Why Autoclave Synthesis is Critical in Next-Generation Energy Storage Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Synthesis Background and Objectives

Autoclave synthesis has emerged as a cornerstone technology in the development of advanced materials for next-generation energy storage systems. This synthesis method, characterized by controlled high-pressure and high-temperature conditions within a sealed vessel, has evolved significantly since its initial applications in materials science during the mid-20th century. The technology has progressed from basic hydrothermal processes to sophisticated multi-parameter controlled synthesis environments that enable precise manipulation of material properties at the nanoscale.

The evolution of autoclave synthesis techniques has closely paralleled the increasing demands for higher energy density, improved cycling stability, and enhanced safety in energy storage technologies. Historical milestones include the development of specialized autoclave liners in the 1970s, the integration of microwave-assisted processes in the 1990s, and the recent advent of in-situ monitoring capabilities that allow real-time observation of crystallization and growth mechanisms.

Current technological trends in autoclave synthesis focus on scalability, reproducibility, and sustainability. The field is moving toward continuous flow autoclave systems that promise industrial-scale production while maintaining the precise control traditionally associated with batch processes. Additionally, there is growing emphasis on green chemistry approaches that reduce solvent usage and energy consumption during synthesis procedures.

The primary objective of advancing autoclave synthesis technology is to enable the creation of novel electrode materials, electrolytes, and separator components with precisely tailored properties for specific energy storage applications. These materials must meet increasingly stringent requirements for energy density, power capability, cycle life, and safety performance to support emerging applications in electric vehicles, grid-scale storage, and portable electronics.

A critical goal is to establish predictive synthesis protocols that can reliably produce materials with consistent performance characteristics at scale. This includes developing comprehensive understanding of the complex relationships between synthesis parameters (temperature, pressure, time, precursor chemistry) and the resulting material properties (morphology, crystal structure, surface chemistry, electrochemical behavior).

Furthermore, autoclave synthesis aims to address key limitations in current energy storage technologies by enabling the creation of materials with novel architectures, such as hierarchical porous structures, core-shell configurations, and heterostructured composites that can overcome traditional performance trade-offs. The ultimate objective is to facilitate a paradigm shift in energy storage capabilities that can meet the demands of a carbon-neutral economy through materials innovation.

The evolution of autoclave synthesis techniques has closely paralleled the increasing demands for higher energy density, improved cycling stability, and enhanced safety in energy storage technologies. Historical milestones include the development of specialized autoclave liners in the 1970s, the integration of microwave-assisted processes in the 1990s, and the recent advent of in-situ monitoring capabilities that allow real-time observation of crystallization and growth mechanisms.

Current technological trends in autoclave synthesis focus on scalability, reproducibility, and sustainability. The field is moving toward continuous flow autoclave systems that promise industrial-scale production while maintaining the precise control traditionally associated with batch processes. Additionally, there is growing emphasis on green chemistry approaches that reduce solvent usage and energy consumption during synthesis procedures.

The primary objective of advancing autoclave synthesis technology is to enable the creation of novel electrode materials, electrolytes, and separator components with precisely tailored properties for specific energy storage applications. These materials must meet increasingly stringent requirements for energy density, power capability, cycle life, and safety performance to support emerging applications in electric vehicles, grid-scale storage, and portable electronics.

A critical goal is to establish predictive synthesis protocols that can reliably produce materials with consistent performance characteristics at scale. This includes developing comprehensive understanding of the complex relationships between synthesis parameters (temperature, pressure, time, precursor chemistry) and the resulting material properties (morphology, crystal structure, surface chemistry, electrochemical behavior).

Furthermore, autoclave synthesis aims to address key limitations in current energy storage technologies by enabling the creation of materials with novel architectures, such as hierarchical porous structures, core-shell configurations, and heterostructured composites that can overcome traditional performance trade-offs. The ultimate objective is to facilitate a paradigm shift in energy storage capabilities that can meet the demands of a carbon-neutral economy through materials innovation.

Market Demand Analysis for Advanced Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources, electrification of transportation, and the growing need for grid stability. Market research indicates that the global advanced energy storage market is projected to reach $546 billion by 2035, with a compound annual growth rate of 19.7% from 2023 to 2035. This remarkable expansion underscores the critical importance of next-generation energy storage technologies, particularly those developed through autoclave synthesis methods.

