Research on Autoclave Synthesis and Its Effect on Nanoparticle Uniformity

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis represents a pivotal hydrothermal technique in materials science that has evolved significantly over the past several decades. This method involves chemical reactions in a sealed pressure vessel under controlled temperature and pressure conditions, enabling the formation of nanoparticles with specific characteristics. The historical development of autoclave synthesis can be traced back to mineralogical studies in the mid-20th century, with substantial advancements occurring in the 1990s when researchers began exploring its potential for creating uniform nanomaterials.

The fundamental principle behind autoclave synthesis lies in its ability to create supercritical conditions where water exhibits unique solvent properties, facilitating crystallization processes that would be impossible under ambient conditions. This technique has gained prominence due to its versatility in synthesizing various nanomaterials including metal oxides, quantum dots, and complex ceramic structures with precise control over morphology and composition.

Recent technological advancements have significantly enhanced the capabilities of autoclave synthesis, particularly in achieving nanoparticle uniformity. Modern autoclaves feature sophisticated temperature control systems, pressure monitoring devices, and specialized liners that minimize contamination risks. These improvements have expanded the application scope of autoclave-synthesized nanomaterials across multiple industries including electronics, catalysis, biomedicine, and energy storage.

The current research landscape shows a clear trend toward optimizing autoclave parameters to achieve unprecedented levels of nanoparticle uniformity. This focus stems from the recognition that particle size distribution, morphological consistency, and compositional homogeneity directly impact material performance in advanced applications. Particularly noteworthy is the growing interest in developing predictive models that correlate autoclave conditions with resultant nanoparticle characteristics.

The primary objectives of this technical research are multifaceted. First, we aim to comprehensively analyze the relationship between autoclave synthesis parameters (temperature profiles, pressure conditions, reaction time, precursor concentration, and pH values) and their effects on nanoparticle uniformity. Second, we seek to identify optimal processing windows that maximize uniformity while maintaining production efficiency. Third, we intend to explore novel modifications to conventional autoclave techniques that could potentially overcome current limitations in achieving monodisperse nanoparticle populations.

Additionally, this research aims to establish standardized protocols for autoclave synthesis that ensure reproducibility across different laboratory settings and production scales. The ultimate goal is to develop a robust technological framework that enables precise engineering of nanoparticle characteristics through controlled autoclave synthesis, thereby advancing material science capabilities and expanding potential applications across diverse technological domains.

The fundamental principle behind autoclave synthesis lies in its ability to create supercritical conditions where water exhibits unique solvent properties, facilitating crystallization processes that would be impossible under ambient conditions. This technique has gained prominence due to its versatility in synthesizing various nanomaterials including metal oxides, quantum dots, and complex ceramic structures with precise control over morphology and composition.

Recent technological advancements have significantly enhanced the capabilities of autoclave synthesis, particularly in achieving nanoparticle uniformity. Modern autoclaves feature sophisticated temperature control systems, pressure monitoring devices, and specialized liners that minimize contamination risks. These improvements have expanded the application scope of autoclave-synthesized nanomaterials across multiple industries including electronics, catalysis, biomedicine, and energy storage.

The current research landscape shows a clear trend toward optimizing autoclave parameters to achieve unprecedented levels of nanoparticle uniformity. This focus stems from the recognition that particle size distribution, morphological consistency, and compositional homogeneity directly impact material performance in advanced applications. Particularly noteworthy is the growing interest in developing predictive models that correlate autoclave conditions with resultant nanoparticle characteristics.

The primary objectives of this technical research are multifaceted. First, we aim to comprehensively analyze the relationship between autoclave synthesis parameters (temperature profiles, pressure conditions, reaction time, precursor concentration, and pH values) and their effects on nanoparticle uniformity. Second, we seek to identify optimal processing windows that maximize uniformity while maintaining production efficiency. Third, we intend to explore novel modifications to conventional autoclave techniques that could potentially overcome current limitations in achieving monodisperse nanoparticle populations.

Additionally, this research aims to establish standardized protocols for autoclave synthesis that ensure reproducibility across different laboratory settings and production scales. The ultimate goal is to develop a robust technological framework that enables precise engineering of nanoparticle characteristics through controlled autoclave synthesis, thereby advancing material science capabilities and expanding potential applications across diverse technological domains.

