Microfluidics vs HPLC: Analytical Efficiency for Small Volumes

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidics and HPLC Technology Evolution and Objectives

Microfluidics and High-Performance Liquid Chromatography (HPLC) represent two distinct yet complementary analytical technologies that have evolved significantly over the past decades. HPLC emerged in the 1960s as a refinement of traditional column chromatography, offering improved separation efficiency and quantitative analysis capabilities. The technology matured rapidly through the 1970s and 1980s with the development of more efficient stationary phases, pumping systems, and detection methods, establishing itself as the gold standard for analytical chemistry.

Microfluidics, by contrast, emerged in the 1990s as part of the broader miniaturization trend in analytical sciences. Drawing inspiration from semiconductor fabrication techniques, microfluidic systems manipulate fluids at the microscale, typically handling volumes in the nanoliter to picoliter range. This represents a reduction of several orders of magnitude compared to conventional HPLC systems that typically process microliter to milliliter volumes.

The evolution of both technologies has been driven by similar objectives: achieving higher sensitivity, better resolution, faster analysis times, and reduced sample and reagent consumption. However, their developmental trajectories reflect different approaches to these challenges. HPLC has evolved toward ultra-high-pressure systems (UHPLC) capable of operating at pressures exceeding 15,000 psi, enabling the use of smaller particles and faster flow rates for improved separation efficiency.

Microfluidics has pursued integration and parallelization, with the development of lab-on-a-chip devices that combine multiple analytical functions on a single platform. These systems leverage unique physical phenomena at the microscale, such as laminar flow and enhanced surface-to-volume ratios, to achieve novel functionalities not possible in macroscale systems.

The convergence of these technologies has become increasingly evident in recent years, with the emergence of microchip-based HPLC systems that combine the separation efficiency of HPLC with the small-volume handling capabilities of microfluidics. This hybrid approach aims to address the growing demand for analytical methods capable of processing extremely limited samples, such as single-cell analysis, rare biomarkers in clinical diagnostics, and high-throughput screening in drug discovery.

The ultimate technical objective in comparing microfluidics and HPLC for small-volume analysis is to determine the optimal approach for specific analytical challenges. This involves evaluating trade-offs between separation efficiency, detection sensitivity, sample throughput, system complexity, and cost-effectiveness. As both technologies continue to evolve, their complementary strengths suggest that integrated approaches may offer the most promising path forward for next-generation analytical systems designed for small-volume applications.

Microfluidics, by contrast, emerged in the 1990s as part of the broader miniaturization trend in analytical sciences. Drawing inspiration from semiconductor fabrication techniques, microfluidic systems manipulate fluids at the microscale, typically handling volumes in the nanoliter to picoliter range. This represents a reduction of several orders of magnitude compared to conventional HPLC systems that typically process microliter to milliliter volumes.

The evolution of both technologies has been driven by similar objectives: achieving higher sensitivity, better resolution, faster analysis times, and reduced sample and reagent consumption. However, their developmental trajectories reflect different approaches to these challenges. HPLC has evolved toward ultra-high-pressure systems (UHPLC) capable of operating at pressures exceeding 15,000 psi, enabling the use of smaller particles and faster flow rates for improved separation efficiency.

Microfluidics has pursued integration and parallelization, with the development of lab-on-a-chip devices that combine multiple analytical functions on a single platform. These systems leverage unique physical phenomena at the microscale, such as laminar flow and enhanced surface-to-volume ratios, to achieve novel functionalities not possible in macroscale systems.

The convergence of these technologies has become increasingly evident in recent years, with the emergence of microchip-based HPLC systems that combine the separation efficiency of HPLC with the small-volume handling capabilities of microfluidics. This hybrid approach aims to address the growing demand for analytical methods capable of processing extremely limited samples, such as single-cell analysis, rare biomarkers in clinical diagnostics, and high-throughput screening in drug discovery.