Consumer electronics continue to demand batteries with higher energy density, faster charging capabilities, and improved safety profiles. The electric vehicle (EV) sector represents one of the most significant market drivers, with global EV sales exceeding 10 million units in 2022 and expected to reach 40 million by 2030. This exponential growth necessitates advanced battery technologies that can deliver longer ranges, faster charging times, and enhanced safety—all areas where autoclave-synthesized materials show particular promise.

Grid-scale energy storage represents another substantial market segment, with installed capacity projected to increase from 17 GW in 2022 to over 400 GW by 2030. Utility companies and grid operators are actively seeking storage solutions that offer longer duration, improved cycle life, and reduced levelized cost of storage (LCOS). Materials synthesized through autoclave processes have demonstrated superior performance metrics in these critical areas.

Regional analysis reveals varying market dynamics. Asia-Pacific dominates manufacturing capacity, with China accounting for approximately 75% of global battery production. However, recent policy initiatives in North America and Europe aim to establish domestic supply chains, creating new market opportunities for advanced synthesis technologies. The European Battery Alliance and the U.S. Inflation Reduction Act have allocated substantial funding specifically for next-generation battery technologies.

Industry surveys indicate that battery manufacturers are increasingly prioritizing sustainability and resource efficiency. Autoclave synthesis methods that enable the use of abundant, low-cost precursors and reduce energy consumption during manufacturing align perfectly with this market trend. Additionally, the ability to precisely control material properties through autoclave processes addresses the growing demand for customized energy storage solutions across different applications.

Consumer willingness to pay premiums for superior performance has created a viable market entry point for advanced energy storage technologies. Market segmentation analysis shows that high-performance sectors such as aerospace, premium EVs, and critical infrastructure backup systems are particularly receptive to the enhanced capabilities offered by autoclave-synthesized energy storage materials, despite potentially higher initial costs.

Consumer electronics continue to demand batteries with higher energy density, faster charging capabilities, and improved safety profiles. The electric vehicle (EV) sector represents one of the most significant market drivers, with global EV sales exceeding 10 million units in 2022 and expected to reach 40 million by 2030. This exponential growth necessitates advanced battery technologies that can deliver longer ranges, faster charging times, and enhanced safety—all areas where autoclave-synthesized materials show particular promise.

Grid-scale energy storage represents another substantial market segment, with installed capacity projected to increase from 17 GW in 2022 to over 400 GW by 2030. Utility companies and grid operators are actively seeking storage solutions that offer longer duration, improved cycle life, and reduced levelized cost of storage (LCOS). Materials synthesized through autoclave processes have demonstrated superior performance metrics in these critical areas.

Regional analysis reveals varying market dynamics. Asia-Pacific dominates manufacturing capacity, with China accounting for approximately 75% of global battery production. However, recent policy initiatives in North America and Europe aim to establish domestic supply chains, creating new market opportunities for advanced synthesis technologies. The European Battery Alliance and the U.S. Inflation Reduction Act have allocated substantial funding specifically for next-generation battery technologies.

Industry surveys indicate that battery manufacturers are increasingly prioritizing sustainability and resource efficiency. Autoclave synthesis methods that enable the use of abundant, low-cost precursors and reduce energy consumption during manufacturing align perfectly with this market trend. Additionally, the ability to precisely control material properties through autoclave processes addresses the growing demand for customized energy storage solutions across different applications.

Consumer willingness to pay premiums for superior performance has created a viable market entry point for advanced energy storage technologies. Market segmentation analysis shows that high-performance sectors such as aerospace, premium EVs, and critical infrastructure backup systems are particularly receptive to the enhanced capabilities offered by autoclave-synthesized energy storage materials, despite potentially higher initial costs.

Technical Challenges in Autoclave Synthesis

Autoclave synthesis presents several significant technical challenges that researchers and manufacturers must overcome to fully leverage its potential in next-generation energy storage systems. The high-pressure and high-temperature environment, while beneficial for creating unique material structures, introduces considerable engineering difficulties in terms of equipment design, safety protocols, and process control.

The primary challenge lies in achieving precise control over reaction parameters. Temperature gradients within the autoclave vessel can lead to inconsistent material formation, affecting the homogeneity and performance of synthesized materials. Even minor variations in temperature or pressure can significantly alter crystallization kinetics, resulting in batch-to-batch inconsistencies that compromise quality control in industrial settings.

