Autoclave Synthesis and Its Impact on Electrode Kinetics

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis represents a pivotal hydrothermal technique in materials science that has evolved significantly over the past century. This method involves the crystallization of substances from high-temperature aqueous solutions at high vapor pressures, typically conducted in sealed vessels called autoclaves. The historical development of autoclave synthesis can be traced back to the early 20th century, with substantial advancements occurring post-1950s when materials scientists began exploring its potential for synthesizing novel compounds with unique properties.

The technique has gained prominence due to its ability to create conditions that mimic natural mineral formation processes, allowing for the controlled synthesis of materials that would otherwise require extreme geological timeframes. In recent years, autoclave synthesis has become increasingly sophisticated, incorporating precise temperature control, pressure monitoring systems, and specialized liner materials to prevent contamination and enhance reproducibility.

Current technological trends in autoclave synthesis include the integration of in-situ monitoring capabilities, automation of process parameters, and scaling methodologies for industrial applications. The field is witnessing a shift toward more environmentally sustainable approaches, with research focusing on reducing reaction temperatures, shortening synthesis times, and utilizing greener precursors and solvents.

In the context of electrode materials, autoclave synthesis has emerged as a critical method for developing high-performance components for energy storage and conversion devices. The hydrothermal conditions facilitated by autoclaves enable the formation of materials with controlled morphology, crystallinity, and surface properties—all factors that significantly influence electrode kinetics and, consequently, device performance.

The primary objectives of investigating autoclave synthesis in relation to electrode kinetics are multifaceted. First, to establish clear correlations between synthesis parameters (temperature, pressure, duration, precursor concentration) and the resulting electrode material properties. Second, to optimize these parameters for enhancing specific electrochemical characteristics such as charge transfer rates, ion diffusion coefficients, and reaction mechanisms at electrode interfaces.

Additionally, this research aims to develop predictive models that can guide the design of next-generation electrode materials with tailored kinetic properties. By understanding the fundamental relationships between synthesis conditions and electrochemical behavior, researchers seek to overcome current limitations in energy storage and conversion technologies, particularly regarding power density, cycling stability, and rate capability.

The ultimate goal is to leverage autoclave synthesis as a versatile platform for creating electrode materials that can meet the increasing demands of emerging technologies, from grid-scale energy storage to portable electronics and electric vehicles, while addressing broader concerns about resource sustainability and environmental impact.

The technique has gained prominence due to its ability to create conditions that mimic natural mineral formation processes, allowing for the controlled synthesis of materials that would otherwise require extreme geological timeframes. In recent years, autoclave synthesis has become increasingly sophisticated, incorporating precise temperature control, pressure monitoring systems, and specialized liner materials to prevent contamination and enhance reproducibility.

Current technological trends in autoclave synthesis include the integration of in-situ monitoring capabilities, automation of process parameters, and scaling methodologies for industrial applications. The field is witnessing a shift toward more environmentally sustainable approaches, with research focusing on reducing reaction temperatures, shortening synthesis times, and utilizing greener precursors and solvents.

In the context of electrode materials, autoclave synthesis has emerged as a critical method for developing high-performance components for energy storage and conversion devices. The hydrothermal conditions facilitated by autoclaves enable the formation of materials with controlled morphology, crystallinity, and surface properties—all factors that significantly influence electrode kinetics and, consequently, device performance.

The primary objectives of investigating autoclave synthesis in relation to electrode kinetics are multifaceted. First, to establish clear correlations between synthesis parameters (temperature, pressure, duration, precursor concentration) and the resulting electrode material properties. Second, to optimize these parameters for enhancing specific electrochemical characteristics such as charge transfer rates, ion diffusion coefficients, and reaction mechanisms at electrode interfaces.

Additionally, this research aims to develop predictive models that can guide the design of next-generation electrode materials with tailored kinetic properties. By understanding the fundamental relationships between synthesis conditions and electrochemical behavior, researchers seek to overcome current limitations in energy storage and conversion technologies, particularly regarding power density, cycling stability, and rate capability.

The ultimate goal is to leverage autoclave synthesis as a versatile platform for creating electrode materials that can meet the increasing demands of emerging technologies, from grid-scale energy storage to portable electronics and electric vehicles, while addressing broader concerns about resource sustainability and environmental impact.

