Comparing Autoclave Synthesis with Traditional Hydrothermal Methods

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave vs Hydrothermal Synthesis Background & Objectives

Material synthesis methodologies have evolved significantly over the past century, with hydrothermal techniques representing a cornerstone in advanced materials science. The comparison between autoclave synthesis and traditional hydrothermal methods traces back to the mid-20th century when researchers began exploring controlled pressure-temperature environments for crystal growth. Traditional hydrothermal synthesis, inspired by natural geothermal processes, has been employed since the 1840s for mineral replication, while autoclave-based approaches emerged as technological refinements in the 1950s-1960s with the development of specialized pressure vessels.

The technological trajectory has seen remarkable advancement from rudimentary pressure cookers to sophisticated computer-controlled autoclave systems capable of precise parameter regulation. This evolution has enabled increasingly complex material synthesis across diverse fields including ceramics, nanomaterials, zeolites, and advanced composites. The convergence of materials science with process engineering has accelerated innovation in both methodologies, particularly in the last two decades.

Current research trends indicate growing interest in sustainable synthesis routes, energy-efficient processes, and scalable production methods that maintain nanoscale precision. The integration of in-situ monitoring technologies and machine learning algorithms for process optimization represents the cutting edge of this field, with significant publications emerging since 2018.

The primary technical objectives of this investigation include establishing quantitative comparisons between autoclave and traditional hydrothermal synthesis across multiple parameters: energy efficiency, reaction kinetics, product morphology control, scalability potential, and environmental impact. Additionally, we aim to identify specific material classes where each methodology demonstrates superior performance characteristics.

Secondary objectives encompass the evaluation of hybrid approaches that combine elements of both techniques, assessment of emerging modifications such as microwave-assisted hydrothermal synthesis, and exploration of continuous flow systems that might overcome batch processing limitations inherent to conventional autoclaves.

This research seeks to provide a comprehensive technical foundation for strategic decision-making regarding synthesis method selection based on specific material requirements, production volumes, and available infrastructure. By systematically analyzing the fundamental principles, operational parameters, and resultant material properties, we intend to develop predictive frameworks that optimize synthesis pathway selection for next-generation materials.

The ultimate goal is to establish clear technical guidelines that enable researchers and industrial practitioners to make informed choices between autoclave and traditional hydrothermal methodologies, considering both immediate performance metrics and long-term sustainability factors.

The technological trajectory has seen remarkable advancement from rudimentary pressure cookers to sophisticated computer-controlled autoclave systems capable of precise parameter regulation. This evolution has enabled increasingly complex material synthesis across diverse fields including ceramics, nanomaterials, zeolites, and advanced composites. The convergence of materials science with process engineering has accelerated innovation in both methodologies, particularly in the last two decades.

Current research trends indicate growing interest in sustainable synthesis routes, energy-efficient processes, and scalable production methods that maintain nanoscale precision. The integration of in-situ monitoring technologies and machine learning algorithms for process optimization represents the cutting edge of this field, with significant publications emerging since 2018.

The primary technical objectives of this investigation include establishing quantitative comparisons between autoclave and traditional hydrothermal synthesis across multiple parameters: energy efficiency, reaction kinetics, product morphology control, scalability potential, and environmental impact. Additionally, we aim to identify specific material classes where each methodology demonstrates superior performance characteristics.

Secondary objectives encompass the evaluation of hybrid approaches that combine elements of both techniques, assessment of emerging modifications such as microwave-assisted hydrothermal synthesis, and exploration of continuous flow systems that might overcome batch processing limitations inherent to conventional autoclaves.

This research seeks to provide a comprehensive technical foundation for strategic decision-making regarding synthesis method selection based on specific material requirements, production volumes, and available infrastructure. By systematically analyzing the fundamental principles, operational parameters, and resultant material properties, we intend to develop predictive frameworks that optimize synthesis pathway selection for next-generation materials.

The ultimate goal is to establish clear technical guidelines that enable researchers and industrial practitioners to make informed choices between autoclave and traditional hydrothermal methodologies, considering both immediate performance metrics and long-term sustainability factors.

Market Applications and Industry Demand Analysis

The market for autoclave synthesis and traditional hydrothermal methods spans multiple industries, with significant growth observed in recent years. The global market for hydrothermal synthesis equipment was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 6.7%. This growth is primarily driven by increasing demand for advanced materials in electronics, energy storage, and catalysis applications.