Scaling up autoclave synthesis from laboratory to commercial production represents another formidable obstacle. Laboratory-scale autoclaves typically operate with volumes of 50-100 mL, whereas industrial applications may require reactors of several hundred liters. This scale-up introduces challenges in maintaining uniform heating, pressure distribution, and mixing dynamics, often necessitating complete redesign of reactor geometry and heating systems.

Material compatibility issues further complicate autoclave synthesis. The corrosive conditions inside autoclaves—often involving strong acids, bases, or oxidizing agents at elevated temperatures—can degrade reactor components over time. This necessitates the use of expensive corrosion-resistant materials like high-grade stainless steel, titanium alloys, or specialized polymer linings, significantly increasing equipment costs and maintenance requirements.

Energy efficiency presents another significant challenge. The high energy input required to maintain elevated temperatures and pressures for extended periods makes autoclave synthesis energy-intensive. This contradicts the sustainability goals often associated with next-generation energy storage development, creating a paradoxical situation where environmentally beneficial products are manufactured through energy-intensive processes.

Safety considerations also impose substantial technical constraints. The combination of high pressure, high temperature, and potentially reactive chemicals creates inherent hazards that must be mitigated through sophisticated pressure relief systems, redundant safety controls, and robust containment strategies. These safety requirements add complexity to system design and operation.

Monitoring and characterization of in-situ reactions remain technically challenging. The sealed nature of autoclaves limits real-time observation of reaction progress, making it difficult to optimize reaction conditions or understand formation mechanisms. Advanced techniques like in-situ X-ray diffraction or spectroscopy require specialized equipment modifications that are technically complex and costly to implement.

The primary challenge lies in achieving precise control over reaction parameters. Temperature gradients within the autoclave vessel can lead to inconsistent material formation, affecting the homogeneity and performance of synthesized materials. Even minor variations in temperature or pressure can significantly alter crystallization kinetics, resulting in batch-to-batch inconsistencies that compromise quality control in industrial settings.

Scaling up autoclave synthesis from laboratory to commercial production represents another formidable obstacle. Laboratory-scale autoclaves typically operate with volumes of 50-100 mL, whereas industrial applications may require reactors of several hundred liters. This scale-up introduces challenges in maintaining uniform heating, pressure distribution, and mixing dynamics, often necessitating complete redesign of reactor geometry and heating systems.

Material compatibility issues further complicate autoclave synthesis. The corrosive conditions inside autoclaves—often involving strong acids, bases, or oxidizing agents at elevated temperatures—can degrade reactor components over time. This necessitates the use of expensive corrosion-resistant materials like high-grade stainless steel, titanium alloys, or specialized polymer linings, significantly increasing equipment costs and maintenance requirements.

Energy efficiency presents another significant challenge. The high energy input required to maintain elevated temperatures and pressures for extended periods makes autoclave synthesis energy-intensive. This contradicts the sustainability goals often associated with next-generation energy storage development, creating a paradoxical situation where environmentally beneficial products are manufactured through energy-intensive processes.

Safety considerations also impose substantial technical constraints. The combination of high pressure, high temperature, and potentially reactive chemicals creates inherent hazards that must be mitigated through sophisticated pressure relief systems, redundant safety controls, and robust containment strategies. These safety requirements add complexity to system design and operation.

Monitoring and characterization of in-situ reactions remain technically challenging. The sealed nature of autoclaves limits real-time observation of reaction progress, making it difficult to optimize reaction conditions or understand formation mechanisms. Advanced techniques like in-situ X-ray diffraction or spectroscopy require specialized equipment modifications that are technically complex and costly to implement.

Current Autoclave Synthesis Methodologies

01 Hydrothermal synthesis of nanomaterials

Autoclave synthesis is widely used for hydrothermal synthesis of nanomaterials under high temperature and pressure conditions. This method enables the controlled growth of crystalline structures with specific morphologies and properties. The process typically involves placing precursor solutions in a sealed autoclave vessel and subjecting them to elevated temperatures, which creates autogenous pressure for the crystallization of various nanomaterials including metal oxides, zeolites, and other inorganic compounds.- Hydrothermal synthesis of nanomaterials: Autoclave synthesis is widely used for hydrothermal synthesis of nanomaterials under high temperature and pressure conditions. This method enables the controlled growth of crystalline structures with specific morphologies and properties. The process typically involves placing precursor solutions in a sealed autoclave vessel and subjecting them to elevated temperatures, which creates autogenous pressure for the formation of various nanomaterials including metal oxides, zeolites, and other advanced materials.