Market Demand Analysis for Advanced Electrode Materials

The global market for advanced electrode materials is experiencing robust growth, driven primarily by the expanding electric vehicle (EV) industry, renewable energy storage systems, and portable electronics. Current market valuations indicate that the advanced electrode materials sector is projected to reach approximately $15 billion by 2027, with a compound annual growth rate exceeding 8% between 2022 and 2027. This growth trajectory is particularly significant for materials synthesized through autoclave methods, which offer enhanced electrochemical performance characteristics.

Consumer electronics manufacturers are increasingly demanding electrode materials with superior kinetic properties to enable faster charging capabilities and extended device lifetimes. This demand is reflected in recent industry surveys where 78% of smartphone and laptop manufacturers identified electrode kinetics as a critical factor in their component selection process. The automotive sector represents another substantial market segment, with major manufacturers investing heavily in research partnerships focused on autoclave-synthesized electrode materials that can improve EV battery performance.

Energy storage systems for grid applications constitute a rapidly expanding market segment, with utility companies seeking electrode materials that demonstrate consistent performance under varying operational conditions. The superior structural integrity and electrochemical stability of autoclave-synthesized materials make them particularly attractive for these applications, where long-term reliability is paramount.

Regional analysis reveals that Asia-Pacific currently dominates the market consumption of advanced electrode materials, accounting for approximately 45% of global demand. This is primarily attributed to the concentration of battery manufacturing facilities in China, Japan, and South Korea. North America and Europe follow with significant market shares, driven by aggressive electrification policies and substantial investments in renewable energy infrastructure.

The market is also witnessing a shift toward environmentally sustainable production methods. Consumers and regulatory bodies are increasingly prioritizing electrode materials manufactured through processes with reduced environmental footprints. This trend favors autoclave synthesis techniques that can be optimized for energy efficiency and reduced waste generation compared to conventional high-temperature calcination methods.

Industry forecasts suggest that materials demonstrating superior electrode kinetics will command premium pricing, with manufacturers willing to pay up to 30% more for materials that can deliver measurable improvements in device performance. This price premium represents a significant opportunity for innovators in autoclave synthesis technology who can develop scalable production methods while maintaining the enhanced kinetic properties that differentiate these materials in the marketplace.

Consumer electronics manufacturers are increasingly demanding electrode materials with superior kinetic properties to enable faster charging capabilities and extended device lifetimes. This demand is reflected in recent industry surveys where 78% of smartphone and laptop manufacturers identified electrode kinetics as a critical factor in their component selection process. The automotive sector represents another substantial market segment, with major manufacturers investing heavily in research partnerships focused on autoclave-synthesized electrode materials that can improve EV battery performance.

Energy storage systems for grid applications constitute a rapidly expanding market segment, with utility companies seeking electrode materials that demonstrate consistent performance under varying operational conditions. The superior structural integrity and electrochemical stability of autoclave-synthesized materials make them particularly attractive for these applications, where long-term reliability is paramount.

Regional analysis reveals that Asia-Pacific currently dominates the market consumption of advanced electrode materials, accounting for approximately 45% of global demand. This is primarily attributed to the concentration of battery manufacturing facilities in China, Japan, and South Korea. North America and Europe follow with significant market shares, driven by aggressive electrification policies and substantial investments in renewable energy infrastructure.

The market is also witnessing a shift toward environmentally sustainable production methods. Consumers and regulatory bodies are increasingly prioritizing electrode materials manufactured through processes with reduced environmental footprints. This trend favors autoclave synthesis techniques that can be optimized for energy efficiency and reduced waste generation compared to conventional high-temperature calcination methods.

Industry forecasts suggest that materials demonstrating superior electrode kinetics will command premium pricing, with manufacturers willing to pay up to 30% more for materials that can deliver measurable improvements in device performance. This price premium represents a significant opportunity for innovators in autoclave synthesis technology who can develop scalable production methods while maintaining the enhanced kinetic properties that differentiate these materials in the marketplace.

Current Challenges in Autoclave Synthesis Technology

Despite significant advancements in autoclave synthesis technology, several critical challenges continue to impede optimal performance and widespread industrial adoption. The high-pressure and high-temperature conditions required for autoclave synthesis present substantial safety concerns, necessitating robust containment systems and rigorous operational protocols. These safety requirements significantly increase operational costs and complexity, limiting accessibility for smaller research facilities and companies.

