How to Detect Impurities in Microfluidics-Based Reactions

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Impurity Detection Background and Objectives

Microfluidics technology has evolved significantly over the past three decades, transforming from a theoretical concept to a practical tool with diverse applications across multiple industries. The detection of impurities in microfluidic-based reactions represents a critical challenge that has gained increasing attention since the early 2000s, particularly as microfluidic platforms have become more integrated into pharmaceutical development, chemical synthesis, and biological research workflows.

The evolution of impurity detection methods in microfluidics has followed a trajectory from basic optical techniques to sophisticated integrated sensing systems. Initially, researchers relied primarily on off-chip analysis, where samples were collected from microfluidic devices and analyzed using conventional analytical instruments. This approach, while functional, limited the real-time monitoring capabilities essential for process optimization and quality control.

Recent technological advancements have enabled the integration of detection mechanisms directly within microfluidic platforms, allowing for in-line and real-time monitoring of reaction processes. These developments have been driven by the increasing demand for higher throughput, greater sensitivity, and improved reproducibility in microfluidic applications, particularly in pharmaceutical manufacturing and point-of-care diagnostics.

The primary objective of impurity detection in microfluidics is to identify and quantify unwanted substances that may compromise reaction outcomes, product quality, or analytical results. These impurities can originate from various sources, including starting materials, reaction intermediates, degradation products, or contamination from the microfluidic environment itself. The ability to detect these impurities at low concentrations and in small volumes presents unique challenges that conventional analytical methods often cannot address effectively.

Current technological trends point toward miniaturized, integrated detection systems that combine multiple sensing modalities to provide comprehensive impurity profiles. These systems aim to achieve higher sensitivity, broader detection ranges, and greater specificity while maintaining the small footprint and low sample volume requirements inherent to microfluidic platforms.

The ultimate goal of advancing impurity detection in microfluidics is to develop robust, sensitive, and versatile detection methods that can be seamlessly integrated into microfluidic reaction systems. Such integration would enable real-time monitoring and feedback control, facilitating process optimization, quality assurance, and regulatory compliance across various applications from drug discovery to environmental monitoring.

The evolution of impurity detection methods in microfluidics has followed a trajectory from basic optical techniques to sophisticated integrated sensing systems. Initially, researchers relied primarily on off-chip analysis, where samples were collected from microfluidic devices and analyzed using conventional analytical instruments. This approach, while functional, limited the real-time monitoring capabilities essential for process optimization and quality control.

Recent technological advancements have enabled the integration of detection mechanisms directly within microfluidic platforms, allowing for in-line and real-time monitoring of reaction processes. These developments have been driven by the increasing demand for higher throughput, greater sensitivity, and improved reproducibility in microfluidic applications, particularly in pharmaceutical manufacturing and point-of-care diagnostics.

The primary objective of impurity detection in microfluidics is to identify and quantify unwanted substances that may compromise reaction outcomes, product quality, or analytical results. These impurities can originate from various sources, including starting materials, reaction intermediates, degradation products, or contamination from the microfluidic environment itself. The ability to detect these impurities at low concentrations and in small volumes presents unique challenges that conventional analytical methods often cannot address effectively.

Current technological trends point toward miniaturized, integrated detection systems that combine multiple sensing modalities to provide comprehensive impurity profiles. These systems aim to achieve higher sensitivity, broader detection ranges, and greater specificity while maintaining the small footprint and low sample volume requirements inherent to microfluidic platforms.

The ultimate goal of advancing impurity detection in microfluidics is to develop robust, sensitive, and versatile detection methods that can be seamlessly integrated into microfluidic reaction systems. Such integration would enable real-time monitoring and feedback control, facilitating process optimization, quality assurance, and regulatory compliance across various applications from drug discovery to environmental monitoring.