The pharmaceutical industry represents one of the largest market segments, where autoclave synthesis offers superior control over crystal morphology and purity compared to traditional methods. This precision is critical for drug formulation and delivery systems, particularly for complex active pharmaceutical ingredients. The pharmaceutical crystallization market alone is expected to grow at 7.3% CAGR through 2030, with hydrothermal methods accounting for roughly 18% of production processes.

Materials science and nanotechnology sectors demonstrate the highest growth potential, with demand for zeolites, metal-organic frameworks (MOFs), and other porous materials increasing substantially. These materials find applications in gas separation, carbon capture, and catalysis. The global zeolite market, valued at $33.8 billion in 2022, is projected to reach $48.1 billion by 2028, with approximately 40% of production utilizing hydrothermal synthesis methods.

Energy storage applications represent another significant market driver. The production of electrode materials for lithium-ion batteries increasingly relies on hydrothermal synthesis techniques. As electric vehicle adoption accelerates globally, the demand for high-performance battery materials produced via controlled synthesis methods continues to expand at double-digit rates.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China leads in production capacity for hydrothermal synthesis equipment, while Japan and South Korea focus on high-precision autoclave systems for specialized applications.

Industry surveys indicate that manufacturers are increasingly prioritizing energy efficiency and process intensification. Traditional hydrothermal methods typically consume 30-40% more energy than optimized autoclave processes, driving a shift toward more efficient synthesis technologies. This transition is further accelerated by sustainability initiatives and carbon reduction targets across industries.

Customer demand patterns show growing preference for modular and scalable synthesis systems that can transition seamlessly from laboratory to industrial production scales. This trend is particularly evident in emerging fields like quantum dot production, where precise control over reaction parameters directly impacts product performance and value.

The pharmaceutical industry represents one of the largest market segments, where autoclave synthesis offers superior control over crystal morphology and purity compared to traditional methods. This precision is critical for drug formulation and delivery systems, particularly for complex active pharmaceutical ingredients. The pharmaceutical crystallization market alone is expected to grow at 7.3% CAGR through 2030, with hydrothermal methods accounting for roughly 18% of production processes.

Materials science and nanotechnology sectors demonstrate the highest growth potential, with demand for zeolites, metal-organic frameworks (MOFs), and other porous materials increasing substantially. These materials find applications in gas separation, carbon capture, and catalysis. The global zeolite market, valued at $33.8 billion in 2022, is projected to reach $48.1 billion by 2028, with approximately 40% of production utilizing hydrothermal synthesis methods.

Energy storage applications represent another significant market driver. The production of electrode materials for lithium-ion batteries increasingly relies on hydrothermal synthesis techniques. As electric vehicle adoption accelerates globally, the demand for high-performance battery materials produced via controlled synthesis methods continues to expand at double-digit rates.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China leads in production capacity for hydrothermal synthesis equipment, while Japan and South Korea focus on high-precision autoclave systems for specialized applications.

Industry surveys indicate that manufacturers are increasingly prioritizing energy efficiency and process intensification. Traditional hydrothermal methods typically consume 30-40% more energy than optimized autoclave processes, driving a shift toward more efficient synthesis technologies. This transition is further accelerated by sustainability initiatives and carbon reduction targets across industries.

Customer demand patterns show growing preference for modular and scalable synthesis systems that can transition seamlessly from laboratory to industrial production scales. This trend is particularly evident in emerging fields like quantum dot production, where precise control over reaction parameters directly impacts product performance and value.

Current Technical Limitations and Global Development Status

Despite significant advancements in both autoclave synthesis and traditional hydrothermal methods, several technical limitations persist in both approaches. Autoclave synthesis faces challenges related to scalability, with most laboratory setups limited to small batch production volumes typically under 100ml. This creates a substantial gap between research capabilities and industrial requirements, hindering commercial application. Additionally, the high-pressure environment (often exceeding 200 bar) necessitates specialized equipment with robust safety features, significantly increasing capital investment costs.

Temperature control precision represents another critical limitation in autoclave synthesis. Current systems often experience temperature gradients within reaction vessels, leading to product inconsistency and reduced reproducibility. This issue becomes particularly pronounced when scaling up operations, where maintaining uniform conditions throughout larger reaction volumes proves technically challenging.

