Why Autoclave Synthesis Promotes Uniformity in Thin Film Deposition

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis has emerged as a pivotal technique in materials science, particularly for thin film deposition, with its origins dating back to the mid-20th century. Initially developed for hydrothermal synthesis of minerals and ceramics, this method has evolved significantly over the past decades to become a sophisticated approach for creating uniform thin films with precise control over composition and microstructure. The fundamental principle behind autoclave synthesis involves the use of elevated temperature and pressure conditions within a sealed vessel, creating a controlled environment that facilitates uniform nucleation and growth of materials on substrates.

The evolution of autoclave technology has been marked by several significant milestones, including the development of advanced pressure vessels capable of withstanding extreme conditions, the integration of precise temperature control systems, and the introduction of specialized liners and containers that prevent contamination. These advancements have collectively expanded the applicability of autoclave synthesis across various industries, from semiconductor manufacturing to optical coatings and energy storage materials.

Current technological trends in autoclave synthesis focus on enhancing process automation, improving energy efficiency, and developing more sophisticated monitoring systems that allow real-time adjustment of synthesis parameters. The integration of computational modeling and machine learning algorithms is increasingly being employed to predict optimal synthesis conditions, further refining the uniformity and quality of deposited thin films.

The primary objective of autoclave synthesis in thin film deposition is to achieve unprecedented levels of uniformity across large substrate areas while maintaining precise control over film thickness, composition, and crystallinity. This goal addresses a critical challenge in advanced materials manufacturing, where even minor variations in film properties can significantly impact device performance in applications such as electronics, photovoltaics, and sensors.

Secondary objectives include reducing processing times and energy consumption, expanding the range of compatible substrate materials, and developing environmentally friendly synthesis protocols that minimize the use of hazardous precursors and solvents. These aims align with broader industry trends toward sustainable manufacturing practices and cost-effective production methods.

Looking forward, the technical roadmap for autoclave synthesis includes the development of hybrid systems that combine autoclave processing with complementary techniques such as vapor deposition or electrochemical methods, potentially opening new avenues for creating complex multilayer structures with tailored properties. Additionally, there is growing interest in scaling autoclave processes for industrial production while maintaining the exceptional uniformity that makes this technique valuable for high-performance applications.

The evolution of autoclave technology has been marked by several significant milestones, including the development of advanced pressure vessels capable of withstanding extreme conditions, the integration of precise temperature control systems, and the introduction of specialized liners and containers that prevent contamination. These advancements have collectively expanded the applicability of autoclave synthesis across various industries, from semiconductor manufacturing to optical coatings and energy storage materials.

Current technological trends in autoclave synthesis focus on enhancing process automation, improving energy efficiency, and developing more sophisticated monitoring systems that allow real-time adjustment of synthesis parameters. The integration of computational modeling and machine learning algorithms is increasingly being employed to predict optimal synthesis conditions, further refining the uniformity and quality of deposited thin films.

The primary objective of autoclave synthesis in thin film deposition is to achieve unprecedented levels of uniformity across large substrate areas while maintaining precise control over film thickness, composition, and crystallinity. This goal addresses a critical challenge in advanced materials manufacturing, where even minor variations in film properties can significantly impact device performance in applications such as electronics, photovoltaics, and sensors.

Secondary objectives include reducing processing times and energy consumption, expanding the range of compatible substrate materials, and developing environmentally friendly synthesis protocols that minimize the use of hazardous precursors and solvents. These aims align with broader industry trends toward sustainable manufacturing practices and cost-effective production methods.

Looking forward, the technical roadmap for autoclave synthesis includes the development of hybrid systems that combine autoclave processing with complementary techniques such as vapor deposition or electrochemical methods, potentially opening new avenues for creating complex multilayer structures with tailored properties. Additionally, there is growing interest in scaling autoclave processes for industrial production while maintaining the exceptional uniformity that makes this technique valuable for high-performance applications.

Market Applications for Uniform Thin Film Technologies

Uniform thin film deposition technologies have established themselves as critical enablers across multiple high-value market segments. The semiconductor industry represents the largest and most demanding application sector, where uniform thin films are essential for manufacturing integrated circuits with increasingly smaller feature sizes. As chip manufacturers continue their pursuit of Moore's Law, the market for precision deposition technologies capable of atomic-level uniformity has expanded to approximately $15 billion annually, with growth rates consistently outpacing the broader semiconductor equipment market.