Market Analysis for Microfluidic Contamination Detection

The global market for microfluidic contamination detection is experiencing robust growth, driven by increasing applications in pharmaceutical research, clinical diagnostics, and environmental monitoring. Current market valuations place this segment at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 11.7% through 2030, potentially reaching 7.1 billion USD by the end of the forecast period.

Demand for impurity detection in microfluidic systems stems primarily from three key sectors. The pharmaceutical and biotechnology industry represents the largest market share at 42%, where precise contamination control directly impacts drug efficacy and safety. Healthcare diagnostics follows at 28%, with point-of-care testing applications requiring increasingly sensitive detection methods. The remaining market is distributed among academic research, environmental monitoring, and food safety applications.

Regional analysis reveals North America currently dominates the market with 38% share, benefiting from substantial R&D investments and presence of major industry players. Europe follows at 31%, with particular strength in pharmaceutical applications. The Asia-Pacific region, while currently holding 22% market share, demonstrates the fastest growth trajectory at 14.3% annually, driven by expanding healthcare infrastructure and increasing adoption of advanced diagnostic technologies.

Customer segmentation shows large pharmaceutical companies and research institutions as primary buyers, accounting for 65% of market revenue. These entities prioritize detection sensitivity and reliability over cost considerations. Mid-sized laboratories and clinical facilities represent 25% of the market, seeking balanced performance-to-cost solutions. The remaining 10% consists of emerging startups and academic institutions with more price-sensitive purchasing behaviors.

Key market drivers include increasingly stringent regulatory requirements for product purity in pharmaceuticals, growing demand for rapid and accurate diagnostic tools, and technological advancements enabling higher detection sensitivities. The COVID-19 pandemic has accelerated market growth by highlighting the importance of rapid, accurate testing methodologies and creating new opportunities for microfluidic applications.

Market challenges include high initial equipment costs, technical complexity requiring specialized expertise, and integration difficulties with existing laboratory workflows. Additionally, standardization issues across different microfluidic platforms create interoperability concerns that limit broader market adoption.

Future market trends point toward increased integration of artificial intelligence for automated contamination detection, development of portable and field-deployable systems, and growing demand for multiplexed detection capabilities that can identify multiple contaminants simultaneously.

Demand for impurity detection in microfluidic systems stems primarily from three key sectors. The pharmaceutical and biotechnology industry represents the largest market share at 42%, where precise contamination control directly impacts drug efficacy and safety. Healthcare diagnostics follows at 28%, with point-of-care testing applications requiring increasingly sensitive detection methods. The remaining market is distributed among academic research, environmental monitoring, and food safety applications.

Regional analysis reveals North America currently dominates the market with 38% share, benefiting from substantial R&D investments and presence of major industry players. Europe follows at 31%, with particular strength in pharmaceutical applications. The Asia-Pacific region, while currently holding 22% market share, demonstrates the fastest growth trajectory at 14.3% annually, driven by expanding healthcare infrastructure and increasing adoption of advanced diagnostic technologies.

Customer segmentation shows large pharmaceutical companies and research institutions as primary buyers, accounting for 65% of market revenue. These entities prioritize detection sensitivity and reliability over cost considerations. Mid-sized laboratories and clinical facilities represent 25% of the market, seeking balanced performance-to-cost solutions. The remaining 10% consists of emerging startups and academic institutions with more price-sensitive purchasing behaviors.

Key market drivers include increasingly stringent regulatory requirements for product purity in pharmaceuticals, growing demand for rapid and accurate diagnostic tools, and technological advancements enabling higher detection sensitivities. The COVID-19 pandemic has accelerated market growth by highlighting the importance of rapid, accurate testing methodologies and creating new opportunities for microfluidic applications.

Market challenges include high initial equipment costs, technical complexity requiring specialized expertise, and integration difficulties with existing laboratory workflows. Additionally, standardization issues across different microfluidic platforms create interoperability concerns that limit broader market adoption.

Future market trends point toward increased integration of artificial intelligence for automated contamination detection, development of portable and field-deployable systems, and growing demand for multiplexed detection capabilities that can identify multiple contaminants simultaneously.

