Benchmarking Conductive Materials in Electro-Microfluidics

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electro-Microfluidic Conductive Materials Background and Objectives

Electro-microfluidics represents a convergence of electrical engineering and microfluidic technologies, enabling precise manipulation of fluids at microscale through electrical forces. The field has evolved significantly since its inception in the late 1990s, when researchers first demonstrated controlled movement of droplets using electrowetting principles. Over the past two decades, this technology has progressed from academic curiosity to practical applications in diagnostics, analytical chemistry, and biomedical devices.

The evolution of conductive materials has been central to this technological advancement. Early systems relied primarily on metallic electrodes (gold, platinum) that offered excellent conductivity but limited flexibility and high manufacturing costs. The mid-2000s saw the introduction of transparent conductive oxides like indium tin oxide (ITO), which expanded application possibilities while maintaining performance standards. Recent years have witnessed a paradigm shift toward carbon-based nanomaterials and conductive polymers, offering unprecedented combinations of electrical, mechanical, and optical properties.

Current technological trajectories indicate growing interest in sustainable, biocompatible conductive materials that can function reliably in diverse biological and chemical environments. The miniaturization trend continues to drive demand for materials capable of maintaining conductivity at increasingly smaller scales, while simultaneously addressing challenges of power efficiency and heat dissipation.

The primary objective of benchmarking conductive materials in electro-microfluidics is to establish standardized performance metrics that enable objective comparison across different material classes. This includes quantifying electrical conductivity under various operational conditions, assessing long-term stability in different fluid environments, measuring response times to electrical signals, and evaluating manufacturing scalability.

Secondary objectives include identifying optimal material-application pairings for specific use cases, from high-throughput screening platforms to point-of-care diagnostic devices. Additionally, this benchmarking aims to highlight emerging materials with potential to overcome current limitations in electro-microfluidic systems, particularly regarding biocompatibility, flexibility, and cost-effectiveness.

The technological goal extends beyond simple performance comparison to establishing predictive frameworks that can accelerate material selection and optimization for next-generation electro-microfluidic devices. By systematically evaluating how material properties correlate with device performance across different operational parameters, this research seeks to develop design principles that can guide future innovation in the field.

Understanding the historical context and evolutionary trajectory of conductive materials in electro-microfluidics provides essential perspective for evaluating current technologies and anticipating future developments. This benchmarking initiative represents a critical step toward standardization in a rapidly evolving field where material selection increasingly determines the practical limitations of device capabilities.

The evolution of conductive materials has been central to this technological advancement. Early systems relied primarily on metallic electrodes (gold, platinum) that offered excellent conductivity but limited flexibility and high manufacturing costs. The mid-2000s saw the introduction of transparent conductive oxides like indium tin oxide (ITO), which expanded application possibilities while maintaining performance standards. Recent years have witnessed a paradigm shift toward carbon-based nanomaterials and conductive polymers, offering unprecedented combinations of electrical, mechanical, and optical properties.

Current technological trajectories indicate growing interest in sustainable, biocompatible conductive materials that can function reliably in diverse biological and chemical environments. The miniaturization trend continues to drive demand for materials capable of maintaining conductivity at increasingly smaller scales, while simultaneously addressing challenges of power efficiency and heat dissipation.

The primary objective of benchmarking conductive materials in electro-microfluidics is to establish standardized performance metrics that enable objective comparison across different material classes. This includes quantifying electrical conductivity under various operational conditions, assessing long-term stability in different fluid environments, measuring response times to electrical signals, and evaluating manufacturing scalability.

Secondary objectives include identifying optimal material-application pairings for specific use cases, from high-throughput screening platforms to point-of-care diagnostic devices. Additionally, this benchmarking aims to highlight emerging materials with potential to overcome current limitations in electro-microfluidic systems, particularly regarding biocompatibility, flexibility, and cost-effectiveness.