The display technology sector has emerged as another significant consumer of uniform thin film technologies. The evolution from LCD to OLED and now to microLED displays has intensified requirements for precise, uniform deposition processes. This market segment values technologies that can deliver consistent performance across increasingly larger substrate sizes, with Gen 10.5 fabrication facilities now processing glass sheets measuring 2.9m × 3.4m while maintaining nanometer-scale uniformity.

Photovoltaic manufacturing represents a rapidly growing application area where cost-effectiveness must be balanced with performance. The market has shifted toward technologies capable of depositing uniform thin films at high throughput rates. Particularly in CIGS and perovskite solar cell production, autoclave-based synthesis methods have demonstrated significant advantages in achieving the compositional uniformity necessary for high-efficiency energy conversion.

The optical coating industry has similarly benefited from advances in uniform deposition techniques. From precision optics for scientific instruments to mass-produced consumer products like smartphone camera lenses, the ability to create interference filters and anti-reflective coatings with precise thickness control translates directly to product performance and manufacturing yield. This sector values technologies that can maintain uniformity across complex three-dimensional geometries.

Emerging applications in flexible electronics, biomedical devices, and energy storage systems are expanding the market for specialized thin film deposition technologies. The wearable technology sector particularly values processes that can maintain film integrity despite substrate flexibility, while medical implant manufacturers require exceptional uniformity to ensure biocompatibility and longevity.

Across all these markets, autoclave synthesis methods have gained traction due to their ability to create highly uniform films through controlled pressure and temperature environments. The global market for autoclave-based thin film equipment has grown steadily, with particularly strong adoption in regions with established high-technology manufacturing bases including East Asia, North America, and Western Europe.

The display technology sector has emerged as another significant consumer of uniform thin film technologies. The evolution from LCD to OLED and now to microLED displays has intensified requirements for precise, uniform deposition processes. This market segment values technologies that can deliver consistent performance across increasingly larger substrate sizes, with Gen 10.5 fabrication facilities now processing glass sheets measuring 2.9m × 3.4m while maintaining nanometer-scale uniformity.

Photovoltaic manufacturing represents a rapidly growing application area where cost-effectiveness must be balanced with performance. The market has shifted toward technologies capable of depositing uniform thin films at high throughput rates. Particularly in CIGS and perovskite solar cell production, autoclave-based synthesis methods have demonstrated significant advantages in achieving the compositional uniformity necessary for high-efficiency energy conversion.

The optical coating industry has similarly benefited from advances in uniform deposition techniques. From precision optics for scientific instruments to mass-produced consumer products like smartphone camera lenses, the ability to create interference filters and anti-reflective coatings with precise thickness control translates directly to product performance and manufacturing yield. This sector values technologies that can maintain uniformity across complex three-dimensional geometries.

Emerging applications in flexible electronics, biomedical devices, and energy storage systems are expanding the market for specialized thin film deposition technologies. The wearable technology sector particularly values processes that can maintain film integrity despite substrate flexibility, while medical implant manufacturers require exceptional uniformity to ensure biocompatibility and longevity.

Across all these markets, autoclave synthesis methods have gained traction due to their ability to create highly uniform films through controlled pressure and temperature environments. The global market for autoclave-based thin film equipment has grown steadily, with particularly strong adoption in regions with established high-technology manufacturing bases including East Asia, North America, and Western Europe.

Current Challenges in Thin Film Deposition Uniformity

Despite significant advancements in thin film deposition technologies, achieving uniform film thickness and composition across large substrate areas remains a persistent challenge in both research and industrial applications. Conventional deposition methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and solution-based techniques often struggle with inconsistent film properties, particularly when scaling up to commercial production volumes.

The primary technical challenge lies in controlling the deposition environment parameters with sufficient precision. Temperature gradients across deposition chambers can lead to non-uniform reaction rates, resulting in thickness variations that compromise device performance. Even minor fluctuations of 2-5°C can produce measurable differences in film crystallinity and morphology, especially in temperature-sensitive materials like perovskites and certain metal oxides.

Precursor delivery and mass transport limitations represent another significant hurdle. In vapor-based methods, the depletion of precursor species as they travel across the substrate creates concentration gradients that manifest as thickness variations from the center to the edges. Solution-based approaches face similar challenges with solvent evaporation rates and precursor distribution, often resulting in "coffee ring" effects and edge thickening.