Current Challenges in Microfluidic Impurity Detection

Despite significant advancements in microfluidic technology, detecting impurities in microfluidics-based reactions remains a formidable challenge. The miniaturized nature of microfluidic systems, while advantageous for many applications, creates substantial difficulties for conventional detection methods. The microscale dimensions of channels (typically 10-500 μm) severely limit the available sample volume for analysis, resulting in extremely low concentrations of impurities that fall below the detection limits of many analytical techniques.

Real-time monitoring presents another significant hurdle. Traditional analytical methods often require sample extraction and preparation steps that disrupt the continuous flow nature of microfluidic systems. This creates a fundamental disconnect between the dynamic processes occurring within the microchannels and the static analysis performed externally, potentially missing critical transient impurities or reaction intermediates that may significantly impact product quality.

The complex matrix effects inherent in microfluidic reactions further complicate impurity detection. Reaction mixtures often contain multiple components including catalysts, surfactants, and stabilizers that can interfere with detection methods. These matrix effects can mask impurity signals or generate false positives, reducing the reliability of analytical results and necessitating sophisticated signal processing algorithms to extract meaningful data.

Integration of detection systems with microfluidic platforms poses substantial engineering challenges. Conventional analytical instruments are typically bulky and not designed for seamless integration with microfluidic chips. This incompatibility often forces compromises in either the microfluidic design or the detection capability, limiting the overall system performance. Additionally, the need for specialized interfaces between microfluidic devices and detection systems introduces potential points of failure and contamination.

Sensitivity and selectivity requirements present perhaps the most demanding technical challenge. Impurities in microfluidic reactions may be present at parts-per-billion or even parts-per-trillion levels, requiring extraordinarily sensitive detection methods. Simultaneously, these methods must be highly selective to distinguish between structurally similar compounds and to identify unknown impurities without prior reference standards.

Cost and accessibility barriers further impede widespread adoption of advanced impurity detection in microfluidic systems. High-end analytical equipment such as mass spectrometers or specialized spectroscopic tools often come with prohibitive costs and require specialized expertise to operate and maintain. This economic reality restricts many research groups and smaller companies from implementing comprehensive impurity detection strategies in their microfluidic workflows.

Standardization remains elusive in this rapidly evolving field. The lack of universally accepted protocols for impurity detection in microfluidic systems makes cross-comparison between different research findings challenging and hinders the establishment of regulatory frameworks necessary for commercial applications, particularly in pharmaceutical and clinical diagnostics sectors.

Real-time monitoring presents another significant hurdle. Traditional analytical methods often require sample extraction and preparation steps that disrupt the continuous flow nature of microfluidic systems. This creates a fundamental disconnect between the dynamic processes occurring within the microchannels and the static analysis performed externally, potentially missing critical transient impurities or reaction intermediates that may significantly impact product quality.

The complex matrix effects inherent in microfluidic reactions further complicate impurity detection. Reaction mixtures often contain multiple components including catalysts, surfactants, and stabilizers that can interfere with detection methods. These matrix effects can mask impurity signals or generate false positives, reducing the reliability of analytical results and necessitating sophisticated signal processing algorithms to extract meaningful data.

Integration of detection systems with microfluidic platforms poses substantial engineering challenges. Conventional analytical instruments are typically bulky and not designed for seamless integration with microfluidic chips. This incompatibility often forces compromises in either the microfluidic design or the detection capability, limiting the overall system performance. Additionally, the need for specialized interfaces between microfluidic devices and detection systems introduces potential points of failure and contamination.

Sensitivity and selectivity requirements present perhaps the most demanding technical challenge. Impurities in microfluidic reactions may be present at parts-per-billion or even parts-per-trillion levels, requiring extraordinarily sensitive detection methods. Simultaneously, these methods must be highly selective to distinguish between structurally similar compounds and to identify unknown impurities without prior reference standards.

