Why Autoclave Synthesis Enhances the Efficiency of Photovoltaic Cells

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis has emerged as a transformative technique in the field of photovoltaic cell manufacturing, representing a significant advancement in materials processing technology. The method, which utilizes high-pressure and high-temperature conditions within a sealed vessel, has evolved considerably since its initial applications in materials science during the mid-20th century. Originally developed for hydrothermal synthesis of minerals and ceramics, autoclave techniques have progressively been adapted for semiconductor and photovoltaic materials over the past three decades.

The evolution of autoclave synthesis in photovoltaic applications has been driven by increasing demands for higher efficiency solar cells and the need to overcome limitations in traditional manufacturing processes. Early photovoltaic cells suffered from structural defects, poor crystallinity, and inconsistent performance characteristics that significantly limited their efficiency. Conventional synthesis methods often produced materials with suboptimal properties for photovoltaic applications, creating a technological bottleneck in the industry's development.

Recent technological trends indicate a growing emphasis on precise control of nanostructures and interfaces within photovoltaic materials, areas where autoclave synthesis demonstrates particular advantages. The controlled environment of an autoclave allows for unprecedented manipulation of crystal growth dynamics, enabling the formation of highly ordered structures with minimal defects. This trend aligns with the broader movement toward nanoscale engineering in semiconductor technologies.

The primary objective of implementing autoclave synthesis in photovoltaic cell production is to achieve substantial improvements in energy conversion efficiency through enhanced material quality. Specifically, this technique aims to produce semiconductor materials with superior crystallinity, controlled morphology, and optimized electronic properties. These improvements directly address the fundamental limitations that have historically constrained photovoltaic performance.

Secondary objectives include developing scalable and economically viable manufacturing processes that can transition from laboratory demonstrations to industrial production. The autoclave synthesis approach must balance the benefits of improved material properties against considerations of production throughput, equipment costs, and energy consumption. This balance is critical for the commercial viability of advanced photovoltaic technologies.

Furthermore, autoclave synthesis techniques aim to enable the development of next-generation photovoltaic materials that can overcome the theoretical efficiency limits of conventional silicon-based cells. This includes facilitating the production of novel compound semiconductors, quantum dot structures, and perovskite materials that show promise for pushing efficiency boundaries beyond current limitations.

The long-term technological goal extends beyond immediate efficiency improvements to establishing sustainable manufacturing paradigms that reduce reliance on rare or toxic elements while minimizing environmental impact. This aligns with global sustainability objectives and regulatory trends toward greener technology production methods.

The evolution of autoclave synthesis in photovoltaic applications has been driven by increasing demands for higher efficiency solar cells and the need to overcome limitations in traditional manufacturing processes. Early photovoltaic cells suffered from structural defects, poor crystallinity, and inconsistent performance characteristics that significantly limited their efficiency. Conventional synthesis methods often produced materials with suboptimal properties for photovoltaic applications, creating a technological bottleneck in the industry's development.

Recent technological trends indicate a growing emphasis on precise control of nanostructures and interfaces within photovoltaic materials, areas where autoclave synthesis demonstrates particular advantages. The controlled environment of an autoclave allows for unprecedented manipulation of crystal growth dynamics, enabling the formation of highly ordered structures with minimal defects. This trend aligns with the broader movement toward nanoscale engineering in semiconductor technologies.

The primary objective of implementing autoclave synthesis in photovoltaic cell production is to achieve substantial improvements in energy conversion efficiency through enhanced material quality. Specifically, this technique aims to produce semiconductor materials with superior crystallinity, controlled morphology, and optimized electronic properties. These improvements directly address the fundamental limitations that have historically constrained photovoltaic performance.

Secondary objectives include developing scalable and economically viable manufacturing processes that can transition from laboratory demonstrations to industrial production. The autoclave synthesis approach must balance the benefits of improved material properties against considerations of production throughput, equipment costs, and energy consumption. This balance is critical for the commercial viability of advanced photovoltaic technologies.

Furthermore, autoclave synthesis techniques aim to enable the development of next-generation photovoltaic materials that can overcome the theoretical efficiency limits of conventional silicon-based cells. This includes facilitating the production of novel compound semiconductors, quantum dot structures, and perovskite materials that show promise for pushing efficiency boundaries beyond current limitations.

The long-term technological goal extends beyond immediate efficiency improvements to establishing sustainable manufacturing paradigms that reduce reliance on rare or toxic elements while minimizing environmental impact. This aligns with global sustainability objectives and regulatory trends toward greener technology production methods.

Market Analysis of High-Efficiency Photovoltaic Technologies

The global photovoltaic (PV) market has experienced remarkable growth over the past decade, with high-efficiency technologies becoming increasingly dominant. The market for high-efficiency photovoltaic cells, particularly those enhanced through autoclave synthesis processes, has expanded at a compound annual growth rate of approximately 25% since 2018, outpacing the broader solar market's 15% growth rate.

Consumer demand for higher energy conversion efficiency has been a primary market driver, with residential and commercial sectors seeking maximum power generation from limited installation spaces. This trend is particularly evident in densely populated urban areas across Europe and Asia, where space constraints make efficiency paramount. Market research indicates that consumers are willing to pay a premium of 20-30% for PV systems that deliver 5-7% higher efficiency rates.