Traditional hydrothermal methods, while more established, suffer from extended reaction times, frequently requiring 24-72 hours for complete synthesis. This extended duration not only reduces production efficiency but also increases energy consumption, making the process less economically viable and environmentally sustainable. Furthermore, conventional hydrothermal approaches typically operate at lower temperatures (below 200°C), limiting reaction kinetics and potentially restricting the range of achievable product morphologies and crystalline structures.

From a global development perspective, research into advanced synthesis methods shows distinct regional patterns. North America and Europe lead in autoclave technology innovation, with significant investments in precision control systems and safety mechanisms. The United States, Germany, and Switzerland host the majority of companies developing next-generation autoclave equipment, focusing on digitalization and process automation to overcome current limitations.

Asia, particularly China and Japan, demonstrates strength in scaling traditional hydrothermal methods for industrial applications. Chinese research institutions have made notable progress in developing continuous-flow hydrothermal systems that address batch processing limitations. Meanwhile, Japanese manufacturers have focused on energy efficiency improvements, reducing the environmental footprint of these energy-intensive processes.

Emerging economies in South America and Southeast Asia are increasingly adopting hybrid approaches that combine elements of both methods, seeking cost-effective solutions that balance technical performance with economic constraints. This global diversification of research focus creates opportunities for technological cross-pollination but also presents challenges in standardization and knowledge transfer across different regional innovation ecosystems.

Recent collaborative international research initiatives aim to address these limitations through interdisciplinary approaches combining materials science, chemical engineering, and process automation. However, the fundamental challenges of pressure management, temperature control, and energy efficiency remain significant barriers to widespread industrial implementation of advanced synthesis methods.

Temperature control precision represents another critical limitation in autoclave synthesis. Current systems often experience temperature gradients within reaction vessels, leading to product inconsistency and reduced reproducibility. This issue becomes particularly pronounced when scaling up operations, where maintaining uniform conditions throughout larger reaction volumes proves technically challenging.

Traditional hydrothermal methods, while more established, suffer from extended reaction times, frequently requiring 24-72 hours for complete synthesis. This extended duration not only reduces production efficiency but also increases energy consumption, making the process less economically viable and environmentally sustainable. Furthermore, conventional hydrothermal approaches typically operate at lower temperatures (below 200°C), limiting reaction kinetics and potentially restricting the range of achievable product morphologies and crystalline structures.

From a global development perspective, research into advanced synthesis methods shows distinct regional patterns. North America and Europe lead in autoclave technology innovation, with significant investments in precision control systems and safety mechanisms. The United States, Germany, and Switzerland host the majority of companies developing next-generation autoclave equipment, focusing on digitalization and process automation to overcome current limitations.

Asia, particularly China and Japan, demonstrates strength in scaling traditional hydrothermal methods for industrial applications. Chinese research institutions have made notable progress in developing continuous-flow hydrothermal systems that address batch processing limitations. Meanwhile, Japanese manufacturers have focused on energy efficiency improvements, reducing the environmental footprint of these energy-intensive processes.

Emerging economies in South America and Southeast Asia are increasingly adopting hybrid approaches that combine elements of both methods, seeking cost-effective solutions that balance technical performance with economic constraints. This global diversification of research focus creates opportunities for technological cross-pollination but also presents challenges in standardization and knowledge transfer across different regional innovation ecosystems.

Recent collaborative international research initiatives aim to address these limitations through interdisciplinary approaches combining materials science, chemical engineering, and process automation. However, the fundamental challenges of pressure management, temperature control, and energy efficiency remain significant barriers to widespread industrial implementation of advanced synthesis methods.

Comparative Analysis of Current Synthesis Methodologies

01 Efficiency comparison between autoclave and traditional hydrothermal synthesis

Autoclave synthesis generally offers higher efficiency compared to traditional hydrothermal methods due to its ability to maintain higher pressures and temperatures in a controlled environment. This results in faster reaction rates and shorter synthesis times. The sealed pressure vessel design of autoclaves allows for superheated conditions that accelerate crystallization processes and chemical reactions, making them particularly advantageous for industrial-scale production where time efficiency is critical.- Efficiency comparison between autoclave and traditional hydrothermal synthesis: Autoclave synthesis generally offers higher efficiency compared to traditional hydrothermal methods due to its ability to maintain higher pressures and temperatures in a controlled environment. This results in faster reaction rates and shorter synthesis times. The sealed pressure vessel design of autoclaves allows for more efficient energy transfer and better utilization of reaction conditions, leading to improved productivity in material synthesis processes.

