Autoclave Synthesis Regulations in Industrial Polymer Production

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Evolution and Objectives

Autoclave synthesis technology in industrial polymer production has evolved significantly since its inception in the early 20th century. Initially developed as a batch process for high-pressure polymerization, autoclave technology represented a breakthrough in controlling polymer properties through precise manipulation of reaction conditions. The evolution began with basic pressure vessels capable of withstanding moderate pressures, advancing to today's sophisticated systems that integrate advanced monitoring, control systems, and safety mechanisms capable of operating under extreme conditions exceeding 3000 bar and temperatures up to 300°C.

The 1950s marked a pivotal era with the introduction of free-radical polymerization techniques in autoclaves, enabling the commercial production of polyethylene and other polymers with controlled molecular weight distributions. Subsequent decades witnessed substantial improvements in heat transfer efficiency, reaction control precision, and process automation, transforming autoclave synthesis from an art to a science-driven manufacturing process.

Current autoclave technology objectives center on enhancing sustainability, energy efficiency, and product quality while maintaining stringent safety standards. Key goals include reducing energy consumption by optimizing heating and cooling cycles, minimizing reaction times through improved catalyst systems, and developing more efficient mixing technologies to ensure homogeneous reaction conditions throughout the vessel volume.

Regulatory compliance represents another critical objective, with increasing focus on emissions control, worker safety protocols, and environmental impact mitigation. Modern autoclave systems must incorporate sophisticated monitoring systems to ensure compliance with evolving global regulations while maintaining production efficiency.

Digitalization and Industry 4.0 integration have emerged as transformative objectives, with manufacturers seeking to implement predictive maintenance systems, real-time quality control, and data-driven process optimization. These technologies aim to reduce downtime, improve batch-to-batch consistency, and enable more responsive production scheduling.

Material innovation drives further development, with research focused on enabling the synthesis of novel polymer architectures, including block copolymers, hyperbranched polymers, and materials with precisely controlled tacticity. These advanced materials demand increasingly sophisticated reaction control capabilities from autoclave systems.

Scale-up efficiency represents a persistent challenge, with objectives focused on developing modular autoclave designs that can facilitate seamless transition from laboratory to industrial production scales while maintaining product quality and process safety. This includes the development of computational fluid dynamics models and scale-up methodologies specific to high-pressure polymerization processes.

The 1950s marked a pivotal era with the introduction of free-radical polymerization techniques in autoclaves, enabling the commercial production of polyethylene and other polymers with controlled molecular weight distributions. Subsequent decades witnessed substantial improvements in heat transfer efficiency, reaction control precision, and process automation, transforming autoclave synthesis from an art to a science-driven manufacturing process.

Current autoclave technology objectives center on enhancing sustainability, energy efficiency, and product quality while maintaining stringent safety standards. Key goals include reducing energy consumption by optimizing heating and cooling cycles, minimizing reaction times through improved catalyst systems, and developing more efficient mixing technologies to ensure homogeneous reaction conditions throughout the vessel volume.

Regulatory compliance represents another critical objective, with increasing focus on emissions control, worker safety protocols, and environmental impact mitigation. Modern autoclave systems must incorporate sophisticated monitoring systems to ensure compliance with evolving global regulations while maintaining production efficiency.

Digitalization and Industry 4.0 integration have emerged as transformative objectives, with manufacturers seeking to implement predictive maintenance systems, real-time quality control, and data-driven process optimization. These technologies aim to reduce downtime, improve batch-to-batch consistency, and enable more responsive production scheduling.

Material innovation drives further development, with research focused on enabling the synthesis of novel polymer architectures, including block copolymers, hyperbranched polymers, and materials with precisely controlled tacticity. These advanced materials demand increasingly sophisticated reaction control capabilities from autoclave systems.

Scale-up efficiency represents a persistent challenge, with objectives focused on developing modular autoclave designs that can facilitate seamless transition from laboratory to industrial production scales while maintaining product quality and process safety. This includes the development of computational fluid dynamics models and scale-up methodologies specific to high-pressure polymerization processes.

Market Analysis for Autoclave-Produced Polymers

The global market for autoclave-produced polymers continues to expand significantly, driven by increasing demand across multiple industries including aerospace, automotive, construction, and healthcare. The autoclave polymerization process, known for producing high-quality polymers with superior mechanical properties, has established itself as a premium manufacturing method despite its higher production costs compared to alternative techniques.