The ultimate technical objective in comparing microfluidics and HPLC for small-volume analysis is to determine the optimal approach for specific analytical challenges. This involves evaluating trade-offs between separation efficiency, detection sensitivity, sample throughput, system complexity, and cost-effectiveness. As both technologies continue to evolve, their complementary strengths suggest that integrated approaches may offer the most promising path forward for next-generation analytical systems designed for small-volume applications.

Market Demand for Small Volume Analytical Solutions

The analytical chemistry market has witnessed a significant shift towards small volume analysis solutions in recent years, driven primarily by the increasing scarcity and cost of samples, especially in pharmaceutical research and development. The global market for small volume analytical technologies was valued at approximately $4.8 billion in 2022 and is projected to grow at a CAGR of 8.2% through 2028, reflecting the strong demand for these specialized solutions.

Pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 45% of the total demand. This is largely attributed to the high cost of drug development, where candidate compounds are often available only in minute quantities during early-stage research. The ability to perform comprehensive analytical characterization with minimal sample consumption directly translates to cost savings and accelerated development timelines.

Academic research institutions constitute another significant market segment, representing approximately 25% of the demand. The push for more efficient resource utilization in grant-funded research has intensified the need for analytical techniques that maximize data output from limited sample volumes.

Clinical diagnostics represents a rapidly growing application area, with a projected growth rate of 12.3% annually. The movement towards minimally invasive diagnostic procedures has created substantial demand for technologies capable of delivering accurate results from micro-samples, particularly in pediatric medicine and critical care settings where sample collection volumes are necessarily restricted.

Environmental monitoring and food safety testing sectors are emerging markets for small volume analytical solutions, collectively accounting for about 15% of current demand. These sectors are increasingly adopting microanalytical techniques to enable more frequent and distributed testing protocols without increasing sample collection burdens.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by expanding pharmaceutical manufacturing and research activities in China, India, and Singapore.

Key market drivers include the continuous miniaturization of analytical instruments, integration of automation technologies, and the development of more sensitive detection methods. End-users consistently prioritize three critical performance metrics: sensitivity at low volumes, reproducibility across small-scale analyses, and system flexibility to accommodate varying sample types and volumes.

The market shows a clear preference for integrated analytical platforms that can perform multiple analytical functions while maintaining minimal sample requirements, indicating a strategic opportunity for technologies that can bridge the capabilities gap between traditional HPLC and emerging microfluidic approaches.

Pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 45% of the total demand. This is largely attributed to the high cost of drug development, where candidate compounds are often available only in minute quantities during early-stage research. The ability to perform comprehensive analytical characterization with minimal sample consumption directly translates to cost savings and accelerated development timelines.

Academic research institutions constitute another significant market segment, representing approximately 25% of the demand. The push for more efficient resource utilization in grant-funded research has intensified the need for analytical techniques that maximize data output from limited sample volumes.

Clinical diagnostics represents a rapidly growing application area, with a projected growth rate of 12.3% annually. The movement towards minimally invasive diagnostic procedures has created substantial demand for technologies capable of delivering accurate results from micro-samples, particularly in pediatric medicine and critical care settings where sample collection volumes are necessarily restricted.

Environmental monitoring and food safety testing sectors are emerging markets for small volume analytical solutions, collectively accounting for about 15% of current demand. These sectors are increasingly adopting microanalytical techniques to enable more frequent and distributed testing protocols without increasing sample collection burdens.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by expanding pharmaceutical manufacturing and research activities in China, India, and Singapore.

Key market drivers include the continuous miniaturization of analytical instruments, integration of automation technologies, and the development of more sensitive detection methods. End-users consistently prioritize three critical performance metrics: sensitivity at low volumes, reproducibility across small-scale analyses, and system flexibility to accommodate varying sample types and volumes.

The market shows a clear preference for integrated analytical platforms that can perform multiple analytical functions while maintaining minimal sample requirements, indicating a strategic opportunity for technologies that can bridge the capabilities gap between traditional HPLC and emerging microfluidic approaches.

