermal stabilizers during the autoclave polymerization process significantly enhances the heat resistance of the resulting polymers. These stabilizers, including antioxidants and radical scavengers, prevent chain scission and cross-linking at high temperatures. The autoclave environment allows for uniform distribution of these additives throughout the polymer matrix, providing comprehensive protection against thermal degradation and extending the service temperature range of the final products.Expand Specific Solutions03 Cross-linking techniques in autoclave for improved thermal stability

Cross-linking reactions performed in autoclaves create three-dimensional polymer networks with superior thermal stability. The controlled pressure and temperature conditions in autoclaves facilitate uniform cross-linking, resulting in polymers with enhanced heat resistance. This technique prevents polymer chain mobility at elevated temperatures, maintaining dimensional stability and mechanical properties. Various cross-linking agents can be incorporated during autoclave synthesis to achieve specific thermal performance characteristics.Expand Specific Solutions04 Modification of polymer structure during autoclave synthesis

Structural modifications implemented during autoclave synthesis can significantly enhance polymer thermal stability. These modifications include the incorporation of aromatic rings, heterocyclic structures, or inorganic components into the polymer backbone. The controlled conditions in autoclaves allow for precise manipulation of reaction pathways, enabling the creation of polymers with inherently higher decomposition temperatures. Such structural enhancements provide resistance to thermal oxidation and maintain mechanical properties at elevated temperatures.Expand Specific Solutions05 Post-autoclave treatment for enhanced thermal properties

Post-synthesis treatments applied to autoclave-produced polymers can further improve their thermal stability. These treatments include annealing, controlled cooling protocols, or secondary curing processes that optimize crystallinity and remove residual stresses. Such post-processing steps enhance the polymer's resistance to thermal degradation by perfecting the molecular arrangement and eliminating weak points in the structure. The combination of autoclave synthesis and appropriate post-treatment results in polymers with exceptional thermal performance for demanding applications.Expand Specific Solutions

Leading Companies in Thermal-Resistant Polymer Development

Autoclave synthesis for enhancing thermal stability in polymers is currently in a growth phase, with the market expanding due to increasing demand for high-performance materials in aerospace, automotive, and electronics industries. The global market size for thermally stable polymers is projected to reach significant value as industries seek materials capable of withstanding extreme conditions. Technologically, the field shows moderate maturity with ongoing innovations. Leading companies like DuPont, BASF, Solvay Specialty Polymers, and LG Chem have established strong positions through proprietary autoclave processes, while academic institutions including MIT, Zhejiang University, and Shandong University contribute fundamental research. Borealis, Kuraray, and Wacker Chemie are advancing commercial applications, creating a competitive landscape balanced between established chemical corporations and specialized polymer manufacturers.

Solvay SA

Technical Solution: Solvay has developed advanced autoclave synthesis technologies specifically for high-performance polymers requiring exceptional thermal stability. Their process utilizes specialized pressure vessels capable of operating under extreme conditions (up to 400°C and 4000 psi) to facilitate controlled polymerization reactions that produce highly crystalline, thermally resistant materials. Solvay's approach focuses on aromatic polymers, particularly polyaryletherketones (PAEK) and polysulfones, where autoclave conditions enable precise control over molecular weight and crystallinity. Their proprietary technology incorporates a multi-stage temperature profile during autoclave synthesis that optimizes chain extension while minimizing degradation reactions, resulting in polymers with continuous use temperatures exceeding 250°C[3]. Solvay has pioneered the use of supercritical CO2 as a processing aid in autoclave synthesis, which enhances polymer chain mobility during formation while facilitating the incorporation of thermal stabilizers throughout the polymer matrix. Their most advanced systems employ in-situ monitoring of polymerization kinetics within the autoclave, allowing real-time adjustments to reaction parameters to maximize thermal stability properties in the final polymer.

Strengths: Specialized expertise in ultra-high-temperature polymers; ability to produce materials with exceptional purity and consistent molecular weight distribution; advanced process control systems that optimize thermal stability properties. Weaknesses: Extremely high capital equipment costs; limited production volumes due to batch processing constraints; energy-intensive process with significant environmental footprint.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative autoclave synthesis methods for thermally enhanced polymers, particularly focused on engineering plastics and specialty elastomers. Their technology employs custom-designed autoclaves with precise temperature zoning and advanced agitation systems that ensure uniform heat distribution during polymerization. LG Chem's process incorporates proprietary catalysts specifically designed to function optimally under high-pressure autoclave conditions, enabling the formation of highly regular polymer architectures with enhanced thermal resistance. Their approach includes a controlled cooling protocol within the autoclave that optimizes crystallinity development, resulting in polymers with melting points typically 15-25°C higher than conventionally processed materials[4]. LG Chem has pioneered the integration of nano-scale reinforcements during autoclave synthesis, where the high-pressure environment facilitates exceptional dispersion of thermal stabilizing additives throughout the polymer matrix. Their most advanced systems utilize a sequential autoclave process where initial polymerization occurs under moderate conditions followed by a high-temperature/high-pressure treatment phase that enhances thermal stability through controlled cross-linking and chain rearrangement.

