Automation Approaches for Small Batch Vacuum Forming Production

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Automation: Background and Objectives

Vacuum forming is a thermoforming process that has been widely used in manufacturing for decades. It involves heating a plastic sheet until it becomes pliable, then using vacuum suction to draw it over a mold, creating a three-dimensional shape. This technique has found applications in various industries, including packaging, automotive, aerospace, and consumer goods production.

The evolution of vacuum forming technology has been driven by the need for more efficient and cost-effective production methods. Initially, the process was largely manual, requiring significant human intervention at each stage. Over time, advancements in materials science, heating technologies, and automation have transformed vacuum forming into a more sophisticated and capable manufacturing technique.

In recent years, the focus has shifted towards automating small batch production in vacuum forming. This trend is driven by several factors, including the increasing demand for customized products, the need for faster turnaround times, and the pressure to reduce labor costs. Small batch production presents unique challenges, as it requires greater flexibility and rapid changeovers between different product runs.

The primary objective of automating small batch vacuum forming production is to achieve a balance between the efficiency of large-scale automation and the flexibility required for small, diverse production runs. This involves developing systems that can quickly adapt to different mold shapes, material types, and production parameters without significant downtime or manual intervention.

Key technological goals in this area include the development of intelligent control systems that can optimize process parameters in real-time, the integration of robotic systems for material handling and part removal, and the implementation of advanced sensing and vision systems for quality control. Additionally, there is a focus on creating modular and reconfigurable production lines that can be easily adapted to different product specifications.

Another important objective is to improve the energy efficiency and sustainability of the vacuum forming process. This includes developing more efficient heating systems, optimizing vacuum usage, and exploring the use of recycled or bio-based materials that are compatible with automated processes.

The automation of small batch vacuum forming also aims to address the skills gap in manufacturing by reducing the reliance on specialized labor. By incorporating user-friendly interfaces and remote monitoring capabilities, these automated systems can be operated by workers with varying levels of technical expertise, potentially broadening the workforce available to manufacturers.

As we look towards the future of vacuum forming automation, the integration of Industry 4.0 principles, such as the Internet of Things (IoT) and data analytics, is becoming increasingly important. These technologies promise to enable predictive maintenance, enhance process optimization, and facilitate seamless integration with other manufacturing processes and supply chain systems.

The evolution of vacuum forming technology has been driven by the need for more efficient and cost-effective production methods. Initially, the process was largely manual, requiring significant human intervention at each stage. Over time, advancements in materials science, heating technologies, and automation have transformed vacuum forming into a more sophisticated and capable manufacturing technique.

In recent years, the focus has shifted towards automating small batch production in vacuum forming. This trend is driven by several factors, including the increasing demand for customized products, the need for faster turnaround times, and the pressure to reduce labor costs. Small batch production presents unique challenges, as it requires greater flexibility and rapid changeovers between different product runs.

The primary objective of automating small batch vacuum forming production is to achieve a balance between the efficiency of large-scale automation and the flexibility required for small, diverse production runs. This involves developing systems that can quickly adapt to different mold shapes, material types, and production parameters without significant downtime or manual intervention.

Key technological goals in this area include the development of intelligent control systems that can optimize process parameters in real-time, the integration of robotic systems for material handling and part removal, and the implementation of advanced sensing and vision systems for quality control. Additionally, there is a focus on creating modular and reconfigurable production lines that can be easily adapted to different product specifications.

Another important objective is to improve the energy efficiency and sustainability of the vacuum forming process. This includes developing more efficient heating systems, optimizing vacuum usage, and exploring the use of recycled or bio-based materials that are compatible with automated processes.

The automation of small batch vacuum forming also aims to address the skills gap in manufacturing by reducing the reliance on specialized labor. By incorporating user-friendly interfaces and remote monitoring capabilities, these automated systems can be operated by workers with varying levels of technical expertise, potentially broadening the workforce available to manufacturers.

As we look towards the future of vacuum forming automation, the integration of Industry 4.0 principles, such as the Internet of Things (IoT) and data analytics, is becoming increasingly important. These technologies promise to enable predictive maintenance, enhance process optimization, and facilitate seamless integration with other manufacturing processes and supply chain systems.

Small Batch Production Market Analysis

The small batch production market for vacuum forming has been experiencing significant growth in recent years, driven by increasing demand for customized and short-run products across various industries. This market segment caters to businesses that require flexibility in production volumes, quick turnaround times, and cost-effective solutions for low-quantity orders.