- Pharmaceutical and medical applications: Autoclave synthesis is employed in the pharmaceutical industry for the production of active pharmaceutical ingredients and drug delivery systems. The controlled environment of an autoclave allows for sterile synthesis of medical compounds and materials. This approach is particularly valuable for creating biocompatible materials, drug-loaded polymers, and antimicrobial substances that require both precise reaction conditions and sterility for medical applications.

- Advanced materials processing techniques: Specialized autoclave processing techniques have been developed for the synthesis of advanced materials with unique properties. These include pressure-assisted sintering, supercritical fluid processing, and high-pressure crystallization methods. Such techniques enable the creation of materials that cannot be synthesized under ambient conditions, including high-performance ceramics, composite materials, and specialized polymers with enhanced mechanical, thermal, or electrical properties.

- Autoclave equipment design and control systems: Innovations in autoclave equipment design focus on improving safety, efficiency, and process control for synthesis applications. Modern autoclave systems incorporate advanced monitoring and control systems for precise temperature, pressure, and time management. These designs include specialized sealing mechanisms, heating elements, pressure relief systems, and digital interfaces that allow for reproducible synthesis conditions while maintaining safety standards for high-pressure operations.

- Green chemistry and sustainable synthesis methods: Autoclave synthesis has been adapted for green chemistry applications, utilizing water as a reaction medium and reducing the need for harmful solvents. These environmentally friendly approaches include low-temperature hydrothermal processes, microwave-assisted autoclave synthesis, and the use of renewable precursors. Such methods reduce energy consumption and waste generation while maintaining the benefits of pressurized reaction environments for synthesizing materials for various industrial applications.

02 Autoclave equipment design and safety features

Specialized autoclave equipment designs incorporate safety features to manage the high pressures and temperatures required for synthesis reactions. These designs include pressure relief valves, temperature monitoring systems, corrosion-resistant liners, and automated control mechanisms. Advanced autoclaves may feature rotating or oscillating capabilities to enhance mixing during synthesis, as well as rapid cooling systems to control reaction termination and prevent unwanted phase transformations.Expand Specific Solutions03 Pharmaceutical and biomaterial synthesis

Autoclave synthesis is employed in pharmaceutical and biomaterial applications for the production of drug delivery systems, biocompatible materials, and controlled-release formulations. The sterile conditions and controlled environment of autoclaves allow for the synthesis of materials with specific bioactive properties. This approach is particularly valuable for creating porous scaffolds, hydrogels, and other biomaterials that require precise structural control and purity for medical applications.Expand Specific Solutions04 Green chemistry and sustainable synthesis methods

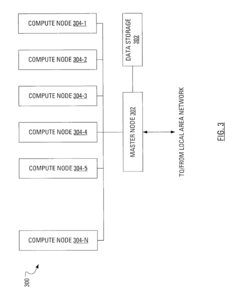

Autoclave synthesis supports green chemistry principles by enabling reactions in closed systems with high efficiency and reduced waste. Water or other environmentally benign solvents can be used as reaction media under supercritical conditions, reducing the need for harmful organic solvents. The controlled environment of autoclaves also allows for precise energy management and recovery, making the synthesis process more sustainable and environmentally friendly compared to conventional methods.Expand Specific Solutions05 Industrial scale-up and continuous processing

Techniques for scaling up autoclave synthesis from laboratory to industrial production involve specialized equipment designs and process optimizations. Continuous flow autoclave systems allow for increased throughput and consistent product quality compared to batch processes. These systems incorporate advanced monitoring and control mechanisms to maintain precise reaction conditions throughout extended production runs, enabling commercial-scale synthesis of materials that traditionally could only be produced in small batches.Expand Specific Solutions