The technological goal extends beyond simple performance comparison to establishing predictive frameworks that can accelerate material selection and optimization for next-generation electro-microfluidic devices. By systematically evaluating how material properties correlate with device performance across different operational parameters, this research seeks to develop design principles that can guide future innovation in the field.

Understanding the historical context and evolutionary trajectory of conductive materials in electro-microfluidics provides essential perspective for evaluating current technologies and anticipating future developments. This benchmarking initiative represents a critical step toward standardization in a rapidly evolving field where material selection increasingly determines the practical limitations of device capabilities.

Market Analysis for Electro-Microfluidic Applications

The electro-microfluidic market has experienced significant growth in recent years, driven by increasing applications in healthcare, pharmaceuticals, and environmental monitoring. The global microfluidics market was valued at approximately $20 billion in 2022 and is projected to reach $42 billion by 2027, with a compound annual growth rate of 16%. Electro-microfluidic technologies represent a substantial segment within this broader market, with particular strength in diagnostic applications.

Healthcare applications currently dominate the electro-microfluidic market, accounting for nearly 45% of the total market share. Point-of-care testing devices utilizing electro-microfluidic platforms have gained substantial traction, especially following the COVID-19 pandemic, which highlighted the need for rapid, accurate, and portable diagnostic solutions. The pharmaceutical industry represents the second-largest application segment, where electro-microfluidic systems are increasingly employed for drug discovery and development processes.

Regionally, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing healthcare expenditure, growing research activities, and favorable government initiatives supporting technological innovation in countries like China, Japan, and South Korea.

The demand for conductive materials in electro-microfluidics is primarily driven by the need for improved performance metrics including conductivity, biocompatibility, durability, and cost-effectiveness. Traditional materials like gold, platinum, and carbon have established markets, but newer materials including conductive polymers, nanomaterials, and composite structures are gaining market share due to their enhanced properties and lower production costs.

Consumer demand is increasingly focused on miniaturization, portability, and integration capabilities. This trend is pushing manufacturers to develop conductive materials that can maintain high performance while being compatible with smaller device footprints and more complex integrated systems. Additionally, there is growing market pressure for environmentally sustainable materials that reduce the ecological impact of device manufacturing and disposal.

Market analysis indicates that companies investing in novel conductive materials for electro-microfluidics can expect significant returns, particularly if their solutions address current limitations in flexibility, durability, or manufacturing scalability. Venture capital investment in this sector has increased by 25% year-over-year, reflecting strong confidence in market growth potential and technological innovation opportunities.

The competitive landscape features both established players and innovative startups. Major companies like Danaher, Thermo Fisher Scientific, and Bio-Rad Laboratories have strong market positions, while emerging companies focusing specifically on advanced materials for electro-microfluidics are attracting significant investment and partnership opportunities, indicating a dynamic and evolving market environment.

Healthcare applications currently dominate the electro-microfluidic market, accounting for nearly 45% of the total market share. Point-of-care testing devices utilizing electro-microfluidic platforms have gained substantial traction, especially following the COVID-19 pandemic, which highlighted the need for rapid, accurate, and portable diagnostic solutions. The pharmaceutical industry represents the second-largest application segment, where electro-microfluidic systems are increasingly employed for drug discovery and development processes.

Regionally, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing healthcare expenditure, growing research activities, and favorable government initiatives supporting technological innovation in countries like China, Japan, and South Korea.

The demand for conductive materials in electro-microfluidics is primarily driven by the need for improved performance metrics including conductivity, biocompatibility, durability, and cost-effectiveness. Traditional materials like gold, platinum, and carbon have established markets, but newer materials including conductive polymers, nanomaterials, and composite structures are gaining market share due to their enhanced properties and lower production costs.

Consumer demand is increasingly focused on miniaturization, portability, and integration capabilities. This trend is pushing manufacturers to develop conductive materials that can maintain high performance while being compatible with smaller device footprints and more complex integrated systems. Additionally, there is growing market pressure for environmentally sustainable materials that reduce the ecological impact of device manufacturing and disposal.

