Autoclave Synthesis and Its Role in Advanced Battery Electrolytes

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Technology Evolution and Objectives

Autoclave synthesis technology has evolved significantly over the past several decades, transforming from a basic high-pressure reaction vessel to a sophisticated tool for advanced materials synthesis. Originally developed for industrial applications in the early 20th century, autoclaves were primarily used in chemical manufacturing processes requiring elevated pressures and temperatures. By the 1950s, these systems began finding applications in materials science, particularly for hydrothermal synthesis of ceramics and minerals.

The 1970s marked a pivotal shift when researchers began exploring autoclave synthesis for energy storage materials, though with limited control over reaction parameters. The 1980s and 1990s witnessed substantial improvements in autoclave design, including enhanced pressure monitoring, temperature control systems, and corrosion-resistant materials that expanded their application scope significantly.

The early 2000s brought computerized control systems and in-situ monitoring capabilities, allowing for precise reaction environment manipulation and real-time data collection. This technological advancement coincided with growing interest in advanced battery technologies, creating a synergistic relationship between autoclave synthesis capabilities and electrolyte development needs.

In the context of battery electrolytes, autoclave synthesis offers unique advantages for creating materials under controlled solvothermal conditions. These conditions enable the formation of novel electrolyte components with tailored properties that are otherwise unattainable through conventional synthesis methods. The high-pressure, high-temperature environment facilitates reactions between precursors that might remain inert under ambient conditions.

Current objectives in autoclave synthesis technology for battery electrolytes focus on several key areas. First is the development of scalable processes that can bridge laboratory discoveries with industrial production requirements. Second is the integration of real-time characterization techniques to better understand reaction mechanisms and kinetics during synthesis. Third is the design of specialized autoclave systems optimized specifically for electrolyte component synthesis, featuring enhanced safety features and precise control over reaction parameters.

Another critical objective is the exploration of green chemistry approaches within autoclave synthesis, reducing reliance on toxic solvents and energy-intensive processes. Researchers are also pursuing the development of combinatorial autoclave systems capable of high-throughput screening of multiple reaction conditions simultaneously, accelerating the discovery of novel electrolyte materials.

The ultimate goal of these technological advancements is to enable the synthesis of next-generation electrolyte components with superior ionic conductivity, electrochemical stability, and safety characteristics, directly addressing the current limitations in battery technology and supporting the global transition toward sustainable energy systems.

The 1970s marked a pivotal shift when researchers began exploring autoclave synthesis for energy storage materials, though with limited control over reaction parameters. The 1980s and 1990s witnessed substantial improvements in autoclave design, including enhanced pressure monitoring, temperature control systems, and corrosion-resistant materials that expanded their application scope significantly.

The early 2000s brought computerized control systems and in-situ monitoring capabilities, allowing for precise reaction environment manipulation and real-time data collection. This technological advancement coincided with growing interest in advanced battery technologies, creating a synergistic relationship between autoclave synthesis capabilities and electrolyte development needs.

In the context of battery electrolytes, autoclave synthesis offers unique advantages for creating materials under controlled solvothermal conditions. These conditions enable the formation of novel electrolyte components with tailored properties that are otherwise unattainable through conventional synthesis methods. The high-pressure, high-temperature environment facilitates reactions between precursors that might remain inert under ambient conditions.

Current objectives in autoclave synthesis technology for battery electrolytes focus on several key areas. First is the development of scalable processes that can bridge laboratory discoveries with industrial production requirements. Second is the integration of real-time characterization techniques to better understand reaction mechanisms and kinetics during synthesis. Third is the design of specialized autoclave systems optimized specifically for electrolyte component synthesis, featuring enhanced safety features and precise control over reaction parameters.

Another critical objective is the exploration of green chemistry approaches within autoclave synthesis, reducing reliance on toxic solvents and energy-intensive processes. Researchers are also pursuing the development of combinatorial autoclave systems capable of high-throughput screening of multiple reaction conditions simultaneously, accelerating the discovery of novel electrolyte materials.

The ultimate goal of these technological advancements is to enable the synthesis of next-generation electrolyte components with superior ionic conductivity, electrochemical stability, and safety characteristics, directly addressing the current limitations in battery technology and supporting the global transition toward sustainable energy systems.