Technical Challenges in Small Volume Analysis

The analysis of small volume samples presents significant technical challenges that both microfluidics and High-Performance Liquid Chromatography (HPLC) systems must address. Traditional HPLC systems typically require sample volumes in the microliter to milliliter range, which becomes problematic when working with precious or limited samples such as rare biological specimens, forensic evidence, or pharmaceutical development compounds.

Sample loss during handling represents one of the most critical challenges in small volume analysis. In conventional HPLC systems, dead volumes in connection tubing, injection ports, and detection cells can absorb or dilute significant portions of small samples, compromising analytical integrity. This issue is particularly pronounced when sample volumes fall below 10 microliters, where even minor system inefficiencies can lead to substantial relative losses.

Detection sensitivity constitutes another major hurdle. As sample volumes decrease, the absolute quantity of analytes available for detection diminishes proportionally. HPLC systems traditionally rely on optical detection methods that have inherent sensitivity limitations, requiring minimum analyte concentrations to generate reliable signals above background noise. This challenge necessitates either higher sample concentrations or more sensitive detection technologies.

Microfluidic platforms offer potential solutions through dramatically reduced internal volumes, but introduce their own set of technical complications. Channel fabrication precision becomes crucial at the microscale, where even nanometer-scale variations can significantly impact flow characteristics and separation efficiency. Surface interactions between analytes and channel walls become disproportionately influential as the surface-to-volume ratio increases dramatically in microchannels.

Integration of detection systems with microfluidic platforms presents additional challenges. While microfluidic channels can efficiently handle small volumes, coupling these systems with detection technologies that maintain sensitivity while accommodating reduced dimensions requires sophisticated engineering solutions. Optical path lengths are inherently shortened in microfluidic devices, potentially limiting detection capabilities for certain spectroscopic methods.

Sample introduction mechanisms for small volumes demand precise control systems. Traditional autosampler technologies often struggle with reliable delivery of sub-microliter volumes, leading to poor reproducibility. The physics of fluid handling changes significantly at the microscale, where surface tension and capillary forces dominate over gravitational effects, requiring fundamentally different approaches to sample manipulation.

Cross-contamination risks increase substantially when working with minute sample quantities. Even trace carryover between analyses can significantly impact results when target analyte quantities are extremely small. This necessitates development of specialized cleaning protocols or disposable components that add complexity to system design and operation.

Sample loss during handling represents one of the most critical challenges in small volume analysis. In conventional HPLC systems, dead volumes in connection tubing, injection ports, and detection cells can absorb or dilute significant portions of small samples, compromising analytical integrity. This issue is particularly pronounced when sample volumes fall below 10 microliters, where even minor system inefficiencies can lead to substantial relative losses.

Detection sensitivity constitutes another major hurdle. As sample volumes decrease, the absolute quantity of analytes available for detection diminishes proportionally. HPLC systems traditionally rely on optical detection methods that have inherent sensitivity limitations, requiring minimum analyte concentrations to generate reliable signals above background noise. This challenge necessitates either higher sample concentrations or more sensitive detection technologies.

Microfluidic platforms offer potential solutions through dramatically reduced internal volumes, but introduce their own set of technical complications. Channel fabrication precision becomes crucial at the microscale, where even nanometer-scale variations can significantly impact flow characteristics and separation efficiency. Surface interactions between analytes and channel walls become disproportionately influential as the surface-to-volume ratio increases dramatically in microchannels.

Integration of detection systems with microfluidic platforms presents additional challenges. While microfluidic channels can efficiently handle small volumes, coupling these systems with detection technologies that maintain sensitivity while accommodating reduced dimensions requires sophisticated engineering solutions. Optical path lengths are inherently shortened in microfluidic devices, potentially limiting detection capabilities for certain spectroscopic methods.