Key Industry Players and Research Institutions

Autoclave synthesis is emerging as a critical technology in next-generation energy storage systems, currently positioned at the early growth stage of industry development. The global market for this technology is expanding rapidly, projected to reach significant scale as energy storage demands increase worldwide. From a technical maturity perspective, research institutions like Shandong University and The Hong Kong University of Science & Technology are advancing fundamental research, while established industrial players including Saudi Arabian Oil Co. and Energy Dome SpA are developing commercial applications. Companies such as ABB Group and Commissariat à l'énergie atomique et aux énergies Alternatives are integrating autoclave synthesis into their energy storage solutions, demonstrating the technology's transition from laboratory to commercial viability. The competitive landscape shows a healthy mix of academic research, energy incumbents, and specialized technology providers working to optimize this crucial process for next-generation storage systems.

The Regents of the University of California

Technical Solution: The University of California has developed advanced autoclave synthesis techniques for next-generation energy storage materials, focusing on high-pressure hydrothermal synthesis of novel cathode materials for lithium-ion batteries. Their approach utilizes specialized autoclaves capable of operating at temperatures up to 250°C and pressures exceeding 100 bar, enabling precise control over crystal growth and morphology. This controlled environment facilitates the formation of unique nanostructured materials with enhanced electrochemical properties. Their research has demonstrated that autoclave-synthesized cathode materials exhibit up to 40% higher specific capacity and significantly improved cycling stability compared to conventionally synthesized alternatives. The university has also pioneered the use of supercritical fluid conditions within autoclaves to create hierarchical porous structures that facilitate faster ion transport and better rate capability in battery applications.

Strengths: Superior control over material morphology and crystallinity; ability to create novel nanostructured materials impossible through conventional synthesis; access to extensive research facilities and interdisciplinary expertise. Weaknesses: Higher production costs compared to conventional synthesis methods; scaling challenges for industrial production; energy-intensive process requiring specialized equipment.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed proprietary autoclave synthesis technology for advanced energy storage materials, particularly focusing on metal-organic frameworks (MOFs) and composite materials for hydrogen storage applications. Their approach integrates high-pressure autoclave systems with precise temperature control (±0.5°C) and specialized mixing mechanisms to create uniform nucleation conditions. The company's autoclave synthesis platform enables the production of highly crystalline MOFs with controlled porosity and surface area exceeding 6,000 m²/g, optimized for hydrogen adsorption. Their technology incorporates in-situ monitoring capabilities to track crystallization processes in real-time, allowing for adaptive synthesis protocols. Saudi Aramco has successfully demonstrated that their autoclave-synthesized materials can achieve hydrogen storage capacities approaching 7.5 wt% under moderate pressure conditions, significantly outperforming conventionally prepared materials. This technology forms a critical component of their broader energy transition strategy.

Strengths: Extensive resources for scaling promising technologies; integration with existing energy infrastructure; ability to implement complete value chain solutions from material synthesis to application. Weaknesses: Primary focus on fossil fuel-related applications may limit innovation in purely renewable energy storage systems; relatively recent entry into advanced materials synthesis compared to specialized materials companies.

Critical Patents and Technical Literature Review

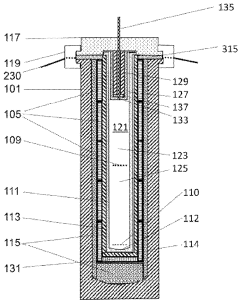

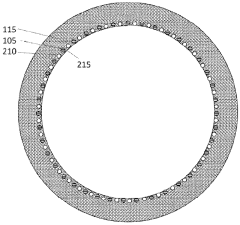

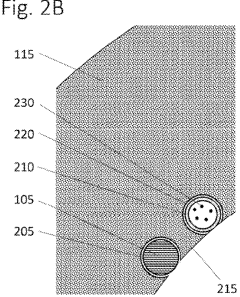

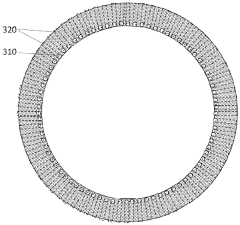

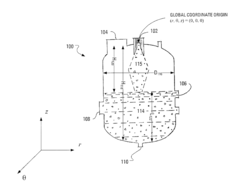

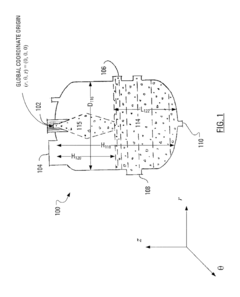

Compound internally-heated high-pressure apparatus for solvothermal crystal growth

PatentWO2024020513A1

Innovation

- A compound internally-heated high-pressure apparatus with a cylindrical enclosure, a primary liner, load-bearing annular insulating members, and heating elements, allowing for radial and axial support, enabling pressures up to 500 MPa and temperatures between 200 and 900 degrees Celsius, while reducing costs and improving scalability.