Market Demand Analysis for Advanced Battery Electrolytes

The global market for advanced battery electrolytes is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate that the advanced battery electrolyte market reached approximately 4.2 billion USD in 2022 and is projected to grow at a compound annual growth rate of 15.7% through 2030, potentially reaching 13.6 billion USD.

The demand for autoclave-synthesized electrolytes stems from their superior performance characteristics, particularly in high-energy-density applications. Industry analysis reveals that automotive applications currently represent the largest market segment, accounting for nearly 60% of the total demand. This is primarily due to the automotive industry's push toward longer-range EVs and faster charging capabilities, both of which require electrolytes with enhanced thermal stability and ionic conductivity that autoclave synthesis can provide.

Consumer electronics manufacturers constitute the second-largest market segment, representing approximately 25% of demand. These manufacturers seek electrolytes that enable higher energy density in smaller form factors while maintaining safety standards. The remaining market share is distributed among grid storage applications, aerospace, and military sectors, all of which prioritize reliability and performance under extreme conditions.

Geographically, Asia-Pacific dominates the market with over 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America and Europe follow with approximately 30% and 20% market shares respectively, with both regions showing accelerated growth rates due to governmental policies supporting electrification and renewable energy integration.

Market research indicates that customers are increasingly prioritizing electrolytes that offer enhanced safety profiles, longer cycle life, and improved performance at temperature extremes. Autoclave synthesis methods address these demands by enabling the creation of more stable electrolyte formulations with reduced impurities and more consistent molecular structures.

The market also shows growing interest in sustainable and environmentally friendly electrolyte solutions. This trend is evidenced by increasing research investments in green synthesis methods and bio-derived components that can be incorporated into autoclave processes. Companies that can demonstrate reduced environmental impact while maintaining performance metrics are gaining competitive advantages in tender processes, particularly for government and large corporate contracts.

Supply chain considerations are becoming increasingly critical, with recent global disruptions highlighting vulnerabilities in the procurement of raw materials for advanced electrolytes. This has led to increased interest in autoclave synthesis methods that can utilize alternative precursors or enable more efficient use of scarce resources.

The demand for autoclave-synthesized electrolytes stems from their superior performance characteristics, particularly in high-energy-density applications. Industry analysis reveals that automotive applications currently represent the largest market segment, accounting for nearly 60% of the total demand. This is primarily due to the automotive industry's push toward longer-range EVs and faster charging capabilities, both of which require electrolytes with enhanced thermal stability and ionic conductivity that autoclave synthesis can provide.

Consumer electronics manufacturers constitute the second-largest market segment, representing approximately 25% of demand. These manufacturers seek electrolytes that enable higher energy density in smaller form factors while maintaining safety standards. The remaining market share is distributed among grid storage applications, aerospace, and military sectors, all of which prioritize reliability and performance under extreme conditions.

Geographically, Asia-Pacific dominates the market with over 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America and Europe follow with approximately 30% and 20% market shares respectively, with both regions showing accelerated growth rates due to governmental policies supporting electrification and renewable energy integration.

Market research indicates that customers are increasingly prioritizing electrolytes that offer enhanced safety profiles, longer cycle life, and improved performance at temperature extremes. Autoclave synthesis methods address these demands by enabling the creation of more stable electrolyte formulations with reduced impurities and more consistent molecular structures.

The market also shows growing interest in sustainable and environmentally friendly electrolyte solutions. This trend is evidenced by increasing research investments in green synthesis methods and bio-derived components that can be incorporated into autoclave processes. Companies that can demonstrate reduced environmental impact while maintaining performance metrics are gaining competitive advantages in tender processes, particularly for government and large corporate contracts.

Supply chain considerations are becoming increasingly critical, with recent global disruptions highlighting vulnerabilities in the procurement of raw materials for advanced electrolytes. This has led to increased interest in autoclave synthesis methods that can utilize alternative precursors or enable more efficient use of scarce resources.

Current Status and Challenges in Autoclave Synthesis

Autoclave synthesis has emerged as a critical method in the development of advanced battery electrolytes, with significant progress made globally in recent years. Currently, this technology is predominantly utilized in research institutions and specialized manufacturing facilities across North America, Europe, and East Asia, with China, Japan, and South Korea leading in commercial applications.