Sample introduction mechanisms for small volumes demand precise control systems. Traditional autosampler technologies often struggle with reliable delivery of sub-microliter volumes, leading to poor reproducibility. The physics of fluid handling changes significantly at the microscale, where surface tension and capillary forces dominate over gravitational effects, requiring fundamentally different approaches to sample manipulation.

Cross-contamination risks increase substantially when working with minute sample quantities. Even trace carryover between analyses can significantly impact results when target analyte quantities are extremely small. This necessitates development of specialized cleaning protocols or disposable components that add complexity to system design and operation.

Current Analytical Methods for Small Volume Samples

01 Miniaturized HPLC systems with microfluidic integration

Integration of microfluidic technology with HPLC systems enables miniaturization of analytical instruments, resulting in reduced sample and solvent consumption while maintaining high separation efficiency. These systems incorporate microchannels, micropumps, and microvalves to precisely control fluid flow at the microscale level, allowing for faster analysis times and improved sensitivity compared to conventional HPLC systems.- Miniaturized HPLC systems with microfluidic integration: Integration of microfluidic technology with HPLC systems enables miniaturization of analytical platforms, resulting in reduced sample and solvent consumption while maintaining high separation efficiency. These systems incorporate microscale channels, pumps, and detectors to create compact, portable analytical devices that can perform rapid separations with high resolution. The miniaturization also allows for parallel processing and automation of multiple samples, enhancing throughput and analytical efficiency.

- Novel microfluidic chip designs for chromatographic separation: Advanced microfluidic chip designs specifically engineered for chromatographic applications feature optimized channel geometries, integrated stationary phases, and novel substrate materials. These chips incorporate multiple separation channels, sample preparation zones, and detection areas on a single platform. The innovative designs enable improved flow distribution, reduced band broadening, and enhanced separation efficiency compared to conventional HPLC columns, while requiring significantly smaller sample volumes and generating less waste.

- Enhanced detection methods for microfluidic HPLC: Integration of sensitive detection technologies with microfluidic HPLC systems enables improved analytical performance. These include miniaturized optical detection systems, electrochemical sensors, and mass spectrometry interfaces specifically designed for microfluidic platforms. The detection methods are optimized for small sample volumes and flow rates characteristic of microfluidic systems, providing enhanced sensitivity, selectivity, and real-time monitoring capabilities for complex sample analysis.

- Sample preparation and injection techniques for microfluidic HPLC: Specialized sample preparation and injection techniques have been developed to address the unique requirements of microfluidic HPLC systems. These include on-chip sample concentration, filtration, and derivatization methods that integrate seamlessly with separation channels. Advanced injection mechanisms ensure precise sample introduction with minimal band broadening, while automated sample handling systems enable high-throughput analysis with reduced operator intervention, significantly improving analytical efficiency and reproducibility.

- Multi-dimensional separation using microfluidic HPLC platforms: Microfluidic platforms enable efficient implementation of multi-dimensional separation techniques by integrating multiple separation modes on a single chip. These systems combine different chromatographic mechanisms such as reversed-phase, ion-exchange, and size exclusion to achieve enhanced resolution of complex samples. The seamless connection between separation dimensions eliminates sample loss and reduces analysis time compared to conventional multi-dimensional HPLC approaches, resulting in significantly improved peak capacity and analytical efficiency for complex biological and environmental samples.

02 Novel microfluidic chip designs for chromatographic separation

Advanced microfluidic chip designs specifically engineered for chromatographic applications feature optimized channel geometries, integrated stationary phases, and innovative detection zones. These chips incorporate multiple separation channels, gradient generators, and sample preparation modules on a single platform, enhancing separation efficiency and resolution while reducing analysis time and improving reproducibility.Expand Specific Solutions03 On-chip sample preparation and pretreatment techniques