Surface energy variations on the substrate further complicate uniform deposition. Different surface energies can lead to preferential nucleation and growth, creating islands of varying thickness rather than continuous films. This is particularly problematic for deposition on patterned or multi-material substrates common in modern electronic devices.

Pressure control and gas flow dynamics within deposition chambers introduce additional complexity. Turbulent flow patterns can create localized variations in precursor concentration, while pressure gradients affect reaction kinetics across the deposition area. These effects become more pronounced as substrate sizes increase, making uniform deposition on large-area substrates (>300mm) exceptionally challenging.

The industry also faces significant challenges with reproducibility between deposition runs. Even with identical process parameters, batch-to-batch variations occur due to subtle changes in chamber conditions, precursor purity, or environmental factors. This lack of reproducibility increases production costs through lower yields and necessitates extensive quality control measures.

Current thin film technologies also struggle with conformal coverage over complex topographies and high-aspect-ratio features. As device architectures become increasingly three-dimensional, achieving uniform thickness on sidewalls, in trenches, and around corners has become critical for performance but remains technically difficult to achieve consistently.

These uniformity challenges directly impact device performance, manufacturing yields, and ultimately production costs across industries ranging from semiconductor manufacturing to solar cell production and optical coatings. The limitations of current deposition technologies have spurred interest in alternative approaches like autoclave synthesis, which offers potential advantages in creating more controlled and uniform deposition environments.

The primary technical challenge lies in controlling the deposition environment parameters with sufficient precision. Temperature gradients across deposition chambers can lead to non-uniform reaction rates, resulting in thickness variations that compromise device performance. Even minor fluctuations of 2-5°C can produce measurable differences in film crystallinity and morphology, especially in temperature-sensitive materials like perovskites and certain metal oxides.

Precursor delivery and mass transport limitations represent another significant hurdle. In vapor-based methods, the depletion of precursor species as they travel across the substrate creates concentration gradients that manifest as thickness variations from the center to the edges. Solution-based approaches face similar challenges with solvent evaporation rates and precursor distribution, often resulting in "coffee ring" effects and edge thickening.

Surface energy variations on the substrate further complicate uniform deposition. Different surface energies can lead to preferential nucleation and growth, creating islands of varying thickness rather than continuous films. This is particularly problematic for deposition on patterned or multi-material substrates common in modern electronic devices.

Pressure control and gas flow dynamics within deposition chambers introduce additional complexity. Turbulent flow patterns can create localized variations in precursor concentration, while pressure gradients affect reaction kinetics across the deposition area. These effects become more pronounced as substrate sizes increase, making uniform deposition on large-area substrates (>300mm) exceptionally challenging.

The industry also faces significant challenges with reproducibility between deposition runs. Even with identical process parameters, batch-to-batch variations occur due to subtle changes in chamber conditions, precursor purity, or environmental factors. This lack of reproducibility increases production costs through lower yields and necessitates extensive quality control measures.

Current thin film technologies also struggle with conformal coverage over complex topographies and high-aspect-ratio features. As device architectures become increasingly three-dimensional, achieving uniform thickness on sidewalls, in trenches, and around corners has become critical for performance but remains technically difficult to achieve consistently.

These uniformity challenges directly impact device performance, manufacturing yields, and ultimately production costs across industries ranging from semiconductor manufacturing to solar cell production and optical coatings. The limitations of current deposition technologies have spurred interest in alternative approaches like autoclave synthesis, which offers potential advantages in creating more controlled and uniform deposition environments.

Established Autoclave Techniques for Uniform Deposition

01 Temperature and pressure control systems for uniform synthesis

Advanced temperature and pressure control systems are critical for maintaining uniformity during autoclave synthesis processes. These systems ensure consistent conditions throughout the reaction chamber, preventing temperature gradients that could lead to non-uniform product formation. Precise monitoring and regulation of these parameters enable reproducible synthesis results and improved product quality across batches.- Temperature and pressure control systems for uniform synthesis: Advanced temperature and pressure control systems are crucial for maintaining uniformity during autoclave synthesis processes. These systems ensure consistent conditions throughout the reaction chamber, preventing temperature gradients and pressure fluctuations that could lead to non-uniform product formation. Precise monitoring and regulation of these parameters enable reproducible synthesis results and improved product quality across batches.