One of the key factors contributing to the expansion of this market is the rising trend of personalization and customization in consumer goods. Industries such as packaging, automotive, aerospace, and medical devices are increasingly seeking small batch production capabilities to meet diverse customer needs and reduce inventory costs. The ability to produce small quantities of vacuum-formed parts allows companies to test new designs, create prototypes, and respond quickly to market changes without the need for large-scale production commitments.

The market for small batch vacuum forming is particularly attractive to small and medium-sized enterprises (SMEs) that may not have the resources or demand for high-volume production. These businesses benefit from the lower initial investment required for small batch production equipment and the flexibility to produce a wide range of products in limited quantities. Additionally, the growing adoption of rapid prototyping and additive manufacturing technologies has created new opportunities for small batch vacuum forming in product development and testing phases.

In terms of geographical distribution, North America and Europe currently dominate the small batch vacuum forming market, owing to their well-established manufacturing sectors and high demand for customized products. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid industrialization of countries like China and India, and the increasing adoption of advanced manufacturing technologies.

The market is characterized by a fragmented landscape, with numerous small to medium-sized players offering specialized services. This fragmentation has led to intense competition and a focus on niche markets and specialized applications. As a result, many companies are investing in automation technologies to improve efficiency, reduce labor costs, and maintain competitiveness in the small batch production segment.

Despite the positive growth outlook, the small batch vacuum forming market faces challenges such as the need for skilled labor, increasing raw material costs, and the pressure to adopt more sustainable production practices. These factors are driving the demand for innovative automation solutions that can address these challenges while maintaining the flexibility and cost-effectiveness required for small batch production.

One of the key factors contributing to the expansion of this market is the rising trend of personalization and customization in consumer goods. Industries such as packaging, automotive, aerospace, and medical devices are increasingly seeking small batch production capabilities to meet diverse customer needs and reduce inventory costs. The ability to produce small quantities of vacuum-formed parts allows companies to test new designs, create prototypes, and respond quickly to market changes without the need for large-scale production commitments.

The market for small batch vacuum forming is particularly attractive to small and medium-sized enterprises (SMEs) that may not have the resources or demand for high-volume production. These businesses benefit from the lower initial investment required for small batch production equipment and the flexibility to produce a wide range of products in limited quantities. Additionally, the growing adoption of rapid prototyping and additive manufacturing technologies has created new opportunities for small batch vacuum forming in product development and testing phases.

In terms of geographical distribution, North America and Europe currently dominate the small batch vacuum forming market, owing to their well-established manufacturing sectors and high demand for customized products. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid industrialization of countries like China and India, and the increasing adoption of advanced manufacturing technologies.

The market is characterized by a fragmented landscape, with numerous small to medium-sized players offering specialized services. This fragmentation has led to intense competition and a focus on niche markets and specialized applications. As a result, many companies are investing in automation technologies to improve efficiency, reduce labor costs, and maintain competitiveness in the small batch production segment.

Despite the positive growth outlook, the small batch vacuum forming market faces challenges such as the need for skilled labor, increasing raw material costs, and the pressure to adopt more sustainable production practices. These factors are driving the demand for innovative automation solutions that can address these challenges while maintaining the flexibility and cost-effectiveness required for small batch production.

Current Challenges in Vacuum Forming Automation

Vacuum forming automation for small batch production faces several significant challenges that hinder widespread adoption and efficiency. One of the primary obstacles is the high initial investment required for automation equipment. Small and medium-sized enterprises often struggle to justify the cost of implementing automated systems, especially when their production volumes are relatively low.

The complexity of setting up and programming automated systems for diverse product ranges poses another challenge. Small batch production typically involves frequent changeovers and adjustments to accommodate different product designs. This variability makes it difficult to create standardized automation processes that can efficiently handle a wide range of products without extensive reprogramming or retooling.

Material handling in vacuum forming automation presents unique difficulties, particularly for small batches. The automation system must be capable of accurately positioning and removing various sheet materials of different sizes, thicknesses, and compositions. This requires sophisticated gripping mechanisms and precise control systems, which can be challenging to implement cost-effectively for small-scale operations.

Quality control and consistency are also major concerns in automated vacuum forming for small batches. Ensuring uniform heating, forming, and cooling across different product runs can be challenging, especially when dealing with materials that have varying properties. Automated systems must be able to adapt to these variations while maintaining product quality, which often requires advanced sensing and control technologies.

The integration of automated vacuum forming systems with existing production workflows can be problematic for small batch manufacturers. Many companies have established manual or semi-automated processes, and transitioning to fully automated systems may require significant changes to their production layout, employee training, and quality assurance procedures.