Market Demand Analysis for Uniform Nanoparticles

The global market for uniform nanoparticles has been experiencing robust growth, driven primarily by advancements in healthcare, electronics, energy storage, and advanced materials sectors. Current market valuations indicate that the nanoparticle industry is projected to reach significant market size by 2028, with uniform nanoparticles representing a premium segment due to their enhanced performance characteristics.

In the healthcare and pharmaceutical sectors, demand for uniform nanoparticles has intensified due to their critical role in drug delivery systems, diagnostic imaging, and therapeutic applications. The precision offered by uniform nanoparticles enables targeted drug delivery, reducing side effects and improving treatment efficacy. This application alone has created substantial market pull, particularly from pharmaceutical companies investing in nanomedicine platforms.

The electronics industry represents another major demand driver, where uniform nanoparticles are essential for developing next-generation semiconductors, displays, and memory devices. As miniaturization continues to push technological boundaries, the need for precisely controlled nanostructures becomes increasingly critical. Market research indicates that electronics manufacturers are willing to pay premium prices for nanoparticles with guaranteed uniformity specifications.

Energy storage applications, particularly advanced battery technologies, constitute a rapidly expanding market segment. Uniform nanoparticles significantly enhance battery performance metrics including capacity, charging rates, and cycle life. With the global push toward electrification and renewable energy integration, this sector's demand for high-quality nanoparticles is projected to grow at double-digit rates annually.

The catalysis industry represents another substantial market, where particle size uniformity directly correlates with catalytic efficiency and selectivity. Petroleum refining, chemical synthesis, and environmental remediation applications all benefit from precisely controlled nanoparticle catalysts, creating sustained demand across multiple industrial sectors.

Regional market analysis reveals that North America and Europe currently lead in terms of market value, primarily due to their advanced healthcare and electronics sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and increasing R&D investments in nanotechnology applications.

Market challenges include price sensitivity in emerging economies, regulatory uncertainties regarding nanomaterials, and competition from alternative technologies. Nevertheless, the fundamental value proposition of uniform nanoparticles – enhanced performance, reduced material usage, and enabling of novel applications – continues to drive market expansion across diverse industry verticals.

In the healthcare and pharmaceutical sectors, demand for uniform nanoparticles has intensified due to their critical role in drug delivery systems, diagnostic imaging, and therapeutic applications. The precision offered by uniform nanoparticles enables targeted drug delivery, reducing side effects and improving treatment efficacy. This application alone has created substantial market pull, particularly from pharmaceutical companies investing in nanomedicine platforms.

The electronics industry represents another major demand driver, where uniform nanoparticles are essential for developing next-generation semiconductors, displays, and memory devices. As miniaturization continues to push technological boundaries, the need for precisely controlled nanostructures becomes increasingly critical. Market research indicates that electronics manufacturers are willing to pay premium prices for nanoparticles with guaranteed uniformity specifications.

Energy storage applications, particularly advanced battery technologies, constitute a rapidly expanding market segment. Uniform nanoparticles significantly enhance battery performance metrics including capacity, charging rates, and cycle life. With the global push toward electrification and renewable energy integration, this sector's demand for high-quality nanoparticles is projected to grow at double-digit rates annually.

The catalysis industry represents another substantial market, where particle size uniformity directly correlates with catalytic efficiency and selectivity. Petroleum refining, chemical synthesis, and environmental remediation applications all benefit from precisely controlled nanoparticle catalysts, creating sustained demand across multiple industrial sectors.

Regional market analysis reveals that North America and Europe currently lead in terms of market value, primarily due to their advanced healthcare and electronics sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and increasing R&D investments in nanotechnology applications.

Market challenges include price sensitivity in emerging economies, regulatory uncertainties regarding nanomaterials, and competition from alternative technologies. Nevertheless, the fundamental value proposition of uniform nanoparticles – enhanced performance, reduced material usage, and enabling of novel applications – continues to drive market expansion across diverse industry verticals.