Cost and accessibility barriers further impede widespread adoption of advanced impurity detection in microfluidic systems. High-end analytical equipment such as mass spectrometers or specialized spectroscopic tools often come with prohibitive costs and require specialized expertise to operate and maintain. This economic reality restricts many research groups and smaller companies from implementing comprehensive impurity detection strategies in their microfluidic workflows.

Standardization remains elusive in this rapidly evolving field. The lack of universally accepted protocols for impurity detection in microfluidic systems makes cross-comparison between different research findings challenging and hinders the establishment of regulatory frameworks necessary for commercial applications, particularly in pharmaceutical and clinical diagnostics sectors.

Existing Impurity Detection Methods in Microfluidics

01 Microfluidic devices for impurity detection in chemical reactions

Microfluidic devices can be used to detect impurities in chemical reactions with high sensitivity and precision. These systems typically incorporate specialized sensors or detection mechanisms that can identify trace amounts of impurities in reaction mixtures. The miniaturized nature of microfluidic platforms allows for rapid analysis using minimal sample volumes, making them ideal for real-time monitoring of reaction processes and quality control in pharmaceutical and chemical manufacturing.- Microfluidic devices for impurity detection in chemical reactions: Microfluidic devices can be used to detect impurities in chemical reactions with high sensitivity and precision. These systems typically incorporate specialized sensors or detection mechanisms that can identify trace amounts of impurities in reaction mixtures. The miniaturized nature of microfluidic platforms allows for rapid analysis using minimal sample volumes, making them ideal for monitoring reaction purity in real-time or for quality control applications.

- Integration of spectroscopic techniques in microfluidic systems: Spectroscopic techniques such as Raman, infrared, and UV-visible spectroscopy can be integrated into microfluidic platforms to enable real-time detection of impurities during chemical reactions. These integrated systems allow for continuous monitoring of reaction progress and impurity formation without the need for sample extraction. The combination of microfluidics with spectroscopic analysis provides enhanced sensitivity and specificity for detecting various types of impurities in complex reaction mixtures.

- Lab-on-a-chip systems for automated impurity analysis: Lab-on-a-chip systems incorporate multiple analytical functions on a single microfluidic platform, enabling automated detection and characterization of impurities in reaction systems. These integrated devices can perform sample preparation, separation, and detection steps in sequence, minimizing human intervention and reducing contamination risks. The automation capabilities of these systems make them particularly valuable for high-throughput screening of reaction products and impurity profiling in pharmaceutical and chemical manufacturing processes.

- Nanoparticle-enhanced detection methods in microfluidic channels: Nanoparticles can be incorporated into microfluidic systems to enhance the detection sensitivity for various impurities. These nanoparticles can be functionalized with specific recognition elements that selectively bind to target impurities, enabling their detection at extremely low concentrations. The use of metallic nanoparticles, quantum dots, or magnetic nanoparticles in microfluidic channels provides enhanced optical, electrical, or magnetic signals that facilitate more accurate impurity detection in complex reaction mixtures.

- Droplet-based microfluidics for impurity isolation and characterization: Droplet-based microfluidic systems enable the encapsulation of reaction mixtures in discrete droplets, allowing for high-throughput screening and isolation of impurities. Each droplet can function as an individual reaction vessel, facilitating parallel analysis of multiple samples. This approach is particularly useful for identifying and characterizing low-abundance impurities that might be missed in conventional analysis methods. The ability to manipulate individual droplets also enables selective isolation of impurity-containing fractions for further detailed characterization.