Flexibility and scalability remain critical challenges for small batch vacuum forming automation. Systems need to be adaptable enough to handle changing product designs and production volumes without requiring extensive modifications or downtime. This flexibility is essential for small batch producers who may need to quickly respond to market demands or customer requests.

Lastly, the shortage of skilled personnel who can operate, maintain, and troubleshoot automated vacuum forming systems is a significant hurdle. Small batch manufacturers often lack the resources to hire or train specialized technicians, which can lead to underutilization of automated equipment or increased downtime due to maintenance issues.

The complexity of setting up and programming automated systems for diverse product ranges poses another challenge. Small batch production typically involves frequent changeovers and adjustments to accommodate different product designs. This variability makes it difficult to create standardized automation processes that can efficiently handle a wide range of products without extensive reprogramming or retooling.

Material handling in vacuum forming automation presents unique difficulties, particularly for small batches. The automation system must be capable of accurately positioning and removing various sheet materials of different sizes, thicknesses, and compositions. This requires sophisticated gripping mechanisms and precise control systems, which can be challenging to implement cost-effectively for small-scale operations.

Quality control and consistency are also major concerns in automated vacuum forming for small batches. Ensuring uniform heating, forming, and cooling across different product runs can be challenging, especially when dealing with materials that have varying properties. Automated systems must be able to adapt to these variations while maintaining product quality, which often requires advanced sensing and control technologies.

The integration of automated vacuum forming systems with existing production workflows can be problematic for small batch manufacturers. Many companies have established manual or semi-automated processes, and transitioning to fully automated systems may require significant changes to their production layout, employee training, and quality assurance procedures.

Flexibility and scalability remain critical challenges for small batch vacuum forming automation. Systems need to be adaptable enough to handle changing product designs and production volumes without requiring extensive modifications or downtime. This flexibility is essential for small batch producers who may need to quickly respond to market demands or customer requests.

Lastly, the shortage of skilled personnel who can operate, maintain, and troubleshoot automated vacuum forming systems is a significant hurdle. Small batch manufacturers often lack the resources to hire or train specialized technicians, which can lead to underutilization of automated equipment or increased downtime due to maintenance issues.

Existing Small Batch Automation Solutions

01 Automated control systems for vacuum forming

Advanced control systems are implemented to automate the vacuum forming process. These systems integrate sensors, actuators, and programmable logic controllers to manage various aspects of the process, including temperature control, material feeding, and forming cycle timing. This automation improves consistency, reduces human error, and increases production efficiency.- Automated control systems for vacuum forming: Advanced control systems are implemented to automate the vacuum forming process. These systems integrate sensors, actuators, and programmable logic controllers to monitor and adjust various parameters such as temperature, pressure, and timing. This automation improves consistency, reduces human error, and increases overall efficiency in vacuum forming operations.

- Robotic handling and material feeding: Robotic systems are employed for material handling and feeding in vacuum forming processes. These robots can precisely place sheets into the forming area, remove finished parts, and manage the flow of materials throughout the production line. This automation reduces cycle times, improves safety, and allows for continuous operation with minimal human intervention.

- Vision systems for quality control: Computer vision and machine learning technologies are integrated into vacuum forming lines for automated quality control. These systems can detect defects, ensure proper part dimensions, and verify surface finish in real-time. By automating inspection processes, manufacturers can achieve higher quality standards and reduce waste.

- Intelligent mold design and rapid tooling: Advanced software and rapid prototyping techniques are used to design and produce molds for vacuum forming. These tools allow for quick iterations and optimizations of mold designs, improving product quality and reducing setup times. Automated systems can also adjust mold parameters during production to compensate for material variations.

- Integration with Industry 4.0 and IoT: Vacuum forming processes are being integrated into broader Industry 4.0 frameworks, incorporating Internet of Things (IoT) devices and data analytics. This connectivity allows for real-time monitoring, predictive maintenance, and optimization of production schedules. It also enables remote operation and troubleshooting of vacuum forming equipment.

