Benchmark Direct Lithium Extraction: Environmental Compliance Rates

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods such as evaporation ponds and hard rock mining. The evolution of DLE began in the early 2000s, with substantial technological advancements occurring over the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental footprint, and accelerated production timelines compared to conventional methods. The technological trajectory has been driven by the limitations of traditional approaches, which typically require 18-24 months for extraction, consume vast quantities of water, and occupy large land areas for evaporation ponds.

The primary objective of benchmarking DLE environmental compliance rates is to establish standardized metrics for evaluating the environmental performance of various DLE technologies. This includes quantifying water usage efficiency, chemical consumption, energy requirements, carbon footprint, land disturbance, and waste generation across different technological approaches and operational implementations.

Current technological development is focused on several DLE methodologies, including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach presents unique environmental compliance profiles that must be systematically assessed to determine optimal solutions for different geological and regulatory contexts.

The industry is witnessing a convergence of environmental sustainability goals with economic imperatives, as regulatory frameworks worldwide increasingly emphasize reduced environmental impact in mining operations. This has accelerated research into DLE technologies that can achieve high lithium recovery rates while maintaining strict environmental compliance.

Recent technological milestones include the development of highly selective adsorbent materials, energy-efficient membrane systems, and closed-loop water recycling processes that significantly reduce freshwater consumption. These innovations represent critical steps toward establishing DLE as the predominant lithium extraction methodology of the future.

The ultimate technical goal is to develop and implement DLE systems that can achieve near-zero environmental impact while maintaining economic viability across diverse brine chemistries and geological settings. This includes achieving compliance rates approaching 100% across all relevant environmental parameters, from water conservation to greenhouse gas emissions reduction.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental footprint, and accelerated production timelines compared to conventional methods. The technological trajectory has been driven by the limitations of traditional approaches, which typically require 18-24 months for extraction, consume vast quantities of water, and occupy large land areas for evaporation ponds.

The primary objective of benchmarking DLE environmental compliance rates is to establish standardized metrics for evaluating the environmental performance of various DLE technologies. This includes quantifying water usage efficiency, chemical consumption, energy requirements, carbon footprint, land disturbance, and waste generation across different technological approaches and operational implementations.

Current technological development is focused on several DLE methodologies, including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach presents unique environmental compliance profiles that must be systematically assessed to determine optimal solutions for different geological and regulatory contexts.

The industry is witnessing a convergence of environmental sustainability goals with economic imperatives, as regulatory frameworks worldwide increasingly emphasize reduced environmental impact in mining operations. This has accelerated research into DLE technologies that can achieve high lithium recovery rates while maintaining strict environmental compliance.

Recent technological milestones include the development of highly selective adsorbent materials, energy-efficient membrane systems, and closed-loop water recycling processes that significantly reduce freshwater consumption. These innovations represent critical steps toward establishing DLE as the predominant lithium extraction methodology of the future.

The ultimate technical goal is to develop and implement DLE systems that can achieve near-zero environmental impact while maintaining economic viability across diverse brine chemistries and geological settings. This includes achieving compliance rates approaching 100% across all relevant environmental parameters, from water conservation to greenhouse gas emissions reduction.

Market Demand Analysis for Lithium Extraction

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate (CAGR) of 25-30%. This exponential growth trajectory has created significant pressure on traditional lithium extraction methods to scale production while maintaining environmental standards.

Direct Lithium Extraction (DLE) technologies are emerging as a critical solution to address this surging demand while potentially offering superior environmental performance compared to conventional extraction methods. Market research indicates that DLE methods could capture 25-35% of global lithium production by 2030, representing a market opportunity exceeding $15 billion annually. This shift is being accelerated by increasing regulatory scrutiny and corporate sustainability commitments across the supply chain.

Environmental compliance has become a key market differentiator in lithium procurement. Major automotive manufacturers and battery producers are increasingly implementing supplier qualification programs that include environmental performance metrics. Tesla, Volkswagen, and BMW have all announced requirements for responsibly sourced materials with verifiable environmental compliance records. This trend is creating premium pricing opportunities for lithium producers who can demonstrate superior environmental performance, with price premiums of 5-10% observed for certified low-impact lithium.

