Maximizing Throughput in Microfluidic Array Systems Effectively

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Array Throughput Evolution and Objectives

Microfluidic array systems have evolved significantly over the past two decades, transforming from simple single-channel devices to sophisticated integrated platforms capable of handling thousands of parallel reactions. The initial development phase (2000-2005) focused primarily on proof-of-concept demonstrations with limited throughput capabilities, typically processing fewer than 10 samples simultaneously. During this period, the fundamental physics of fluid behavior at the microscale was being established, laying the groundwork for future advancements.

The second evolutionary phase (2006-2012) witnessed the emergence of multiplexed systems, where researchers successfully integrated multiple channels and reaction chambers within a single device. This period marked a significant leap in throughput capabilities, with systems capable of handling hundreds of simultaneous reactions. Key innovations during this phase included improved fabrication techniques, particularly in soft lithography and micromolding, which enabled more complex channel architectures.

From 2013 to 2018, the field experienced rapid advancement in integration technologies, with microfluidic arrays becoming increasingly automated and standardized. Throughput capabilities expanded exponentially, with some platforms achieving thousands of parallel operations. This period also saw the convergence of microfluidics with other technologies such as advanced imaging systems, machine learning algorithms for data analysis, and improved detection methodologies.

The current generation of microfluidic array systems (2019-present) focuses on maximizing throughput while maintaining precision and reliability. Key objectives include achieving ultra-high parallelization (>10,000 simultaneous reactions), reducing sample volumes to nanoliter or picoliter scales, and decreasing processing times from hours to minutes. These advancements aim to address the growing demand for high-throughput screening in drug discovery, genomics, and diagnostics.

Looking forward, the field is trending toward fully integrated "lab-on-a-chip" solutions that combine sample preparation, processing, and analysis within a single platform. The ultimate goal is to develop systems capable of millions of parallel operations with minimal human intervention, effectively bridging the gap between traditional laboratory techniques and industrial-scale processing capabilities.

Technical objectives for maximizing throughput include optimizing flow dynamics to prevent cross-contamination between array elements, developing novel valve and pump technologies for precise fluid control, and creating adaptive systems that can self-regulate based on real-time feedback. Additionally, there is significant focus on reducing manufacturing costs and increasing accessibility, particularly for point-of-care applications in resource-limited settings.

The second evolutionary phase (2006-2012) witnessed the emergence of multiplexed systems, where researchers successfully integrated multiple channels and reaction chambers within a single device. This period marked a significant leap in throughput capabilities, with systems capable of handling hundreds of simultaneous reactions. Key innovations during this phase included improved fabrication techniques, particularly in soft lithography and micromolding, which enabled more complex channel architectures.

From 2013 to 2018, the field experienced rapid advancement in integration technologies, with microfluidic arrays becoming increasingly automated and standardized. Throughput capabilities expanded exponentially, with some platforms achieving thousands of parallel operations. This period also saw the convergence of microfluidics with other technologies such as advanced imaging systems, machine learning algorithms for data analysis, and improved detection methodologies.

The current generation of microfluidic array systems (2019-present) focuses on maximizing throughput while maintaining precision and reliability. Key objectives include achieving ultra-high parallelization (>10,000 simultaneous reactions), reducing sample volumes to nanoliter or picoliter scales, and decreasing processing times from hours to minutes. These advancements aim to address the growing demand for high-throughput screening in drug discovery, genomics, and diagnostics.

Looking forward, the field is trending toward fully integrated "lab-on-a-chip" solutions that combine sample preparation, processing, and analysis within a single platform. The ultimate goal is to develop systems capable of millions of parallel operations with minimal human intervention, effectively bridging the gap between traditional laboratory techniques and industrial-scale processing capabilities.

Technical objectives for maximizing throughput include optimizing flow dynamics to prevent cross-contamination between array elements, developing novel valve and pump technologies for precise fluid control, and creating adaptive systems that can self-regulate based on real-time feedback. Additionally, there is significant focus on reducing manufacturing costs and increasing accessibility, particularly for point-of-care applications in resource-limited settings.