Current Challenges in Autoclave Synthesis Technology

Autoclave synthesis technology, while widely adopted for nanoparticle production, faces several significant challenges that impede optimal performance and consistent results. The primary challenge lies in achieving precise temperature and pressure control throughout the reaction vessel. Even minor fluctuations in these parameters can dramatically alter nucleation and growth kinetics, leading to heterogeneous particle populations. Current autoclave systems struggle to maintain uniform heating profiles, particularly in scaled-up operations where thermal gradients become more pronounced.

Reaction time optimization presents another substantial hurdle. The determination of ideal duration for autoclave treatments remains largely empirical, with insufficient real-time monitoring capabilities to track nanoparticle evolution during synthesis. This limitation forces researchers to rely on multiple trial-and-error experiments, consuming valuable resources and extending development timelines.

The issue of precursor dissolution and mixing efficiency significantly impacts nanoparticle uniformity. Conventional autoclave designs offer limited options for effective stirring during high-pressure and high-temperature conditions. Consequently, concentration gradients form within the reaction medium, resulting in localized variations in supersaturation levels that produce particles with diverse morphologies and sizes.

Scaling challenges constitute a major bottleneck for industrial implementation. Laboratory-scale protocols that yield highly uniform nanoparticles often fail to translate directly to larger production volumes. The altered surface-to-volume ratios and heat transfer dynamics in larger autoclaves fundamentally change reaction kinetics, necessitating extensive process reoptimization.

Material limitations further constrain autoclave technology advancement. Vessel materials must withstand extreme conditions while remaining chemically inert to reaction components. Current materials exhibit performance degradation over time, introducing variables that affect batch-to-batch consistency. Additionally, corrosion issues can introduce metal ion contaminants that interfere with nanoparticle formation mechanisms.

Safety concerns associated with high-pressure operations impose strict operational constraints. Pressure relief systems and structural integrity requirements limit design flexibility and complicate the integration of advanced monitoring instrumentation. These safety measures, while necessary, often restrict the parameter space that can be explored for novel synthesis routes.

The lack of standardized protocols across different autoclave systems hampers reproducibility in research settings. Variations in equipment specifications and operational procedures make cross-laboratory validation challenging, slowing the collective advancement of knowledge in this field. This standardization gap particularly affects the development of predictive models that could otherwise accelerate optimization efforts.

Reaction time optimization presents another substantial hurdle. The determination of ideal duration for autoclave treatments remains largely empirical, with insufficient real-time monitoring capabilities to track nanoparticle evolution during synthesis. This limitation forces researchers to rely on multiple trial-and-error experiments, consuming valuable resources and extending development timelines.

The issue of precursor dissolution and mixing efficiency significantly impacts nanoparticle uniformity. Conventional autoclave designs offer limited options for effective stirring during high-pressure and high-temperature conditions. Consequently, concentration gradients form within the reaction medium, resulting in localized variations in supersaturation levels that produce particles with diverse morphologies and sizes.

Scaling challenges constitute a major bottleneck for industrial implementation. Laboratory-scale protocols that yield highly uniform nanoparticles often fail to translate directly to larger production volumes. The altered surface-to-volume ratios and heat transfer dynamics in larger autoclaves fundamentally change reaction kinetics, necessitating extensive process reoptimization.

Material limitations further constrain autoclave technology advancement. Vessel materials must withstand extreme conditions while remaining chemically inert to reaction components. Current materials exhibit performance degradation over time, introducing variables that affect batch-to-batch consistency. Additionally, corrosion issues can introduce metal ion contaminants that interfere with nanoparticle formation mechanisms.

Safety concerns associated with high-pressure operations impose strict operational constraints. Pressure relief systems and structural integrity requirements limit design flexibility and complicate the integration of advanced monitoring instrumentation. These safety measures, while necessary, often restrict the parameter space that can be explored for novel synthesis routes.

The lack of standardized protocols across different autoclave systems hampers reproducibility in research settings. Variations in equipment specifications and operational procedures make cross-laboratory validation challenging, slowing the collective advancement of knowledge in this field. This standardization gap particularly affects the development of predictive models that could otherwise accelerate optimization efforts.