Market analysis indicates that companies investing in novel conductive materials for electro-microfluidics can expect significant returns, particularly if their solutions address current limitations in flexibility, durability, or manufacturing scalability. Venture capital investment in this sector has increased by 25% year-over-year, reflecting strong confidence in market growth potential and technological innovation opportunities.

The competitive landscape features both established players and innovative startups. Major companies like Danaher, Thermo Fisher Scientific, and Bio-Rad Laboratories have strong market positions, while emerging companies focusing specifically on advanced materials for electro-microfluidics are attracting significant investment and partnership opportunities, indicating a dynamic and evolving market environment.

Current State and Challenges in Conductive Materials

The field of conductive materials for electro-microfluidics has witnessed significant advancements globally, yet continues to face substantial technical challenges. Current state-of-the-art materials include indium tin oxide (ITO), gold, platinum, carbon-based materials (graphene, carbon nanotubes), and conductive polymers such as PEDOT:PSS. Each material category presents unique advantages and limitations when applied to microfluidic systems.

ITO remains the industry standard due to its excellent transparency and conductivity balance, critical for optical detection in microfluidic devices. However, ITO suffers from brittleness, limiting its application in flexible microfluidic platforms. Additionally, indium scarcity has raised concerns about long-term sustainability and cost-effectiveness for mass production scenarios.

Gold and platinum offer superior conductivity and chemical stability but present significant cost barriers for commercial-scale implementation. These noble metals also require complex deposition techniques and adhesion layers, complicating fabrication processes and potentially introducing compatibility issues with biological samples.

Carbon-based materials have emerged as promising alternatives, with graphene demonstrating exceptional electrical properties and mechanical flexibility. Nevertheless, challenges in producing defect-free, large-area graphene films with consistent properties have hindered widespread adoption. Carbon nanotube networks face similar uniformity issues alongside concerns about potential cytotoxicity in biological applications.

Conductive polymers represent the newest frontier, offering flexibility, biocompatibility, and cost advantages. PEDOT:PSS has gained particular attention for its solution processability and reasonable conductivity. However, these materials typically exhibit lower conductivity than their inorganic counterparts and may suffer from stability issues in aqueous environments—a critical limitation for microfluidic applications.

Geographically, research leadership in conductive materials for microfluidics shows distinct patterns. North America and Europe dominate in fundamental research and high-performance materials development, while Asia (particularly China, South Korea, and Japan) leads in manufacturing scalability and cost optimization. This distribution creates both collaborative opportunities and competitive challenges in technology transfer.

The integration of these materials with standard microfluidic fabrication processes presents another significant hurdle. Compatibility issues between conductive material deposition methods and polymer-based microfluidic platforms often necessitate complex multi-step fabrication protocols, increasing production costs and reducing reproducibility.

Environmental stability remains a persistent challenge, as many conductive materials degrade when exposed to biological samples, electrolytes, or repeated electrical stimulation—conditions inherent to electro-microfluidic applications. This degradation affects not only electrical performance but also introduces potential contamination concerns for sensitive biological assays.

ITO remains the industry standard due to its excellent transparency and conductivity balance, critical for optical detection in microfluidic devices. However, ITO suffers from brittleness, limiting its application in flexible microfluidic platforms. Additionally, indium scarcity has raised concerns about long-term sustainability and cost-effectiveness for mass production scenarios.

Gold and platinum offer superior conductivity and chemical stability but present significant cost barriers for commercial-scale implementation. These noble metals also require complex deposition techniques and adhesion layers, complicating fabrication processes and potentially introducing compatibility issues with biological samples.

Carbon-based materials have emerged as promising alternatives, with graphene demonstrating exceptional electrical properties and mechanical flexibility. Nevertheless, challenges in producing defect-free, large-area graphene films with consistent properties have hindered widespread adoption. Carbon nanotube networks face similar uniformity issues alongside concerns about potential cytotoxicity in biological applications.