The industrial sector represents the largest market segment for high-efficiency PV technologies, accounting for 45% of total market share. This is followed by utility-scale installations at 30%, residential applications at 15%, and specialized applications such as aerospace and automotive at 10%. Geographically, China leads manufacturing capacity with 68% of global production, while Europe and North America represent the highest-value markets due to stronger environmental policies and incentive programs.

Market forecasts project that high-efficiency PV technologies utilizing advanced manufacturing methods like autoclave synthesis will capture over 60% of the total solar market by 2028, up from 37% in 2023. This growth is supported by declining production costs, which have decreased by an average of 18% annually over the past five years, making these premium technologies increasingly competitive with conventional alternatives.

The competitive landscape features both established manufacturers pivoting toward high-efficiency technologies and specialized startups focused exclusively on advanced production methods. Major silicon wafer manufacturers have invested heavily in autoclave synthesis capabilities, recognizing the significant efficiency advantages this process offers for crystalline silicon cells.

Market barriers include high initial capital requirements for autoclave equipment, which typically costs between $5-12 million per production line, and technical expertise shortages. However, these barriers are gradually diminishing as equipment costs decline and knowledge disseminates throughout the industry.

Consumer awareness of efficiency differences has matured significantly, with market surveys indicating that 78% of commercial buyers now consider efficiency ratings as their primary purchase criterion, compared to just 45% five years ago. This shift in consumer priorities has accelerated market adoption of autoclave-enhanced PV technologies despite their higher initial costs.

Consumer demand for higher energy conversion efficiency has been a primary market driver, with residential and commercial sectors seeking maximum power generation from limited installation spaces. This trend is particularly evident in densely populated urban areas across Europe and Asia, where space constraints make efficiency paramount. Market research indicates that consumers are willing to pay a premium of 20-30% for PV systems that deliver 5-7% higher efficiency rates.

The industrial sector represents the largest market segment for high-efficiency PV technologies, accounting for 45% of total market share. This is followed by utility-scale installations at 30%, residential applications at 15%, and specialized applications such as aerospace and automotive at 10%. Geographically, China leads manufacturing capacity with 68% of global production, while Europe and North America represent the highest-value markets due to stronger environmental policies and incentive programs.

Market forecasts project that high-efficiency PV technologies utilizing advanced manufacturing methods like autoclave synthesis will capture over 60% of the total solar market by 2028, up from 37% in 2023. This growth is supported by declining production costs, which have decreased by an average of 18% annually over the past five years, making these premium technologies increasingly competitive with conventional alternatives.

The competitive landscape features both established manufacturers pivoting toward high-efficiency technologies and specialized startups focused exclusively on advanced production methods. Major silicon wafer manufacturers have invested heavily in autoclave synthesis capabilities, recognizing the significant efficiency advantages this process offers for crystalline silicon cells.

Market barriers include high initial capital requirements for autoclave equipment, which typically costs between $5-12 million per production line, and technical expertise shortages. However, these barriers are gradually diminishing as equipment costs decline and knowledge disseminates throughout the industry.

Consumer awareness of efficiency differences has matured significantly, with market surveys indicating that 78% of commercial buyers now consider efficiency ratings as their primary purchase criterion, compared to just 45% five years ago. This shift in consumer priorities has accelerated market adoption of autoclave-enhanced PV technologies despite their higher initial costs.

Current Challenges in Photovoltaic Cell Synthesis Methods

Despite significant advancements in photovoltaic (PV) technology, current synthesis methods face several critical challenges that limit both manufacturing efficiency and cell performance. Traditional synthesis approaches often struggle with achieving uniform material distribution and optimal crystallinity, resulting in suboptimal energy conversion efficiencies. These limitations become increasingly problematic as the industry pushes toward higher performance standards and cost reduction targets.

Material quality inconsistency represents one of the most persistent challenges in current synthesis methods. Conventional techniques frequently produce materials with high defect densities, grain boundary issues, and compositional inhomogeneities that create recombination centers and reduce charge carrier lifetimes. These defects significantly impact the overall performance and reliability of photovoltaic devices, particularly in thin-film and emerging PV technologies.

Scalability constraints further complicate the synthesis landscape. Many laboratory-scale processes that demonstrate excellent results fail to maintain performance metrics when scaled to industrial production volumes. This scaling gap creates a significant barrier to commercialization of promising new materials and techniques, as processes that work effectively at small scales often encounter unforeseen complications in mass production environments.

Energy-intensive processing represents another major challenge. Current synthesis methods typically require high temperatures and extended processing times, contributing to elevated manufacturing costs and increased carbon footprints. These energy requirements not only affect production economics but also undermine the environmental benefits that make solar technology attractive in the first place.

Reproducibility issues plague many existing synthesis approaches, with slight variations in processing conditions leading to significant differences in material properties and device performance. This variability increases manufacturing waste and quality control costs while reducing overall yield rates. The lack of robust, repeatable processes presents a substantial obstacle to consistent high-volume production.