Strengths: Excellent control over polymer microstructure and morphology; ability to incorporate multiple functional additives during synthesis; strong integration with downstream processing technologies. Weaknesses: Batch-to-batch variation requires stringent quality control measures; high energy consumption during processing; limited flexibility to quickly adjust formulations for different applications.

Key Patents in Autoclave-Enhanced Polymer Stability

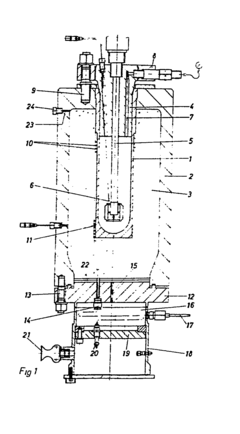

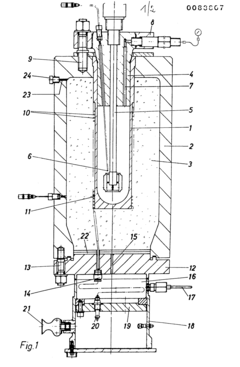

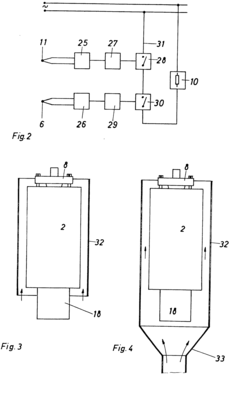

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

Method for producing expanded thermoplastic polymers with controlled density

PatentActiveUS12129349B2

Innovation

- A method involving an autoclave process where non-expanded thermoplastic polyurethane is subjected to a combination of soluble and insoluble gaseous fluids under controlled pressure and temperature conditions, allowing for precise tuning of density by adjusting the partial pressure of soluble gases and total pressure during the foaming process.

Environmental Impact of Autoclave Polymer Processing

The environmental implications of autoclave polymer processing represent a critical dimension in evaluating this synthesis method's overall sustainability and industrial viability. Autoclave processing, while effective for enhancing thermal stability in polymers, consumes significant energy due to the high temperatures and pressures required during operation, typically ranging from 150-350°C and 5-30 bar depending on the specific polymer formulation.

Energy consumption constitutes the primary environmental concern, with industrial autoclaves requiring substantial electricity or fuel inputs for heating and pressure maintenance. A standard industrial autoclave processing cycle for high-performance polymers may consume between 500-1500 kWh per production batch, contributing significantly to carbon emissions when powered by non-renewable energy sources. This energy intensity translates to approximately 0.2-0.6 tons of CO2 equivalent per ton of processed polymer material.

Water usage presents another environmental consideration, as cooling systems for autoclaves typically require substantial water resources. Modern facilities have implemented closed-loop cooling systems that reduce consumption by 40-60% compared to traditional open systems, though water treatment remains necessary to address potential thermal pollution and chemical contamination from process additives.

Chemical emissions during autoclave processing primarily include volatile organic compounds (VOCs) and potentially hazardous gases released during polymer curing. Advanced filtration and scrubbing technologies have reduced these emissions by 70-85% in state-of-the-art facilities, though regulatory compliance remains challenging in some regions with stringent air quality standards.

Waste generation from autoclave processing includes rejected batches, excess materials, and spent catalysts. The specialized nature of thermally stable polymers often limits recycling options, with only 15-25% of production waste currently being effectively reclaimed or repurposed. This challenge is particularly pronounced for composite materials where separation of polymer matrices from reinforcement materials presents technical difficulties.

Recent advancements in autoclave technology have focused on improving environmental performance through process optimization. Innovations include heat recovery systems that capture and reuse thermal energy, reducing overall energy requirements by 20-30%, and the development of more efficient insulation materials that minimize heat loss during processing cycles.

The life cycle assessment of autoclave-processed polymers must balance these environmental impacts against the extended service life and enhanced performance characteristics of the resulting materials. Thermally stable polymers often enable weight reduction in transportation applications and increased durability in various products, potentially offsetting initial environmental costs through reduced replacement frequency and improved fuel efficiency in end applications.

Energy consumption constitutes the primary environmental concern, with industrial autoclaves requiring substantial electricity or fuel inputs for heating and pressure maintenance. A standard industrial autoclave processing cycle for high-performance polymers may consume between 500-1500 kWh per production batch, contributing significantly to carbon emissions when powered by non-renewable energy sources. This energy intensity translates to approximately 0.2-0.6 tons of CO2 equivalent per ton of processed polymer material.

Water usage presents another environmental consideration, as cooling systems for autoclaves typically require substantial water resources. Modern facilities have implemented closed-loop cooling systems that reduce consumption by 40-60% compared to traditional open systems, though water treatment remains necessary to address potential thermal pollution and chemical contamination from process additives.