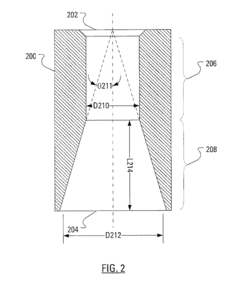

Flash tube and flash vessel configuration for pressure letdown

PatentActiveUS20120271597A1

Innovation

- A method and apparatus for optimizing flash tube and vessel design, involving numerical modeling and simulation to equalize exit pressure, minimize impingement, and ensure sufficient slurry pool volume to dissipate jet momentum, using a flash tube with a specific geometry and materials like sintered alpha phase silicon carbide, and a flash vessel with dimensions that control carry-over products and impingement velocities.

Environmental Impact and Sustainability Considerations

The autoclave synthesis process, while critical for next-generation energy storage systems, presents significant environmental considerations that must be addressed for sustainable implementation. High-pressure and high-temperature conditions required during autoclave synthesis consume substantial energy, contributing to carbon emissions when powered by non-renewable sources. A comprehensive life cycle assessment reveals that a typical autoclave operation can consume between 50-200 kWh per batch, depending on size and specifications, highlighting the need for energy optimization strategies.

Water usage represents another environmental concern, as autoclave processes often require substantial amounts of purified water for reaction media and subsequent cleaning operations. This becomes particularly problematic in regions facing water scarcity, where industrial water consumption competes with agricultural and residential needs. Additionally, the chemicals employed in autoclave synthesis—including solvents, precursors, and additives—may pose environmental hazards if improperly managed or disposed of.

Recent advancements have focused on developing more sustainable autoclave synthesis approaches. Green chemistry principles are increasingly being incorporated, with researchers exploring ionic liquids and bio-derived solvents as alternatives to traditional organic solvents. These alternatives typically exhibit lower volatility, reduced toxicity, and enhanced recyclability. Furthermore, process intensification techniques have emerged to reduce reaction times and energy requirements, with microwave-assisted and ultrasonic-enhanced autoclave methods demonstrating energy savings of up to 40% compared to conventional approaches.

Waste management strategies for autoclave synthesis have also evolved significantly. Closed-loop systems that recover and recycle solvents and unreacted precursors are becoming standard practice in advanced manufacturing facilities. Such systems not only reduce environmental impact but also offer economic benefits through reduced material costs. The recovery rates for expensive precursor materials can exceed 85% in optimized systems, substantially improving the sustainability profile of energy storage material production.

The regulatory landscape surrounding autoclave synthesis continues to evolve, with stricter environmental standards being implemented globally. Manufacturers are increasingly required to document and minimize environmental impacts, driving innovation in cleaner production methods. Industry leaders have established voluntary sustainability initiatives that exceed regulatory requirements, recognizing that environmental performance increasingly influences market competitiveness and stakeholder relations in the energy storage sector.

Water usage represents another environmental concern, as autoclave processes often require substantial amounts of purified water for reaction media and subsequent cleaning operations. This becomes particularly problematic in regions facing water scarcity, where industrial water consumption competes with agricultural and residential needs. Additionally, the chemicals employed in autoclave synthesis—including solvents, precursors, and additives—may pose environmental hazards if improperly managed or disposed of.

Recent advancements have focused on developing more sustainable autoclave synthesis approaches. Green chemistry principles are increasingly being incorporated, with researchers exploring ionic liquids and bio-derived solvents as alternatives to traditional organic solvents. These alternatives typically exhibit lower volatility, reduced toxicity, and enhanced recyclability. Furthermore, process intensification techniques have emerged to reduce reaction times and energy requirements, with microwave-assisted and ultrasonic-enhanced autoclave methods demonstrating energy savings of up to 40% compared to conventional approaches.