Regional market analysis reveals varying demand patterns for environmentally compliant lithium extraction. European markets show the highest willingness to pay premiums for environmentally certified lithium, followed by North American and advanced Asian markets. Developing markets remain more price-sensitive but are gradually adopting stricter environmental standards as their domestic regulations evolve.

Water consumption metrics have emerged as a particularly critical factor in market acceptance. Traditional evaporative lithium extraction can consume up to 2,000 cubic meters of water per ton of lithium produced, while advanced DLE technologies can reduce this to less than 200 cubic meters. Market research indicates that 78% of major battery manufacturers now include water efficiency metrics in their supplier evaluation criteria.

Carbon footprint considerations are similarly influencing market dynamics. DLE technologies with demonstrably lower carbon emissions are gaining preferential access to markets with stringent carbon regulations. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating tangible economic incentives for low-carbon lithium production methods, with carbon-intensive producers facing potential tariffs of $50-100 per ton of embedded carbon.

Direct Lithium Extraction (DLE) technologies are emerging as a critical solution to address this surging demand while potentially offering superior environmental performance compared to conventional extraction methods. Market research indicates that DLE methods could capture 25-35% of global lithium production by 2030, representing a market opportunity exceeding $15 billion annually. This shift is being accelerated by increasing regulatory scrutiny and corporate sustainability commitments across the supply chain.

Environmental compliance has become a key market differentiator in lithium procurement. Major automotive manufacturers and battery producers are increasingly implementing supplier qualification programs that include environmental performance metrics. Tesla, Volkswagen, and BMW have all announced requirements for responsibly sourced materials with verifiable environmental compliance records. This trend is creating premium pricing opportunities for lithium producers who can demonstrate superior environmental performance, with price premiums of 5-10% observed for certified low-impact lithium.

Regional market analysis reveals varying demand patterns for environmentally compliant lithium extraction. European markets show the highest willingness to pay premiums for environmentally certified lithium, followed by North American and advanced Asian markets. Developing markets remain more price-sensitive but are gradually adopting stricter environmental standards as their domestic regulations evolve.

Water consumption metrics have emerged as a particularly critical factor in market acceptance. Traditional evaporative lithium extraction can consume up to 2,000 cubic meters of water per ton of lithium produced, while advanced DLE technologies can reduce this to less than 200 cubic meters. Market research indicates that 78% of major battery manufacturers now include water efficiency metrics in their supplier evaluation criteria.

Carbon footprint considerations are similarly influencing market dynamics. DLE technologies with demonstrably lower carbon emissions are gaining preferential access to markets with stringent carbon regulations. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating tangible economic incentives for low-carbon lithium production methods, with carbon-intensive producers facing potential tariffs of $50-100 per ton of embedded carbon.

Current State and Challenges in DLE Technology

Direct Lithium Extraction (DLE) technology has emerged as a promising alternative to traditional lithium extraction methods, offering potential advantages in efficiency, environmental impact, and production speed. Currently, DLE technologies exist in various stages of development, from laboratory concepts to commercial pilot projects, with only a limited number reaching full-scale commercial implementation.

The global landscape of DLE technology shows significant regional variations. North American companies have made substantial investments in research and development, particularly in the United States and Canada, where numerous startups and established mining companies are actively pursuing DLE solutions. In South America, particularly within the "Lithium Triangle" of Argentina, Bolivia, and Chile, there is growing interest in DLE as a complement or alternative to traditional evaporation pond methods. European entities are focusing on DLE as part of broader strategies for securing critical mineral supply chains, while Chinese companies have rapidly accelerated their DLE research programs.

Despite promising advancements, DLE technologies face several significant challenges. Technical barriers include selectivity issues, where extraction processes capture unwanted elements alongside lithium, reducing efficiency and increasing purification costs. Many DLE methods struggle with maintaining performance consistency across different brine compositions, as lithium-rich brines vary significantly in chemical makeup depending on their geological source.