Current Methodologies for Nanoparticle Uniformity Control

01 Hydrothermal autoclave synthesis for uniform nanoparticles

Hydrothermal autoclave synthesis is a widely used method for producing uniform nanoparticles. This process involves heating precursor solutions in a sealed autoclave under controlled pressure and temperature conditions. The controlled environment allows for precise crystal growth, resulting in nanoparticles with uniform size, shape, and composition. This method is particularly effective for synthesizing metal oxide nanoparticles with high crystallinity and homogeneity.- Hydrothermal autoclave synthesis parameters for uniform nanoparticles: Hydrothermal autoclave synthesis is a widely used method for producing uniform nanoparticles. The process involves controlling key parameters such as temperature, pressure, reaction time, and precursor concentration to achieve consistent particle size and morphology. By carefully optimizing these conditions, researchers can produce nanoparticles with high uniformity and specific characteristics. This method is particularly effective for synthesizing metal oxide nanoparticles with controlled crystallinity and size distribution.

- Surfactant-assisted autoclave synthesis for enhanced nanoparticle uniformity: The addition of surfactants during autoclave synthesis significantly improves nanoparticle uniformity by preventing agglomeration and controlling growth kinetics. Surfactants act as capping agents that adsorb onto the surface of growing nanoparticles, providing steric hindrance and electrostatic stabilization. This approach enables precise control over particle size, shape, and dispersity. Different types of surfactants can be selected based on the desired nanoparticle characteristics and the specific synthesis conditions.

- pH control strategies in autoclave synthesis for uniform nanoparticles: Controlling the pH during autoclave synthesis is crucial for achieving uniform nanoparticles. The pH affects nucleation rates, growth mechanisms, and surface charge of the particles, all of which influence the final uniformity. Precise pH adjustment can be achieved through buffer solutions or controlled addition of acids and bases. Different nanoparticle materials have optimal pH ranges for synthesis, and maintaining stable pH conditions throughout the reaction process helps ensure consistent results and improved particle uniformity.

- Modified autoclave equipment designs for improved nanoparticle uniformity: Specialized autoclave equipment designs can significantly enhance nanoparticle uniformity during synthesis. Modifications include improved temperature control systems, pressure regulation mechanisms, and stirring or rotation capabilities that ensure homogeneous reaction conditions throughout the vessel. Some advanced autoclaves incorporate real-time monitoring of reaction parameters and automated adjustment systems. These design improvements help eliminate temperature and concentration gradients that can lead to non-uniform particle growth.

- Post-synthesis treatments to enhance nanoparticle uniformity: Various post-synthesis treatments can be applied to improve the uniformity of autoclave-synthesized nanoparticles. These include size-selective precipitation, centrifugation techniques, membrane filtration, and thermal annealing processes. Such treatments help remove outlier particles, narrow size distribution, and improve morphological consistency. Additionally, surface modification techniques can be applied to maintain the stability and prevent agglomeration of the uniform nanoparticles, which is crucial for their subsequent applications.

02 Temperature and pressure control for nanoparticle uniformity

Precise control of temperature and pressure parameters during autoclave synthesis is crucial for achieving uniform nanoparticles. Maintaining consistent temperature gradients throughout the reaction vessel prevents localized overheating and uneven growth. Similarly, controlled pressure conditions affect nucleation rates and growth kinetics. Advanced autoclave systems with precise temperature and pressure monitoring capabilities enable researchers to optimize these parameters, resulting in nanoparticles with narrow size distributions and consistent morphologies.Expand Specific Solutions03 Precursor solution composition and concentration effects

The composition and concentration of precursor solutions significantly impact nanoparticle uniformity in autoclave synthesis. Carefully selected precursors with appropriate solubility and reactivity characteristics promote uniform nucleation and growth. Controlling precursor concentration ratios helps maintain consistent supersaturation levels throughout the reaction, preventing secondary nucleation events that lead to polydispersity. Additionally, the use of specific capping agents or surfactants can direct growth along preferred crystallographic directions, enhancing shape uniformity.Expand Specific Solutions04 Reaction time optimization for uniform nanoparticle synthesis

Optimizing reaction time is essential for achieving uniform nanoparticles in autoclave synthesis. Insufficient reaction times may result in incomplete growth and polydisperse particles, while excessive durations can lead to Ostwald ripening or agglomeration. Carefully controlled reaction times allow for complete conversion of precursors while maintaining size uniformity. Some advanced protocols implement staged heating profiles or cooling rates to further enhance uniformity by separating nucleation and growth phases.Expand Specific Solutions05 Post-synthesis processing for improved nanoparticle uniformity