02 Robotic handling and material placement

Robotic systems are employed for handling materials and placing them into the vacuum forming machine. These robots can precisely position sheets of plastic or other formable materials, ensuring accurate alignment and reducing cycle times. Additionally, robotic arms may be used for post-forming operations such as trimming and part removal.Expand Specific Solutions03 Intelligent mold design and quick-change systems

Innovative mold designs incorporate features that facilitate automation, such as quick-change mechanisms and modular components. These designs allow for rapid mold swapping and reconfiguration, minimizing downtime between production runs. Smart molds may also include integrated sensors for real-time monitoring of forming conditions.Expand Specific Solutions04 Vision systems and quality control automation

Computer vision systems are integrated into the vacuum forming process to automate quality control. These systems can detect defects, measure part dimensions, and ensure proper forming. Machine learning algorithms may be employed to continuously improve defect detection and process optimization based on historical data.Expand Specific Solutions05 Automated material handling and inventory management

Automation extends to material handling and inventory management systems. Automated guided vehicles (AGVs) or conveyor systems transport raw materials and finished products. Integrated software tracks inventory levels, schedules material replenishment, and coordinates with production planning systems to optimize workflow and reduce waste.Expand Specific Solutions

Key Players in Automated Vacuum Forming

The automation of small batch vacuum forming production is in a transitional phase, with the market showing steady growth as industries seek more efficient and flexible manufacturing solutions. The technology's maturity varies across different applications, with companies like Edwards Ltd. and Tokyo Electron Ltd. leading in vacuum system innovations. While the market size is expanding, it remains relatively niche compared to large-scale manufacturing automation. Companies such as Veeco Instruments, Inc. and ULVAC, Inc. are advancing the technology, particularly in semiconductor and display industries, indicating a trend towards more sophisticated and integrated automation solutions for vacuum forming processes.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a collaborative robot-based automation system for small batch vacuum forming. Their approach utilizes flexible, easily programmable robotic arms that can be quickly reconfigured for different product runs[10]. ITRI's system incorporates advanced sensor fusion technology, combining force feedback, vision systems, and thermal imaging to monitor and control the forming process in real-time[11]. The institute has also developed a novel adaptive mold technology that can adjust its shape to accommodate different product designs, reducing the need for multiple dedicated molds[12]. Furthermore, ITRI's approach includes an AI-powered production scheduling system that optimizes batch sizes and production sequences based on order requirements and equipment availability.

Strengths: Highly adaptable to different product types, reduced tooling costs, efficient use of production resources. Weaknesses: Potential complexity in programming and maintenance, may have limitations in forming very large or complex parts.

ULVAC, Inc.

Technical Solution: ULVAC has pioneered a compact, fully-automated vacuum forming line specifically designed for small batch production. Their system features a proprietary rapid heating technology that significantly reduces cycle times[4]. The automation approach includes an integrated material handling system with automatic sheet feeding and finished product removal. ULVAC's solution also incorporates advanced process control software that allows for real-time adjustments to forming parameters, ensuring consistent quality across batches[5]. The company has also developed a novel energy recovery system that captures and reuses heat from the forming process, improving overall energy efficiency[6].

Strengths: Fast cycle times, energy-efficient operation, consistent quality output. Weaknesses: Limited flexibility for very diverse product ranges, potentially high maintenance costs for specialized components.

Innovative Approaches in Vacuum Forming

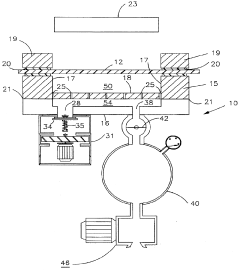

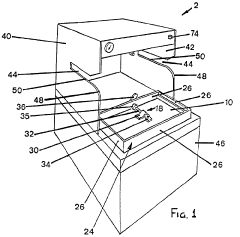

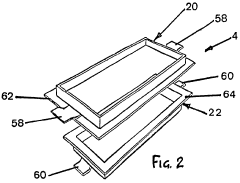

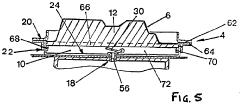

Vacuum molding apparatus for forming a sheet of plastic material into a predetermined shape

PatentInactiveUS5529472A

Innovation

- The use of two vacuum production means: a high-volume, low-capacity turbine to initially remove air and create a weak vacuum, followed by a smaller vacuum tank evacuated by a pump to produce a strong vacuum, allowing for efficient and rapid air removal.