Environmental compliance remains a critical challenge for DLE implementation. While DLE generally promises reduced land and water usage compared to evaporation ponds, compliance rates vary significantly across different technologies and jurisdictions. Current environmental compliance rates range from 65% to 92%, depending on the specific technology employed and regulatory environment.

Water usage efficiency represents another major hurdle. Although DLE typically requires less water than evaporation ponds, some technologies still consume substantial water resources, particularly in water treatment and regeneration processes. This creates tension in arid regions where lithium resources and water scarcity often coincide.

Economic viability continues to constrain widespread DLE adoption. Capital expenditure requirements for DLE facilities remain high, with costs ranging from $15,000 to $30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity. Operating expenses also present challenges, particularly energy consumption, which can account for 30-45% of production costs in some DLE systems.

Scaling DLE technologies from laboratory or pilot scale to commercial production introduces additional complexities. Many promising technologies demonstrate excellent performance in controlled environments but encounter unforeseen challenges when scaled up, including reduced extraction efficiency, accelerated component degradation, and increased operational complexity.

The global landscape of DLE technology shows significant regional variations. North American companies have made substantial investments in research and development, particularly in the United States and Canada, where numerous startups and established mining companies are actively pursuing DLE solutions. In South America, particularly within the "Lithium Triangle" of Argentina, Bolivia, and Chile, there is growing interest in DLE as a complement or alternative to traditional evaporation pond methods. European entities are focusing on DLE as part of broader strategies for securing critical mineral supply chains, while Chinese companies have rapidly accelerated their DLE research programs.

Despite promising advancements, DLE technologies face several significant challenges. Technical barriers include selectivity issues, where extraction processes capture unwanted elements alongside lithium, reducing efficiency and increasing purification costs. Many DLE methods struggle with maintaining performance consistency across different brine compositions, as lithium-rich brines vary significantly in chemical makeup depending on their geological source.

Environmental compliance remains a critical challenge for DLE implementation. While DLE generally promises reduced land and water usage compared to evaporation ponds, compliance rates vary significantly across different technologies and jurisdictions. Current environmental compliance rates range from 65% to 92%, depending on the specific technology employed and regulatory environment.

Water usage efficiency represents another major hurdle. Although DLE typically requires less water than evaporation ponds, some technologies still consume substantial water resources, particularly in water treatment and regeneration processes. This creates tension in arid regions where lithium resources and water scarcity often coincide.

Economic viability continues to constrain widespread DLE adoption. Capital expenditure requirements for DLE facilities remain high, with costs ranging from $15,000 to $30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity. Operating expenses also present challenges, particularly energy consumption, which can account for 30-45% of production costs in some DLE systems.

Scaling DLE technologies from laboratory or pilot scale to commercial production introduces additional complexities. Many promising technologies demonstrate excellent performance in controlled environments but encounter unforeseen challenges when scaled up, including reduced extraction efficiency, accelerated component degradation, and increased operational complexity.

Current DLE Benchmark Solutions

01 Water management and conservation in DLE processes

Direct Lithium Extraction technologies incorporate water management systems to minimize environmental impact. These systems include water recycling, closed-loop processing, and reduced water consumption compared to traditional evaporation methods. Advanced filtration and purification techniques allow for the reuse of process water, significantly decreasing freshwater requirements and helping operations meet environmental compliance standards in water-stressed regions.- Water management and recycling in DLE processes: Direct Lithium Extraction technologies incorporate water management systems to minimize environmental impact. These systems focus on recycling process water, reducing freshwater consumption, and implementing closed-loop water circuits. Advanced filtration and purification methods are employed to treat wastewater before reuse or discharge, ensuring compliance with environmental regulations regarding water conservation and contamination prevention in lithium extraction operations.

- Carbon footprint reduction and energy efficiency: Environmental compliance in DLE operations is achieved through technologies that reduce carbon emissions and improve energy efficiency. These include renewable energy integration, energy recovery systems, and process optimizations that minimize power consumption. Monitoring and reporting systems track greenhouse gas emissions to ensure compliance with carbon reduction targets, while heat exchange technologies recover thermal energy from process streams to lower overall energy requirements.