The state-of-the-art autoclave synthesis techniques employ high-pressure reactors capable of operating at pressures up to 200 bar and temperatures reaching 400°C, allowing for precise control of reaction parameters that conventional methods cannot achieve. These advanced systems incorporate real-time monitoring capabilities, enabling researchers to track reaction kinetics and adjust conditions dynamically during synthesis processes.

Despite these advancements, several significant challenges persist in autoclave synthesis for battery electrolyte development. Scalability remains a primary concern, as transitioning from laboratory-scale production to industrial manufacturing often results in inconsistent product quality and yield reduction. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods also presents economic and sustainability challenges for commercial implementation.

Safety considerations constitute another major obstacle, particularly when working with volatile precursors common in electrolyte synthesis. The risk of pressure vessel failure, though rare with modern equipment, necessitates stringent safety protocols and specialized training, limiting widespread adoption of these techniques outside of well-equipped facilities.

Material compatibility issues further complicate autoclave synthesis processes. The corrosive nature of many electrolyte components requires specialized reactor materials that can withstand both high pressures and chemical attack, often necessitating expensive alloys or protective linings that significantly increase equipment costs.

Reproducibility challenges also persist across different autoclave systems and between laboratories. Minor variations in heating rates, cooling profiles, and agitation methods can substantially impact the final electrolyte properties, making standardization difficult across the industry.

Geographically, autoclave technology development shows distinct regional characteristics. European research centers focus predominantly on environmentally sustainable synthesis routes, while Asian manufacturers emphasize high-throughput production methods. North American institutions lead in developing novel reactor designs with enhanced monitoring capabilities.

The integration of artificial intelligence and machine learning approaches for optimizing reaction parameters represents an emerging trend, though implementation remains in early stages. These computational methods show promise for addressing the parameter optimization challenges that currently require extensive experimental iterations.

The state-of-the-art autoclave synthesis techniques employ high-pressure reactors capable of operating at pressures up to 200 bar and temperatures reaching 400°C, allowing for precise control of reaction parameters that conventional methods cannot achieve. These advanced systems incorporate real-time monitoring capabilities, enabling researchers to track reaction kinetics and adjust conditions dynamically during synthesis processes.

Despite these advancements, several significant challenges persist in autoclave synthesis for battery electrolyte development. Scalability remains a primary concern, as transitioning from laboratory-scale production to industrial manufacturing often results in inconsistent product quality and yield reduction. The high energy consumption associated with maintaining elevated temperatures and pressures for extended periods also presents economic and sustainability challenges for commercial implementation.

Safety considerations constitute another major obstacle, particularly when working with volatile precursors common in electrolyte synthesis. The risk of pressure vessel failure, though rare with modern equipment, necessitates stringent safety protocols and specialized training, limiting widespread adoption of these techniques outside of well-equipped facilities.

Material compatibility issues further complicate autoclave synthesis processes. The corrosive nature of many electrolyte components requires specialized reactor materials that can withstand both high pressures and chemical attack, often necessitating expensive alloys or protective linings that significantly increase equipment costs.

Reproducibility challenges also persist across different autoclave systems and between laboratories. Minor variations in heating rates, cooling profiles, and agitation methods can substantially impact the final electrolyte properties, making standardization difficult across the industry.

Geographically, autoclave technology development shows distinct regional characteristics. European research centers focus predominantly on environmentally sustainable synthesis routes, while Asian manufacturers emphasize high-throughput production methods. North American institutions lead in developing novel reactor designs with enhanced monitoring capabilities.

The integration of artificial intelligence and machine learning approaches for optimizing reaction parameters represents an emerging trend, though implementation remains in early stages. These computational methods show promise for addressing the parameter optimization challenges that currently require extensive experimental iterations.