Market Demand Analysis for High-Throughput Microfluidics

The global microfluidics market has experienced significant growth, driven primarily by the increasing demand for high-throughput systems across various industries. Current market valuations place the high-throughput microfluidics sector at approximately 15 billion USD, with projections indicating a compound annual growth rate of 18% through 2028. This remarkable growth trajectory reflects the expanding applications of microfluidic array systems in pharmaceutical development, clinical diagnostics, and academic research.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of the total demand for high-throughput microfluidic technologies. These organizations require systems capable of processing thousands of samples simultaneously for drug discovery and development processes. The ability to maximize throughput while maintaining precision has become a critical competitive advantage in this sector, where reducing time-to-market for new therapeutics translates directly to significant financial benefits.

Clinical diagnostics constitutes the fastest-growing segment, with a 22% annual growth rate. The COVID-19 pandemic dramatically accelerated adoption of high-throughput microfluidic testing platforms, establishing new standards for testing capacity that continue to influence market expectations. Healthcare providers now demand systems capable of processing hundreds to thousands of patient samples daily with minimal human intervention.

Academic and research institutions form another substantial market segment, contributing approximately 25% of the current demand. These organizations prioritize flexibility and customization in high-throughput systems to accommodate diverse experimental protocols across multiple research domains.

Regional analysis reveals North America as the dominant market, holding 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India making substantial investments in biotechnology infrastructure and research capabilities.

Key market drivers include increasing prevalence of chronic diseases requiring extensive diagnostic testing, growing emphasis on personalized medicine necessitating high-throughput screening of patient samples, and rising R&D investments in life sciences. Additionally, the miniaturization trend in laboratory equipment continues to push demand for more efficient microfluidic array systems.

Customer surveys indicate that throughput optimization ranks as the top priority for 68% of potential buyers, followed by reliability (58%) and integration capabilities with existing laboratory systems (52%). End-users consistently express willingness to invest in premium solutions that demonstrably increase processing capacity while maintaining or improving analytical precision.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, and regulatory hurdles for clinical applications. Despite these challenges, the fundamental market demand for maximizing throughput in microfluidic array systems remains robust and is expected to continue expanding across multiple industries.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of the total demand for high-throughput microfluidic technologies. These organizations require systems capable of processing thousands of samples simultaneously for drug discovery and development processes. The ability to maximize throughput while maintaining precision has become a critical competitive advantage in this sector, where reducing time-to-market for new therapeutics translates directly to significant financial benefits.

Clinical diagnostics constitutes the fastest-growing segment, with a 22% annual growth rate. The COVID-19 pandemic dramatically accelerated adoption of high-throughput microfluidic testing platforms, establishing new standards for testing capacity that continue to influence market expectations. Healthcare providers now demand systems capable of processing hundreds to thousands of patient samples daily with minimal human intervention.

Academic and research institutions form another substantial market segment, contributing approximately 25% of the current demand. These organizations prioritize flexibility and customization in high-throughput systems to accommodate diverse experimental protocols across multiple research domains.

Regional analysis reveals North America as the dominant market, holding 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India making substantial investments in biotechnology infrastructure and research capabilities.

Key market drivers include increasing prevalence of chronic diseases requiring extensive diagnostic testing, growing emphasis on personalized medicine necessitating high-throughput screening of patient samples, and rising R&D investments in life sciences. Additionally, the miniaturization trend in laboratory equipment continues to push demand for more efficient microfluidic array systems.

Customer surveys indicate that throughput optimization ranks as the top priority for 68% of potential buyers, followed by reliability (58%) and integration capabilities with existing laboratory systems (52%). End-users consistently express willingness to invest in premium solutions that demonstrably increase processing capacity while maintaining or improving analytical precision.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, and regulatory hurdles for clinical applications. Despite these challenges, the fundamental market demand for maximizing throughput in microfluidic array systems remains robust and is expected to continue expanding across multiple industries.