Energy consumption remains a major challenge, as maintaining elevated temperatures and pressures for extended periods demands considerable power input. This energy-intensive nature not only increases production costs but also raises environmental sustainability concerns, particularly in an era of growing climate awareness and regulatory pressure for reduced carbon footprints.

Scalability presents another significant hurdle. While autoclave synthesis can be effectively implemented at laboratory scale, transitioning to industrial production volumes often encounters efficiency losses and technical complications. The non-linear scaling relationships between reactor size, heat transfer, and reaction kinetics create complex engineering problems that remain incompletely solved.

Process control and reproducibility issues persist across the field. Maintaining precise and uniform conditions throughout the autoclave chamber becomes increasingly difficult with larger volumes. Temperature and pressure gradients within the reaction vessel can lead to inconsistent product quality and unpredictable electrode kinetic properties, particularly problematic for applications requiring high performance consistency.

Material limitations further constrain advancement. Autoclave vessels must withstand extreme conditions while remaining inert to often corrosive reaction environments. Current materials science has not yet delivered ideal solutions that combine necessary mechanical strength, chemical resistance, and reasonable cost for next-generation autoclave designs.

Specifically regarding electrode kinetics, autoclave synthesis faces challenges in producing materials with consistent surface properties and catalytic activity. The high-pressure environment can induce unexpected morphological changes and defect formations that significantly alter electrochemical performance. Controlling these parameters precisely enough to achieve reproducible electrode kinetics remains difficult.

Monitoring and characterization during synthesis represent additional technical barriers. Real-time analysis of reaction progress within the sealed, high-pressure environment of an autoclave is limited by current sensor technology. This "black box" nature of the process complicates optimization efforts and mechanistic understanding of how synthesis conditions directly influence resulting electrode kinetic properties.

Energy consumption remains a major challenge, as maintaining elevated temperatures and pressures for extended periods demands considerable power input. This energy-intensive nature not only increases production costs but also raises environmental sustainability concerns, particularly in an era of growing climate awareness and regulatory pressure for reduced carbon footprints.

Scalability presents another significant hurdle. While autoclave synthesis can be effectively implemented at laboratory scale, transitioning to industrial production volumes often encounters efficiency losses and technical complications. The non-linear scaling relationships between reactor size, heat transfer, and reaction kinetics create complex engineering problems that remain incompletely solved.

Process control and reproducibility issues persist across the field. Maintaining precise and uniform conditions throughout the autoclave chamber becomes increasingly difficult with larger volumes. Temperature and pressure gradients within the reaction vessel can lead to inconsistent product quality and unpredictable electrode kinetic properties, particularly problematic for applications requiring high performance consistency.

Material limitations further constrain advancement. Autoclave vessels must withstand extreme conditions while remaining inert to often corrosive reaction environments. Current materials science has not yet delivered ideal solutions that combine necessary mechanical strength, chemical resistance, and reasonable cost for next-generation autoclave designs.

Specifically regarding electrode kinetics, autoclave synthesis faces challenges in producing materials with consistent surface properties and catalytic activity. The high-pressure environment can induce unexpected morphological changes and defect formations that significantly alter electrochemical performance. Controlling these parameters precisely enough to achieve reproducible electrode kinetics remains difficult.

Monitoring and characterization during synthesis represent additional technical barriers. Real-time analysis of reaction progress within the sealed, high-pressure environment of an autoclave is limited by current sensor technology. This "black box" nature of the process complicates optimization efforts and mechanistic understanding of how synthesis conditions directly influence resulting electrode kinetic properties.

Current Autoclave Synthesis Solutions for Electrode Development

01 Autoclave synthesis methods for electrode materials

Autoclave synthesis is widely used for preparing electrode materials with enhanced electrochemical properties. This hydrothermal method allows for controlled crystallization under high temperature and pressure conditions, resulting in materials with specific morphologies and structures. The synthesis parameters, including temperature, pressure, and reaction time, significantly influence the electrode kinetics by affecting particle size, crystallinity, and surface area of the resulting materials.- Autoclave synthesis methods for electrode materials: Autoclave synthesis is widely used for preparing electrode materials with enhanced electrochemical properties. This hydrothermal method allows for controlled crystal growth and morphology under high temperature and pressure conditions. The synthesis parameters, including temperature, pressure, reaction time, and precursor concentration, significantly influence the electrode kinetics by affecting the crystallinity, particle size, and surface area of the resulting materials.