Current Autoclave Synthesis Methods for Electrolytes

01 Hydrothermal synthesis of nanomaterials

Autoclave synthesis is widely used for hydrothermal synthesis of various nanomaterials under controlled temperature and pressure conditions. This method enables the formation of crystalline structures with specific morphologies and properties. The process typically involves placing precursor materials in a sealed autoclave vessel with water or other solvents, which is then heated to create high-pressure conditions that facilitate crystal growth and formation of nanomaterials with desired characteristics.- Hydrothermal synthesis of nanomaterials: Autoclave synthesis is widely used for hydrothermal synthesis of various nanomaterials under controlled temperature and pressure conditions. This method enables the growth of high-quality crystals and nanostructures by utilizing water as a reaction medium at elevated temperatures and pressures. The controlled environment within the autoclave facilitates the formation of unique crystal structures and morphologies that are difficult to achieve through conventional synthesis methods.

- Pharmaceutical and medical applications: Autoclave synthesis is employed in the pharmaceutical and medical industries for the production of sterile compounds and medical materials. The high-pressure and high-temperature conditions in autoclaves enable the synthesis of pharmaceutical ingredients with high purity and specific properties. This method is particularly valuable for creating materials used in medical devices, drug delivery systems, and biocompatible implants where sterility and precise material properties are critical.

- Advanced ceramic and composite materials synthesis: Autoclaves provide controlled environments for synthesizing advanced ceramic and composite materials with specific properties. The high-pressure conditions facilitate the formation of dense materials with reduced porosity and enhanced mechanical properties. This synthesis method allows for the creation of specialized ceramics and composites used in high-performance applications where material integrity and specific physical characteristics are essential.

- Autoclave equipment and process optimization: Innovations in autoclave equipment design and process optimization have enhanced synthesis capabilities and efficiency. These advancements include improved temperature and pressure control systems, specialized vessel materials, and automated monitoring technologies. Modern autoclave systems incorporate safety features, energy efficiency improvements, and precise parameter control to achieve consistent synthesis results while minimizing operational risks.

- Green chemistry and sustainable synthesis methods: Autoclave synthesis supports green chemistry principles by enabling efficient reactions in closed systems with minimal waste generation. The controlled environment allows for the use of environmentally friendly solvents and reduces the need for harmful reagents. This approach to synthesis aligns with sustainable manufacturing practices by optimizing resource utilization, reducing energy consumption, and minimizing environmental impact while maintaining high product quality.

02 Autoclave equipment design and optimization

Specialized autoclave equipment designs have been developed to enhance synthesis efficiency and safety. These designs include features such as improved sealing mechanisms, precise temperature control systems, pressure monitoring devices, and corrosion-resistant materials. Advanced autoclaves may incorporate automated control systems, specialized heating elements, and safety features to prevent accidents during high-pressure synthesis operations.Expand Specific Solutions03 Pharmaceutical and medical material synthesis

Autoclave synthesis is employed in the pharmaceutical industry for the production of various medical compounds and materials. The controlled environment of an autoclave allows for sterile synthesis conditions and enables specific chemical reactions that require elevated temperatures and pressures. This approach is particularly valuable for creating specialized medical materials, drug delivery systems, and biocompatible compounds with specific properties.Expand Specific Solutions04 Sustainable materials production

Autoclave synthesis methods have been developed for environmentally friendly production of materials from waste products or renewable resources. These processes often utilize lower energy consumption compared to traditional synthesis methods and can incorporate principles of green chemistry. The high-pressure environment of autoclaves enables efficient conversion of biomass and other sustainable feedstocks into valuable materials and chemicals.Expand Specific Solutions05 Industrial scale autoclave processes

Scaling up autoclave synthesis from laboratory to industrial production presents unique challenges and solutions. Industrial autoclave systems incorporate specialized designs for handling large volumes of materials, maintaining uniform conditions throughout the reaction vessel, and ensuring operational safety at scale. These systems often feature advanced monitoring and control mechanisms, heat recovery systems, and automated material handling to optimize efficiency and product quality in commercial production environments.Expand Specific Solutions

Key Industry Players in Battery Electrolyte Manufacturing

The autoclave synthesis market for advanced battery electrolytes is currently in a growth phase, characterized by increasing demand driven by the electric vehicle and energy storage sectors. The global market size is expanding rapidly, projected to reach significant volumes as battery technologies evolve. Technologically, autoclave synthesis remains in mid-maturity, with established players like DuPont de Nemours and Sumitomo Chemical leading commercial applications, while research institutions such as Shanghai Jiao Tong University and Southeast University drive innovation. Companies like Shenzhen Dynanonic and Tianmu Lake Institute are emerging as specialized players focusing on nanomaterials and advanced energy storage solutions. The competitive landscape features both chemical conglomerates (Idemitsu Kosan) and specialized battery material developers, with increasing collaboration between industry and academic institutions to overcome technical challenges in electrolyte stability and performance.