Current market valuations indicate that autoclave-produced polymers represent approximately 28% of the high-performance polymer market, with annual growth rates consistently outpacing GDP growth in most developed economies. This segment is particularly strong in regions with advanced manufacturing capabilities such as North America, Western Europe, and parts of East Asia, where stringent quality requirements justify the higher production costs.

The aerospace sector remains the largest consumer of autoclave-produced polymers, accounting for nearly 40% of market demand. This dominance stems from the uncompromising quality requirements for structural components in aircraft manufacturing, where the superior void-free characteristics of autoclave-cured composites are essential for safety-critical applications.

Automotive applications represent the fastest-growing segment, with a compound annual growth rate of 7.3% over the past five years. This growth is primarily driven by the increasing adoption of lightweight materials in electric vehicles, where high-performance polymers contribute significantly to extending range capabilities through weight reduction while maintaining structural integrity.

Market analysis reveals a price premium of 30-45% for autoclave-produced polymers compared to those manufactured using alternative methods. Despite this premium, demand remains robust due to the performance advantages these materials offer in critical applications where failure is not an option.

Regional market distribution shows North America leading with 37% market share, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world accounting for the remaining 7%. However, the Asia-Pacific region is experiencing the most rapid growth as manufacturing capabilities in China, Japan, and South Korea continue to advance.

Consumer trends indicate increasing preference for environmentally sustainable production methods, creating both challenges and opportunities for autoclave polymer manufacturers. The high energy consumption associated with autoclave processes has prompted research into more efficient curing cycles and energy recovery systems to reduce the carbon footprint while maintaining product quality.

The competitive landscape features a mix of large diversified chemical companies and specialized polymer manufacturers, with market concentration increasing through strategic acquisitions aimed at securing proprietary technology and expanding application expertise.

Current market valuations indicate that autoclave-produced polymers represent approximately 28% of the high-performance polymer market, with annual growth rates consistently outpacing GDP growth in most developed economies. This segment is particularly strong in regions with advanced manufacturing capabilities such as North America, Western Europe, and parts of East Asia, where stringent quality requirements justify the higher production costs.

The aerospace sector remains the largest consumer of autoclave-produced polymers, accounting for nearly 40% of market demand. This dominance stems from the uncompromising quality requirements for structural components in aircraft manufacturing, where the superior void-free characteristics of autoclave-cured composites are essential for safety-critical applications.

Automotive applications represent the fastest-growing segment, with a compound annual growth rate of 7.3% over the past five years. This growth is primarily driven by the increasing adoption of lightweight materials in electric vehicles, where high-performance polymers contribute significantly to extending range capabilities through weight reduction while maintaining structural integrity.

Market analysis reveals a price premium of 30-45% for autoclave-produced polymers compared to those manufactured using alternative methods. Despite this premium, demand remains robust due to the performance advantages these materials offer in critical applications where failure is not an option.

Regional market distribution shows North America leading with 37% market share, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world accounting for the remaining 7%. However, the Asia-Pacific region is experiencing the most rapid growth as manufacturing capabilities in China, Japan, and South Korea continue to advance.

Consumer trends indicate increasing preference for environmentally sustainable production methods, creating both challenges and opportunities for autoclave polymer manufacturers. The high energy consumption associated with autoclave processes has prompted research into more efficient curing cycles and energy recovery systems to reduce the carbon footprint while maintaining product quality.

The competitive landscape features a mix of large diversified chemical companies and specialized polymer manufacturers, with market concentration increasing through strategic acquisitions aimed at securing proprietary technology and expanding application expertise.

Global Autoclave Technology Status and Barriers

Autoclave technology in industrial polymer production has reached varying levels of maturity across different regions globally. In North America and Western Europe, advanced autoclave systems with sophisticated control mechanisms dominate the market, featuring high-precision temperature and pressure management capabilities. These regions have established comprehensive regulatory frameworks governing autoclave operations, particularly focusing on safety standards and environmental impact mitigation. The technological landscape in these regions is characterized by significant automation and integration with digital monitoring systems.