Current Limitations and Technical Barriers in Microfluidic Arrays

Despite significant advancements in microfluidic array technologies, several critical limitations continue to impede optimal throughput maximization. The primary constraint remains the inherent trade-off between processing speed and analytical accuracy. Current microfluidic arrays struggle to maintain precision when flow rates are increased beyond certain thresholds, creating a bottleneck that restricts overall system performance. This fundamental limitation stems from fluid dynamics principles where increased velocities lead to turbulence, disrupting the laminar flow essential for predictable sample manipulation.

Material compatibility presents another significant barrier, as many high-throughput applications require chemical resistance that current polymer-based microfluidic platforms cannot consistently provide. PDMS (polydimethylsiloxane), while popular for prototyping, exhibits problematic absorption of small hydrophobic molecules and suffers from swelling when exposed to certain organic solvents, compromising channel geometry and flow characteristics during extended operations.

Scaling challenges persist in transitioning from laboratory prototypes to industrial-scale production. The fabrication techniques that work effectively for single devices often prove inadequate for mass production, creating inconsistencies in channel dimensions and surface properties across arrays. This variability directly impacts flow behavior and ultimately reduces throughput reliability in larger systems.

Integration difficulties between microfluidic components and external instrumentation constitute another major hurdle. Current detection systems frequently require samples to remain stationary for accurate measurement, contradicting the continuous flow needed for high throughput. This creates a fundamental operational conflict that forces compromises in either processing speed or detection sensitivity.

Cross-contamination between array elements remains problematic, particularly as channel dimensions decrease to accommodate higher density arrays. Diffusion effects become increasingly significant at smaller scales, allowing sample components to migrate between adjacent channels and compromising sample integrity. Current isolation techniques add complexity and often reduce overall system throughput.

Pressure limitations represent a technical barrier that directly impacts flow rates. As channel dimensions decrease to improve integration density, the pressure required to maintain adequate flow increases exponentially. Current pumping technologies struggle to deliver precise pressure control across wide operating ranges without introducing pulsation effects that disrupt sensitive microfluidic processes.

Clogging and fouling present persistent challenges, particularly in biological applications where protein adsorption and cell aggregation can obstruct microchannels. Current surface treatment technologies provide only temporary solutions, with performance degradation occurring over operational time. This necessitates frequent maintenance interventions that significantly reduce effective throughput in continuous processing scenarios.

Material compatibility presents another significant barrier, as many high-throughput applications require chemical resistance that current polymer-based microfluidic platforms cannot consistently provide. PDMS (polydimethylsiloxane), while popular for prototyping, exhibits problematic absorption of small hydrophobic molecules and suffers from swelling when exposed to certain organic solvents, compromising channel geometry and flow characteristics during extended operations.

Scaling challenges persist in transitioning from laboratory prototypes to industrial-scale production. The fabrication techniques that work effectively for single devices often prove inadequate for mass production, creating inconsistencies in channel dimensions and surface properties across arrays. This variability directly impacts flow behavior and ultimately reduces throughput reliability in larger systems.

Integration difficulties between microfluidic components and external instrumentation constitute another major hurdle. Current detection systems frequently require samples to remain stationary for accurate measurement, contradicting the continuous flow needed for high throughput. This creates a fundamental operational conflict that forces compromises in either processing speed or detection sensitivity.

Cross-contamination between array elements remains problematic, particularly as channel dimensions decrease to accommodate higher density arrays. Diffusion effects become increasingly significant at smaller scales, allowing sample components to migrate between adjacent channels and compromising sample integrity. Current isolation techniques add complexity and often reduce overall system throughput.

Pressure limitations represent a technical barrier that directly impacts flow rates. As channel dimensions decrease to improve integration density, the pressure required to maintain adequate flow increases exponentially. Current pumping technologies struggle to deliver precise pressure control across wide operating ranges without introducing pulsation effects that disrupt sensitive microfluidic processes.

Clogging and fouling present persistent challenges, particularly in biological applications where protein adsorption and cell aggregation can obstruct microchannels. Current surface treatment technologies provide only temporary solutions, with performance degradation occurring over operational time. This necessitates frequent maintenance interventions that significantly reduce effective throughput in continuous processing scenarios.