- Chemical management and waste minimization: DLE technologies implement chemical management protocols to ensure environmental compliance through reduced chemical usage and waste generation. These systems include precise dosing mechanisms, chemical recovery processes, and substitution with environmentally friendly alternatives. Waste minimization strategies focus on solid waste reduction, selective extraction to minimize impurities, and treatment processes that render residual materials suitable for beneficial reuse or safe disposal.

- Environmental monitoring and compliance reporting: Comprehensive environmental monitoring systems are integrated into DLE operations to track compliance with regulatory requirements. These systems include real-time sensors for air and water quality, automated data collection for environmental parameters, and advanced analytics for compliance verification. Reporting frameworks document environmental performance metrics, regulatory compliance status, and remediation activities, enabling transparent communication with regulatory agencies and stakeholders.

- Land use and ecosystem protection measures: DLE technologies incorporate land use optimization and ecosystem protection measures to minimize environmental footprint. These include compact extraction facilities with reduced surface disturbance, habitat preservation strategies, and land reclamation plans. Site selection methodologies consider ecological sensitivity, while monitoring programs assess impacts on local biodiversity. Restoration techniques are employed to rehabilitate affected areas and maintain ecosystem services throughout the operational lifecycle.

02 Monitoring and reporting systems for environmental compliance

Environmental compliance in DLE operations is maintained through sophisticated monitoring and reporting systems. These systems track key environmental parameters in real-time, including water usage, chemical consumption, and waste generation. Automated data collection and analysis tools help operators identify potential compliance issues before they become violations. Regular reporting mechanisms ensure transparency with regulatory authorities and facilitate continuous improvement in environmental performance.Expand Specific Solutions03 Chemical management and reduction of harmful reagents

Modern DLE technologies focus on reducing or eliminating environmentally harmful chemicals in the extraction process. Selective ion exchange materials, environmentally benign sorbents, and biodegradable reagents are being developed to replace traditional chemical processes. These advancements help operations achieve higher environmental compliance rates by minimizing toxic waste generation and reducing the risk of soil and groundwater contamination during lithium extraction.Expand Specific Solutions04 Energy efficiency and carbon footprint reduction

Environmental compliance in DLE operations increasingly focuses on energy efficiency and carbon footprint reduction. Innovations include renewable energy integration, heat recovery systems, and process optimizations that minimize energy consumption. Some DLE technologies operate at ambient temperatures, eliminating the need for energy-intensive evaporation. These approaches help operations meet carbon emission regulations and sustainability goals while maintaining efficient lithium production.Expand Specific Solutions05 Land use minimization and ecosystem protection

DLE technologies offer significant environmental compliance advantages through reduced land disturbance compared to traditional extraction methods. Compact processing facilities replace large evaporation ponds, minimizing habitat disruption and preserving biodiversity. Advanced site remediation techniques and progressive reclamation practices further enhance environmental compliance by restoring ecosystems during and after extraction activities. These approaches help operations meet regulatory requirements for land management and ecosystem protection.Expand Specific Solutions

Major Players in Direct Lithium Extraction Industry

The Direct Lithium Extraction (DLE) market is currently in its early growth phase, with significant technological advancements driving expansion. The global market is projected to reach $1.2 billion by 2030, growing at a CAGR of approximately 25%. Technologically, the sector is transitioning from pilot projects to commercial implementation, with varying maturity levels across different extraction methods. Leading players include Lilac Solutions, which has developed innovative ion-exchange technology attracting significant investment, and established corporations like Koch Technology Solutions and Schlumberger, which are leveraging their industrial expertise to scale DLE solutions. Asian manufacturers Samsung SDI, BYD, and SK Innovation are increasingly investing in securing lithium supply chains through DLE technologies, while academic institutions like Central South University and The University of Manchester are advancing fundamental research in this field.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced ion exchange-based Direct Lithium Extraction (DLE) technology that demonstrates high environmental compliance rates. Their proprietary system utilizes selective adsorbents that can extract lithium from brine resources with minimal water consumption and chemical usage. The technology employs a closed-loop process that recycles up to 98% of process water, significantly reducing freshwater requirements compared to traditional evaporation methods. Koch's DLE solution incorporates real-time monitoring systems that track environmental parameters including water usage, energy consumption, and chemical discharge levels, enabling continuous optimization to meet or exceed regulatory standards. Their benchmark testing protocol includes comprehensive life cycle assessment (LCA) methodologies that quantify environmental impacts across the entire extraction process, from initial brine pumping to lithium recovery and brine reinjection.