Conductive polymers represent the newest frontier, offering flexibility, biocompatibility, and cost advantages. PEDOT:PSS has gained particular attention for its solution processability and reasonable conductivity. However, these materials typically exhibit lower conductivity than their inorganic counterparts and may suffer from stability issues in aqueous environments—a critical limitation for microfluidic applications.

Geographically, research leadership in conductive materials for microfluidics shows distinct patterns. North America and Europe dominate in fundamental research and high-performance materials development, while Asia (particularly China, South Korea, and Japan) leads in manufacturing scalability and cost optimization. This distribution creates both collaborative opportunities and competitive challenges in technology transfer.

The integration of these materials with standard microfluidic fabrication processes presents another significant hurdle. Compatibility issues between conductive material deposition methods and polymer-based microfluidic platforms often necessitate complex multi-step fabrication protocols, increasing production costs and reducing reproducibility.

Environmental stability remains a persistent challenge, as many conductive materials degrade when exposed to biological samples, electrolytes, or repeated electrical stimulation—conditions inherent to electro-microfluidic applications. This degradation affects not only electrical performance but also introduces potential contamination concerns for sensitive biological assays.

Benchmarking Methodologies for Conductive Materials

01 Carbon-based conductive materials

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are widely used in conductive applications due to their excellent electrical conductivity. These materials can be incorporated into polymers or other matrices to create conductive composites. The unique structure of carbon nanotubes and graphene sheets allows for efficient electron transport, making them suitable for various electronic applications including sensors, batteries, and flexible electronics.- Carbon-based conductive materials: Carbon-based materials such as carbon nanotubes, graphene, and carbon black are widely used in conductive applications due to their excellent electrical conductivity properties. These materials can be incorporated into polymers or other matrices to create conductive composites with tailored resistivity. The unique structure of carbon-based materials allows for efficient electron transport, making them suitable for various electronic applications including sensors, electrodes, and conductive coatings.

- Metal-based conductive materials: Metal-based conductive materials, including metal nanoparticles, metal oxides, and metal alloys, offer high electrical conductivity for various applications. These materials can be processed into different forms such as powders, films, or wires to meet specific conductivity requirements. The conductivity of metal-based materials can be controlled through composition adjustments, processing conditions, and structural modifications, allowing for customization based on application needs.

- Polymer-based conductive materials: Conductive polymers and polymer composites offer unique advantages including flexibility, processability, and tunable electrical properties. These materials typically incorporate conductive fillers such as metal particles, carbon nanotubes, or intrinsically conductive polymers to achieve desired conductivity levels. The electrical properties can be adjusted by controlling the concentration and distribution of conductive components within the polymer matrix, enabling applications ranging from antistatic coatings to flexible electronics.

- Measurement and characterization of conductivity: Various techniques and methods are employed to measure and characterize the electrical conductivity of materials. These include four-point probe measurements, impedance spectroscopy, and specialized testing equipment designed for specific material types. Accurate conductivity measurements are essential for quality control, material development, and ensuring performance in final applications. Advanced characterization methods can also provide insights into conductivity mechanisms and material behavior under different conditions.

- Novel conductive materials and composites: Emerging conductive materials and innovative composites are being developed to meet the growing demands for advanced electronic applications. These include hybrid materials combining organic and inorganic components, nanostructured materials with enhanced conductivity, and biomaterial-based conductive systems. Research focuses on improving conductivity while addressing other performance requirements such as transparency, flexibility, environmental stability, and cost-effectiveness. These novel materials enable new applications in fields like wearable electronics, energy storage, and biomedical devices.