In contrast, emerging economies in Asia, particularly China and India, are rapidly advancing their autoclave technologies but still face challenges in achieving the precision and efficiency levels of their Western counterparts. These regions are experiencing the fastest growth in autoclave technology adoption, driven by expanding manufacturing sectors and increasing demand for high-quality polymer products.

The primary technological barriers in autoclave synthesis include energy efficiency limitations, with current systems typically operating at 60-70% efficiency. Heat distribution uniformity remains problematic, particularly in large-scale industrial autoclaves, leading to inconsistent polymer quality across production batches. Pressure maintenance at optimal levels throughout the synthesis process presents significant engineering challenges, especially during extended production cycles.

Material constraints constitute another major barrier, as autoclave vessels must withstand extreme conditions while maintaining structural integrity. Current materials often face accelerated degradation under repeated high-pressure and high-temperature cycles, necessitating frequent maintenance and replacement. This degradation pattern significantly impacts operational costs and production continuity.

Regulatory disparities across regions create additional complexities for global manufacturers. While European standards emphasize environmental impact and worker safety, regulations in developing markets may prioritize production output and economic considerations. These regulatory differences necessitate region-specific autoclave designs and operational protocols, complicating standardization efforts for multinational corporations.

Scaling challenges persist as a significant barrier, with difficulties in maintaining reaction kinetics consistency when transitioning from laboratory-scale to industrial-scale production. The non-linear relationship between autoclave size and process parameters requires sophisticated mathematical modeling and control systems that remain imperfectly developed.

Recent technological innovations are addressing these barriers through advanced materials science, computational fluid dynamics for improved heat distribution modeling, and AI-driven process control systems. However, implementation of these solutions varies significantly across different regions and industry segments, creating an uneven global landscape of autoclave technology capabilities.

In contrast, emerging economies in Asia, particularly China and India, are rapidly advancing their autoclave technologies but still face challenges in achieving the precision and efficiency levels of their Western counterparts. These regions are experiencing the fastest growth in autoclave technology adoption, driven by expanding manufacturing sectors and increasing demand for high-quality polymer products.

The primary technological barriers in autoclave synthesis include energy efficiency limitations, with current systems typically operating at 60-70% efficiency. Heat distribution uniformity remains problematic, particularly in large-scale industrial autoclaves, leading to inconsistent polymer quality across production batches. Pressure maintenance at optimal levels throughout the synthesis process presents significant engineering challenges, especially during extended production cycles.

Material constraints constitute another major barrier, as autoclave vessels must withstand extreme conditions while maintaining structural integrity. Current materials often face accelerated degradation under repeated high-pressure and high-temperature cycles, necessitating frequent maintenance and replacement. This degradation pattern significantly impacts operational costs and production continuity.

Regulatory disparities across regions create additional complexities for global manufacturers. While European standards emphasize environmental impact and worker safety, regulations in developing markets may prioritize production output and economic considerations. These regulatory differences necessitate region-specific autoclave designs and operational protocols, complicating standardization efforts for multinational corporations.

Scaling challenges persist as a significant barrier, with difficulties in maintaining reaction kinetics consistency when transitioning from laboratory-scale to industrial-scale production. The non-linear relationship between autoclave size and process parameters requires sophisticated mathematical modeling and control systems that remain imperfectly developed.

Recent technological innovations are addressing these barriers through advanced materials science, computational fluid dynamics for improved heat distribution modeling, and AI-driven process control systems. However, implementation of these solutions varies significantly across different regions and industry segments, creating an uneven global landscape of autoclave technology capabilities.