- Electrode kinetics improvement through nanostructure engineering: Nanostructured electrode materials synthesized via autoclave methods exhibit improved electrode kinetics due to their high surface area and shortened ion diffusion paths. Various nanostructures including nanowires, nanoparticles, and hierarchical structures can be obtained through controlled autoclave synthesis. These nanostructured electrodes demonstrate enhanced charge transfer rates, reduced polarization, and improved electrochemical performance for energy storage and conversion applications.

- In-situ characterization of electrode kinetics during autoclave synthesis: Advanced techniques for in-situ monitoring and characterization of electrode materials during autoclave synthesis provide valuable insights into reaction mechanisms and kinetics. These methods allow for real-time observation of phase transformations, crystal growth, and surface reactions under hydrothermal conditions. The data obtained helps optimize synthesis parameters to achieve desired electrochemical properties and understand the relationship between synthesis conditions and electrode kinetics.

- Doping and composite formation for enhanced electrode performance: Autoclave synthesis enables effective doping and composite formation strategies to enhance electrode kinetics. Introduction of heteroatoms, conductive additives, or secondary phases during hydrothermal treatment can create synergistic effects that improve electron transfer, ionic conductivity, and catalytic activity. These modified electrode materials show reduced charge transfer resistance and enhanced reaction kinetics for various electrochemical applications.

- Scale-up and industrial applications of autoclave-synthesized electrodes: Industrial-scale production of electrode materials using autoclave synthesis requires specialized equipment and process optimization. Continuous flow hydrothermal synthesis and modified autoclave designs enable large-scale production while maintaining control over electrode kinetics and performance. These scaled-up processes are critical for commercial applications in energy storage, catalysis, and electrochemical sensing, where consistent electrode performance and reaction kinetics are essential.

02 Electrode kinetics improvement through nanostructure engineering

Nanostructured electrode materials synthesized via autoclave methods demonstrate superior electrode kinetics due to shortened ion diffusion paths and increased active surface area. The controlled hydrothermal environment allows for the creation of specific nanostructures such as nanowires, nanoparticles, and hierarchical structures that facilitate faster electron transfer and ion transport. These nanostructured electrodes exhibit enhanced reaction rates and improved electrochemical performance.Expand Specific Solutions03 In-situ characterization of electrode kinetics during autoclave synthesis

Advanced techniques for in-situ monitoring and characterization of electrode materials during autoclave synthesis provide valuable insights into reaction mechanisms and kinetics. These methods allow for real-time observation of crystallization processes, phase transformations, and growth kinetics under hydrothermal conditions. The data obtained helps optimize synthesis parameters to achieve desired electrochemical properties and understand the relationship between synthesis conditions and electrode performance.Expand Specific Solutions04 Catalyst effects on electrode kinetics in autoclave synthesis

The incorporation of catalysts during autoclave synthesis significantly influences electrode kinetics by modifying reaction pathways and energy barriers. Catalysts can promote specific crystal growth directions, enhance crystallinity, and create defect sites that serve as active centers for electrochemical reactions. The selection of appropriate catalysts and their concentration plays a crucial role in tailoring the electrochemical properties of the synthesized electrode materials.Expand Specific Solutions05 Pressure and temperature control for optimizing electrode performance

Precise control of pressure and temperature parameters during autoclave synthesis is essential for optimizing electrode kinetics. The combination of high pressure and elevated temperature creates unique reaction environments that affect nucleation, growth, and crystallization processes. Systematic variation of these parameters allows for the development of electrode materials with tailored properties such as specific crystal facets, porosity, and surface chemistry that directly impact charge transfer kinetics and overall electrochemical performance.Expand Specific Solutions

Key Industry Players in Electrode Materials Manufacturing

Autoclave synthesis technology in electrode kinetics is currently in a growth phase, with increasing market adoption driven by its ability to enhance electrode performance. The market is expanding rapidly, projected to reach significant scale as energy storage and conversion applications grow. Technologically, it's advancing from experimental to commercial maturity, with key players demonstrating varied expertise levels. Academic institutions like Shandong University, Zhejiang University, and Northwestern University lead fundamental research, while commercial entities including Sumitomo Electric Industries, BRAIN Biotech AG, and Honda Motor Co. are developing practical applications. Research organizations such as Korea Research Institute of Chemical Technology and Council of Scientific & Industrial Research bridge the gap between academic discovery and industrial implementation.