Current Approaches to Maximize Microfluidic Array Throughput

01 Parallel processing in microfluidic arrays

Microfluidic array systems can achieve higher throughput through parallel processing of multiple samples simultaneously. These systems incorporate multiple channels, chambers, or wells that operate in parallel, allowing for the concurrent analysis of numerous samples. This parallel architecture significantly increases the throughput capacity compared to sequential processing methods, making it suitable for high-throughput screening applications in drug discovery, genomics, and diagnostics.- Parallel processing in microfluidic arrays: Microfluidic array systems can achieve high throughput by implementing parallel processing architectures. These systems allow for simultaneous analysis of multiple samples across numerous reaction chambers or channels. By integrating multiple reaction sites on a single chip, these platforms can significantly increase the number of assays performed in a given time period. Advanced designs incorporate multiplexed channel networks that enable independent control of fluid flow to different regions of the array, further enhancing throughput capabilities.

- Automated sample handling and processing: Automation technologies integrated into microfluidic array systems substantially improve throughput by reducing manual intervention and handling time. These systems incorporate robotic sample loading, automated reagent dispensing, and programmed workflow sequences. Advanced platforms feature continuous flow operations that maintain constant sample processing without interruption. The integration of automated detection systems further streamlines the analytical process by eliminating manual data collection steps, resulting in significantly higher sample processing rates.

- Miniaturization and high-density arrays: Miniaturization techniques enable the development of high-density microfluidic arrays that dramatically increase throughput capabilities. By reducing the size of individual reaction chambers and channels, these systems can accommodate thousands of assay sites within a compact footprint. Advanced fabrication methods allow for precise patterning of microstructures that maintain consistent performance across the array. The reduced volumes also decrease reagent consumption and reaction times, further contributing to enhanced throughput performance.

- Integration of detection and analysis systems: High-throughput microfluidic arrays incorporate integrated detection systems that enable real-time monitoring and analysis. These platforms combine optical, electrochemical, or mass spectrometry detection methods directly within the microfluidic system. By eliminating the need to transfer samples to separate analytical instruments, these integrated approaches significantly reduce processing time. Advanced systems feature multiplexed detection capabilities that can simultaneously measure multiple parameters across numerous samples, further enhancing throughput efficiency.

- Novel microfluidic architectures for throughput optimization: Innovative microfluidic architectures specifically designed for throughput optimization incorporate droplet-based systems, digital microfluidics, and reconfigurable array platforms. These advanced designs enable dynamic control of fluid movement and reaction conditions across the array. Some systems utilize gradient generators to perform multiple reaction conditions simultaneously, while others implement novel valve technologies that allow for rapid reconfiguration of flow paths. These architectural innovations significantly increase the number of assays that can be performed in parallel while maintaining analytical precision.

02 Integration of automation and robotics

The integration of automation and robotics in microfluidic array systems enhances throughput by minimizing manual intervention and reducing processing time. Automated liquid handling, sample preparation, and detection systems work in coordination to streamline workflows. Robotic components can precisely control fluid movement, timing, and detection parameters, enabling continuous operation and higher sample processing rates while maintaining consistency and reproducibility across experiments.Expand Specific Solutions03 Advanced detection and analysis methods

Implementing advanced detection and analysis methods in microfluidic array systems significantly improves throughput by reducing analysis time and increasing sensitivity. These methods include integrated optical detection systems, electrochemical sensors, and mass spectrometry interfaces that can rapidly analyze samples within the microfluidic platform. Real-time data acquisition and processing algorithms further enhance the speed of analysis, allowing for faster result generation and higher system throughput.Expand Specific Solutions04 Optimized microfluidic channel design

Optimized channel designs in microfluidic array systems enhance fluid flow dynamics and reduce processing time, thereby increasing throughput. These designs incorporate features such as gradient generators, mixers, and specialized geometries that facilitate rapid sample processing. Advanced fabrication techniques allow for the creation of complex channel networks that optimize sample distribution, reaction kinetics, and waste removal, resulting in more efficient and higher throughput operations.Expand Specific Solutions05 Multiplexed assay capabilities