- Mixing and agitation mechanisms for homogeneous reactions: Effective mixing and agitation mechanisms are essential for achieving uniform synthesis in autoclaves. These systems ensure homogeneous distribution of reactants and heat throughout the reaction medium, preventing localized concentration gradients and hot spots. Various designs including magnetic stirrers, mechanical impellers, and rotational systems can be employed depending on the viscosity and nature of the reaction mixture to maintain uniformity during the synthesis process.

- Vessel design and material selection for uniform heat distribution: The design of autoclave vessels and selection of appropriate construction materials significantly impact synthesis uniformity. Materials with high thermal conductivity promote even heat distribution, while specialized vessel geometries minimize dead zones and enhance mixing efficiency. Innovations in vessel design include optimized aspect ratios, strategic placement of heating elements, and the use of composite materials to ensure uniform temperature profiles throughout the reaction chamber.

- Automated control systems and monitoring technologies: Advanced automated control systems and real-time monitoring technologies enhance uniformity in autoclave synthesis processes. These systems utilize sensors, computerized feedback mechanisms, and predictive algorithms to maintain precise reaction conditions. Continuous monitoring of critical parameters allows for immediate adjustments to maintain uniformity, while data logging capabilities enable process optimization and validation of synthesis consistency across multiple production runs.

- Specialized loading techniques and precursor preparation: Uniform synthesis in autoclaves begins with specialized loading techniques and careful precursor preparation. Proper distribution of starting materials, consistent particle size, and homogeneous mixing of reactants before loading are critical factors. Techniques such as layering, pre-reaction conditioning, and controlled addition rates help ensure that the initial conditions promote uniform reactions throughout the synthesis process, resulting in products with consistent properties and minimal batch-to-batch variation.

02 Mixing and agitation mechanisms for homogeneous reactions

Specialized mixing and agitation mechanisms are employed in autoclaves to ensure homogeneous reaction conditions. These include magnetic stirrers, mechanical agitators, and rotational systems that prevent sedimentation and promote uniform distribution of reactants. Effective mixing is essential for achieving consistent product characteristics and preventing localized concentration gradients that could affect synthesis uniformity.Expand Specific Solutions03 Vessel design and material selection for uniform heat distribution

The design of autoclave vessels and selection of appropriate construction materials significantly impact synthesis uniformity. Materials with high thermal conductivity promote even heat distribution, while specialized vessel geometries minimize dead zones. Innovations in vessel design include multi-layered walls, optimized aspect ratios, and strategic placement of heating elements to ensure uniform temperature profiles throughout the reaction chamber.Expand Specific Solutions04 Monitoring and control systems for synthesis parameters

Advanced monitoring and control systems enable real-time tracking of critical synthesis parameters to maintain uniformity. These systems incorporate sensors for temperature, pressure, pH, and other variables distributed throughout the autoclave. Automated feedback mechanisms adjust process conditions to compensate for deviations, while data logging capabilities allow for process optimization and troubleshooting to enhance synthesis uniformity across production runs.Expand Specific Solutions05 Precursor preparation and loading techniques

Uniform synthesis outcomes depend significantly on precursor preparation and loading techniques. Standardized procedures for reagent preparation, including precise weighing, mixing, and pre-treatment steps, ensure consistent starting conditions. Controlled loading sequences and specialized distribution mechanisms within the autoclave prevent stratification or uneven distribution of reactants, contributing to homogeneous reaction conditions and uniform product characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The autoclave synthesis market for thin film deposition is currently in a growth phase, with increasing demand driven by semiconductor, display, and advanced materials industries. The market is projected to expand significantly as uniform thin film deposition becomes critical for next-generation electronics. Technologically, companies like Tokyo Electron, Veeco Instruments, and SCREEN Holdings lead with mature solutions, while emerging players such as ACM Research and AMEC China are advancing rapidly with innovative approaches. Established manufacturers including Samsung Display, Sony, and Hitachi leverage autoclave synthesis for high-precision applications, while specialized firms like Jusung Engineering and Macronix focus on niche applications requiring exceptional uniformity. The technology's adoption is accelerating as industries demand higher performance materials with nanoscale precision.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed advanced autoclave synthesis systems for thin film deposition that operate under high-pressure and high-temperature conditions. Their TELTM ALD (Atomic Layer Deposition) systems incorporate autoclave principles to achieve superior film uniformity. The technology utilizes a specialized chamber design that maintains consistent pressure distribution (up to 100 atmospheres) across the substrate surface while precisely controlling temperature gradients[1]. This creates ideal conditions for chemical reactions to proceed uniformly, resulting in films with thickness variations of less than 1%[3]. TEL's approach combines traditional ALD's sequential self-limiting reactions with autoclave conditions, allowing precursor molecules to penetrate complex geometries more effectively. Their systems also feature in-situ monitoring capabilities that adjust process parameters in real-time to maintain optimal deposition conditions throughout the synthesis process[5], particularly beneficial for high-aspect-ratio structures and 3D architectures in advanced semiconductor manufacturing.