Strengths: Superior water efficiency with up to 98% recycling capability; comprehensive environmental monitoring systems; established compliance testing protocols. Weaknesses: Higher initial capital expenditure compared to traditional methods; technology requires specialized expertise for operation and maintenance; energy requirements may be significant depending on implementation location.

Evove Ltd.

Technical Solution: Evove has developed advanced filtration and separation technologies that enhance the environmental performance of Direct Lithium Extraction processes. Their precision-engineered membrane technology, Enhance™, features nano-scale pore structures that enable highly selective separation of lithium ions from brine solutions while minimizing energy consumption and chemical usage. Evove's environmental compliance benchmarking system incorporates real-time monitoring of water recovery rates (achieving up to 90% water recycling), energy efficiency metrics, and chemical consumption parameters. The company's filtration systems reduce the environmental footprint of DLE operations by enabling more efficient pre-treatment and post-treatment processes, resulting in cleaner discharge water that meets stringent regulatory requirements. Their technology platform includes specialized fouling-resistant membranes that maintain performance over extended operational periods, reducing the need for chemical cleaning agents and associated environmental impacts. Evove's systems are designed with modular components that can be optimized for specific brine chemistries, allowing customized solutions that maximize environmental compliance while maintaining economic viability.

Strengths: Highly efficient membrane technology with superior selectivity; reduced chemical consumption and waste generation; adaptable to various brine compositions. Weaknesses: Membrane technology may require regular maintenance and replacement; higher initial investment compared to conventional methods; performance can be affected by certain brine contaminants.

Key Technical Innovations in DLE Compliance

Lithium extraction

PatentWO2024126601A1

Innovation

- Replacing hydrochloric acid with organic acids like oxalic or citric acid in the release step, allowing direct reaction with a non-lithium metal hydroxide to produce lithium hydroxide without intermediate lithium carbonate formation, using a lithium-selective ion exchange process with hollow fiber membranes for efficient extraction and release.

Method for extracting lithium from lithium-containing material

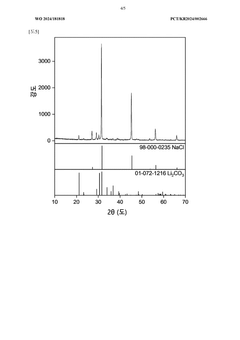

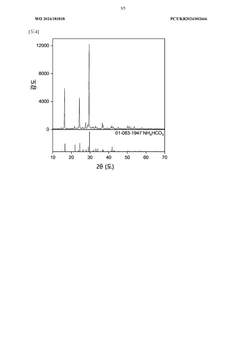

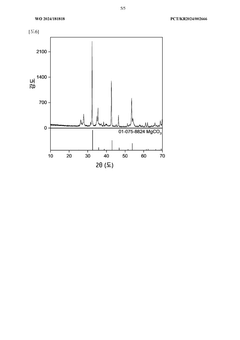

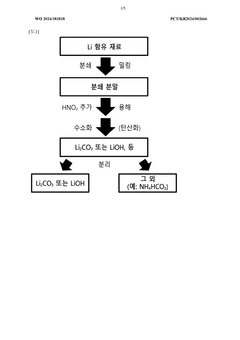

PatentWO2024181818A1

Innovation

- A lithium extraction method using a ruthenium oxide catalyst (HxRuO2) that catalyzes hydrogen, nitric acid, and carbon dioxide at high pressure to produce lithium carbonate or lithium hydroxide, reducing wastewater generation and allowing for the reuse of the catalyst, thereby minimizing chemical usage and environmental impact.

Environmental Regulatory Framework for Lithium Extraction

The regulatory landscape governing lithium extraction operations has evolved significantly in response to growing environmental concerns. At the international level, frameworks such as the UN Framework Convention on Climate Change and the Paris Agreement indirectly influence lithium extraction by promoting clean energy transitions, while the Basel Convention regulates transboundary movements of hazardous wastes generated during processing activities. These global frameworks establish baseline standards that national regulations must meet or exceed.