02 Integration of spectroscopic techniques in microfluidic systems

Spectroscopic techniques such as Raman, infrared, and UV-visible spectroscopy can be integrated into microfluidic platforms to enable real-time detection of impurities in reaction systems. These integrated systems allow for continuous monitoring of reaction progress and impurity formation without the need for offline sampling. The combination of microfluidics with spectroscopic analysis provides enhanced sensitivity and specificity for detecting various types of impurities, including organic contaminants, byproducts, and degradation products.Expand Specific Solutions03 Lab-on-a-chip systems for automated impurity analysis

Lab-on-a-chip systems integrate multiple analytical functions into a single microfluidic device, enabling automated impurity detection in reaction mixtures. These systems can perform sample preparation, separation, and detection steps in a continuous flow process. The automation reduces human error and increases throughput, making these platforms suitable for high-volume screening applications. Advanced lab-on-a-chip devices may incorporate machine learning algorithms to improve detection accuracy and identify unknown impurities based on their chemical signatures.Expand Specific Solutions04 Droplet-based microfluidics for impurity isolation and characterization

Droplet-based microfluidic systems enable the compartmentalization of reactions into discrete droplets, facilitating the isolation and characterization of impurities. Each droplet can serve as an individual reaction vessel, allowing for high-throughput screening of reaction conditions and impurity profiles. This approach is particularly useful for detecting low-concentration impurities that might be missed in bulk analysis methods. The technology enables precise control over reaction parameters and can be coupled with various detection methods for comprehensive impurity characterization.Expand Specific Solutions05 Microfluidic systems with integrated sample preparation for impurity detection

Microfluidic platforms with integrated sample preparation capabilities enhance the efficiency and accuracy of impurity detection in complex reaction mixtures. These systems incorporate on-chip extraction, concentration, and purification steps to isolate impurities from the matrix before detection. The integration of sample preparation with analysis reduces sample handling, minimizes contamination risks, and improves detection limits. Such systems are particularly valuable for analyzing trace impurities in pharmaceutical products, where regulatory requirements demand high sensitivity and specificity in impurity profiling.Expand Specific Solutions

Leading Companies in Microfluidic Detection Industry

The microfluidics-based impurity detection market is currently in a growth phase, characterized by increasing adoption across pharmaceutical and biomedical industries. The global market size is expanding rapidly, projected to reach significant value as demand for precise analytical methods grows. Technologically, the field shows varying maturity levels, with established players like Koninklijke Philips, Samsung Electronics, and HP Development offering commercial solutions, while research institutions such as The University of California, National University of Singapore, and CNRS drive innovation through fundamental research. Pharmaceutical companies including Teva and OPKO Diagnostics are integrating these technologies into quality control processes. The competitive landscape features collaboration between academic institutions and industry leaders, with companies like Siemens and Life Technologies developing specialized detection systems that combine microfluidics with advanced analytical capabilities.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced optical detection systems for microfluidic impurity analysis. Their technology integrates high-resolution spectroscopic methods with microfluidic chips to enable real-time monitoring of reaction contaminants. The system employs multiple wavelength light sources and photodetector arrays to detect impurities based on their unique spectral signatures. Philips' approach incorporates machine learning algorithms that analyze spectral data patterns to identify and quantify impurities at concentrations as low as parts per billion. Their platform includes automated calibration procedures that compensate for environmental variations, ensuring consistent detection performance across different operating conditions. The technology is particularly effective for detecting organic and inorganic contaminants in pharmaceutical and diagnostic applications, where reaction purity is critical for product efficacy and safety.

Strengths: Superior optical detection sensitivity with multi-wavelength analysis capabilities; integrated machine learning for automated impurity identification; robust calibration system for consistent performance. Weaknesses: Higher implementation cost compared to simpler detection methods; requires specialized expertise for system optimization; limited effectiveness for certain non-optically active impurities.

OPKO Diagnostics LLC

Technical Solution: OPKO Diagnostics has developed a proprietary microfluidic impurity detection system based on their Lab-on-a-Chip technology. Their approach utilizes a combination of colorimetric and fluorescence detection methods integrated directly into disposable microfluidic cartridges. The system employs specialized reagents that selectively bind to common impurities, producing measurable optical signals proportional to contaminant concentration. OPKO's technology features multiplexed detection channels that can simultaneously monitor multiple impurity types within a single reaction. Their platform incorporates internal calibration standards and reference channels to ensure measurement accuracy and reliability. The system is designed for point-of-use applications, with simplified user interfaces that enable non-specialists to perform complex impurity analyses. OPKO's technology is particularly well-suited for clinical diagnostics and pharmaceutical quality control, where rapid impurity detection is critical for ensuring product safety and efficacy.