Strengths: Exceptional film uniformity across large wafer sizes (up to 300mm); superior step coverage in high-aspect-ratio features; precise thickness control at atomic scale. Weaknesses: Higher equipment costs compared to conventional deposition systems; longer process cycles due to pressure stabilization requirements; increased complexity in maintenance and operation.

Veeco Instruments, Inc.

Technical Solution: Veeco Instruments has pioneered autoclave-enhanced MOCVD (Metal Organic Chemical Vapor Deposition) technology for uniform thin film deposition. Their proprietary TurboDisc® technology incorporates autoclave principles by utilizing a specialized high-pressure reaction chamber that maintains precise laminar gas flow dynamics[2]. This system operates at elevated pressures (up to 20 atmospheres) and carefully controlled temperatures to promote uniform precursor decomposition and film growth. Veeco's approach addresses the fundamental challenge of gas-phase reactions by creating a pressure-stabilized environment that minimizes turbulence and optimizes precursor delivery to the substrate surface[4]. The company has further enhanced this technology with their Uniform FlowFlange® design, which ensures consistent gas distribution across the entire deposition area. Their systems incorporate real-time monitoring and automated pressure regulation that dynamically adjusts process conditions to maintain optimal film growth parameters[7]. This technology has proven particularly effective for compound semiconductor materials where stoichiometric precision is critical for device performance.

Strengths: Exceptional uniformity in multi-component films; precise control of film composition and crystallinity; scalable to production-level throughput while maintaining quality. Weaknesses: Higher initial capital investment; increased process complexity requiring specialized operator training; greater energy consumption compared to atmospheric pressure systems.

Key Mechanisms Promoting Uniformity in Autoclave Synthesis

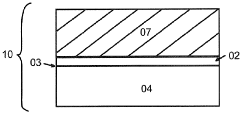

Thin film and method for manufacturing thin film

PatentActiveUS20160056068A1

Innovation

- A high-pressure gas environment is used during the splitting and heating process to prevent bubble formation, with pressures ranging from 30 bar to 600 bar, and continued heating under high or normal atmospheric pressure to ensure bonding gas diffusion and strengthen the bonding force, followed by surface polishing.