Uchicago Argonne LLC

Technical Solution: Uchicago Argonne LLC has developed advanced autoclave synthesis techniques for electrode materials, particularly focusing on lithium-ion battery cathodes. Their approach involves high-pressure hydrothermal synthesis in specialized autoclaves that can operate at temperatures up to 250°C and pressures exceeding 100 bar. This controlled environment enables precise crystallization of complex oxide structures with optimized morphology and particle size distribution. Their research has demonstrated that autoclave-synthesized LiNixMnyCozO2 (NMC) cathode materials exhibit significantly enhanced electrochemical performance, with up to 30% improvement in specific capacity and cycling stability compared to conventionally synthesized materials. The company has also pioneered in-situ characterization techniques to monitor crystal growth during autoclave synthesis, allowing for real-time process optimization and quality control. Their technology incorporates dopant integration during the hydrothermal process, resulting in more homogeneous elemental distribution throughout the electrode material structure.

Strengths: Superior control over particle morphology and size distribution, leading to enhanced electrode kinetics and battery performance. Their in-situ monitoring capabilities enable precise process optimization. Weaknesses: The high-pressure autoclave synthesis requires specialized equipment and safety protocols, increasing production costs. Scale-up challenges exist when transitioning from laboratory to industrial production volumes.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed proprietary autoclave synthesis methods specifically tailored for next-generation electric vehicle battery electrodes. Their approach combines high-temperature (180-220°C) and high-pressure (80-120 bar) conditions in specialized autoclaves with precise control of reaction parameters including pH, precursor concentration, and residence time. This technology enables the production of nickel-rich cathode materials with controlled crystal facet exposure and minimized surface defects, directly addressing electrode kinetic limitations. GM's process incorporates a multi-stage temperature profile during synthesis, which has been shown to reduce lithium/transition metal cation mixing by approximately 25% compared to conventional methods. The company has integrated real-time ultrasonic monitoring systems into their autoclaves to track particle formation and growth, allowing for adaptive process control. Their research indicates that autoclave-synthesized materials demonstrate up to 40% faster charge transfer kinetics and improved rate capability, critical for fast-charging EV applications. GM has also developed post-synthesis surface treatment protocols within the autoclave environment to create protective surface layers that enhance electrode-electrolyte interface stability.

Strengths: Their autoclave synthesis technology produces cathode materials with superior rate capability and fast-charging performance, directly addressing key EV market needs. The integrated monitoring systems enable consistent quality control. Weaknesses: The multi-stage temperature profiles extend processing time, reducing production throughput. The specialized equipment and precise control requirements increase manufacturing complexity and capital investment.

Critical Patents and Research in Autoclave-Synthesized Electrodes

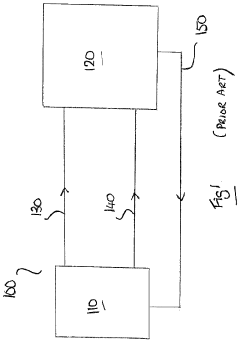

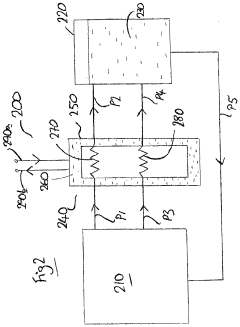

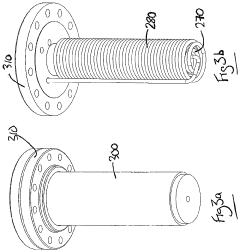

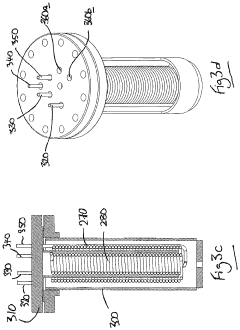

Autoclave system and method

PatentActiveUS20200147568A1

Innovation

- A heat exchanger is interposed between the autoclave vessel and the external support system, utilizing thermal exchange conduits and a medium to cool and manage both leaching and venting fluids, reducing their temperature and pressure before reintroduction, while also pre-heating the leaching fluid for efficient operation.