Idemitsu Kosan Co., Ltd.

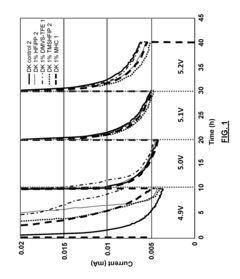

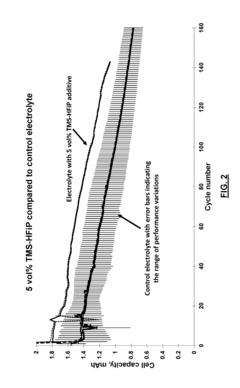

Technical Solution: Idemitsu Kosan has pioneered an advanced autoclave synthesis method for developing novel electrolyte formulations with enhanced thermal stability and electrochemical performance. Their approach utilizes supercritical fluid processing in specialized autoclaves, where carefully selected precursors are subjected to precisely controlled temperature and pressure conditions (typically 300-400°C and 200-300 bar). This enables the formation of unique molecular structures and solvation environments that conventional synthesis methods cannot achieve. The company has successfully developed fluorinated electrolyte additives through this process that significantly improve the solid electrolyte interphase (SEI) formation on battery anodes, resulting in extended cycle life and improved safety characteristics. Their autoclave synthesis also facilitates the creation of electrolytes with wider electrochemical stability windows (up to 5V), enabling compatibility with high-voltage cathode materials.

Strengths: Produces electrolytes with exceptional thermal stability up to 80°C; enables fast-charging capabilities while minimizing lithium plating; creates self-healing electrolyte interfaces that extend battery lifespan. Weaknesses: Energy-intensive production process; requires specialized handling of high-pressure equipment; some synthesized compounds have complex purification requirements.

GM Global Technology Operations LLC

Technical Solution: GM has developed a proprietary autoclave synthesis platform for next-generation battery electrolytes focused on electric vehicle applications. Their approach centers on hydrothermal autoclave processing of novel electrolyte components under moderate pressure (50-150 bar) and temperature (200-300°C) conditions. This controlled environment enables the synthesis of specialized electrolyte additives and solvents with precisely tailored molecular structures that enhance lithium-ion transport while suppressing parasitic reactions. GM's technology particularly excels in creating electrolyte systems that maintain performance at extreme temperatures (-30°C to +60°C), addressing a critical challenge for automotive applications. The company has also pioneered autoclave-assisted solvent purification techniques that remove trace impurities known to accelerate battery degradation, resulting in electrolytes with exceptional electrochemical stability even after extended cycling.

Strengths: Electrolytes demonstrate superior cold-weather performance with minimal capacity loss; excellent compatibility with silicon-composite anodes enabling higher energy density; reduced flammability compared to conventional carbonate electrolytes. Weaknesses: Higher production costs compared to standard electrolyte manufacturing; longer processing times required for optimal results; some specialized additives have limited shelf life.

Critical Patents and Research in Autoclave Electrolyte Synthesis

Electrolyte solvents and additives for advanced battery chemistries

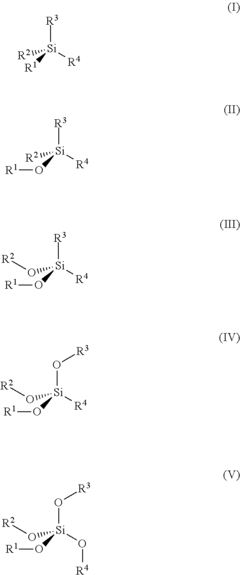

PatentInactiveUS20190027785A1

Innovation

- Development of new nonaqueous electrolyte solvents and additives with integrated functional structure elements such as silane, unsaturated, and fluorinated groups that form protective interphases on both anode and cathode surfaces, enabling stable and conductive performance across a wide temperature range.