Current Autoclave Synthesis Methodologies

01 Hydrothermal synthesis of nanomaterials

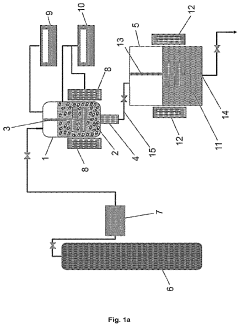

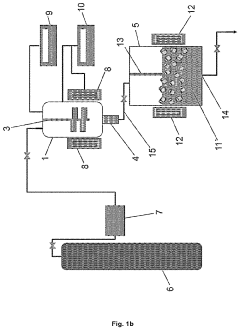

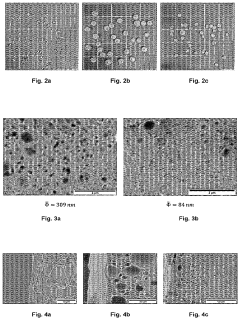

Autoclave synthesis is widely used for hydrothermal synthesis of various nanomaterials under controlled temperature and pressure conditions. This method enables the formation of crystalline structures with specific morphologies and properties. The process typically involves placing precursor materials in a sealed autoclave vessel with water or other solvents, then heating to create high-pressure conditions that facilitate crystal growth and formation of nanomaterials with desired characteristics.- Hydrothermal synthesis of nanomaterials: Autoclave synthesis is widely used for hydrothermal synthesis of nanomaterials under high temperature and pressure conditions. This method enables the controlled growth of crystalline structures with specific morphologies and properties. The process typically involves placing precursor solutions in sealed autoclaves and subjecting them to elevated temperatures, which creates the necessary conditions for crystal formation and growth. This technique is particularly valuable for producing advanced materials with applications in catalysis, energy storage, and electronics.

- Pharmaceutical and medical applications: Autoclave synthesis is employed in the pharmaceutical industry for the production of drug compounds and medical materials under sterile conditions. The high-pressure and high-temperature environment of autoclaves facilitates chemical reactions that might be difficult to achieve under ambient conditions, while simultaneously ensuring sterilization. This approach is particularly useful for synthesizing complex pharmaceutical compounds, biocompatible materials, and medical devices that require both precise chemical composition and sterility.

- Advanced composite materials production: Autoclaves are essential for the synthesis of advanced composite materials, particularly in aerospace and automotive industries. The controlled high-pressure and temperature environment enables proper curing and consolidation of polymer matrix composites, resulting in materials with superior mechanical properties. This process allows for the elimination of voids and ensures complete impregnation of reinforcement fibers with the matrix material, leading to high-quality composite structures with enhanced strength-to-weight ratios.

- Ceramic and inorganic material synthesis: Autoclave synthesis provides an effective method for producing ceramic and other inorganic materials with controlled properties. The hydrothermal conditions in autoclaves facilitate the formation of crystalline structures with specific characteristics, such as particle size, morphology, and purity. This approach is particularly valuable for synthesizing zeolites, metal oxides, and other functional ceramic materials used in catalysis, filtration, and electronic applications. The controlled environment allows for precise tailoring of material properties to meet specific application requirements.

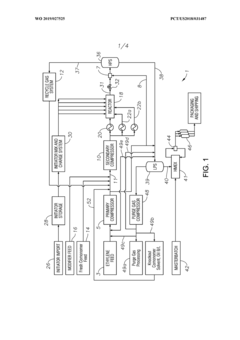

- Process control and automation in autoclave synthesis: Modern autoclave synthesis incorporates advanced process control and automation technologies to enhance reproducibility, safety, and efficiency. These systems include precise temperature and pressure monitoring, automated reaction sequence control, and safety mechanisms to prevent equipment failure. Innovations in this area focus on improving energy efficiency, reducing cycle times, and enabling more complex synthesis protocols while maintaining strict quality control. These advancements have made autoclave synthesis more accessible and reliable for both research and industrial applications.

02 Autoclave equipment design and optimization

Specialized autoclave equipment designs are crucial for different synthesis applications, featuring innovations in pressure control systems, heating mechanisms, and vessel materials. These designs include safety features to manage high-pressure conditions, temperature monitoring systems, and specialized sealing mechanisms. Advanced autoclaves may incorporate stirring capabilities, precise temperature control, and automated operation systems to ensure consistent synthesis results and improved process efficiency.Expand Specific Solutions03 Pharmaceutical and medical material synthesis

Autoclave synthesis is employed in pharmaceutical and medical applications for producing sterile materials, drug formulations, and biocompatible compounds. The high-pressure and high-temperature conditions in autoclaves facilitate chemical reactions that might be difficult to achieve under ambient conditions, while simultaneously ensuring sterility of the final products. This approach is particularly valuable for synthesizing complex pharmaceutical compounds and medical materials with specific properties.Expand Specific Solutions04 Ceramic and inorganic material synthesis

Autoclave synthesis methods are effective for producing various ceramic and inorganic materials with controlled composition and microstructure. The high-pressure environment in autoclaves enables the formation of dense ceramic materials and facilitates reactions between solid precursors. This technique allows for the synthesis of advanced ceramics, zeolites, and other inorganic compounds with specific properties for applications in catalysis, electronics, and structural materials.Expand Specific Solutions05 Green synthesis and sustainable processing