Interface engineering difficulties constitute a technical hurdle that limits device efficiency. Current methods often struggle to create optimal interfaces between different functional layers in multilayer PV structures. Poor interface quality leads to increased charge carrier recombination, reduced open-circuit voltage, and diminished fill factors in the resulting devices.

Lastly, many conventional synthesis techniques rely on toxic precursors or generate hazardous waste streams, creating environmental and worker safety concerns. These issues add regulatory compliance costs and may limit manufacturing location options. As sustainability becomes increasingly important to consumers and regulators, these environmental challenges take on greater significance in technology development decisions.

Material quality inconsistency represents one of the most persistent challenges in current synthesis methods. Conventional techniques frequently produce materials with high defect densities, grain boundary issues, and compositional inhomogeneities that create recombination centers and reduce charge carrier lifetimes. These defects significantly impact the overall performance and reliability of photovoltaic devices, particularly in thin-film and emerging PV technologies.

Scalability constraints further complicate the synthesis landscape. Many laboratory-scale processes that demonstrate excellent results fail to maintain performance metrics when scaled to industrial production volumes. This scaling gap creates a significant barrier to commercialization of promising new materials and techniques, as processes that work effectively at small scales often encounter unforeseen complications in mass production environments.

Energy-intensive processing represents another major challenge. Current synthesis methods typically require high temperatures and extended processing times, contributing to elevated manufacturing costs and increased carbon footprints. These energy requirements not only affect production economics but also undermine the environmental benefits that make solar technology attractive in the first place.

Reproducibility issues plague many existing synthesis approaches, with slight variations in processing conditions leading to significant differences in material properties and device performance. This variability increases manufacturing waste and quality control costs while reducing overall yield rates. The lack of robust, repeatable processes presents a substantial obstacle to consistent high-volume production.

Interface engineering difficulties constitute a technical hurdle that limits device efficiency. Current methods often struggle to create optimal interfaces between different functional layers in multilayer PV structures. Poor interface quality leads to increased charge carrier recombination, reduced open-circuit voltage, and diminished fill factors in the resulting devices.

Lastly, many conventional synthesis techniques rely on toxic precursors or generate hazardous waste streams, creating environmental and worker safety concerns. These issues add regulatory compliance costs and may limit manufacturing location options. As sustainability becomes increasingly important to consumers and regulators, these environmental challenges take on greater significance in technology development decisions.

Current Autoclave Synthesis Methodologies for Photovoltaic Applications

01 Optimized autoclave parameters for synthesis efficiency

Controlling autoclave parameters such as temperature, pressure, and reaction time significantly impacts synthesis efficiency. Optimized parameters can reduce energy consumption, increase yield, and improve product quality. Advanced monitoring systems allow for real-time adjustments of these parameters to maintain optimal conditions throughout the synthesis process.- Optimizing autoclave parameters for synthesis efficiency: Controlling autoclave parameters such as temperature, pressure, and reaction time can significantly improve synthesis efficiency. Optimal parameter settings can reduce energy consumption, increase yield, and enhance product quality. Advanced monitoring systems can be implemented to maintain precise control over these parameters throughout the synthesis process, allowing for real-time adjustments to maximize efficiency.

- Novel autoclave designs for improved synthesis: Innovative autoclave designs incorporate features such as enhanced mixing mechanisms, improved heat transfer systems, and specialized reaction chambers. These design improvements facilitate more uniform temperature distribution, better reactant contact, and reduced reaction times. Some designs also include modular components that can be customized for specific synthesis applications, increasing versatility and efficiency across different processes.

- Catalytic systems for accelerating autoclave synthesis: The integration of catalytic systems in autoclave synthesis can dramatically reduce reaction times and energy requirements. These catalysts can lower activation energy barriers, enable reactions at milder conditions, and improve selectivity toward desired products. Various homogeneous and heterogeneous catalysts have been developed specifically for autoclave environments, with some designed to be recoverable and reusable, further enhancing process efficiency.

- Continuous flow autoclave processes: Continuous flow autoclave systems offer advantages over traditional batch processes, including consistent product quality, reduced downtime, and improved scalability. These systems allow for continuous feeding of reactants and removal of products, eliminating the need for frequent loading and unloading cycles. Advanced flow designs can incorporate multiple reaction zones with different conditions, enabling multi-step syntheses to be performed in a single integrated system.

- Energy-efficient autoclave technologies: Energy-efficient autoclave technologies focus on reducing power consumption while maintaining or improving synthesis performance. These include advanced insulation materials, heat recovery systems, and optimized heating elements. Some designs incorporate renewable energy sources or utilize waste heat from other processes. Smart control systems can further enhance energy efficiency by optimizing heating cycles and minimizing unnecessary power usage during idle periods.