Strengths: Highly portable and user-friendly design; multiplexed detection capabilities; disposable cartridge format eliminates cross-contamination concerns; rapid analysis time (typically under 15 minutes). Weaknesses: Limited to detecting specific pre-targeted impurities; lower sensitivity compared to some laboratory-based methods; reagent shelf-life constraints may affect field deployment.

Key Technologies for Microfluidic Contaminant Analysis

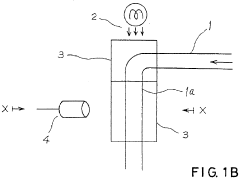

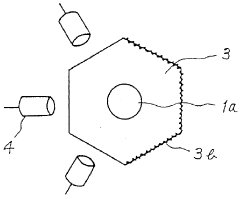

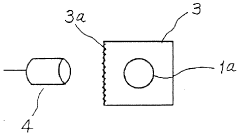

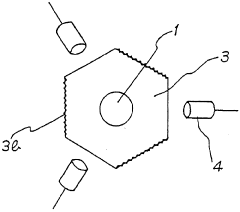

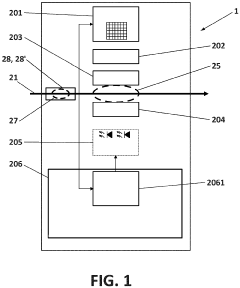

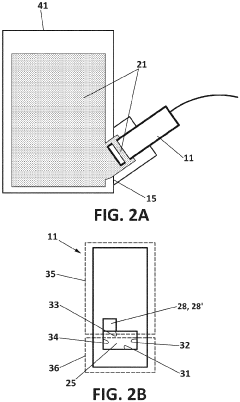

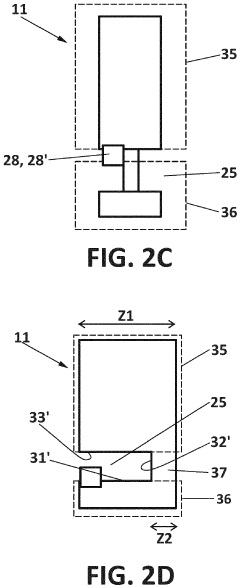

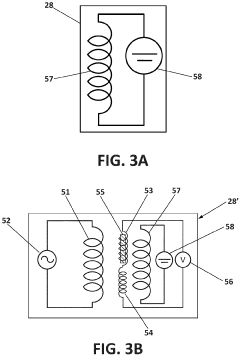

Method and apparatus of detecting impurities in fluid

PatentInactiveUS5495333A

Innovation

- A method and apparatus where a transparent fluid passage is illuminated along its longitudinal axis, and scattered light from impurities is observed perpendicularly, allowing for the detection of minute particles across the entire fluid flow using CCD cameras positioned to capture scattered light from multiple angles, ensuring comprehensive detection.

System and method for inspecting a fluid

PatentPendingEP4375639A1

Innovation

- A system that uses a magnetic field to remove ferromagnetic particles from the image detection area, allowing for precise counting and classification of both ferromagnetic and non-ferromagnetic particles, while also measuring fluid viscosity using a magnetoelastic sensor, enabling accurate assessment of the fluid's condition and machinery health.

Miniaturization Trends in Detection Instrumentation

The miniaturization of detection instrumentation represents a significant advancement in microfluidic technology, enabling more efficient and sensitive detection of impurities in chemical reactions. Over the past decade, detection systems have evolved from bulky laboratory equipment to compact, integrated components that can be incorporated directly into microfluidic chips.