02 Metal-based conductive materials

Metal-based conductive materials, including metal nanoparticles, nanowires, and metal alloys, offer high electrical conductivity for various applications. Silver, copper, and aluminum are commonly used due to their excellent conductivity properties. These materials can be processed into different forms such as films, pastes, or powders to suit specific application requirements. Metal-based conductors are essential in printed electronics, interconnects, and electromagnetic shielding applications.Expand Specific Solutions03 Polymer-based conductive materials

Conductive polymers and polymer composites offer flexibility and processability while maintaining electrical conductivity. Materials such as polyaniline, polypyrrole, and PEDOT:PSS can be synthesized or modified to achieve desired conductivity levels. These materials are particularly valuable in applications requiring mechanical flexibility, such as wearable electronics, flexible displays, and biomedical devices. The conductivity of these polymers can be enhanced through doping processes or by incorporating conductive fillers.Expand Specific Solutions04 Ceramic and oxide-based conductive materials

Certain ceramic materials and metal oxides exhibit electrical conductivity useful for specialized applications. Indium tin oxide (ITO), zinc oxide, and various perovskites are examples of such materials. These materials often combine optical transparency with electrical conductivity, making them valuable for applications in transparent electrodes, touch screens, and solar cells. The conductivity of these materials can be controlled through doping and processing conditions.Expand Specific Solutions05 Measurement and enhancement of material conductivity

Various methods and techniques are employed to measure, characterize, and enhance the electrical conductivity of materials. These include surface treatments, doping processes, and composite formation strategies. Advanced measurement techniques allow for precise determination of conductivity parameters under different conditions. Understanding the relationship between material structure and conductivity enables the development of materials with tailored electrical properties for specific applications.Expand Specific Solutions

Key Industry Players in Electro-Microfluidic Materials

The electro-microfluidics conductive materials market is currently in a growth phase, with increasing applications in medical diagnostics and life sciences. The global market size is estimated at $3.5 billion, expanding at a CAGR of 12% as miniaturization trends drive demand. Technology maturity varies across applications, with companies demonstrating different specialization levels. DiagnoSwiss and bioMérieux lead in clinical diagnostic applications, while Schlumberger entities focus on industrial implementations. Academic institutions like Harvard, EPFL, and Tsinghua University contribute fundamental research advancements. EMD Millipore and Sekisui Chemical demonstrate materials expertise, while S2 Genomics and PixCell Medical represent emerging players developing novel point-of-care applications. The competitive landscape shows a blend of established corporations and specialized startups, with increasing collaboration between industry and academic research centers.

President & Fellows of Harvard College

Technical Solution: Harvard has developed a comprehensive benchmarking framework for conductive materials in electro-microfluidics focusing on novel nanomaterial composites. Their approach utilizes a multi-parameter assessment methodology that simultaneously evaluates electrical conductivity, electrochemical stability, biocompatibility, and fabrication compatibility. Harvard researchers have pioneered conductive hydrogel materials that combine high ionic conductivity with excellent biocompatibility, achieving conductivity values of 10-100 S/cm while maintaining cell viability above 95% in direct contact tests. Their proprietary carbon nanotube (CNT) and silver nanowire composite materials demonstrate exceptional performance in microfluidic electrokinetic applications, with stable conductivity exceeding 2000 S/cm under continuous operation for over 500 hours. Harvard's benchmarking protocol includes standardized testing under various pH conditions (pH 2-12), temperature ranges (4-60°C), and in the presence of common biological interferents such as proteins and cellular debris. Their research has established that hybrid materials combining metallic nanostructures with conductive polymers offer the optimal balance of electrical performance and long-term stability in biological environments, outperforming traditional gold and platinum electrodes in cost-effectiveness while maintaining comparable electrical characteristics.