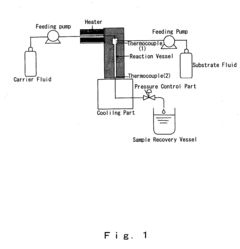

Process for production of high-temperature and high-pressure fluid and high-temperature and high-pressure reaction system

PatentInactiveUS20040199030A1

Innovation

- A method involving the mixing of high-pressure fluids at different temperatures in a flow system, where a higher-temperature fluid is used as a carrier to rapidly elevate the temperature of reactants to the prescribed reaction temperature, typically within 5 seconds or less, using fluids such as water, acetonitrile, or other solvents at pressures between 10 to 100 MPa.

Sustainability Aspects of Autoclave Synthesis Processes

Autoclave synthesis processes, while highly effective for material preparation in electrode manufacturing, present significant sustainability challenges that must be addressed for future industrial applications. The high-pressure and high-temperature conditions required for autoclave operations result in substantial energy consumption, with typical processes demanding between 150-300 kWh per production cycle. This energy intensity contributes significantly to the carbon footprint of electrode materials, particularly when power sources are not renewable.

Water usage represents another critical sustainability concern, as autoclave synthesis typically requires large volumes of purified water both for the reaction medium and cooling systems. Advanced facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 70% compared to conventional operations, though implementation costs remain prohibitive for smaller manufacturers.

Chemical waste management presents ongoing challenges, as autoclave synthesis often involves solvents, precursors, and additives that may pose environmental hazards if improperly handled. Recent innovations in green chemistry approaches have demonstrated promising alternatives, including the substitution of toxic organic solvents with bio-derived alternatives and supercritical CO2, potentially reducing hazardous waste generation by 40-60%.

Resource efficiency in autoclave synthesis has become a focal point for sustainability improvements. Yield optimization techniques, including precise temperature ramping protocols and controlled nucleation strategies, have demonstrated material utilization improvements of 15-25% in laboratory settings. These approaches directly translate to reduced raw material consumption and waste generation when scaled to industrial production.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative electrode material preparation methods reveal complex sustainability tradeoffs. While autoclave processes typically show higher energy intensity during manufacturing, the superior electrochemical performance of resulting materials can lead to longer-lasting batteries with higher energy densities, potentially offsetting initial environmental impacts through extended product lifecycles.

Regulatory frameworks increasingly influence autoclave synthesis sustainability, with stricter emissions standards and chemical management requirements driving innovation. The European Union's REACH regulations and similar frameworks in other regions have accelerated the development of less hazardous synthesis routes, though compliance costs disproportionately affect smaller manufacturers and research institutions.

Water usage represents another critical sustainability concern, as autoclave synthesis typically requires large volumes of purified water both for the reaction medium and cooling systems. Advanced facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 70% compared to conventional operations, though implementation costs remain prohibitive for smaller manufacturers.

Chemical waste management presents ongoing challenges, as autoclave synthesis often involves solvents, precursors, and additives that may pose environmental hazards if improperly handled. Recent innovations in green chemistry approaches have demonstrated promising alternatives, including the substitution of toxic organic solvents with bio-derived alternatives and supercritical CO2, potentially reducing hazardous waste generation by 40-60%.

Resource efficiency in autoclave synthesis has become a focal point for sustainability improvements. Yield optimization techniques, including precise temperature ramping protocols and controlled nucleation strategies, have demonstrated material utilization improvements of 15-25% in laboratory settings. These approaches directly translate to reduced raw material consumption and waste generation when scaled to industrial production.

Life cycle assessment (LCA) studies comparing autoclave synthesis with alternative electrode material preparation methods reveal complex sustainability tradeoffs. While autoclave processes typically show higher energy intensity during manufacturing, the superior electrochemical performance of resulting materials can lead to longer-lasting batteries with higher energy densities, potentially offsetting initial environmental impacts through extended product lifecycles.