Microfluidic platforms that integrate sample preparation steps such as filtration, extraction, concentration, and derivatization directly on-chip before HPLC analysis. These systems eliminate manual handling steps, reduce contamination risks, and improve analytical precision by automating the entire workflow from sample introduction to detection, particularly beneficial for complex biological samples requiring multiple pretreatment steps.Expand Specific Solutions04 Enhanced detection methods for microfluidic HPLC

Integration of advanced detection technologies with microfluidic HPLC systems, including miniaturized optical, electrochemical, and mass spectrometry detectors. These detection methods are specifically adapted for the small volumes and high speeds of microfluidic separations, providing improved sensitivity, selectivity, and the ability to perform real-time monitoring of separation processes with minimal band broadening.Expand Specific Solutions05 Automated microfluidic HPLC systems for high-throughput analysis

Fully automated microfluidic HPLC platforms designed for high-throughput screening and analysis, featuring parallel processing capabilities, integrated sample handling, and multiplexed detection systems. These systems incorporate advanced flow control mechanisms, programmable interfaces, and machine learning algorithms to optimize separation parameters in real-time, significantly increasing analytical throughput while maintaining high separation efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Analytical Chemistry

The microfluidics versus HPLC analytical efficiency landscape is evolving rapidly, with the market currently in a growth phase as demand for small-volume analysis increases. The global market is projected to expand significantly, driven by pharmaceutical and clinical applications. Technologically, established players like Agilent Technologies, Waters Technology, and Thermo Fisher Scientific (through Dionex Softron) dominate the HPLC segment with mature solutions, while microfluidics is gaining momentum through innovations from companies like IDEX Health & Science, Boehringer Ingelheim microParts, and academic institutions including MIT and EPFL. Research collaborations between industry leaders and universities are accelerating development of hybrid systems that combine the precision of HPLC with the small-volume advantages of microfluidics, creating new competitive opportunities.

IDEX Health & Science LLC

Technical Solution: IDEX Health & Science has developed a comprehensive microfluidic solution that bridges the gap between traditional HPLC and microfluidic analysis. Their platform features proprietary NanoViper connections and fittings that enable zero-dead-volume fluid paths critical for maintaining separation efficiency with small volumes. IDEX's approach incorporates specialized microfluidic manifolds with internal volumes below 100 nL and precision-engineered flow splitters that can accurately deliver flow rates down to 10 nL/min. Their technology includes specialized surface treatments that minimize sample adsorption and carryover, achieving recovery rates exceeding 95% even with sub-microliter sample volumes. IDEX has pioneered integrated microfluidic chips with multiple functionalities including sample preparation, separation, and detection capabilities on a single platform. Their microfluidic components achieve pressure ratings up to 20,000 psi while maintaining dimensional tolerances within ±1 μm, enabling highly reproducible separations. The company's microfluidic solutions demonstrate particular advantages in biomarker detection, achieving limits of detection 10-100 times lower than conventional HPLC for equivalent sample volumes.

Strengths: Exceptional fluid path precision with near-zero dead volumes; modular design allowing customization for specific applications; superior sample recovery rates; compatibility with existing HPLC infrastructure for easier adoption. Weaknesses: Higher component costs compared to standard HPLC fittings; more complex system optimization requirements; potential for increased backpressure issues; limited compatibility with certain aggressive mobile phases.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed the Infinity Lab Microfluidic LC system that integrates microfluidic chip technology with HPLC capabilities. Their approach uses nano-flow LC chips with integrated columns and spray tips that handle sample volumes as low as 40 nL. The system incorporates microfluidic flow paths etched into a polymer or glass substrate, with specialized surface treatments to prevent sample adsorption. Agilent's HPLC-Chip/MS technology combines enrichment columns, analytical columns, and nanospray tips into a single integrated microfluidic device, eliminating the need for traditional fittings and connections that contribute to band broadening and dead volumes. This results in improved chromatographic resolution and sensitivity for small volume analysis compared to conventional HPLC systems. Their microfluidic approach achieves separation efficiencies of >100,000 plates/meter while consuming 1000x less solvent than traditional HPLC.