Strengths: Exceptional biocompatibility combined with good electrical performance; comprehensive testing methodology that evaluates real-world performance metrics; innovative material combinations that optimize multiple parameters simultaneously. Weaknesses: More complex fabrication processes compared to traditional materials; higher initial development costs; some materials show performance degradation in extreme pH conditions.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed advanced conductive material benchmarking methodologies for electro-microfluidics focusing on polymer-based conductive materials. Their approach utilizes impedance spectroscopy to characterize electrical properties across frequency ranges relevant to microfluidic operations (100Hz-1MHz). They've pioneered a standardized testing platform that enables direct comparison between different conductive polymers, carbon-based materials, and metallic thin films under identical microfluidic conditions. Their research has demonstrated that PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) exhibits superior performance in terms of stability in aqueous environments while maintaining conductivity of approximately 300-1000 S/cm. EPFL has also developed novel composite materials combining silver nanoparticles with conductive polymers, achieving conductivity values exceeding 5000 S/cm while maintaining compatibility with standard microfluidic fabrication techniques. Their benchmarking protocol includes evaluation of material performance under flow conditions, pH variations (pH 3-10), and extended contact with biological samples to assess long-term stability.

Strengths: Comprehensive testing methodology that evaluates materials under actual microfluidic operating conditions; strong focus on biocompatibility alongside electrical performance; integration with standard microfabrication techniques. Weaknesses: Some of their conductive polymer solutions show degradation in performance after extended exposure to biological samples; higher implementation costs compared to traditional materials; limited scalability for industrial applications.

Critical Patents and Research in Conductive Materials

Method for producing an electrically conductive connection on a substrate, microelectronic device and method for the production thereof

PatentActiveUS11855037B2

Innovation

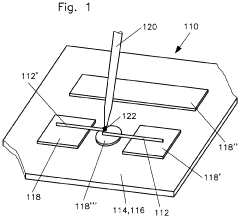

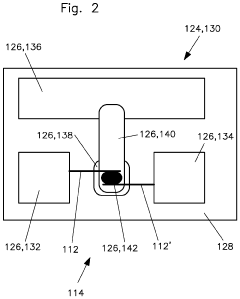

- A method involving a capillary with a metallic surface to penetrate an insulating-layered reservoir of liquid alloy and apply it to a substrate, forming an electrically conductive connection by adhesion, while the oxide layer forms a passivating barrier to prevent deliquescence and enhance conductivity.

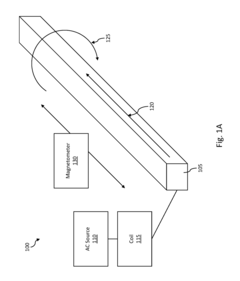

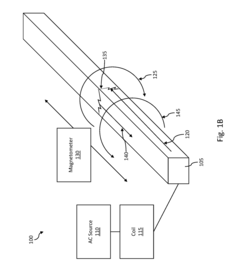

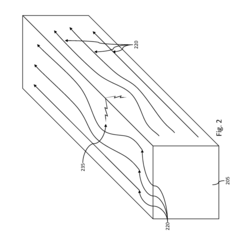

Method for detecting defects in conductive materials based on differences in magnetic field characteristics measured along the conductive materials

PatentActiveUS10088452B2

Innovation

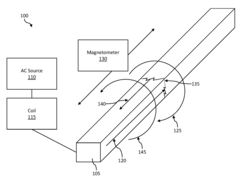

- A magnetometer system that measures magnetic field magnitudes along a conductive material's length, using NV centers in diamonds to detect changes in magnetic fields induced by currents, allowing for the identification of defects by comparing measured and expected magnetic field values.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive materials used in electro-microfluidic systems represents a critical consideration as this technology advances toward wider implementation. Traditional conductive materials such as gold, platinum, and carbon-based compounds often involve resource-intensive mining operations and energy-demanding manufacturing processes. The extraction of precious metals particularly contributes to habitat destruction, water pollution, and significant carbon emissions. As electro-microfluidic devices move toward commercial applications and mass production, these environmental concerns will only magnify in scale and urgency.