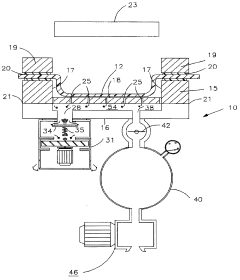

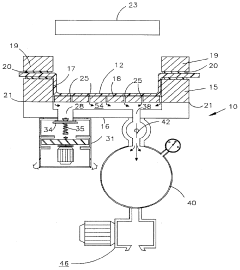

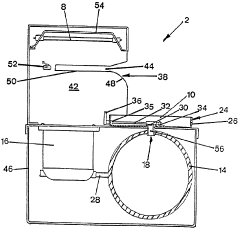

A vacuum forming machine in which vacuum is automatically initiated upon delivery of the sheet to the machine

PatentInactiveGB2248579A

Innovation

- A simplified vacuum forming machine design featuring a holder that moves from a heating position to a forming position automatically operates the valve, creating a vacuum to shape the plastic sheet, with a spring-biased valve plate and guide means for easy operation and reduced manual intervention.

Cost-Benefit Analysis of Automation

Implementing automation in small batch vacuum forming production requires careful consideration of the associated costs and potential benefits. The initial investment in automation technology can be substantial, encompassing expenses for equipment, software, installation, and employee training. However, these upfront costs must be weighed against the long-term advantages that automation can bring to the production process.

One of the primary benefits of automation is increased productivity. Automated systems can operate continuously, reducing downtime and increasing output. This improved efficiency can lead to shorter production cycles and faster turnaround times, allowing manufacturers to meet customer demands more effectively. Additionally, automation can enhance product quality by minimizing human error and ensuring consistent results across production runs.

Labor costs are another significant factor to consider. While automation may reduce the need for manual labor in certain areas, it also creates demand for skilled technicians to operate and maintain the automated systems. The shift in workforce requirements may result in initial retraining costs but can lead to long-term savings in labor expenses, particularly in regions with high labor costs.

Energy efficiency is an often-overlooked benefit of automation in vacuum forming. Automated systems can optimize energy consumption by precisely controlling heating elements, vacuum pressure, and cooling cycles. This can result in reduced energy costs and a smaller carbon footprint, which is increasingly important in today's environmentally conscious market.

The flexibility of automated systems is crucial for small batch production. Modern automation solutions offer quick changeover capabilities, allowing manufacturers to switch between different product designs with minimal downtime. This adaptability is particularly valuable in industries where customization and short production runs are common.

Maintenance and reliability factors must also be evaluated. While automated systems may require specialized maintenance, they often have lower breakdown rates compared to manual processes. This increased reliability can lead to reduced maintenance costs and less production interruption over time.

Finally, the potential for data collection and analysis should not be underestimated. Automated systems can gather vast amounts of production data, enabling manufacturers to identify inefficiencies, predict maintenance needs, and make data-driven decisions to further optimize their processes. This capability can lead to continuous improvement and long-term cost savings.

In conclusion, while the initial investment in automation for small batch vacuum forming can be significant, the potential benefits in terms of productivity, quality, flexibility, and long-term cost savings make it a compelling option for many manufacturers. A thorough cost-benefit analysis, taking into account all these factors, is essential for making an informed decision on implementing automation in this specific production context.

One of the primary benefits of automation is increased productivity. Automated systems can operate continuously, reducing downtime and increasing output. This improved efficiency can lead to shorter production cycles and faster turnaround times, allowing manufacturers to meet customer demands more effectively. Additionally, automation can enhance product quality by minimizing human error and ensuring consistent results across production runs.

Labor costs are another significant factor to consider. While automation may reduce the need for manual labor in certain areas, it also creates demand for skilled technicians to operate and maintain the automated systems. The shift in workforce requirements may result in initial retraining costs but can lead to long-term savings in labor expenses, particularly in regions with high labor costs.

Energy efficiency is an often-overlooked benefit of automation in vacuum forming. Automated systems can optimize energy consumption by precisely controlling heating elements, vacuum pressure, and cooling cycles. This can result in reduced energy costs and a smaller carbon footprint, which is increasingly important in today's environmentally conscious market.

The flexibility of automated systems is crucial for small batch production. Modern automation solutions offer quick changeover capabilities, allowing manufacturers to switch between different product designs with minimal downtime. This adaptability is particularly valuable in industries where customization and short production runs are common.

Maintenance and reliability factors must also be evaluated. While automated systems may require specialized maintenance, they often have lower breakdown rates compared to manual processes. This increased reliability can lead to reduced maintenance costs and less production interruption over time.

Finally, the potential for data collection and analysis should not be underestimated. Automated systems can gather vast amounts of production data, enabling manufacturers to identify inefficiencies, predict maintenance needs, and make data-driven decisions to further optimize their processes. This capability can lead to continuous improvement and long-term cost savings.

In conclusion, while the initial investment in automation for small batch vacuum forming can be significant, the potential benefits in terms of productivity, quality, flexibility, and long-term cost savings make it a compelling option for many manufacturers. A thorough cost-benefit analysis, taking into account all these factors, is essential for making an informed decision on implementing automation in this specific production context.