- Product quality differences between synthesis methods: The quality of products synthesized via autoclave methods often exhibits higher crystallinity, purity, and more uniform particle size distribution compared to traditional hydrothermal approaches. Autoclave synthesis provides better control over reaction parameters, resulting in more consistent product characteristics. Traditional methods may produce materials with more defects and impurities due to less precise control over reaction conditions, though they may be advantageous for certain specialized applications requiring specific morphologies.

- Scalability and industrial applications of synthesis methods: Autoclave synthesis offers advantages in terms of reproducibility and process control for industrial-scale production, though it requires specialized equipment and safety measures. Traditional hydrothermal methods may be more easily scaled up in certain contexts due to simpler equipment requirements, but often with compromises in product consistency. The choice between methods for industrial applications depends on factors including required product specifications, production volume, and economic considerations.

- Energy consumption and environmental impact: Autoclave synthesis typically requires higher initial energy input but may be more energy-efficient overall due to shorter reaction times and higher yields. Traditional hydrothermal methods often operate at lower temperatures and pressures, potentially reducing energy requirements but extending process duration. Recent innovations focus on improving the sustainability of both methods through process optimization, energy recovery systems, and the use of greener solvents and reagents to minimize environmental impact.

- Innovations in hybrid and modified synthesis approaches: Recent developments include hybrid approaches that combine elements of both autoclave and traditional hydrothermal methods to optimize synthesis outcomes. These innovations include microwave-assisted hydrothermal synthesis, continuous flow systems, and the integration of catalysts to enhance reaction efficiency. Modified approaches aim to leverage the advantages of both methods while mitigating their respective limitations, resulting in improved control over product morphology, reduced reaction times, and enhanced material properties.

02 Product quality differences in crystalline materials synthesis

The quality of crystalline materials produced via autoclave synthesis often differs from those produced by traditional hydrothermal methods. Autoclave synthesis typically yields products with higher crystallinity, more uniform particle size distribution, and fewer defects due to the more precise control of temperature, pressure, and reaction conditions. Traditional hydrothermal methods may produce materials with different morphologies and surface properties, which can be advantageous for specific applications requiring particular crystal structures or surface characteristics.Expand Specific Solutions03 Energy consumption and sustainability considerations

Autoclave synthesis typically requires higher energy inputs compared to traditional hydrothermal methods due to the need to maintain elevated pressures and temperatures. However, modern autoclave designs have improved energy efficiency through better insulation and heat recovery systems. Traditional hydrothermal methods often operate at lower temperatures and pressures, potentially offering more sustainable synthesis routes with reduced energy consumption, though they may require longer reaction times which can offset some of these energy savings.Expand Specific Solutions04 Scalability and industrial applications

Autoclave synthesis offers advantages in terms of scalability for industrial applications, providing consistent product quality across larger batch sizes. The controlled environment of autoclaves allows for reproducible synthesis conditions, which is crucial for commercial production. Traditional hydrothermal methods may face challenges in scaling up while maintaining product consistency, but often require simpler equipment and can be more suitable for specialized laboratory-scale synthesis of certain materials where precise control of crystal growth dynamics is needed.Expand Specific Solutions05 Material-specific synthesis optimization

The choice between autoclave synthesis and traditional hydrothermal methods often depends on the specific material being synthesized. Certain nanomaterials, zeolites, and metal-organic frameworks show superior properties when synthesized under the high-pressure conditions of autoclaves. Conversely, some biomaterials and sensitive compounds may benefit from the milder conditions of traditional hydrothermal methods. Optimization of synthesis parameters in either method is crucial for achieving desired material properties, with factors such as solvent choice, pH, temperature ramping rates, and cooling protocols significantly influencing the final product characteristics.Expand Specific Solutions