Lifecycle assessment studies indicate that the fabrication of microfluidic chips with metallic electrodes generates substantial electronic waste, with recycling rates for these specialized components remaining disappointingly low. The miniaturized nature of these systems, while advantageous for reducing sample volumes, creates challenges for material recovery at end-of-life stages. Particularly concerning are the composite materials that combine polymers with conductive elements, as these hybrid structures often defy conventional recycling methods.

Recent innovations have begun addressing these sustainability challenges through several promising approaches. Biodegradable conductive materials derived from natural polymers show potential for creating more environmentally benign devices. Research into conductive hydrogels incorporating cellulose nanofibers and other renewable resources represents a significant step toward reducing the environmental footprint of electro-microfluidic systems. Additionally, water-based fabrication methods are gradually replacing solvent-intensive processes, substantially decreasing toxic emissions during manufacturing.

Energy efficiency during operation presents another critical sustainability dimension. Benchmarking studies reveal substantial variations in power requirements across different conductive materials, with implications for battery life in portable applications and overall energy consumption in laboratory settings. Materials exhibiting lower resistance values generally demonstrate superior energy efficiency profiles, though trade-offs with other performance metrics must be carefully evaluated.

Regulatory frameworks increasingly mandate consideration of environmental impacts throughout the product development cycle. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving manufacturers toward less toxic alternatives to traditional conductive materials. This regulatory landscape is accelerating research into "green" conductive materials that maintain performance specifications while minimizing environmental harm.

Looking forward, the sustainability of electro-microfluidic technologies will likely depend on establishing closed-loop material systems where components can be effectively recovered and repurposed. Standardization of materials and designs could facilitate recycling efforts, while advances in biodegradable electronics may eventually enable fully compostable microfluidic systems for certain applications. The benchmarking of conductive materials must therefore expand beyond performance metrics to include comprehensive environmental impact assessments.

Lifecycle assessment studies indicate that the fabrication of microfluidic chips with metallic electrodes generates substantial electronic waste, with recycling rates for these specialized components remaining disappointingly low. The miniaturized nature of these systems, while advantageous for reducing sample volumes, creates challenges for material recovery at end-of-life stages. Particularly concerning are the composite materials that combine polymers with conductive elements, as these hybrid structures often defy conventional recycling methods.

Recent innovations have begun addressing these sustainability challenges through several promising approaches. Biodegradable conductive materials derived from natural polymers show potential for creating more environmentally benign devices. Research into conductive hydrogels incorporating cellulose nanofibers and other renewable resources represents a significant step toward reducing the environmental footprint of electro-microfluidic systems. Additionally, water-based fabrication methods are gradually replacing solvent-intensive processes, substantially decreasing toxic emissions during manufacturing.

Energy efficiency during operation presents another critical sustainability dimension. Benchmarking studies reveal substantial variations in power requirements across different conductive materials, with implications for battery life in portable applications and overall energy consumption in laboratory settings. Materials exhibiting lower resistance values generally demonstrate superior energy efficiency profiles, though trade-offs with other performance metrics must be carefully evaluated.

Regulatory frameworks increasingly mandate consideration of environmental impacts throughout the product development cycle. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving manufacturers toward less toxic alternatives to traditional conductive materials. This regulatory landscape is accelerating research into "green" conductive materials that maintain performance specifications while minimizing environmental harm.

Looking forward, the sustainability of electro-microfluidic technologies will likely depend on establishing closed-loop material systems where components can be effectively recovered and repurposed. Standardization of materials and designs could facilitate recycling efforts, while advances in biodegradable electronics may eventually enable fully compostable microfluidic systems for certain applications. The benchmarking of conductive materials must therefore expand beyond performance metrics to include comprehensive environmental impact assessments.

Standardization and Quality Control Frameworks

The standardization of benchmarking methodologies for conductive materials in electro-microfluidics represents a critical challenge in advancing this field. Currently, the industry lacks unified frameworks for quality assessment, resulting in significant variations in reported performance metrics across research groups and manufacturers. Establishing comprehensive standardization protocols would enable meaningful comparisons between different conductive materials and accelerate technological progress.