Battery electrolytes and batteries

PatentInactiveUS6168889B1

Innovation

- A battery electrolyte composition using a solvent blend of ethylene carbonate, propylene carbonate, and 1,2-dimethoxyethane with lithium salts like LiN(CF3SO2)2, LiAsF6, LiBF4, LiPF6, and LiCF3SO3, which provides superior ionic conductivity and thermal stability, enhancing discharge performance across a wide temperature range.

Environmental Impact and Sustainability Considerations

The autoclave synthesis process for advanced battery electrolytes presents significant environmental considerations that must be addressed as this technology scales. High-pressure and high-temperature conditions required during autoclave synthesis consume substantial energy, contributing to carbon emissions when powered by non-renewable sources. A life cycle assessment of autoclave-synthesized electrolytes reveals that energy consumption during manufacturing represents approximately 40-60% of their total environmental footprint, highlighting the need for more efficient processing methods.

Chemical waste management poses another critical challenge. The synthesis of advanced electrolytes often involves solvents and precursors that may be toxic or environmentally persistent. Current data indicates that for every kilogram of electrolyte produced, approximately 15-20 liters of waste solvent may be generated, necessitating proper treatment and disposal protocols to prevent environmental contamination.

Resource efficiency represents a growing concern as demand for battery materials increases. Many advanced electrolytes incorporate rare earth elements or other critical materials with limited global supplies. Autoclave synthesis techniques that maximize yield and minimize material waste become increasingly important for sustainable production. Recent innovations have demonstrated potential for reducing raw material requirements by 15-25% through optimized autoclave parameters and recycling of process materials.

Water usage during synthesis and subsequent cleaning processes presents another environmental consideration. Depending on the specific electrolyte formulation, water consumption can range from 50-200 liters per kilogram of product. Closed-loop water systems and water recovery technologies are being implemented to reduce this environmental burden, with potential water savings of up to 70%.

The development of green chemistry approaches to autoclave synthesis shows promising sustainability improvements. Bio-derived solvents, catalysts that function at lower temperatures, and reaction pathways that eliminate hazardous intermediates are emerging as viable alternatives. These approaches can reduce the environmental impact of electrolyte production while maintaining or even enhancing performance characteristics.

End-of-life considerations for batteries containing these advanced electrolytes must also be addressed. Designing electrolytes with recyclability in mind can significantly reduce their lifetime environmental impact. Recent research indicates that properly designed electrolytes can improve battery recycling efficiency by 20-30%, recovering valuable materials and preventing hazardous components from entering waste streams.

Chemical waste management poses another critical challenge. The synthesis of advanced electrolytes often involves solvents and precursors that may be toxic or environmentally persistent. Current data indicates that for every kilogram of electrolyte produced, approximately 15-20 liters of waste solvent may be generated, necessitating proper treatment and disposal protocols to prevent environmental contamination.

Resource efficiency represents a growing concern as demand for battery materials increases. Many advanced electrolytes incorporate rare earth elements or other critical materials with limited global supplies. Autoclave synthesis techniques that maximize yield and minimize material waste become increasingly important for sustainable production. Recent innovations have demonstrated potential for reducing raw material requirements by 15-25% through optimized autoclave parameters and recycling of process materials.

Water usage during synthesis and subsequent cleaning processes presents another environmental consideration. Depending on the specific electrolyte formulation, water consumption can range from 50-200 liters per kilogram of product. Closed-loop water systems and water recovery technologies are being implemented to reduce this environmental burden, with potential water savings of up to 70%.

The development of green chemistry approaches to autoclave synthesis shows promising sustainability improvements. Bio-derived solvents, catalysts that function at lower temperatures, and reaction pathways that eliminate hazardous intermediates are emerging as viable alternatives. These approaches can reduce the environmental impact of electrolyte production while maintaining or even enhancing performance characteristics.

End-of-life considerations for batteries containing these advanced electrolytes must also be addressed. Designing electrolytes with recyclability in mind can significantly reduce their lifetime environmental impact. Recent research indicates that properly designed electrolytes can improve battery recycling efficiency by 20-30%, recovering valuable materials and preventing hazardous components from entering waste streams.