Autoclave synthesis offers environmentally friendly approaches to material production by enabling reactions in closed systems with minimal waste generation. The controlled environment allows for efficient use of reagents and solvents, often requiring lower quantities than conventional methods. Additionally, autoclave processes can utilize water as a reaction medium instead of harmful organic solvents, and the high efficiency of these reactions typically results in higher yields and reduced energy consumption compared to traditional synthesis methods.Expand Specific Solutions

Leading Industrial Polymer Autoclave Manufacturers

The autoclave synthesis regulations in industrial polymer production landscape is characterized by a mature market with established players and evolving regulatory frameworks. The industry is currently in a consolidation phase, with global market size estimated at $15-20 billion and growing at 4-5% annually. Major petrochemical corporations like ExxonMobil Chemical, DuPont, Dow Global Technologies, and SABIC dominate with advanced autoclave technologies and comprehensive regulatory compliance systems. These companies have developed proprietary high-pressure polymerization processes with sophisticated safety protocols. Academic institutions such as Zhejiang University and Shandong University are collaborating with industry leaders like LG Chem and Univation Technologies to develop next-generation autoclave synthesis methods that meet increasingly stringent environmental and safety regulations while improving production efficiency.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed sophisticated autoclave synthesis regulations for industrial polymer production, particularly for specialty polyethylene and polypropylene grades. Their approach integrates advanced computational fluid dynamics modeling with physical process controls to optimize reaction conditions. ExxonMobil's autoclave technology features proprietary mixing elements that enhance heat transfer while maintaining precise temperature profiles (typically 150-280°C) throughout the reaction vessel. Their regulatory framework includes comprehensive risk assessment protocols specifically designed for high-pressure operations (1000-2500 bar), with automated safety interlocks that respond to deviations in critical process parameters. The company has implemented advanced catalyst injection systems that allow for precise dosing and distribution, resulting in more uniform polymer properties. ExxonMobil's autoclave regulations also address environmental considerations through closed-loop monomer recovery systems that capture and recycle unreacted materials, reducing emissions and improving resource efficiency.

Strengths: Exceptional process modeling capabilities leading to optimized reaction conditions; superior heat transfer technology minimizing temperature gradients; comprehensive safety systems with predictive maintenance capabilities. Weaknesses: Higher operational complexity requiring specialized operator training; greater initial capital investment compared to tubular reactors; somewhat limited production volumes for certain specialty grades.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered autoclave synthesis regulations for high-performance polymers, particularly focusing on fluoropolymers and specialty engineering resins. Their autoclave technology employs a staged pressure approach (ranging from 500-2500 bar) with proprietary agitation systems that ensure uniform heat distribution and prevent localized hotspots. DuPont's regulatory framework incorporates advanced process analytical technology (PAT) for real-time monitoring of polymerization kinetics, allowing for adaptive control of reaction parameters. Their autoclaves feature specialized corrosion-resistant alloys to handle aggressive monomers and initiators used in specialty polymer production. DuPont has developed comprehensive standard operating procedures that address critical safety parameters including emergency cooling systems, pressure relief mechanisms, and automated shutdown protocols that exceed industry standards for high-pressure vessel operations.

Strengths: Exceptional capability for producing high-performance specialty polymers with precise properties; superior corrosion resistance for handling aggressive chemical environments; comprehensive safety systems with redundant controls. Weaknesses: Higher production costs compared to conventional polymerization methods; longer cycle times for specialty polymers; limited batch sizes for certain high-performance materials.

Key Patents in Autoclave Polymer Processing

High pressure polymerisation process for producing ethylene copolymers

PatentWO2019027525A1

Innovation

- A process for producing ethylene copolymers in a tubular reactor by controlling reactor pressure, initiator inlet temperature, and modifier flow to achieve an autoclave-like molecular architecture, including broad molecular weight distribution and high long chain branching without sacrificing conversion rate and throughput.