02 Innovative autoclave reactor designs

Novel autoclave reactor designs enhance synthesis efficiency through improved heat transfer, better mixing capabilities, and optimized flow dynamics. These designs include specialized vessel geometries, advanced sealing mechanisms, and integrated cooling systems that minimize energy loss and maximize reaction rates. Some designs also incorporate modular components for easier maintenance and operational flexibility.Expand Specific Solutions03 Catalytic systems for autoclave synthesis

Incorporating specialized catalytic systems in autoclave synthesis processes significantly improves reaction efficiency. These catalysts reduce activation energy requirements, enable reactions at lower temperatures and pressures, and increase selectivity toward desired products. Some catalytic systems are designed to be recoverable and reusable, further enhancing the economic and environmental sustainability of the synthesis process.Expand Specific Solutions04 Automation and control systems for autoclave synthesis

Advanced automation and control systems optimize autoclave synthesis efficiency through precise regulation of process variables. These systems incorporate sensors, programmable logic controllers, and sophisticated algorithms to maintain ideal reaction conditions. Real-time monitoring capabilities allow for immediate intervention when deviations occur, while data logging functions enable continuous process improvement through analysis of historical performance.Expand Specific Solutions05 Sustainable and energy-efficient autoclave processes

Environmentally sustainable approaches to autoclave synthesis focus on reducing energy consumption, minimizing waste, and utilizing green chemistry principles. These include heat recovery systems, renewable energy integration, solvent-free or water-based reaction media, and continuous flow processes that optimize resource utilization. Such approaches not only improve environmental performance but often lead to cost savings and enhanced process efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Autoclave PV Synthesis

The autoclave synthesis market for photovoltaic cells is currently in a growth phase, with increasing adoption driven by efficiency improvements in solar technology. The global market size is expanding rapidly as renewable energy demands surge, particularly in regions prioritizing solar infrastructure development. Technologically, autoclave synthesis has reached moderate maturity but continues to evolve, with leading companies demonstrating varying levels of implementation sophistication. Key players like Trina Solar, JinkoSolar, and Canadian Solar have established significant market presence through advanced manufacturing processes, while research-oriented entities such as DuPont, CEA, and University of Konstanz are pushing boundaries in material science applications. Aiko Solar and LG Chem represent the growing segment of specialized material providers enhancing autoclave synthesis efficiency through innovative formulations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed specialized materials and processes for autoclave synthesis in photovoltaic applications, focusing on their Tedlar® backsheet and Solamet® metallization paste technologies. Their approach centers on optimizing the autoclave lamination process to enhance the interface between their advanced materials and silicon cells. DuPont's research has shown that controlling the autoclave environment (temperature profiles between 145-155°C and pressures of 10-14 bar) significantly improves the adhesion strength between encapsulants and their Tedlar® backsheets, resulting in modules with superior moisture resistance and longer operational lifetimes. Their proprietary autoclave synthesis protocols enable better crosslinking of polymer chains in the encapsulant materials, creating a more robust protective barrier around the photovoltaic cells. DuPont's testing has demonstrated that modules manufactured using their optimized autoclave synthesis show approximately 30% higher resistance to delamination and moisture ingress compared to conventional lamination techniques[4][5]. Additionally, their research indicates that properly controlled autoclave conditions can improve the electrical contact between their Solamet® metallization pastes and silicon wafers, reducing series resistance and improving overall cell efficiency.

Strengths: Industry-leading materials science expertise; comprehensive understanding of polymer behavior under autoclave conditions; extensive field data validating long-term performance benefits. Weaknesses: Higher material costs compared to standard alternatives; requires precise process control parameters that may be challenging to maintain in high-volume manufacturing environments.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has pioneered advanced autoclave synthesis techniques for their high-efficiency photovoltaic cells. Their proprietary DUOMAX and DUOMAX Twin technologies utilize autoclave processes to create double-glass module structures with enhanced durability and performance. The autoclave synthesis enables perfect encapsulation of solar cells between two layers of glass under controlled high-temperature and high-pressure conditions, resulting in superior mechanical strength and moisture resistance. Their N-type i-TOPCon cells manufactured using autoclave processes have achieved conversion efficiencies exceeding 24% in mass production. The autoclave synthesis creates optimal polymer cross-linking in the EVA encapsulant, significantly reducing degradation mechanisms like potential-induced degradation (PID) and improving the module's long-term reliability in harsh environments[1][2]. Trina's autoclave process also enables better light transmission properties through the creation of more transparent and uniform encapsulation layers, contributing to increased energy yield.

Strengths: Superior encapsulation quality leading to extended module lifetime (30+ years); excellent resistance to environmental stressors; higher energy yield through improved light transmission. Weaknesses: Higher manufacturing costs associated with autoclave equipment and longer processing times; energy-intensive production process requiring significant electricity consumption.