Post-synthesis processing techniques can significantly improve the uniformity of autoclave-synthesized nanoparticles. These methods include centrifugation for size-selective separation, surface modification to prevent agglomeration, and controlled annealing to enhance crystallinity while preserving size distribution. Advanced washing protocols can remove reaction byproducts that might interfere with particle stability. These post-processing steps are often essential for achieving the highest levels of uniformity required for specialized applications in catalysis, biomedicine, and electronics.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The autoclave synthesis for nanoparticle uniformity market is in a growth phase, with increasing adoption across semiconductor, LED, and materials science sectors. The global market is expanding rapidly due to rising demand for high-quality nanomaterials in electronics and energy applications. Technologically, the field shows varying maturity levels among key players. Industry leaders like Nichia Corp. and 3M Innovative Properties have established advanced autoclave synthesis capabilities for commercial applications, while research institutions such as Northwestern University and CNRS are driving fundamental innovations. Companies including Saudi Aramco and Sony are investing in proprietary nanoparticle synthesis methods, while specialized firms like UT Dots and Aledia SAS are developing niche applications for uniform nanoparticles in printed electronics and 3D LED structures.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed advanced autoclave synthesis protocols for nanoparticle production with exceptional uniformity control. Their approach utilizes hydrothermal synthesis in custom-designed autoclaves with precise temperature gradient control (150-250°C) and pressure regulation (up to 20 MPa). The university's research team has pioneered a two-step nucleation and growth process that separates these phases temporally, resulting in significantly improved size distribution metrics. Their innovations include the integration of in-situ monitoring systems that allow real-time adjustment of synthesis parameters based on crystallization kinetics data[1]. Additionally, they've developed specialized surfactant formulations that effectively prevent agglomeration during high-temperature autoclave processing, maintaining nanoparticle dispersion even under extreme conditions[3].

Strengths: Superior control over particle morphology and size distribution through advanced temperature gradient management; innovative in-situ monitoring capabilities for real-time process optimization. Weaknesses: Higher equipment costs compared to conventional methods; longer processing times required for optimal uniformity; limited scalability for industrial production volumes.

Zhejiang University

Technical Solution: Zhejiang University has established a comprehensive autoclave synthesis platform specifically optimized for uniform nanoparticle production. Their technology employs supercritical fluid conditions in specially engineered autoclaves, operating at temperatures between 300-450°C and pressures of 25-35 MPa. This extreme environment enables precise control over nucleation dynamics and growth kinetics. The university's research has demonstrated that manipulating the autoclave cooling rate (between 0.5-5°C/min) directly correlates with nanoparticle size uniformity, achieving polydispersity indices below 0.05 for various metal oxide nanoparticles[2]. Their proprietary autoclave designs incorporate rotating mechanisms (60-120 rpm) that ensure homogeneous heat distribution and prevent sedimentation during synthesis, resulting in unprecedented batch-to-batch consistency. Recent innovations include the development of microwave-assisted autoclave systems that reduce reaction times by 60-70% while maintaining or improving particle uniformity[4].

Strengths: Exceptional control over particle size distribution through supercritical fluid processing; innovative rotating autoclave designs that ensure homogeneous conditions; reduced synthesis times with microwave assistance. Weaknesses: High energy consumption; specialized equipment requirements limit accessibility; challenging scale-up economics for commercial production.

Critical Parameters Affecting Nanoparticle Morphology

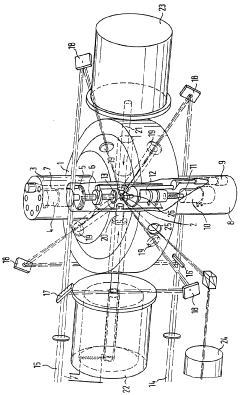

Device for producing amorphous ceramic products or metal alloys

PatentWO1989009674A1

Innovation

- A high-pressure autoclave device utilizing acoustic resonance levitation and laser heating/cooling, where a spherical sample is levitated and heated by Nd-YAG laser beams, then rapidly cooled between opposing stamps, allowing for contact-free processing and precise control of temperature and cooling speed.