Nanocellular expanded polymer beads, method of manufacture and uses

PatentPendingUS20240010809A1

Innovation

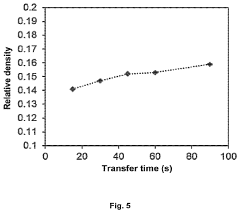

- The development of a bead foaming technology that uses dissolution foaming with inert gases to produce expanded polymer beads with cell sizes less than 1 μm and relative densities less than 0.25, optimizing the foaming process to reduce manufacturing times and minimize solid skin thickness.

Regulatory Framework for Industrial Autoclaves

The regulatory landscape governing industrial autoclave operations represents a complex matrix of international standards, national legislation, and industry-specific protocols. At the global level, organizations such as the International Organization for Standardization (ISO) have established comprehensive frameworks, particularly ISO 17665 for sterilization processes and ISO 9001 for quality management systems, which significantly influence autoclave operation standards in polymer production facilities worldwide.

In the United States, the Occupational Safety and Health Administration (OSHA) enforces stringent regulations concerning pressure vessel safety through 29 CFR 1910.106 and 1910.219, mandating regular inspections, certification, and specific operational protocols for industrial autoclaves. Complementing these federal regulations, the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code provides detailed technical specifications that have become de facto standards for autoclave design, construction, and maintenance.

European regulatory frameworks are primarily governed by the Pressure Equipment Directive (PED) 2014/68/EU, which establishes essential safety requirements for pressure equipment operating above 0.5 bar. This directive necessitates comprehensive risk assessments, technical documentation, and conformity assessment procedures before autoclave systems can be placed on the European market.

Environmental considerations have increasingly shaped regulatory requirements, with the Environmental Protection Agency (EPA) in the US and the European Environment Agency imposing strict controls on emissions, waste management, and energy efficiency in industrial autoclave operations. These regulations often necessitate the implementation of advanced monitoring systems and pollution control technologies.

Industry-specific regulations further refine these broader frameworks, with particular emphasis on polymer production processes. The Society of the Plastics Industry (SPI) has developed specialized guidelines addressing the unique challenges of autoclave-based polymer synthesis, including temperature control protocols, pressure management, and catalyst handling procedures.

Compliance verification mechanisms vary across jurisdictions but typically involve a combination of self-certification, third-party audits, and regulatory inspections. Documentation requirements are particularly stringent, encompassing operational logs, maintenance records, employee training certifications, and incident reports, all of which must be maintained for specified retention periods.

Recent regulatory trends indicate a movement toward harmonization of international standards, with increasing emphasis on risk-based approaches and performance-oriented requirements rather than prescriptive specifications. This evolution reflects the growing complexity of polymer synthesis technologies and the need for regulatory frameworks that can adapt to rapid technological innovation.

In the United States, the Occupational Safety and Health Administration (OSHA) enforces stringent regulations concerning pressure vessel safety through 29 CFR 1910.106 and 1910.219, mandating regular inspections, certification, and specific operational protocols for industrial autoclaves. Complementing these federal regulations, the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code provides detailed technical specifications that have become de facto standards for autoclave design, construction, and maintenance.

European regulatory frameworks are primarily governed by the Pressure Equipment Directive (PED) 2014/68/EU, which establishes essential safety requirements for pressure equipment operating above 0.5 bar. This directive necessitates comprehensive risk assessments, technical documentation, and conformity assessment procedures before autoclave systems can be placed on the European market.

Environmental considerations have increasingly shaped regulatory requirements, with the Environmental Protection Agency (EPA) in the US and the European Environment Agency imposing strict controls on emissions, waste management, and energy efficiency in industrial autoclave operations. These regulations often necessitate the implementation of advanced monitoring systems and pollution control technologies.

Industry-specific regulations further refine these broader frameworks, with particular emphasis on polymer production processes. The Society of the Plastics Industry (SPI) has developed specialized guidelines addressing the unique challenges of autoclave-based polymer synthesis, including temperature control protocols, pressure management, and catalyst handling procedures.

Compliance verification mechanisms vary across jurisdictions but typically involve a combination of self-certification, third-party audits, and regulatory inspections. Documentation requirements are particularly stringent, encompassing operational logs, maintenance records, employee training certifications, and incident reports, all of which must be maintained for specified retention periods.

Recent regulatory trends indicate a movement toward harmonization of international standards, with increasing emphasis on risk-based approaches and performance-oriented requirements rather than prescriptive specifications. This evolution reflects the growing complexity of polymer synthesis technologies and the need for regulatory frameworks that can adapt to rapid technological innovation.