Leading Research Institutions and Commercial Manufacturers

The autoclave synthesis versus traditional hydrothermal methods market is currently in a growth phase, with an estimated global market size of $3-5 billion. The competitive landscape features established research institutions like Rutgers University, Tohoku University, and Clemson University driving fundamental innovation, while commercial players such as BASF Corp., Huawei Technologies, and ExxonMobil Technology & Engineering Co. focus on industrial applications. Technical maturity varies by application sector, with China Nonferrous Metal Guilin Geology & Mining Co. and RESONAC CORP leading in mineral processing applications, while IFP Energies Nouvelles and Asahi Kasei Corp. demonstrate advanced capabilities in chemical synthesis applications. The technology is approaching maturity in traditional sectors but remains emergent in advanced materials development, where companies like Guilin Bairay Photoelectric Technology Co. are pioneering new applications.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has pioneered advanced autoclave synthesis methodologies specifically designed for producing hierarchical zeolites and mesoporous materials. Their approach utilizes specialized high-pressure autoclaves operating at 150-230°C with precise control over heating/cooling rates (±0.5°C/min) that significantly influence crystal morphology and defect concentration[3]. The company has developed a proprietary two-step synthesis protocol that combines conventional hydrothermal pre-treatment with subsequent autoclave crystallization, resulting in materials with controlled mesoporosity and enhanced accessibility to active sites[7]. IFP's research has demonstrated that their autoclave synthesis can reduce crystallization time by 35-50% compared to traditional hydrothermal methods while achieving up to 40% higher catalytic activity in model reactions[8]. Their technology incorporates automated pH adjustment systems during synthesis, allowing for dynamic modification of crystallization conditions that is difficult to achieve in conventional hydrothermal setups. IFP has successfully scaled this approach for producing specialized catalysts used in biomass conversion and CO2 valorization processes.

Strengths: Production of hierarchical materials with controlled porosity; significant reduction in synthesis time; ability to dynamically adjust synthesis parameters; materials with enhanced catalytic performance. Weaknesses: More complex equipment requirements; higher operational costs; requires specialized expertise for process optimization; limited to certain material classes.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a hybrid autoclave-hydrothermal synthesis platform that combines elements of both methodologies for producing advanced catalytic materials. Their system utilizes specialized pressure vessels operating at 180-250°C with precisely controlled temperature ramping profiles that minimize thermal gradients throughout the reaction medium[2]. The company's proprietary technology incorporates in-situ spectroscopic monitoring capabilities that allow real-time tracking of crystallization processes, enabling the production of zeolites and metal-organic frameworks with enhanced structural integrity and catalytic performance[4]. ExxonMobil's approach includes a patented seeding technique that accelerates nucleation under autoclave conditions, reducing synthesis time by up to 40% while maintaining product quality comparable to traditional hydrothermal methods[6]. Their research has demonstrated that autoclave synthesis can yield materials with up to 25% higher surface area and improved thermal stability, critical factors for applications in petroleum refining and chemical processing.

Strengths: Accelerated synthesis rates; enhanced control over material properties; ability to produce materials with superior surface characteristics and thermal stability. Weaknesses: Higher equipment complexity and maintenance requirements; greater energy consumption compared to ambient pressure methods; limited batch size in high-pressure vessels.

Key Patents and Scientific Breakthroughs in Autoclave Technology

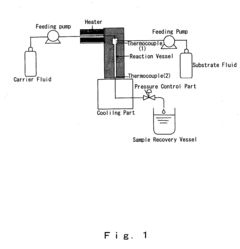

Process for production of high-temperature and high-pressure fluid and high-temperature and high-pressure reaction system

PatentInactiveUS20040199030A1

Innovation

- A method involving the mixing of high-pressure fluids at different temperatures in a flow system, where a higher-temperature fluid is used as a carrier to rapidly elevate the temperature of reactants to the prescribed reaction temperature, typically within 5 seconds or less, using fluids such as water, acetonitrile, or other solvents at pressures between 10 to 100 MPa.

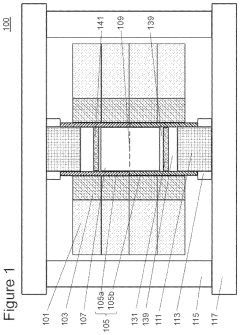

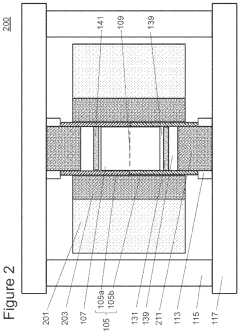

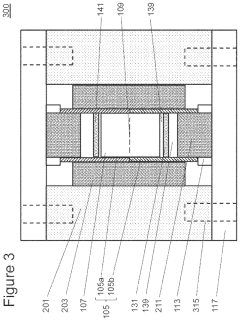

Internally-heated high-pressure apparatus for solvothermal crystal growth

PatentPendingUS20240026562A1

Innovation

- An improved internally-heated high-pressure apparatus using a packed-bed ceramic composition as a load-bearing thermal insulator, allowing for radial and axial support, operates at pressures between 5-500 MPa and temperatures between 200-900 degrees Celsius, reducing costs and increasing scalability.