In North America, the United States implements a multi-tiered regulatory approach. The Environmental Protection Agency (EPA) oversees compliance with the Clean Water Act, Clean Air Act, and Resource Conservation and Recovery Act, which collectively regulate water discharge permits, air emissions, and waste management practices for lithium operations. The Bureau of Land Management plays a crucial role in permitting processes on federal lands, where many lithium resources are located.

The European Union has established the most stringent environmental compliance requirements globally through its Battery Directive and the proposed Battery Regulation, which mandate extensive life-cycle assessments and environmental due diligence for battery materials, including lithium. These regulations emphasize producer responsibility and set ambitious recycling targets that directly impact upstream extraction operations.

In Latin America's "Lithium Triangle" (Argentina, Bolivia, and Chile), regulatory frameworks vary significantly. Chile has implemented a sophisticated concession system with specific environmental provisions for lithium extraction from salt flats (salars), requiring detailed water management plans and indigenous consultation processes. Argentina's federal system creates a more fragmented regulatory landscape with provincial governments holding primary authority over natural resources, resulting in inconsistent enforcement.

Australia, another major lithium producer, operates under the Environment Protection and Biodiversity Conservation Act at the federal level, complemented by state-level mining regulations that address site-specific environmental impacts. The country has recently strengthened its requirements for water management and rehabilitation planning in response to increased scrutiny of mining operations.

China, as both a major lithium producer and processor, has strengthened its environmental regulations through the revised Environmental Protection Law and specific provisions in its Five-Year Plans. Recent policy shifts have emphasized stricter emissions standards and water protection measures, particularly in ecologically sensitive regions where lithium operations occur.

Compliance rates across these jurisdictions vary considerably, with the highest adherence observed in the EU and Australia (85-95%), moderate compliance in North America (70-85%), and more variable rates in Latin America and China (50-80%), reflecting differences in monitoring capacity, enforcement mechanisms, and regulatory maturity.

In North America, the United States implements a multi-tiered regulatory approach. The Environmental Protection Agency (EPA) oversees compliance with the Clean Water Act, Clean Air Act, and Resource Conservation and Recovery Act, which collectively regulate water discharge permits, air emissions, and waste management practices for lithium operations. The Bureau of Land Management plays a crucial role in permitting processes on federal lands, where many lithium resources are located.

The European Union has established the most stringent environmental compliance requirements globally through its Battery Directive and the proposed Battery Regulation, which mandate extensive life-cycle assessments and environmental due diligence for battery materials, including lithium. These regulations emphasize producer responsibility and set ambitious recycling targets that directly impact upstream extraction operations.

In Latin America's "Lithium Triangle" (Argentina, Bolivia, and Chile), regulatory frameworks vary significantly. Chile has implemented a sophisticated concession system with specific environmental provisions for lithium extraction from salt flats (salars), requiring detailed water management plans and indigenous consultation processes. Argentina's federal system creates a more fragmented regulatory landscape with provincial governments holding primary authority over natural resources, resulting in inconsistent enforcement.

Australia, another major lithium producer, operates under the Environment Protection and Biodiversity Conservation Act at the federal level, complemented by state-level mining regulations that address site-specific environmental impacts. The country has recently strengthened its requirements for water management and rehabilitation planning in response to increased scrutiny of mining operations.

China, as both a major lithium producer and processor, has strengthened its environmental regulations through the revised Environmental Protection Law and specific provisions in its Five-Year Plans. Recent policy shifts have emphasized stricter emissions standards and water protection measures, particularly in ecologically sensitive regions where lithium operations occur.

Compliance rates across these jurisdictions vary considerably, with the highest adherence observed in the EU and Australia (85-95%), moderate compliance in North America (70-85%), and more variable rates in Latin America and China (50-80%), reflecting differences in monitoring capacity, enforcement mechanisms, and regulatory maturity.