Chemical emissions during autoclave processing primarily include volatile organic compounds (VOCs) and potentially hazardous gases released during polymer curing. Advanced filtration and scrubbing technologies have reduced these emissions by 70-85% in state-of-the-art facilities, though regulatory compliance remains challenging in some regions with stringent air quality standards.

Waste generation from autoclave processing includes rejected batches, excess materials, and spent catalysts. The specialized nature of thermally stable polymers often limits recycling options, with only 15-25% of production waste currently being effectively reclaimed or repurposed. This challenge is particularly pronounced for composite materials where separation of polymer matrices from reinforcement materials presents technical difficulties.

Recent advancements in autoclave technology have focused on improving environmental performance through process optimization. Innovations include heat recovery systems that capture and reuse thermal energy, reducing overall energy requirements by 20-30%, and the development of more efficient insulation materials that minimize heat loss during processing cycles.

The life cycle assessment of autoclave-processed polymers must balance these environmental impacts against the extended service life and enhanced performance characteristics of the resulting materials. Thermally stable polymers often enable weight reduction in transportation applications and increased durability in various products, potentially offsetting initial environmental costs through reduced replacement frequency and improved fuel efficiency in end applications.

Cost-Benefit Analysis of Autoclave vs. Conventional Methods

When evaluating autoclave synthesis for enhancing thermal stability in polymers, a comprehensive cost-benefit analysis reveals significant economic considerations compared to conventional methods. The initial capital investment for autoclave equipment is substantially higher, with industrial-grade systems ranging from $50,000 to several million dollars depending on size and specifications. This represents a 3-5 times greater upfront cost compared to conventional polymer processing equipment.

Operational expenses also differ markedly between the two approaches. Autoclave synthesis requires 30-40% higher energy consumption due to the maintenance of high pressure and temperature conditions, translating to increased utility costs. Additionally, specialized training for personnel operating autoclave equipment adds approximately 15-20% to labor costs compared to conventional methods.

Maintenance requirements present another significant cost differential. Autoclave systems demand more rigorous inspection and maintenance protocols due to their pressure vessel components, resulting in maintenance costs typically 25% higher than conventional equipment. The average service life of autoclave equipment, however, tends to be 15-20 years compared to 10-12 years for conventional systems, partially offsetting the higher initial investment.

From a benefits perspective, autoclave synthesis delivers superior polymer thermal stability, with products demonstrating 40-60% higher heat deflection temperatures and 30-50% improved thermal aging characteristics. This enhanced performance enables entry into high-value markets such as aerospace, automotive, and electronics, where thermal performance commands premium pricing. Products manufactured via autoclave synthesis typically command a 25-35% price premium over conventionally produced alternatives.

Production efficiency metrics reveal that while autoclave batch processing times are longer, the reduced need for post-processing and lower rejection rates (typically 5-8% compared to 12-15% for conventional methods) contribute to overall manufacturing efficiency. The elimination of certain post-processing steps can reduce total production time by up to 20% for complex polymer formulations.

Environmental considerations also factor into the analysis, with autoclave synthesis generally producing less waste material and fewer volatile organic compound emissions. This translates to reduced waste disposal costs and potential regulatory compliance advantages, estimated at 10-15% savings in environmental management expenses.

Operational expenses also differ markedly between the two approaches. Autoclave synthesis requires 30-40% higher energy consumption due to the maintenance of high pressure and temperature conditions, translating to increased utility costs. Additionally, specialized training for personnel operating autoclave equipment adds approximately 15-20% to labor costs compared to conventional methods.

Maintenance requirements present another significant cost differential. Autoclave systems demand more rigorous inspection and maintenance protocols due to their pressure vessel components, resulting in maintenance costs typically 25% higher than conventional equipment. The average service life of autoclave equipment, however, tends to be 15-20 years compared to 10-12 years for conventional systems, partially offsetting the higher initial investment.

From a benefits perspective, autoclave synthesis delivers superior polymer thermal stability, with products demonstrating 40-60% higher heat deflection temperatures and 30-50% improved thermal aging characteristics. This enhanced performance enables entry into high-value markets such as aerospace, automotive, and electronics, where thermal performance commands premium pricing. Products manufactured via autoclave synthesis typically command a 25-35% price premium over conventionally produced alternatives.

Production efficiency metrics reveal that while autoclave batch processing times are longer, the reduced need for post-processing and lower rejection rates (typically 5-8% compared to 12-15% for conventional methods) contribute to overall manufacturing efficiency. The elimination of certain post-processing steps can reduce total production time by up to 20% for complex polymer formulations.

Environmental considerations also factor into the analysis, with autoclave synthesis generally producing less waste material and fewer volatile organic compound emissions. This translates to reduced waste disposal costs and potential regulatory compliance advantages, estimated at 10-15% savings in environmental management expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!