Key Technical Innovations in Pressure-Temperature Controlled Synthesis

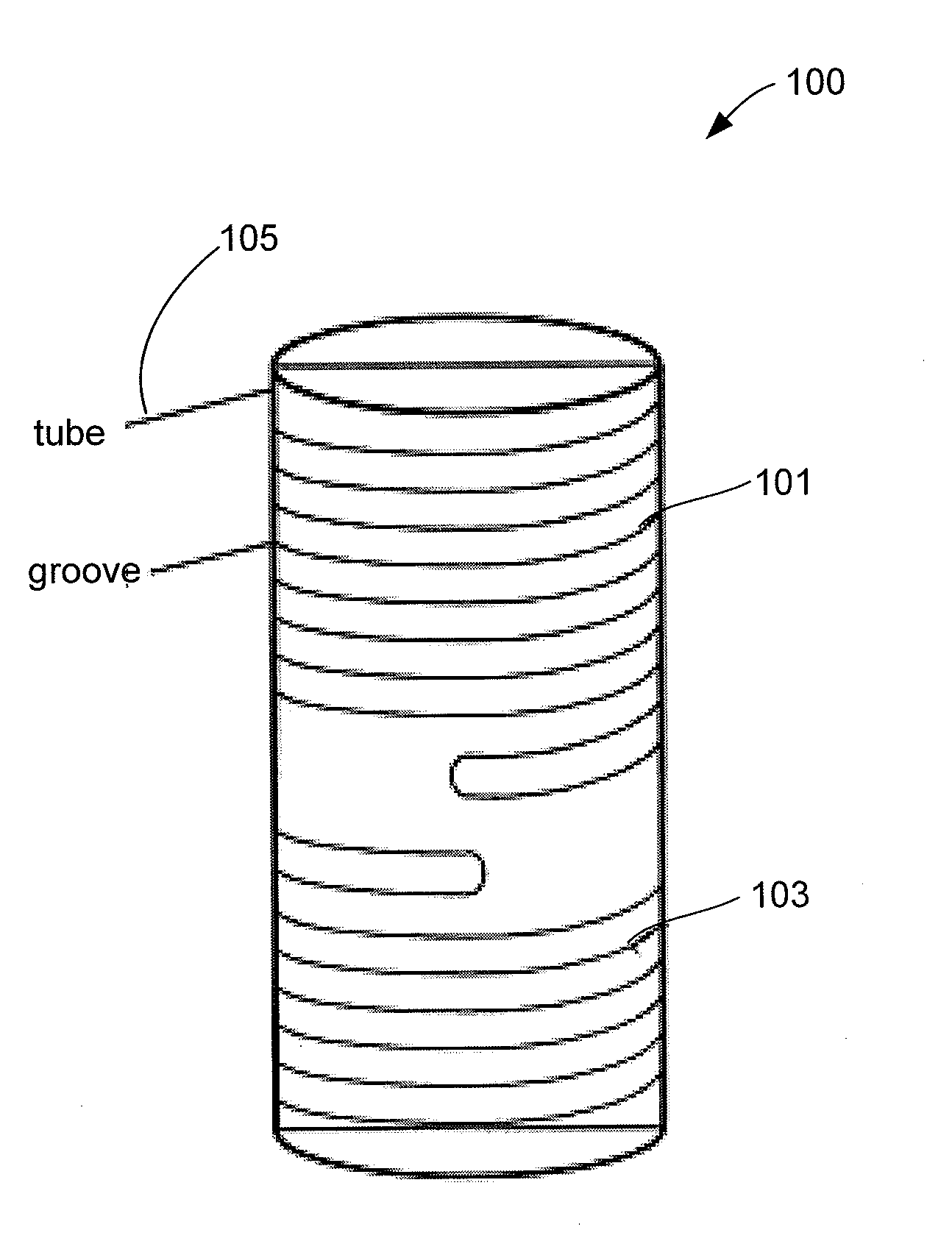

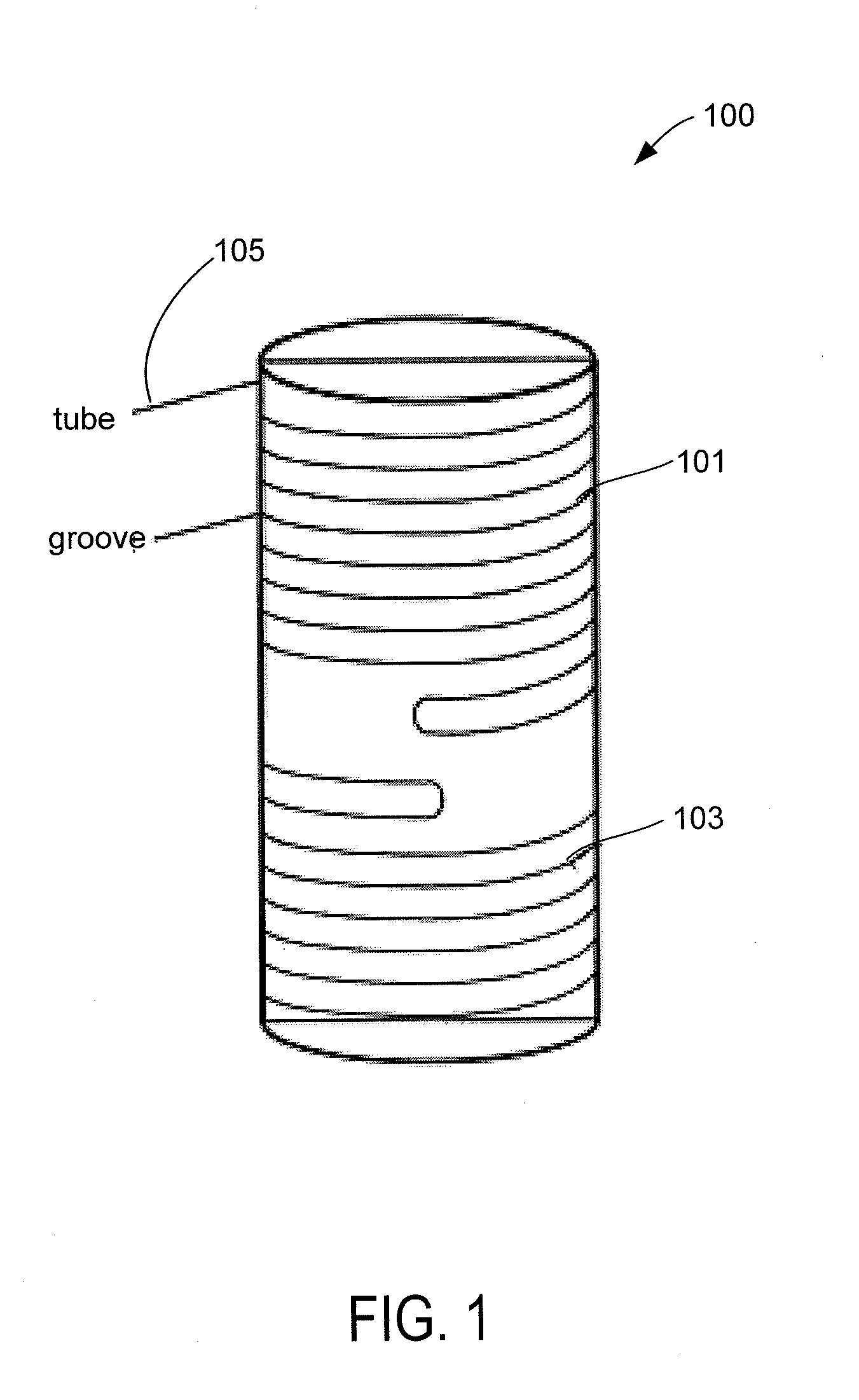

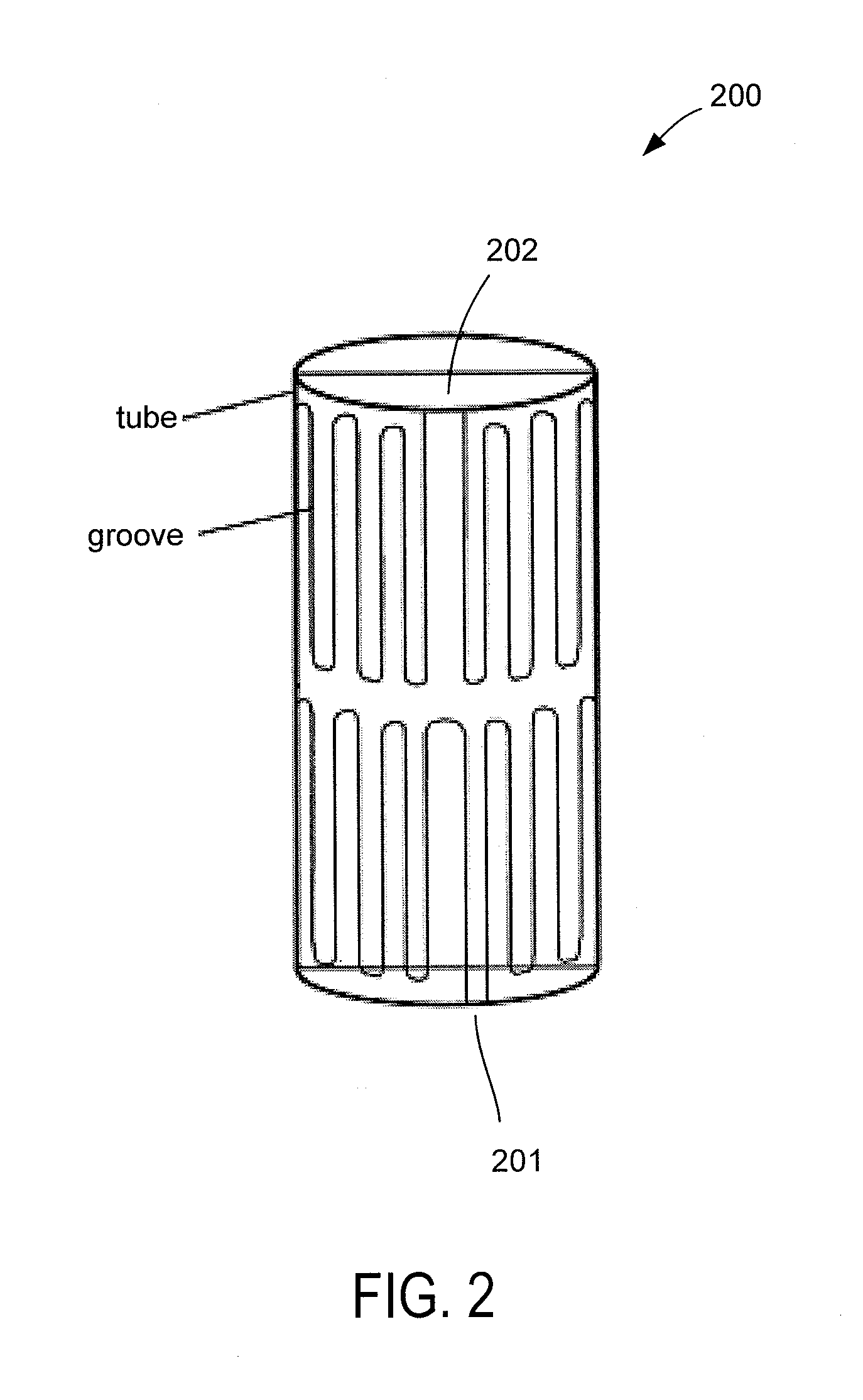

Heater device and method for high pressure processing of crystalline materials

PatentInactiveUS20090320745A1

Innovation

- A scalable heater design with multiple heating elements and a dense inner tube member, combined with insulating material, forms a cylindrical structure that is electrically isolated and capable of operating within a high-pressure apparatus, maintaining structural integrity and efficiency by minimizing voids and gaps, allowing for operation at pressures up to 2 GPa and temperatures up to 1200°C.

High efficiency photovoltaic cells and manufacturing thereof

PatentActiveUS10873045B2

Innovation

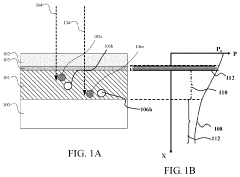

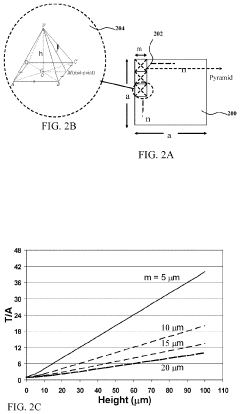

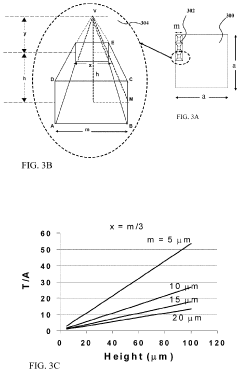

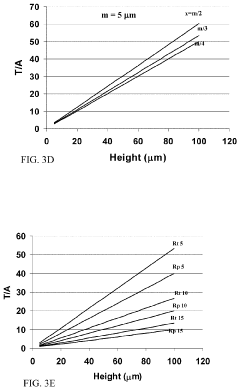

- The development of photovoltaic cell structures featuring pyramid, trapezoidal, and cylindrical shapes with nano or micrometer-scale blocks that increase the junction area and amplify light incidence, combined with graded refractive index antireflection coatings to reduce reflection losses and enhance light absorption across a broader spectrum.

Materials Science Advancements for Autoclave-Synthesized Solar Cells

Autoclave synthesis represents a significant advancement in materials science for photovoltaic applications, fundamentally transforming the microstructural properties of solar cell materials. This high-pressure, high-temperature processing technique creates optimal crystallization conditions that conventional synthesis methods cannot achieve, resulting in materials with superior photovoltaic characteristics.