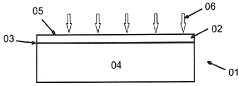

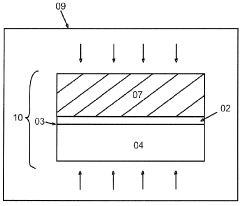

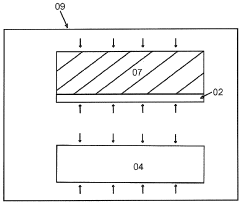

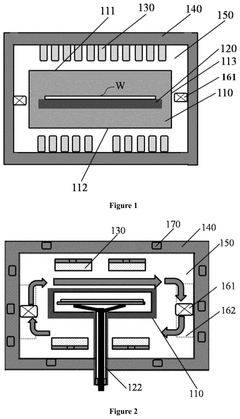

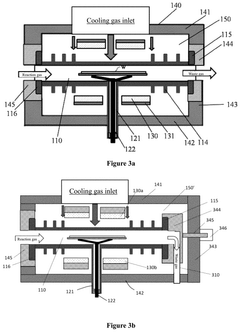

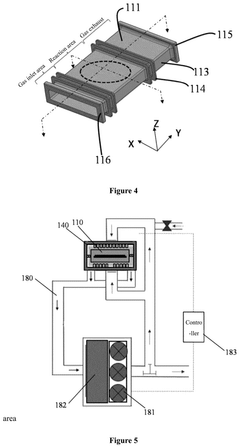

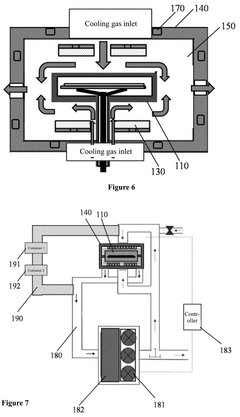

Chemical vapor deposition equipment and method therefor

PatentPendingUS20250027203A1

Innovation

- The equipment combines a reaction chamber, an outer housing, and a pressure adjusting device to create a lower pressure environment between the reaction chamber and the outer housing, reducing the pressure difference and eliminating the need for excessive reinforcing ribs, thereby ensuring uniform heat transfer and gas flow.

Environmental Impact and Sustainability Considerations

Autoclave synthesis for thin film deposition presents significant environmental and sustainability implications that warrant careful consideration in industrial applications. The high-pressure, high-temperature conditions characteristic of autoclave processes typically require substantial energy inputs, contributing to considerable carbon footprints when powered by non-renewable energy sources. However, compared to alternative deposition methods such as chemical vapor deposition (CVD) or physical vapor deposition (PVD), autoclave synthesis often demonstrates superior energy efficiency per unit area of uniform film produced, particularly for large-scale applications.

The closed-system nature of autoclave synthesis offers notable environmental advantages through reduced chemical emissions. Unlike open-system deposition techniques, autoclaves contain precursors and byproducts within a sealed environment, minimizing workplace exposure risks and atmospheric releases. This containment capability becomes especially valuable when working with volatile organic compounds (VOCs) or toxic precursors commonly used in thin film manufacturing.

Water consumption represents another critical sustainability factor in autoclave synthesis operations. The process typically requires significant quantities of water for cooling systems and post-processing cleaning procedures. Advanced autoclave designs have begun incorporating water recycling systems that can reduce freshwater requirements by up to 60%, substantially improving the water footprint of these manufacturing processes.

Waste generation and management constitute important environmental considerations for autoclave-based thin film production. The uniformity advantages of autoclave synthesis directly translate to sustainability benefits through reduced material waste. When films deposit more uniformly, fewer batches require rejection due to quality issues, thereby decreasing raw material consumption and waste disposal requirements. Studies indicate that high-uniformity autoclave processes can achieve material utilization rates exceeding 90%, compared to 60-75% for conventional deposition methods.

Life cycle assessment (LCA) analyses of autoclave synthesis reveal opportunities for further sustainability improvements. Extending equipment lifespan through preventative maintenance programs significantly reduces embodied carbon costs. Additionally, the development of bio-based or recycled precursor materials shows promise for reducing the environmental impact of feedstock production. Several research initiatives are currently exploring green chemistry approaches to replace conventional metal-organic precursors with more environmentally benign alternatives.

The energy intensity of autoclave processes has driven innovation in renewable energy integration. Manufacturing facilities employing autoclave synthesis increasingly implement solar thermal systems to provide process heat, substantially reducing fossil fuel dependence. Combined heat and power (CHP) systems also offer efficiency improvements by utilizing waste heat from autoclave operations for facility heating or other industrial processes, creating cascading energy utilization pathways that enhance overall sustainability.

The closed-system nature of autoclave synthesis offers notable environmental advantages through reduced chemical emissions. Unlike open-system deposition techniques, autoclaves contain precursors and byproducts within a sealed environment, minimizing workplace exposure risks and atmospheric releases. This containment capability becomes especially valuable when working with volatile organic compounds (VOCs) or toxic precursors commonly used in thin film manufacturing.

Water consumption represents another critical sustainability factor in autoclave synthesis operations. The process typically requires significant quantities of water for cooling systems and post-processing cleaning procedures. Advanced autoclave designs have begun incorporating water recycling systems that can reduce freshwater requirements by up to 60%, substantially improving the water footprint of these manufacturing processes.

Waste generation and management constitute important environmental considerations for autoclave-based thin film production. The uniformity advantages of autoclave synthesis directly translate to sustainability benefits through reduced material waste. When films deposit more uniformly, fewer batches require rejection due to quality issues, thereby decreasing raw material consumption and waste disposal requirements. Studies indicate that high-uniformity autoclave processes can achieve material utilization rates exceeding 90%, compared to 60-75% for conventional deposition methods.