Regulatory frameworks increasingly influence autoclave synthesis sustainability, with stricter emissions standards and chemical management requirements driving innovation. The European Union's REACH regulations and similar frameworks in other regions have accelerated the development of less hazardous synthesis routes, though compliance costs disproportionately affect smaller manufacturers and research institutions.

Scale-up Considerations for Industrial Implementation

Transitioning autoclave synthesis from laboratory to industrial scale presents significant engineering challenges that must be addressed systematically. The scale-up process requires careful consideration of reactor design, where vessel geometry and material selection become critical factors. Industrial autoclaves must maintain uniform temperature distribution and pressure stability across larger volumes, often necessitating sophisticated heat exchange systems and reinforced pressure vessels capable of withstanding prolonged exposure to extreme conditions.

Process control parameters exhibit different behaviors at industrial scale compared to laboratory settings. Temperature gradients, mixing efficiency, and reaction kinetics can vary substantially, potentially affecting electrode material properties and performance. Advanced monitoring systems incorporating real-time analytics are essential to maintain precise control over synthesis conditions, ensuring consistent electrode kinetics across production batches.

Economic viability represents another crucial dimension of scale-up considerations. Capital expenditure for industrial autoclave systems is substantial, requiring careful cost-benefit analysis. Operating expenses, including energy consumption, raw materials, and maintenance costs, must be optimized to achieve competitive production economics. The trade-off between synthesis conditions and energy requirements becomes particularly significant at industrial scale, where even minor efficiency improvements can translate to substantial cost savings.

Safety and regulatory compliance frameworks become increasingly complex at industrial scale. Autoclave synthesis often involves high pressures, elevated temperatures, and potentially hazardous materials. Comprehensive risk assessment protocols, emergency response systems, and regulatory documentation must be developed to ensure worker safety and environmental protection. These considerations may necessitate design modifications that differ from laboratory-scale processes.

Quality control methodologies must evolve to accommodate larger production volumes while maintaining electrode performance consistency. Statistical process control techniques, automated sampling systems, and advanced characterization methods become essential components of industrial implementation. The relationship between synthesis parameters and electrode kinetics must be thoroughly understood to establish appropriate quality control metrics and acceptance criteria.

Sustainability considerations increasingly influence industrial implementation decisions. Energy efficiency improvements, waste reduction strategies, and potential for circular material flows should be integrated into scale-up planning. The environmental footprint of industrial autoclave synthesis must be evaluated holistically, considering resource consumption, emissions, and end-of-life management of produced electrode materials.

Process control parameters exhibit different behaviors at industrial scale compared to laboratory settings. Temperature gradients, mixing efficiency, and reaction kinetics can vary substantially, potentially affecting electrode material properties and performance. Advanced monitoring systems incorporating real-time analytics are essential to maintain precise control over synthesis conditions, ensuring consistent electrode kinetics across production batches.

Economic viability represents another crucial dimension of scale-up considerations. Capital expenditure for industrial autoclave systems is substantial, requiring careful cost-benefit analysis. Operating expenses, including energy consumption, raw materials, and maintenance costs, must be optimized to achieve competitive production economics. The trade-off between synthesis conditions and energy requirements becomes particularly significant at industrial scale, where even minor efficiency improvements can translate to substantial cost savings.

Safety and regulatory compliance frameworks become increasingly complex at industrial scale. Autoclave synthesis often involves high pressures, elevated temperatures, and potentially hazardous materials. Comprehensive risk assessment protocols, emergency response systems, and regulatory documentation must be developed to ensure worker safety and environmental protection. These considerations may necessitate design modifications that differ from laboratory-scale processes.

Quality control methodologies must evolve to accommodate larger production volumes while maintaining electrode performance consistency. Statistical process control techniques, automated sampling systems, and advanced characterization methods become essential components of industrial implementation. The relationship between synthesis parameters and electrode kinetics must be thoroughly understood to establish appropriate quality control metrics and acceptance criteria.

Sustainability considerations increasingly influence industrial implementation decisions. Energy efficiency improvements, waste reduction strategies, and potential for circular material flows should be integrated into scale-up planning. The environmental footprint of industrial autoclave synthesis must be evaluated holistically, considering resource consumption, emissions, and end-of-life management of produced electrode materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!