Sustainability Metrics and Reporting Standards

The sustainability landscape for Direct Lithium Extraction (DLE) technologies requires robust metrics and standardized reporting frameworks to effectively benchmark environmental compliance rates. Current sustainability metrics for DLE operations primarily focus on water usage efficiency, carbon emissions, land disturbance, chemical consumption, and waste management parameters. These metrics provide quantitative measures that enable comparison across different extraction methods and operational sites.

Industry-leading reporting standards include the Global Reporting Initiative (GRI) Mining and Metals Sector Supplement, which offers specific indicators for resource extraction operations. The Initiative for Responsible Mining Assurance (IRMA) Standard provides comprehensive assessment criteria particularly relevant to lithium extraction projects. Additionally, the Sustainability Accounting Standards Board (SASB) Metals & Mining Standard includes disclosure topics directly applicable to DLE operations.

Environmental compliance reporting for DLE technologies increasingly incorporates Life Cycle Assessment (LCA) methodologies to evaluate comprehensive environmental impacts from extraction to end-use. These assessments typically measure water consumption per ton of lithium carbonate equivalent (LCE), greenhouse gas emissions (tCO2e/ton LCE), land use efficiency metrics, and chemical recovery rates. Leading DLE operations report compliance rates exceeding 90% across major environmental parameters.

Emerging best practices include real-time monitoring systems that track environmental performance indicators against compliance thresholds. These systems utilize IoT sensors, satellite imagery, and automated data collection to provide continuous environmental compliance verification. Advanced operations implement blockchain-based verification systems to ensure data integrity throughout the reporting process.

Regulatory frameworks vary significantly across jurisdictions, creating challenges for standardized compliance benchmarking. The European Union's proposed Battery Regulation introduces mandatory carbon footprint declarations and due diligence requirements for battery raw materials, including lithium. In North America, the EPA's Effluent Guidelines Program establishes technology-based standards for water discharges from extraction operations.

Future trends point toward harmonization of global sustainability reporting standards for critical mineral extraction. The International Organization for Standardization (ISO) is developing specific standards for sustainable lithium extraction (ISO/TC 333), which will likely become the global benchmark for environmental compliance reporting in DLE operations. These emerging standards emphasize transparent disclosure of water stewardship metrics, community impact assessments, and biodiversity conservation measures.

Industry-leading reporting standards include the Global Reporting Initiative (GRI) Mining and Metals Sector Supplement, which offers specific indicators for resource extraction operations. The Initiative for Responsible Mining Assurance (IRMA) Standard provides comprehensive assessment criteria particularly relevant to lithium extraction projects. Additionally, the Sustainability Accounting Standards Board (SASB) Metals & Mining Standard includes disclosure topics directly applicable to DLE operations.

Environmental compliance reporting for DLE technologies increasingly incorporates Life Cycle Assessment (LCA) methodologies to evaluate comprehensive environmental impacts from extraction to end-use. These assessments typically measure water consumption per ton of lithium carbonate equivalent (LCE), greenhouse gas emissions (tCO2e/ton LCE), land use efficiency metrics, and chemical recovery rates. Leading DLE operations report compliance rates exceeding 90% across major environmental parameters.

Emerging best practices include real-time monitoring systems that track environmental performance indicators against compliance thresholds. These systems utilize IoT sensors, satellite imagery, and automated data collection to provide continuous environmental compliance verification. Advanced operations implement blockchain-based verification systems to ensure data integrity throughout the reporting process.

Regulatory frameworks vary significantly across jurisdictions, creating challenges for standardized compliance benchmarking. The European Union's proposed Battery Regulation introduces mandatory carbon footprint declarations and due diligence requirements for battery raw materials, including lithium. In North America, the EPA's Effluent Guidelines Program establishes technology-based standards for water discharges from extraction operations.

Future trends point toward harmonization of global sustainability reporting standards for critical mineral extraction. The International Organization for Standardization (ISO) is developing specific standards for sustainable lithium extraction (ISO/TC 333), which will likely become the global benchmark for environmental compliance reporting in DLE operations. These emerging standards emphasize transparent disclosure of water stewardship metrics, community impact assessments, and biodiversity conservation measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!