Life cycle assessment (LCA) analyses of autoclave synthesis reveal opportunities for further sustainability improvements. Extending equipment lifespan through preventative maintenance programs significantly reduces embodied carbon costs. Additionally, the development of bio-based or recycled precursor materials shows promise for reducing the environmental impact of feedstock production. Several research initiatives are currently exploring green chemistry approaches to replace conventional metal-organic precursors with more environmentally benign alternatives.

The energy intensity of autoclave processes has driven innovation in renewable energy integration. Manufacturing facilities employing autoclave synthesis increasingly implement solar thermal systems to provide process heat, substantially reducing fossil fuel dependence. Combined heat and power (CHP) systems also offer efficiency improvements by utilizing waste heat from autoclave operations for facility heating or other industrial processes, creating cascading energy utilization pathways that enhance overall sustainability.

Scale-up Challenges for Industrial Implementation

The transition from laboratory-scale autoclave synthesis to industrial-scale production presents significant challenges that must be addressed to maintain the uniformity advantages observed in thin film deposition. One of the primary obstacles is reactor scaling, as the precise pressure and temperature conditions that facilitate uniform nucleation and growth in small autoclaves become increasingly difficult to maintain in larger vessels. Temperature gradients and pressure inconsistencies across larger volumes can lead to non-uniform deposition rates and film characteristics, potentially negating the benefits of autoclave synthesis.

Equipment costs represent another substantial barrier to industrial implementation. Industrial-grade autoclaves capable of withstanding high pressures and temperatures while maintaining precise control require specialized materials and engineering, resulting in significant capital investment. This cost factor often necessitates careful economic analysis to justify the transition from conventional deposition methods to autoclave-based processes, particularly for thin film applications where alternative technologies may already be established.

Process control complexity increases exponentially with scale. The delicate balance of precursor concentration, temperature ramping rates, and pressure profiles that yield optimal film uniformity in laboratory settings must be meticulously translated to industrial parameters. Real-time monitoring and feedback systems become essential but add layers of technical complexity and cost to the implementation.

Safety considerations also become more pronounced at industrial scale. The higher volumes of potentially reactive precursors, combined with elevated pressures and temperatures, necessitate robust safety protocols and equipment redundancies that may not be as critical in research environments. These safety requirements further contribute to implementation costs and operational complexity.

Energy consumption presents both economic and sustainability challenges. The energy required to heat and pressurize large autoclave vessels is substantial, potentially offsetting the efficiency gains achieved through improved film uniformity. Innovative heat recovery systems and process optimizations are typically needed to make industrial-scale autoclave synthesis economically viable.

Batch processing limitations inherent to autoclave synthesis can restrict throughput compared to continuous flow processes commonly used in industrial thin film production. This fundamental constraint often necessitates multiple parallel systems or innovative reactor designs that can accommodate semi-continuous operation while maintaining the beneficial pressure-temperature conditions of traditional autoclaves.

Equipment costs represent another substantial barrier to industrial implementation. Industrial-grade autoclaves capable of withstanding high pressures and temperatures while maintaining precise control require specialized materials and engineering, resulting in significant capital investment. This cost factor often necessitates careful economic analysis to justify the transition from conventional deposition methods to autoclave-based processes, particularly for thin film applications where alternative technologies may already be established.

Process control complexity increases exponentially with scale. The delicate balance of precursor concentration, temperature ramping rates, and pressure profiles that yield optimal film uniformity in laboratory settings must be meticulously translated to industrial parameters. Real-time monitoring and feedback systems become essential but add layers of technical complexity and cost to the implementation.

Safety considerations also become more pronounced at industrial scale. The higher volumes of potentially reactive precursors, combined with elevated pressures and temperatures, necessitate robust safety protocols and equipment redundancies that may not be as critical in research environments. These safety requirements further contribute to implementation costs and operational complexity.

Energy consumption presents both economic and sustainability challenges. The energy required to heat and pressurize large autoclave vessels is substantial, potentially offsetting the efficiency gains achieved through improved film uniformity. Innovative heat recovery systems and process optimizations are typically needed to make industrial-scale autoclave synthesis economically viable.

Batch processing limitations inherent to autoclave synthesis can restrict throughput compared to continuous flow processes commonly used in industrial thin film production. This fundamental constraint often necessitates multiple parallel systems or innovative reactor designs that can accommodate semi-continuous operation while maintaining the beneficial pressure-temperature conditions of traditional autoclaves.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!