Scale-up and Commercialization Strategies

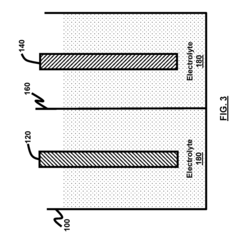

The transition from laboratory-scale autoclave synthesis to commercial production of advanced battery electrolytes presents significant challenges that require strategic planning and technological innovation. Current industrial-scale production typically employs batch processing methods, which offer flexibility but may struggle with consistency across large volumes. Continuous flow processing represents a promising alternative, potentially offering better quality control, reduced energy consumption, and improved safety profiles for handling the often volatile and sensitive electrolyte components.

Equipment modification represents a critical consideration in scale-up efforts. Industrial autoclaves must be designed with enhanced temperature control systems, pressure monitoring capabilities, and specialized mixing mechanisms to ensure uniform reaction conditions throughout larger volumes. Material selection becomes increasingly important at scale, as reactor vessels must withstand not only high pressures and temperatures but also the corrosive nature of many electrolyte components over extended production cycles.

Process parameter optimization requires substantial engineering effort during scale-up. Reaction kinetics often behave differently at industrial scales, necessitating adjustments to heating rates, pressure profiles, and residence times. Many companies implement Design of Experiments (DoE) methodologies to efficiently map the expanded parameter space and identify robust operating windows that maintain product quality while maximizing throughput.

Economic viability remains a central concern for commercialization. Capital expenditure for high-pressure autoclave systems can be substantial, requiring careful assessment of return on investment timelines. Operating costs, particularly energy consumption for maintaining elevated temperatures and pressures, must be optimized through heat recovery systems and process integration. Supply chain considerations also factor prominently, as consistent access to high-purity precursors becomes increasingly critical at commercial scales.

Regulatory compliance and safety protocols become more complex during scale-up. Larger quantities of potentially hazardous materials necessitate comprehensive risk assessments and mitigation strategies. Environmental impact considerations, including waste stream management and emissions control, must be addressed through process design and end-of-pipe treatment systems. Many jurisdictions require specific permits for large-scale pressure vessel operations, adding administrative complexity to commercialization efforts.

Strategic partnerships often prove valuable in navigating the scale-up journey. Collaborations between electrolyte developers, equipment manufacturers, and battery producers can distribute risk while providing complementary expertise. Licensing agreements represent another pathway to commercialization, allowing technology developers to focus on continued innovation while established manufacturers handle production scaling challenges.

Equipment modification represents a critical consideration in scale-up efforts. Industrial autoclaves must be designed with enhanced temperature control systems, pressure monitoring capabilities, and specialized mixing mechanisms to ensure uniform reaction conditions throughout larger volumes. Material selection becomes increasingly important at scale, as reactor vessels must withstand not only high pressures and temperatures but also the corrosive nature of many electrolyte components over extended production cycles.

Process parameter optimization requires substantial engineering effort during scale-up. Reaction kinetics often behave differently at industrial scales, necessitating adjustments to heating rates, pressure profiles, and residence times. Many companies implement Design of Experiments (DoE) methodologies to efficiently map the expanded parameter space and identify robust operating windows that maintain product quality while maximizing throughput.

Economic viability remains a central concern for commercialization. Capital expenditure for high-pressure autoclave systems can be substantial, requiring careful assessment of return on investment timelines. Operating costs, particularly energy consumption for maintaining elevated temperatures and pressures, must be optimized through heat recovery systems and process integration. Supply chain considerations also factor prominently, as consistent access to high-purity precursors becomes increasingly critical at commercial scales.

Regulatory compliance and safety protocols become more complex during scale-up. Larger quantities of potentially hazardous materials necessitate comprehensive risk assessments and mitigation strategies. Environmental impact considerations, including waste stream management and emissions control, must be addressed through process design and end-of-pipe treatment systems. Many jurisdictions require specific permits for large-scale pressure vessel operations, adding administrative complexity to commercialization efforts.

Strategic partnerships often prove valuable in navigating the scale-up journey. Collaborations between electrolyte developers, equipment manufacturers, and battery producers can distribute risk while providing complementary expertise. Licensing agreements represent another pathway to commercialization, allowing technology developers to focus on continued innovation while established manufacturers handle production scaling challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!