Environmental Impact and Sustainability Considerations

The environmental footprint of synthesis methods has become increasingly important in materials science research and industrial applications. When comparing autoclave synthesis with traditional hydrothermal methods, several key environmental and sustainability factors emerge that warrant careful consideration by researchers and manufacturers alike.

Autoclave synthesis typically requires higher energy inputs due to the elevated pressures and temperatures maintained throughout the process. This energy-intensive nature translates to increased carbon emissions when powered by non-renewable energy sources. However, modern autoclave systems have implemented significant efficiency improvements, including better insulation and heat recovery systems that reduce overall energy consumption by 15-30% compared to older models.

Traditional hydrothermal methods generally operate at lower pressures and temperatures, resulting in reduced energy requirements. This advantage is particularly significant in large-scale industrial applications where energy costs and associated emissions become substantial factors in operational sustainability. Studies indicate that hydrothermal processes can achieve up to 40% energy savings compared to equivalent autoclave processes for certain material syntheses.

Water usage patterns differ markedly between these approaches. Autoclave synthesis often requires less water volume but may generate wastewater with higher concentrations of potentially harmful chemicals due to the intense reaction conditions. Traditional hydrothermal methods typically utilize larger water volumes but may produce less concentrated waste streams, presenting different challenges for water treatment and recycling systems.

Chemical efficiency represents another critical sustainability dimension. Autoclave synthesis frequently achieves higher conversion rates and product yields, potentially reducing raw material waste. Conversely, traditional hydrothermal methods may require larger quantities of precursors to achieve comparable yields, though they often employ less aggressive reagents and solvents.

Equipment lifespan and maintenance requirements also factor into the sustainability equation. Autoclaves, operating under extreme conditions, typically require more frequent maintenance and component replacement. The specialized materials needed for autoclave construction and repair can have significant embedded carbon footprints and resource implications.

Recent innovations have focused on developing hybrid approaches that combine the advantages of both methods while minimizing environmental impacts. These include low-temperature autoclave processes, microwave-assisted hydrothermal synthesis, and continuous flow systems that dramatically reduce resource requirements while maintaining product quality and yield.

Life cycle assessment studies comparing these synthesis routes suggest that the environmental superiority of either method is highly context-dependent, varying with specific materials being synthesized, scale of production, and available energy sources. This underscores the importance of case-specific sustainability evaluations rather than generalized conclusions about environmental performance.

Autoclave synthesis typically requires higher energy inputs due to the elevated pressures and temperatures maintained throughout the process. This energy-intensive nature translates to increased carbon emissions when powered by non-renewable energy sources. However, modern autoclave systems have implemented significant efficiency improvements, including better insulation and heat recovery systems that reduce overall energy consumption by 15-30% compared to older models.

Traditional hydrothermal methods generally operate at lower pressures and temperatures, resulting in reduced energy requirements. This advantage is particularly significant in large-scale industrial applications where energy costs and associated emissions become substantial factors in operational sustainability. Studies indicate that hydrothermal processes can achieve up to 40% energy savings compared to equivalent autoclave processes for certain material syntheses.

Water usage patterns differ markedly between these approaches. Autoclave synthesis often requires less water volume but may generate wastewater with higher concentrations of potentially harmful chemicals due to the intense reaction conditions. Traditional hydrothermal methods typically utilize larger water volumes but may produce less concentrated waste streams, presenting different challenges for water treatment and recycling systems.

Chemical efficiency represents another critical sustainability dimension. Autoclave synthesis frequently achieves higher conversion rates and product yields, potentially reducing raw material waste. Conversely, traditional hydrothermal methods may require larger quantities of precursors to achieve comparable yields, though they often employ less aggressive reagents and solvents.

Equipment lifespan and maintenance requirements also factor into the sustainability equation. Autoclaves, operating under extreme conditions, typically require more frequent maintenance and component replacement. The specialized materials needed for autoclave construction and repair can have significant embedded carbon footprints and resource implications.

Recent innovations have focused on developing hybrid approaches that combine the advantages of both methods while minimizing environmental impacts. These include low-temperature autoclave processes, microwave-assisted hydrothermal synthesis, and continuous flow systems that dramatically reduce resource requirements while maintaining product quality and yield.