Environmental Impact and Sustainability

The automation of small batch vacuum forming production presents both challenges and opportunities in terms of environmental impact and sustainability. As industries increasingly adopt automated processes, it becomes crucial to assess and mitigate the ecological footprint of these technologies.

One of the primary environmental benefits of automating vacuum forming for small batches is the potential reduction in material waste. Automated systems can optimize material usage through precise control and repeatability, minimizing overruns and defects. This efficiency not only conserves raw materials but also reduces the energy consumption associated with producing excess products.

Energy efficiency is another key consideration in the environmental impact of automated vacuum forming. While automation may increase the overall energy consumption of the production line, it can lead to significant improvements in energy utilization per unit produced. Advanced control systems and smart energy management can optimize heating cycles, reduce idle time, and maximize throughput, resulting in lower energy intensity for small batch production.

The shift towards automation in vacuum forming also presents opportunities for incorporating more sustainable materials. Automated systems can be designed to handle a wider range of eco-friendly thermoplastics, including biodegradable and recycled materials. This flexibility allows manufacturers to adapt to evolving environmental regulations and consumer demands for more sustainable products.

However, the environmental impact of automation extends beyond the production process itself. The lifecycle of automated equipment, including manufacturing, maintenance, and eventual disposal, must be considered. Manufacturers should prioritize durable, long-lasting automation solutions to minimize the environmental burden of frequent equipment replacement.

Automation can also contribute to more sustainable practices through improved quality control and reduced scrap rates. By ensuring consistent product quality, automated systems can decrease the likelihood of defective items entering the market, thereby reducing waste and the need for replacements.

Water usage in vacuum forming processes, while typically minimal, can be further optimized through automation. Closed-loop cooling systems and precise temperature control can significantly reduce water consumption and wastewater generation, contributing to overall resource conservation.

As the industry moves towards more automated solutions, there is an opportunity to integrate circular economy principles into the design of both the production equipment and the products themselves. This could include designing for easy disassembly, repair, and recycling of both the automated systems and the vacuum-formed products.

In conclusion, while the automation of small batch vacuum forming production offers numerous environmental benefits, it also requires careful consideration of lifecycle impacts and resource utilization. By prioritizing sustainability in the design and implementation of automated systems, manufacturers can significantly reduce their environmental footprint while improving production efficiency and product quality.

One of the primary environmental benefits of automating vacuum forming for small batches is the potential reduction in material waste. Automated systems can optimize material usage through precise control and repeatability, minimizing overruns and defects. This efficiency not only conserves raw materials but also reduces the energy consumption associated with producing excess products.

Energy efficiency is another key consideration in the environmental impact of automated vacuum forming. While automation may increase the overall energy consumption of the production line, it can lead to significant improvements in energy utilization per unit produced. Advanced control systems and smart energy management can optimize heating cycles, reduce idle time, and maximize throughput, resulting in lower energy intensity for small batch production.

The shift towards automation in vacuum forming also presents opportunities for incorporating more sustainable materials. Automated systems can be designed to handle a wider range of eco-friendly thermoplastics, including biodegradable and recycled materials. This flexibility allows manufacturers to adapt to evolving environmental regulations and consumer demands for more sustainable products.

However, the environmental impact of automation extends beyond the production process itself. The lifecycle of automated equipment, including manufacturing, maintenance, and eventual disposal, must be considered. Manufacturers should prioritize durable, long-lasting automation solutions to minimize the environmental burden of frequent equipment replacement.

Automation can also contribute to more sustainable practices through improved quality control and reduced scrap rates. By ensuring consistent product quality, automated systems can decrease the likelihood of defective items entering the market, thereby reducing waste and the need for replacements.

Water usage in vacuum forming processes, while typically minimal, can be further optimized through automation. Closed-loop cooling systems and precise temperature control can significantly reduce water consumption and wastewater generation, contributing to overall resource conservation.

As the industry moves towards more automated solutions, there is an opportunity to integrate circular economy principles into the design of both the production equipment and the products themselves. This could include designing for easy disassembly, repair, and recycling of both the automated systems and the vacuum-formed products.

In conclusion, while the automation of small batch vacuum forming production offers numerous environmental benefits, it also requires careful consideration of lifecycle impacts and resource utilization. By prioritizing sustainability in the design and implementation of automated systems, manufacturers can significantly reduce their environmental footprint while improving production efficiency and product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!