International organizations such as ISO and IEEE have begun developing preliminary standards for microfluidic systems, but specific guidelines for electro-microfluidic conductive materials remain underdeveloped. A robust framework should address multiple dimensions: electrical conductivity measurement protocols, chemical stability assessment methods, biocompatibility testing procedures, and durability evaluation under various operational conditions.

Quality control frameworks must incorporate multi-parameter testing regimes that reflect real-world application scenarios. This includes standardized procedures for measuring conductivity under various pH conditions, temperature ranges, and flow rates typical in microfluidic applications. Additionally, protocols should specify sample preparation methods, measurement equipment calibration requirements, and statistical analysis approaches to ensure reproducibility.

Reference materials play a crucial role in standardization efforts. The development of certified reference materials specifically designed for electro-microfluidic applications would provide benchmarks against which new conductive materials could be evaluated. These reference materials should exhibit well-characterized electrical properties, surface chemistry, and mechanical stability across relevant operational parameters.

Interlaboratory comparison studies represent another essential component of quality control frameworks. Collaborative testing programs involving academic institutions, industry partners, and regulatory bodies would help validate measurement protocols and identify sources of variability. Such collaborative efforts could establish precision and accuracy metrics for various testing methodologies, enhancing confidence in reported performance data.

Digital standardization tools, including shared databases of material properties and performance metrics, would facilitate information exchange within the research community. These repositories should include standardized data formats, metadata requirements, and version control systems to ensure data integrity and traceability. Machine learning algorithms could potentially analyze these datasets to identify correlations between material properties and performance characteristics.

Implementation of these standardization and quality control frameworks would benefit multiple stakeholders. For researchers, standardized testing protocols would enhance experimental reproducibility and facilitate meaningful comparisons with published literature. For manufacturers, clear quality metrics would streamline product development and certification processes. For end-users, standardized performance data would enable informed selection of materials appropriate for specific applications.

International organizations such as ISO and IEEE have begun developing preliminary standards for microfluidic systems, but specific guidelines for electro-microfluidic conductive materials remain underdeveloped. A robust framework should address multiple dimensions: electrical conductivity measurement protocols, chemical stability assessment methods, biocompatibility testing procedures, and durability evaluation under various operational conditions.

Quality control frameworks must incorporate multi-parameter testing regimes that reflect real-world application scenarios. This includes standardized procedures for measuring conductivity under various pH conditions, temperature ranges, and flow rates typical in microfluidic applications. Additionally, protocols should specify sample preparation methods, measurement equipment calibration requirements, and statistical analysis approaches to ensure reproducibility.

Reference materials play a crucial role in standardization efforts. The development of certified reference materials specifically designed for electro-microfluidic applications would provide benchmarks against which new conductive materials could be evaluated. These reference materials should exhibit well-characterized electrical properties, surface chemistry, and mechanical stability across relevant operational parameters.

Interlaboratory comparison studies represent another essential component of quality control frameworks. Collaborative testing programs involving academic institutions, industry partners, and regulatory bodies would help validate measurement protocols and identify sources of variability. Such collaborative efforts could establish precision and accuracy metrics for various testing methodologies, enhancing confidence in reported performance data.

Digital standardization tools, including shared databases of material properties and performance metrics, would facilitate information exchange within the research community. These repositories should include standardized data formats, metadata requirements, and version control systems to ensure data integrity and traceability. Machine learning algorithms could potentially analyze these datasets to identify correlations between material properties and performance characteristics.

Implementation of these standardization and quality control frameworks would benefit multiple stakeholders. For researchers, standardized testing protocols would enhance experimental reproducibility and facilitate meaningful comparisons with published literature. For manufacturers, clear quality metrics would streamline product development and certification processes. For end-users, standardized performance data would enable informed selection of materials appropriate for specific applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!