Strengths: Superior sensitivity for limited samples (picogram detection limits); reduced solvent consumption (>95% reduction); minimized dead volumes leading to sharper peaks and better resolution; integrated design eliminates connection-related band broadening. Weaknesses: Higher initial investment costs; more specialized training required for operation; limited flow rate ranges compared to conventional HPLC; potential for clogging with complex biological samples.

Key Innovations in Microfluidics and HPLC Integration

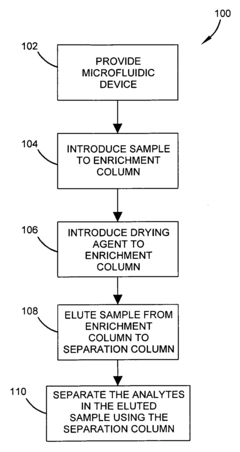

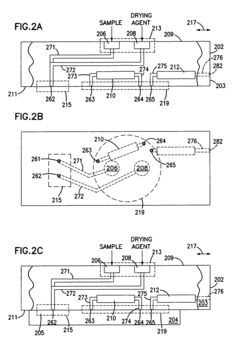

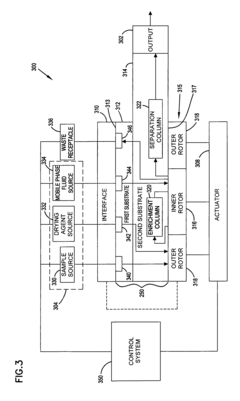

Microfluidic Device for Sample Analysis

PatentActiveUS20090188868A1

Innovation

- A microfluidic device with a substrate featuring a sample input port, drying agent input port, enrichment column, separation column, and switching ports, where a drying agent is used to remove liquid from the sample before separation, allowing for effective separation of analytes using a mobile phase fluid that differs from the original solvent, thereby preventing interference.

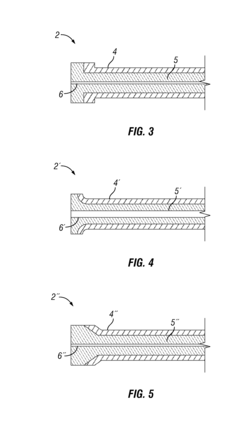

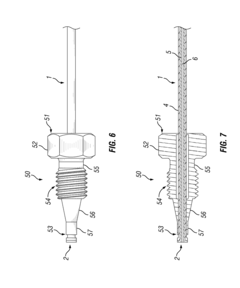

Biocompatible Tubing for Liquid Chromatography Systems

PatentActiveUS20120024411A1

Innovation

- Biocompatible tubing with a fluoropolymer or polyetheretherketone (PEEK) inner layer, isolated from the outer metal layer, is designed for use in high-pressure liquid chromatography systems, featuring flanged, flared, or angled ends and a fitting assembly that provides a secure, leak-proof connection without direct contact between the outer layer and the fluid, ensuring chemical inertness and minimizing contamination.

Cost-Benefit Analysis of Microfluidics vs HPLC

When comparing microfluidics and High-Performance Liquid Chromatography (HPLC) technologies for small volume analysis, cost-benefit considerations become crucial for research institutions and commercial laboratories. The initial investment for traditional HPLC systems typically ranges from $30,000 to $150,000, depending on detection capabilities and automation features. In contrast, microfluidic platforms generally require lower initial capital expenditure, with many systems available between $10,000 and $50,000.

Operational costs present significant differences between these technologies. HPLC systems consume substantial volumes of expensive solvents and mobile phases, with annual costs often exceeding $5,000 for moderate usage laboratories. Microfluidic systems dramatically reduce solvent consumption by up to 95%, with typical annual solvent costs under $1,000, representing significant long-term savings and environmental benefits.