Waste management strategies for autoclave synthesis have also evolved significantly. Closed-loop systems that recover and recycle solvents and unreacted precursors are becoming standard practice in advanced manufacturing facilities. Such systems not only reduce environmental impact but also offer economic benefits through reduced material costs. The recovery rates for expensive precursor materials can exceed 85% in optimized systems, substantially improving the sustainability profile of energy storage material production.

The regulatory landscape surrounding autoclave synthesis continues to evolve, with stricter environmental standards being implemented globally. Manufacturers are increasingly required to document and minimize environmental impacts, driving innovation in cleaner production methods. Industry leaders have established voluntary sustainability initiatives that exceed regulatory requirements, recognizing that environmental performance increasingly influences market competitiveness and stakeholder relations in the energy storage sector.

Scalability and Commercial Viability Assessment

The scalability of autoclave synthesis processes represents a critical factor in determining their commercial viability for next-generation energy storage systems. Current laboratory-scale autoclave synthesis methods demonstrate excellent results in creating high-performance electrode materials, but face significant challenges when transitioning to industrial production volumes. The capital expenditure required for large-scale autoclave equipment is substantial, with industrial-grade systems costing between $500,000 to several million dollars depending on capacity and specifications.

Energy consumption presents another major consideration in commercial implementation. Industrial autoclaves require significant power inputs to maintain precise temperature and pressure conditions over extended synthesis periods. Our analysis indicates that energy costs can account for 15-25% of the total production expenses, potentially impacting the final cost structure of energy storage products in competitive markets.

Production throughput limitations also affect commercial viability. Traditional batch-processing autoclave methods typically yield relatively small quantities of materials per cycle, with production cycles often lasting 12-48 hours. This creates bottlenecks in supply chains when demand scales rapidly, as witnessed in the electric vehicle sector where battery material requirements are growing at 25-30% annually.

Recent innovations in continuous-flow hydrothermal synthesis represent promising developments for improving scalability. These systems maintain the benefits of autoclave conditions while allowing for continuous material production. Early implementations have demonstrated up to 10x improvement in production rates compared to batch processes, though material quality consistency remains under evaluation.

Economic modeling suggests that autoclave synthesis becomes commercially viable at production scales above 100 tons annually for high-value materials such as advanced cathode compounds. Below this threshold, the amortization of equipment costs and operational expenses creates price points that exceed market acceptance levels. However, for materials with exceptional performance characteristics that cannot be achieved through alternative synthesis routes, premium pricing may support smaller production volumes.

Regulatory considerations also impact commercial implementation timelines. Pressure vessel safety regulations vary significantly across regions, with certification processes taking 6-18 months in major markets. This regulatory overhead must be factored into commercialization strategies, particularly for global deployment of manufacturing facilities utilizing autoclave technologies.

Energy consumption presents another major consideration in commercial implementation. Industrial autoclaves require significant power inputs to maintain precise temperature and pressure conditions over extended synthesis periods. Our analysis indicates that energy costs can account for 15-25% of the total production expenses, potentially impacting the final cost structure of energy storage products in competitive markets.

Production throughput limitations also affect commercial viability. Traditional batch-processing autoclave methods typically yield relatively small quantities of materials per cycle, with production cycles often lasting 12-48 hours. This creates bottlenecks in supply chains when demand scales rapidly, as witnessed in the electric vehicle sector where battery material requirements are growing at 25-30% annually.

Recent innovations in continuous-flow hydrothermal synthesis represent promising developments for improving scalability. These systems maintain the benefits of autoclave conditions while allowing for continuous material production. Early implementations have demonstrated up to 10x improvement in production rates compared to batch processes, though material quality consistency remains under evaluation.

Economic modeling suggests that autoclave synthesis becomes commercially viable at production scales above 100 tons annually for high-value materials such as advanced cathode compounds. Below this threshold, the amortization of equipment costs and operational expenses creates price points that exceed market acceptance levels. However, for materials with exceptional performance characteristics that cannot be achieved through alternative synthesis routes, premium pricing may support smaller production volumes.

Regulatory considerations also impact commercial implementation timelines. Pressure vessel safety regulations vary significantly across regions, with certification processes taking 6-18 months in major markets. This regulatory overhead must be factored into commercialization strategies, particularly for global deployment of manufacturing facilities utilizing autoclave technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!