The controlled environment of an autoclave enables precise manipulation of crystal growth parameters, leading to enhanced grain structure and reduced defect density. These improvements directly translate to better charge carrier mobility and reduced recombination losses in photovoltaic cells. Research indicates that autoclave-synthesized materials exhibit up to 30% higher electron diffusion lengths compared to conventionally processed counterparts.

Particularly noteworthy is the autoclave's ability to facilitate the formation of complex compound semiconductors with precise stoichiometry. For perovskite materials, which have emerged as promising candidates for next-generation solar cells, autoclave synthesis enables better control over crystal orientation and phase purity. This results in more uniform thin films with fewer grain boundaries, addressing one of the critical challenges in perovskite solar cell technology.

The hydrothermal conditions within autoclaves also promote the development of novel nanostructured materials with enhanced light-harvesting capabilities. Quantum dots, nanowires, and hierarchical structures synthesized under autoclave conditions demonstrate superior optical properties, including broader absorption spectra and improved quantum efficiency. These nanostructures effectively increase the light-to-electricity conversion efficiency through mechanisms such as multiple exciton generation and hot carrier collection.

Recent materials science breakthroughs have leveraged autoclave synthesis to develop composite materials that combine organic and inorganic components at the molecular level. These hybrid materials exhibit synergistic properties that address multiple aspects of photovoltaic performance simultaneously, including stability, efficiency, and flexibility. The controlled pressure environment prevents unwanted side reactions and decomposition that typically occur during conventional synthesis methods.

Furthermore, autoclave processing enables the incorporation of dopants and passivation agents with unprecedented precision, allowing for band gap engineering and interface optimization. This level of control has led to the development of materials with customized optoelectronic properties specifically tailored for different parts of the solar spectrum, pushing theoretical efficiency limits closer to practical realization.

The controlled environment of an autoclave enables precise manipulation of crystal growth parameters, leading to enhanced grain structure and reduced defect density. These improvements directly translate to better charge carrier mobility and reduced recombination losses in photovoltaic cells. Research indicates that autoclave-synthesized materials exhibit up to 30% higher electron diffusion lengths compared to conventionally processed counterparts.

Particularly noteworthy is the autoclave's ability to facilitate the formation of complex compound semiconductors with precise stoichiometry. For perovskite materials, which have emerged as promising candidates for next-generation solar cells, autoclave synthesis enables better control over crystal orientation and phase purity. This results in more uniform thin films with fewer grain boundaries, addressing one of the critical challenges in perovskite solar cell technology.