Maintenance requirements further differentiate these technologies. HPLC systems demand regular pump maintenance, column replacements, and professional servicing, typically costing $3,000-$7,000 annually. Microfluidic devices often utilize disposable chips ($20-100 per chip) but require less frequent maintenance of the base instrument, resulting in lower overall maintenance expenses despite the recurring chip costs.

Sample preparation efficiency offers compelling advantages for microfluidics when handling small volumes. While HPLC typically requires 10-100 μL minimum sample volumes, microfluidic platforms can effectively analyze volumes as small as 1-10 μL. This capability translates to reduced sample consumption costs, particularly valuable when working with expensive reagents, rare biological samples, or limited clinical specimens.

Time-to-result metrics favor microfluidic approaches, with analysis times often reduced by 50-80% compared to conventional HPLC methods. This efficiency translates to higher throughput capabilities and improved laboratory productivity, allowing more analyses per working day and better utilization of skilled personnel.

Energy consumption presents another cost differential, with HPLC systems typically consuming 1000-1500 watts during operation, while comparable microfluidic systems operate at 100-300 watts. Over annual operation cycles, this represents both direct cost savings and alignment with sustainability initiatives increasingly important to research funding and corporate governance.

Return on investment calculations indicate that while HPLC remains cost-effective for high-volume, routine analyses, microfluidic platforms demonstrate superior economics for applications involving precious samples, rapid analysis requirements, or decentralized testing scenarios. The break-even point typically occurs within 2-3 years for laboratories processing fewer than 50 samples daily with average sample volumes below 20 μL.

Operational costs present significant differences between these technologies. HPLC systems consume substantial volumes of expensive solvents and mobile phases, with annual costs often exceeding $5,000 for moderate usage laboratories. Microfluidic systems dramatically reduce solvent consumption by up to 95%, with typical annual solvent costs under $1,000, representing significant long-term savings and environmental benefits.

Maintenance requirements further differentiate these technologies. HPLC systems demand regular pump maintenance, column replacements, and professional servicing, typically costing $3,000-$7,000 annually. Microfluidic devices often utilize disposable chips ($20-100 per chip) but require less frequent maintenance of the base instrument, resulting in lower overall maintenance expenses despite the recurring chip costs.

Sample preparation efficiency offers compelling advantages for microfluidics when handling small volumes. While HPLC typically requires 10-100 μL minimum sample volumes, microfluidic platforms can effectively analyze volumes as small as 1-10 μL. This capability translates to reduced sample consumption costs, particularly valuable when working with expensive reagents, rare biological samples, or limited clinical specimens.

Time-to-result metrics favor microfluidic approaches, with analysis times often reduced by 50-80% compared to conventional HPLC methods. This efficiency translates to higher throughput capabilities and improved laboratory productivity, allowing more analyses per working day and better utilization of skilled personnel.

Energy consumption presents another cost differential, with HPLC systems typically consuming 1000-1500 watts during operation, while comparable microfluidic systems operate at 100-300 watts. Over annual operation cycles, this represents both direct cost savings and alignment with sustainability initiatives increasingly important to research funding and corporate governance.

Return on investment calculations indicate that while HPLC remains cost-effective for high-volume, routine analyses, microfluidic platforms demonstrate superior economics for applications involving precious samples, rapid analysis requirements, or decentralized testing scenarios. The break-even point typically occurs within 2-3 years for laboratories processing fewer than 50 samples daily with average sample volumes below 20 μL.

Environmental Impact and Sustainability Considerations

The environmental footprint of analytical technologies has become increasingly important as laboratories worldwide strive for more sustainable practices. When comparing microfluidics and High-Performance Liquid Chromatography (HPLC) for small volume analysis, several sustainability factors emerge as significant differentiators.

Microfluidic systems demonstrate remarkable advantages in terms of resource consumption. These platforms typically require only nanoliters to microliters of sample and reagents, representing a 100-1000 fold reduction compared to conventional HPLC methods. This dramatic decrease in solvent usage directly translates to reduced chemical waste generation and lower disposal costs, addressing a major environmental concern in analytical laboratories.