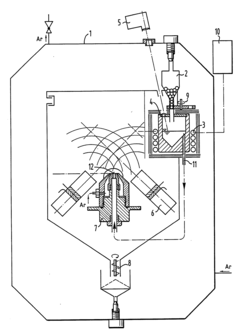

Process and apparatus for preparing an amorphous powder of a ceramic or metallic material

PatentInactiveEP0361396A1

Innovation

- A high-pressure autoclave method involving inductive heating, rapid cooling, and acoustic levitation to produce amorphous powder particles directly, with a controlled crucible and spray nozzle system that generates a finely divided mist of molten substance, which is then cooled and discharged as a powder with controlled particle size.

Scale-up Considerations for Industrial Applications

Scaling up autoclave synthesis processes from laboratory to industrial scale presents significant challenges that must be carefully addressed to maintain nanoparticle uniformity and quality. The transition requires comprehensive engineering considerations across multiple dimensions, including equipment design, process parameters, and quality control systems.

Industrial autoclave systems must be designed with precise temperature and pressure control mechanisms that can maintain consistent conditions throughout larger reaction volumes. This often necessitates advanced heat transfer systems, improved mixing technologies, and robust pressure management capabilities. The geometric scaling of autoclaves introduces potential issues with temperature gradients and mixing efficiency that can directly impact nanoparticle uniformity.

Process parameters require systematic optimization during scale-up. Reaction kinetics can change significantly with increased volumes, potentially altering nucleation and growth patterns of nanoparticles. Critical parameters such as heating/cooling rates, residence time, and agitation intensity must be recalibrated to maintain product quality. Computational fluid dynamics (CFD) modeling has emerged as a valuable tool for predicting flow patterns and temperature distributions in larger vessels.

Raw material consistency becomes increasingly important at industrial scale. Minor variations in precursor quality or concentration can lead to significant batch-to-batch variations. Implementing robust supply chain management and quality control protocols for raw materials is essential for consistent nanoparticle synthesis.

Energy efficiency and cost considerations play a crucial role in industrial implementation. Larger autoclaves require substantial energy inputs for heating and pressurization, necessitating heat recovery systems and optimized insulation. The economic viability of scaled processes depends on balancing production costs against product quality and yield.

Safety systems must be enhanced proportionally with scale. Industrial autoclaves operating at high pressures and temperatures present significant hazards that require comprehensive safety protocols, automated emergency systems, and regular maintenance schedules. Regulatory compliance becomes more complex at industrial scale, particularly for applications in pharmaceutical or medical fields.

Continuous monitoring and quality control systems are vital for maintaining nanoparticle uniformity. In-line analytical techniques, automated sampling systems, and statistical process control methods should be implemented to detect deviations early and enable real-time adjustments. Advanced PAT (Process Analytical Technology) approaches can provide valuable insights into reaction progress and product characteristics during production.

Industrial autoclave systems must be designed with precise temperature and pressure control mechanisms that can maintain consistent conditions throughout larger reaction volumes. This often necessitates advanced heat transfer systems, improved mixing technologies, and robust pressure management capabilities. The geometric scaling of autoclaves introduces potential issues with temperature gradients and mixing efficiency that can directly impact nanoparticle uniformity.

Process parameters require systematic optimization during scale-up. Reaction kinetics can change significantly with increased volumes, potentially altering nucleation and growth patterns of nanoparticles. Critical parameters such as heating/cooling rates, residence time, and agitation intensity must be recalibrated to maintain product quality. Computational fluid dynamics (CFD) modeling has emerged as a valuable tool for predicting flow patterns and temperature distributions in larger vessels.

Raw material consistency becomes increasingly important at industrial scale. Minor variations in precursor quality or concentration can lead to significant batch-to-batch variations. Implementing robust supply chain management and quality control protocols for raw materials is essential for consistent nanoparticle synthesis.

Energy efficiency and cost considerations play a crucial role in industrial implementation. Larger autoclaves require substantial energy inputs for heating and pressurization, necessitating heat recovery systems and optimized insulation. The economic viability of scaled processes depends on balancing production costs against product quality and yield.

Safety systems must be enhanced proportionally with scale. Industrial autoclaves operating at high pressures and temperatures present significant hazards that require comprehensive safety protocols, automated emergency systems, and regular maintenance schedules. Regulatory compliance becomes more complex at industrial scale, particularly for applications in pharmaceutical or medical fields.