The trend toward miniaturization has been driven by several factors, including the need for point-of-care diagnostics, on-site environmental monitoring, and real-time process control in industrial settings. Traditional detection methods often required samples to be removed from microfluidic channels for external analysis, introducing delays and potential contamination. Modern miniaturized detection systems eliminate these issues by integrating sensing capabilities directly into the microfluidic platform.

Recent developments have focused on reducing the size of optical detection systems, which traditionally required bulky light sources, filters, and detectors. Micro-LEDs, miniaturized photodiodes, and integrated waveguides now allow for on-chip optical detection with minimal footprint. These systems can detect impurities through absorbance, fluorescence, or Raman spectroscopy techniques at previously unattainable levels of integration.

Electrochemical detection methods have also undergone significant miniaturization, with microelectrodes being directly fabricated within microfluidic channels. These electrodes can detect impurities through techniques such as amperometry, voltammetry, and impedance spectroscopy, offering high sensitivity in a compact format. The integration of reference and counter electrodes alongside working electrodes has further enhanced the reliability of these miniaturized systems.

Mass spectrometry, traditionally one of the most space-demanding analytical techniques, has seen remarkable miniaturization efforts. Chip-based mass analyzers and ionization sources now enable on-chip mass spectrometric detection of impurities, though these systems still require external vacuum components. Research is actively pursuing fully integrated, miniaturized mass spectrometry systems for comprehensive impurity analysis.

Digital microfluidics has emerged as a platform that inherently supports miniaturized detection, as the manipulation of discrete droplets allows for integrated sensing at each droplet position. This approach enables multiplexed detection of multiple impurities simultaneously, with each droplet serving as an individual reaction vessel with its own detection capabilities.

The future of miniaturized detection instrumentation lies in multifunctional integrated systems that combine various detection modalities on a single chip. These systems will leverage advances in nanomaterials, MEMS technology, and integrated circuit design to achieve unprecedented levels of sensitivity and specificity while maintaining a minimal footprint suitable for portable and wearable applications.

The trend toward miniaturization has been driven by several factors, including the need for point-of-care diagnostics, on-site environmental monitoring, and real-time process control in industrial settings. Traditional detection methods often required samples to be removed from microfluidic channels for external analysis, introducing delays and potential contamination. Modern miniaturized detection systems eliminate these issues by integrating sensing capabilities directly into the microfluidic platform.

Recent developments have focused on reducing the size of optical detection systems, which traditionally required bulky light sources, filters, and detectors. Micro-LEDs, miniaturized photodiodes, and integrated waveguides now allow for on-chip optical detection with minimal footprint. These systems can detect impurities through absorbance, fluorescence, or Raman spectroscopy techniques at previously unattainable levels of integration.

Electrochemical detection methods have also undergone significant miniaturization, with microelectrodes being directly fabricated within microfluidic channels. These electrodes can detect impurities through techniques such as amperometry, voltammetry, and impedance spectroscopy, offering high sensitivity in a compact format. The integration of reference and counter electrodes alongside working electrodes has further enhanced the reliability of these miniaturized systems.

Mass spectrometry, traditionally one of the most space-demanding analytical techniques, has seen remarkable miniaturization efforts. Chip-based mass analyzers and ionization sources now enable on-chip mass spectrometric detection of impurities, though these systems still require external vacuum components. Research is actively pursuing fully integrated, miniaturized mass spectrometry systems for comprehensive impurity analysis.

Digital microfluidics has emerged as a platform that inherently supports miniaturized detection, as the manipulation of discrete droplets allows for integrated sensing at each droplet position. This approach enables multiplexed detection of multiple impurities simultaneously, with each droplet serving as an individual reaction vessel with its own detection capabilities.

The future of miniaturized detection instrumentation lies in multifunctional integrated systems that combine various detection modalities on a single chip. These systems will leverage advances in nanomaterials, MEMS technology, and integrated circuit design to achieve unprecedented levels of sensitivity and specificity while maintaining a minimal footprint suitable for portable and wearable applications.