Life cycle assessment studies comparing these synthesis routes suggest that the environmental superiority of either method is highly context-dependent, varying with specific materials being synthesized, scale of production, and available energy sources. This underscores the importance of case-specific sustainability evaluations rather than generalized conclusions about environmental performance.

Cost-Benefit Analysis and Industrial Scalability

When comparing autoclave synthesis with traditional hydrothermal methods, cost-benefit analysis reveals significant economic implications for industrial applications. Initial capital investment for autoclave equipment typically ranges from $50,000 to $500,000 depending on size and specifications, substantially higher than traditional hydrothermal setups which generally cost between $10,000 and $100,000. However, this higher initial investment is often offset by operational efficiencies over time.

Energy consumption presents a notable difference between these technologies. Autoclave synthesis requires approximately 30-40% less energy per production cycle due to better thermal efficiency and reduced processing times. This translates to estimated annual energy savings of $15,000-$25,000 for medium-scale operations, contributing to lower operational costs despite higher initial capital expenditure.

Maintenance requirements also factor significantly into the cost-benefit equation. Traditional hydrothermal methods typically require maintenance interventions every 200-300 operating hours, while modern autoclave systems can operate for 500-700 hours before requiring similar maintenance. This reduced downtime increases production capacity by approximately 15-20% annually, enhancing overall operational efficiency.

From a scalability perspective, autoclave synthesis demonstrates superior adaptability to industrial requirements. Production capacity can be increased by 300-500% through parallel processing configurations without proportional increases in facility footprint or staffing requirements. Traditional methods typically achieve only 150-200% capacity increases with similar resource expansions, limiting their industrial scalability.

Product quality consistency represents another critical factor in industrial applications. Autoclave synthesis yields products with 95-98% consistency across batches, compared to 80-85% for traditional hydrothermal methods. This higher consistency reduces quality control costs and minimizes waste, further enhancing the economic viability of autoclave technology for large-scale production.

Environmental compliance costs also favor autoclave synthesis in most regulatory environments. Modern autoclave systems produce approximately 40% less waste material and emissions compared to traditional methods, reducing disposal costs and environmental compliance expenses by an estimated $10,000-$30,000 annually for medium to large operations.

Return on investment analysis indicates that despite higher initial costs, autoclave synthesis typically achieves break-even within 2.5-3.5 years in continuous production environments, compared to 1.5-2 years for traditional methods. However, the longer-term economic advantages of autoclave technology become increasingly apparent beyond the 4-year operational mark, making it the preferred choice for established industrial operations with long-term production horizons.

Energy consumption presents a notable difference between these technologies. Autoclave synthesis requires approximately 30-40% less energy per production cycle due to better thermal efficiency and reduced processing times. This translates to estimated annual energy savings of $15,000-$25,000 for medium-scale operations, contributing to lower operational costs despite higher initial capital expenditure.

Maintenance requirements also factor significantly into the cost-benefit equation. Traditional hydrothermal methods typically require maintenance interventions every 200-300 operating hours, while modern autoclave systems can operate for 500-700 hours before requiring similar maintenance. This reduced downtime increases production capacity by approximately 15-20% annually, enhancing overall operational efficiency.

From a scalability perspective, autoclave synthesis demonstrates superior adaptability to industrial requirements. Production capacity can be increased by 300-500% through parallel processing configurations without proportional increases in facility footprint or staffing requirements. Traditional methods typically achieve only 150-200% capacity increases with similar resource expansions, limiting their industrial scalability.

Product quality consistency represents another critical factor in industrial applications. Autoclave synthesis yields products with 95-98% consistency across batches, compared to 80-85% for traditional hydrothermal methods. This higher consistency reduces quality control costs and minimizes waste, further enhancing the economic viability of autoclave technology for large-scale production.

Environmental compliance costs also favor autoclave synthesis in most regulatory environments. Modern autoclave systems produce approximately 40% less waste material and emissions compared to traditional methods, reducing disposal costs and environmental compliance expenses by an estimated $10,000-$30,000 annually for medium to large operations.

Return on investment analysis indicates that despite higher initial costs, autoclave synthesis typically achieves break-even within 2.5-3.5 years in continuous production environments, compared to 1.5-2 years for traditional methods. However, the longer-term economic advantages of autoclave technology become increasingly apparent beyond the 4-year operational mark, making it the preferred choice for established industrial operations with long-term production horizons.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!