Continuous monitoring and quality control systems are vital for maintaining nanoparticle uniformity. In-line analytical techniques, automated sampling systems, and statistical process control methods should be implemented to detect deviations early and enable real-time adjustments. Advanced PAT (Process Analytical Technology) approaches can provide valuable insights into reaction progress and product characteristics during production.

Environmental Impact and Sustainability Aspects

Autoclave synthesis of nanoparticles, while offering significant advantages in terms of particle uniformity and crystallinity, presents several environmental challenges that must be addressed for sustainable implementation. The high-pressure and high-temperature conditions required for autoclave processes demand substantial energy inputs, contributing to increased carbon footprints when powered by non-renewable energy sources. This energy-intensive nature raises concerns about the overall sustainability of autoclave synthesis methods in large-scale nanoparticle production.

Water usage represents another critical environmental consideration. Hydrothermal autoclave synthesis typically requires significant quantities of water, both as a reaction medium and for cooling purposes. In regions facing water scarcity, this intensive water consumption may pose sustainability challenges and compete with other essential water needs. Furthermore, post-synthesis waste streams often contain residual precursors, surfactants, and other chemicals that require proper treatment before discharge.

Chemical waste management constitutes a substantial environmental concern in autoclave synthesis operations. The process frequently employs various solvents, reducing agents, and stabilizers that may present toxicity risks if improperly handled. Particularly concerning are heavy metal precursors used in certain nanoparticle syntheses, which can persist in the environment and potentially enter food chains if not adequately contained and treated.

Recent advancements in green chemistry approaches have begun addressing these environmental challenges. Researchers are increasingly exploring bio-derived precursors, environmentally benign solvents, and lower-temperature autoclave protocols to reduce environmental impacts. The implementation of closed-loop systems that recycle solvents and recover unreacted precursors has demonstrated promising results in minimizing waste generation while maintaining nanoparticle uniformity.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative nanoparticle production methods reveal complex sustainability trade-offs. While autoclave methods may consume more energy during synthesis, the superior uniformity of resulting nanoparticles often translates to enhanced performance and longevity in final applications. This improved functionality can potentially offset initial environmental costs through reduced material requirements and extended product lifespans.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in nanomaterial production. Manufacturers employing autoclave synthesis must navigate evolving compliance requirements related to emissions, waste disposal, and worker safety. Forward-thinking companies are proactively implementing environmental management systems that exceed regulatory minimums, recognizing that sustainable practices often align with long-term economic viability and market acceptance.

Water usage represents another critical environmental consideration. Hydrothermal autoclave synthesis typically requires significant quantities of water, both as a reaction medium and for cooling purposes. In regions facing water scarcity, this intensive water consumption may pose sustainability challenges and compete with other essential water needs. Furthermore, post-synthesis waste streams often contain residual precursors, surfactants, and other chemicals that require proper treatment before discharge.

Chemical waste management constitutes a substantial environmental concern in autoclave synthesis operations. The process frequently employs various solvents, reducing agents, and stabilizers that may present toxicity risks if improperly handled. Particularly concerning are heavy metal precursors used in certain nanoparticle syntheses, which can persist in the environment and potentially enter food chains if not adequately contained and treated.

Recent advancements in green chemistry approaches have begun addressing these environmental challenges. Researchers are increasingly exploring bio-derived precursors, environmentally benign solvents, and lower-temperature autoclave protocols to reduce environmental impacts. The implementation of closed-loop systems that recycle solvents and recover unreacted precursors has demonstrated promising results in minimizing waste generation while maintaining nanoparticle uniformity.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative nanoparticle production methods reveal complex sustainability trade-offs. While autoclave methods may consume more energy during synthesis, the superior uniformity of resulting nanoparticles often translates to enhanced performance and longevity in final applications. This improved functionality can potentially offset initial environmental costs through reduced material requirements and extended product lifespans.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in nanomaterial production. Manufacturers employing autoclave synthesis must navigate evolving compliance requirements related to emissions, waste disposal, and worker safety. Forward-thinking companies are proactively implementing environmental management systems that exceed regulatory minimums, recognizing that sustainable practices often align with long-term economic viability and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!