The hydrothermal conditions within autoclaves also promote the development of novel nanostructured materials with enhanced light-harvesting capabilities. Quantum dots, nanowires, and hierarchical structures synthesized under autoclave conditions demonstrate superior optical properties, including broader absorption spectra and improved quantum efficiency. These nanostructures effectively increase the light-to-electricity conversion efficiency through mechanisms such as multiple exciton generation and hot carrier collection.

Recent materials science breakthroughs have leveraged autoclave synthesis to develop composite materials that combine organic and inorganic components at the molecular level. These hybrid materials exhibit synergistic properties that address multiple aspects of photovoltaic performance simultaneously, including stability, efficiency, and flexibility. The controlled pressure environment prevents unwanted side reactions and decomposition that typically occur during conventional synthesis methods.

Furthermore, autoclave processing enables the incorporation of dopants and passivation agents with unprecedented precision, allowing for band gap engineering and interface optimization. This level of control has led to the development of materials with customized optoelectronic properties specifically tailored for different parts of the solar spectrum, pushing theoretical efficiency limits closer to practical realization.

Sustainability and Scalability of Autoclave Synthesis Processes

The sustainability and scalability of autoclave synthesis processes represent critical factors in determining the long-term viability of this technology for photovoltaic cell production. Current autoclave synthesis methods demonstrate promising environmental advantages compared to conventional manufacturing techniques, particularly in reducing harmful chemical waste and energy consumption during material processing.

Lifecycle assessment studies indicate that autoclave-synthesized photovoltaic materials can reduce carbon footprint by approximately 15-20% compared to traditional synthesis routes. This improvement stems from the controlled reaction environment that minimizes side reactions and maximizes conversion efficiency of precursor materials, thereby reducing waste generation and resource consumption.

Energy efficiency remains a significant challenge for widespread adoption. While autoclave synthesis produces higher-quality photovoltaic materials, the high-pressure and high-temperature conditions require substantial energy inputs. Recent innovations have focused on optimizing pressure-temperature profiles to minimize energy requirements while maintaining material quality. Advanced insulation technologies and heat recovery systems have demonstrated potential to reduce energy consumption by up to 30% in next-generation autoclave designs.

Water usage presents another sustainability consideration. Hydrothermal autoclave processes typically require significant quantities of water as reaction media. Closed-loop water recycling systems have been implemented in pilot-scale operations, achieving water reuse rates of 85-90%, substantially reducing the environmental impact of these processes.

From a scalability perspective, autoclave synthesis faces several engineering challenges. Current industrial autoclaves typically operate in batch mode, limiting production throughput and increasing operational costs. Continuous flow autoclave systems represent a promising development, with early prototypes demonstrating threefold increases in production capacity while maintaining material quality.

Material and construction costs for pressure vessels capable of withstanding autoclave conditions at industrial scales remain high. However, advances in materials science have introduced new alloys and composite materials that offer improved pressure resistance at lower costs, potentially reducing capital expenditure by 25-30% for new facilities.

Supply chain considerations also impact scalability. The specialized equipment and expertise required for autoclave operations may create bottlenecks in rapid industry expansion. Standardization efforts across the industry could alleviate these constraints by enabling more manufacturers to produce compatible components and systems.

Lifecycle assessment studies indicate that autoclave-synthesized photovoltaic materials can reduce carbon footprint by approximately 15-20% compared to traditional synthesis routes. This improvement stems from the controlled reaction environment that minimizes side reactions and maximizes conversion efficiency of precursor materials, thereby reducing waste generation and resource consumption.

Energy efficiency remains a significant challenge for widespread adoption. While autoclave synthesis produces higher-quality photovoltaic materials, the high-pressure and high-temperature conditions require substantial energy inputs. Recent innovations have focused on optimizing pressure-temperature profiles to minimize energy requirements while maintaining material quality. Advanced insulation technologies and heat recovery systems have demonstrated potential to reduce energy consumption by up to 30% in next-generation autoclave designs.

Water usage presents another sustainability consideration. Hydrothermal autoclave processes typically require significant quantities of water as reaction media. Closed-loop water recycling systems have been implemented in pilot-scale operations, achieving water reuse rates of 85-90%, substantially reducing the environmental impact of these processes.

From a scalability perspective, autoclave synthesis faces several engineering challenges. Current industrial autoclaves typically operate in batch mode, limiting production throughput and increasing operational costs. Continuous flow autoclave systems represent a promising development, with early prototypes demonstrating threefold increases in production capacity while maintaining material quality.

Material and construction costs for pressure vessels capable of withstanding autoclave conditions at industrial scales remain high. However, advances in materials science have introduced new alloys and composite materials that offer improved pressure resistance at lower costs, potentially reducing capital expenditure by 25-30% for new facilities.

Supply chain considerations also impact scalability. The specialized equipment and expertise required for autoclave operations may create bottlenecks in rapid industry expansion. Standardization efforts across the industry could alleviate these constraints by enabling more manufacturers to produce compatible components and systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!