Energy efficiency represents another critical sustainability metric. HPLC systems generally consume substantial electrical power due to their high-pressure pumps, temperature control systems, and detection modules. In contrast, many microfluidic platforms operate at lower pressures and can be designed with simplified detection systems, resulting in significantly reduced energy requirements. Some portable microfluidic devices can even operate on battery power, further decreasing their carbon footprint.

The manufacturing processes and materials used in both technologies also warrant consideration. Traditional HPLC systems rely heavily on stainless steel, specialized polymers, and electronic components with complex supply chains. Microfluidic chips, while requiring precision manufacturing, can be produced from more environmentally friendly materials such as biodegradable polymers, paper, or renewable resources. Additionally, the miniaturized nature of microfluidic devices means less raw material is required per unit.

Lifecycle assessment studies have indicated that the environmental impact of analytical equipment extends beyond operational considerations. HPLC systems typically have longer service lives but require regular maintenance involving component replacement and system cleaning with additional solvents. Microfluidic devices, particularly disposable chips, raise concerns about single-use plastic waste, though advances in recyclable and biodegradable chip materials are addressing this issue.

Water consumption presents another important sustainability consideration. HPLC methods often require significant volumes of ultrapure water for mobile phase preparation and system cleaning. Microfluidic approaches drastically reduce this water footprint, which is particularly valuable in regions facing water scarcity challenges.

As regulatory frameworks increasingly emphasize environmental responsibility, the adoption of greener analytical technologies becomes not just an ethical choice but potentially a compliance requirement. Organizations implementing microfluidic approaches in place of traditional HPLC for small volume analysis can demonstrate tangible progress toward sustainability goals while simultaneously benefiting from reduced operational costs associated with lower resource consumption.

Microfluidic systems demonstrate remarkable advantages in terms of resource consumption. These platforms typically require only nanoliters to microliters of sample and reagents, representing a 100-1000 fold reduction compared to conventional HPLC methods. This dramatic decrease in solvent usage directly translates to reduced chemical waste generation and lower disposal costs, addressing a major environmental concern in analytical laboratories.

Energy efficiency represents another critical sustainability metric. HPLC systems generally consume substantial electrical power due to their high-pressure pumps, temperature control systems, and detection modules. In contrast, many microfluidic platforms operate at lower pressures and can be designed with simplified detection systems, resulting in significantly reduced energy requirements. Some portable microfluidic devices can even operate on battery power, further decreasing their carbon footprint.

The manufacturing processes and materials used in both technologies also warrant consideration. Traditional HPLC systems rely heavily on stainless steel, specialized polymers, and electronic components with complex supply chains. Microfluidic chips, while requiring precision manufacturing, can be produced from more environmentally friendly materials such as biodegradable polymers, paper, or renewable resources. Additionally, the miniaturized nature of microfluidic devices means less raw material is required per unit.

Lifecycle assessment studies have indicated that the environmental impact of analytical equipment extends beyond operational considerations. HPLC systems typically have longer service lives but require regular maintenance involving component replacement and system cleaning with additional solvents. Microfluidic devices, particularly disposable chips, raise concerns about single-use plastic waste, though advances in recyclable and biodegradable chip materials are addressing this issue.

Water consumption presents another important sustainability consideration. HPLC methods often require significant volumes of ultrapure water for mobile phase preparation and system cleaning. Microfluidic approaches drastically reduce this water footprint, which is particularly valuable in regions facing water scarcity challenges.

As regulatory frameworks increasingly emphasize environmental responsibility, the adoption of greener analytical technologies becomes not just an ethical choice but potentially a compliance requirement. Organizations implementing microfluidic approaches in place of traditional HPLC for small volume analysis can demonstrate tangible progress toward sustainability goals while simultaneously benefiting from reduced operational costs associated with lower resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!