Integration with Lab-on-a-Chip Systems

The integration of impurity detection systems with Lab-on-a-Chip (LOC) platforms represents a critical advancement in microfluidic technology. These integrated systems combine multiple laboratory functions on a single chip measuring millimeters to a few square centimeters, enabling comprehensive analysis of microfluidic-based reactions while simultaneously monitoring for contaminants. The miniaturization achieved through LOC integration offers significant advantages including reduced reagent consumption, faster analysis times, enhanced sensitivity, and improved reproducibility.

Current integration approaches focus on embedding detection mechanisms directly within the microfluidic channels. Optical detection methods, particularly spectroscopic techniques, have been successfully incorporated into LOC systems through the integration of miniaturized light sources, waveguides, and detectors. These components can be fabricated directly onto the chip substrate using photolithography and other microfabrication techniques, creating seamless detection zones within the microfluidic pathway.

Electrochemical sensors represent another promising integration strategy, where electrode arrays are embedded at strategic points throughout the microfluidic network. These electrodes can perform real-time monitoring of reaction progress while simultaneously detecting electroactive impurities. Recent advances in screen-printing and thin-film deposition technologies have facilitated the mass production of such integrated electrochemical detection systems with high reproducibility and sensitivity.

Data processing capabilities are increasingly being incorporated into LOC platforms through the integration of microcontrollers and wireless communication modules. These components enable automated analysis of detection signals, application of advanced algorithms for impurity identification, and real-time data transmission to external devices. Machine learning algorithms implemented on these integrated systems can continuously improve detection accuracy by learning from historical data patterns.

Multiplexed detection represents the frontier of LOC integration, where multiple detection modalities are combined on a single chip. For instance, systems incorporating both optical and electrochemical detection can provide complementary information about different types of impurities. This approach significantly enhances the versatility and reliability of impurity detection in complex reaction mixtures.

Challenges in LOC integration include ensuring compatibility between different fabrication processes, maintaining detection sensitivity despite miniaturization, and developing standardized interfaces for system components. Addressing these challenges requires interdisciplinary collaboration between microfluidics engineers, materials scientists, and analytical chemists to develop holistic integration strategies that maintain analytical performance while achieving the benefits of miniaturization.

Current integration approaches focus on embedding detection mechanisms directly within the microfluidic channels. Optical detection methods, particularly spectroscopic techniques, have been successfully incorporated into LOC systems through the integration of miniaturized light sources, waveguides, and detectors. These components can be fabricated directly onto the chip substrate using photolithography and other microfabrication techniques, creating seamless detection zones within the microfluidic pathway.

Electrochemical sensors represent another promising integration strategy, where electrode arrays are embedded at strategic points throughout the microfluidic network. These electrodes can perform real-time monitoring of reaction progress while simultaneously detecting electroactive impurities. Recent advances in screen-printing and thin-film deposition technologies have facilitated the mass production of such integrated electrochemical detection systems with high reproducibility and sensitivity.

Data processing capabilities are increasingly being incorporated into LOC platforms through the integration of microcontrollers and wireless communication modules. These components enable automated analysis of detection signals, application of advanced algorithms for impurity identification, and real-time data transmission to external devices. Machine learning algorithms implemented on these integrated systems can continuously improve detection accuracy by learning from historical data patterns.

Multiplexed detection represents the frontier of LOC integration, where multiple detection modalities are combined on a single chip. For instance, systems incorporating both optical and electrochemical detection can provide complementary information about different types of impurities. This approach significantly enhances the versatility and reliability of impurity detection in complex reaction mixtures.

Challenges in LOC integration include ensuring compatibility between different fabrication processes, maintaining detection sensitivity despite miniaturization, and developing standardized interfaces for system components. Addressing these challenges requires interdisciplinary collaboration between microfluidics engineers, materials scientists, and analytical chemists to develop holistic integration strategies that maintain analytical performance while achieving the benefits of miniaturization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!