Safety Standards and Risk Management

The autoclave synthesis process in industrial polymer production involves high-pressure and high-temperature conditions that present significant safety risks. Current safety standards for autoclave operations are governed by multiple regulatory frameworks, including OSHA Process Safety Management (PSM), EPA Risk Management Plan (RMP), and industry-specific standards like ASME Boiler and Pressure Vessel Code. These regulations establish minimum requirements for pressure vessel design, testing protocols, and operational parameters specific to polymer synthesis.

Risk assessment methodologies for autoclave operations have evolved significantly, with Hazard and Operability Studies (HAZOP) and Layer of Protection Analysis (LOPA) becoming standard practices. These systematic approaches identify potential failure modes, assess their consequences, and determine appropriate safeguards. Modern risk management frameworks increasingly incorporate quantitative risk assessment techniques that calculate the probability and severity of potential incidents, enabling more informed decision-making regarding safety investments.

Engineering controls represent the primary defense against autoclave hazards. These include pressure relief systems designed to prevent catastrophic vessel failure, automated emergency shutdown systems that respond to process deviations, and sophisticated monitoring equipment that provides real-time data on critical parameters such as temperature, pressure, and agitation speed. Recent technological advances have introduced smart sensors capable of detecting early warning signs of runaway reactions.

Personnel safety protocols have become increasingly comprehensive, requiring specialized training for operators and maintenance staff. This includes emergency response procedures, proper handling of catalyst systems, and understanding of polymer reaction kinetics. Personal protective equipment requirements have also become more stringent, with specifications for heat-resistant clothing, face shields, and respiratory protection when handling potentially hazardous monomers or additives.

Documentation and compliance verification systems have grown more sophisticated, with electronic batch records and automated compliance checking becoming industry standards. These systems maintain detailed logs of all process parameters, operator actions, and equipment maintenance, creating an audit trail that facilitates regulatory inspections and internal quality assurance reviews. Many facilities now implement digital management systems that track safety incidents, near-misses, and corrective actions.

Incident investigation protocols have been standardized across the industry, with root cause analysis methodologies applied to all safety events. Lessons learned from these investigations are increasingly shared through industry associations and regulatory bulletins, creating a collective knowledge base that enhances safety practices across the sector. This collaborative approach to safety management has contributed to a significant reduction in autoclave-related incidents over the past decade.

Risk assessment methodologies for autoclave operations have evolved significantly, with Hazard and Operability Studies (HAZOP) and Layer of Protection Analysis (LOPA) becoming standard practices. These systematic approaches identify potential failure modes, assess their consequences, and determine appropriate safeguards. Modern risk management frameworks increasingly incorporate quantitative risk assessment techniques that calculate the probability and severity of potential incidents, enabling more informed decision-making regarding safety investments.

Engineering controls represent the primary defense against autoclave hazards. These include pressure relief systems designed to prevent catastrophic vessel failure, automated emergency shutdown systems that respond to process deviations, and sophisticated monitoring equipment that provides real-time data on critical parameters such as temperature, pressure, and agitation speed. Recent technological advances have introduced smart sensors capable of detecting early warning signs of runaway reactions.

Personnel safety protocols have become increasingly comprehensive, requiring specialized training for operators and maintenance staff. This includes emergency response procedures, proper handling of catalyst systems, and understanding of polymer reaction kinetics. Personal protective equipment requirements have also become more stringent, with specifications for heat-resistant clothing, face shields, and respiratory protection when handling potentially hazardous monomers or additives.

Documentation and compliance verification systems have grown more sophisticated, with electronic batch records and automated compliance checking becoming industry standards. These systems maintain detailed logs of all process parameters, operator actions, and equipment maintenance, creating an audit trail that facilitates regulatory inspections and internal quality assurance reviews. Many facilities now implement digital management systems that track safety incidents, near-misses, and corrective actions.

Incident investigation protocols have been standardized across the industry, with root cause analysis methodologies applied to all safety events. Lessons learned from these investigations are increasingly shared through industry associations and regulatory bulletins, creating a collective knowledge base that enhances safety practices across the sector. This collaborative approach to safety management has contributed to a significant reduction in autoclave-related incidents over the past decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!