Microfluidic array systems with multiplexed assay capabilities can simultaneously analyze multiple parameters or targets within a single sample, significantly increasing analytical throughput. These systems incorporate various detection modalities and reagent delivery mechanisms that enable the concurrent measurement of different analytes. By performing multiple assays in parallel on the same sample, these systems reduce the total analysis time and resource requirements while generating comprehensive data sets.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidics

The microfluidic array systems market is currently in a growth phase, with increasing adoption across pharmaceutical, diagnostic, and research applications. The market size is expanding rapidly, projected to reach several billion dollars by 2025, driven by demand for high-throughput screening and point-of-care diagnostics. Technologically, the field shows moderate maturity with established players like Agilent Technologies and Life Technologies offering commercial solutions, while academic institutions (MIT, Duke University) continue pushing boundaries in throughput optimization. Leading companies including Robert Bosch GmbH, 10X Genomics, and Advanced Liquid Logic are developing innovative approaches to maximize throughput efficiency through digital microfluidics, parallel processing architectures, and integrated circuit technologies. Research collaboration between industry players and institutions like Shanghai Institute of Microsystem & Information Technology is accelerating development of next-generation systems with enhanced throughput capabilities.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered several breakthrough approaches to maximize throughput in microfluidic array systems. Their work includes the development of inertial microfluidics techniques that leverage fluid dynamics phenomena to achieve high-throughput particle sorting and manipulation without external forces. MIT's microfluidic platforms incorporate sophisticated parallelization strategies, including radial array designs that efficiently distribute samples from a central inlet to multiple processing channels simultaneously. Their research has produced advanced flow control methodologies using precisely engineered channel geometries that create predictable flow patterns for particle focusing and separation at unprecedented rates. MIT has also developed innovative approaches to overcome traditional throughput bottlenecks, including the implementation of deterministic lateral displacement arrays that can process cellular samples at rates exceeding 1 million cells per second. Additionally, their work on digital microfluidics has yielded electrode addressing schemes that enable independent control of hundreds of droplets simultaneously on a single chip, dramatically increasing processing capacity compared to conventional sequential approaches.

Strengths: Cutting-edge research incorporating advanced physics principles; innovative designs that fundamentally rethink microfluidic architectures; strong theoretical foundation. Weaknesses: Some technologies remain in research phase rather than commercial products; complex systems may require specialized expertise to implement; optimization often focused on specific applications rather than general-purpose solutions.

Advanced Liquid Logic, Inc.

Technical Solution: Advanced Liquid Logic has pioneered digital microfluidics (DMF) technology that manipulates discrete droplets on an electrode array using electrowetting principles. Their platform enables high-throughput parallel processing by independently controlling multiple droplets simultaneously across a 2D array. The company's proprietary technology incorporates sophisticated electrode addressing schemes and optimized driving waveforms that minimize cross-talk between adjacent electrodes, allowing for higher droplet density and throughput. Their system integrates real-time feedback control mechanisms that monitor droplet position and velocity, dynamically adjusting electrical parameters to maintain optimal flow rates even under variable conditions. The platform also features advanced scheduling algorithms that optimize droplet routing paths to minimize transit times and avoid congestion points in complex microfluidic networks.

Strengths: Precise individual droplet control allows for complex parallel operations; eliminates physical channel constraints of traditional microfluidics; highly reconfigurable for different protocols. Weaknesses: Higher power requirements compared to passive systems; potential for electrode degradation over time; more complex manufacturing process requiring specialized materials and fabrication techniques.

Critical Patents and Innovations in High-Throughput Microfluidics

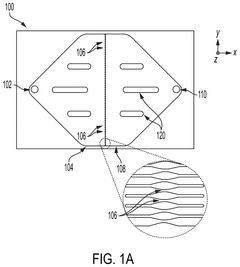

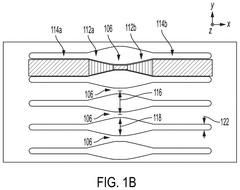

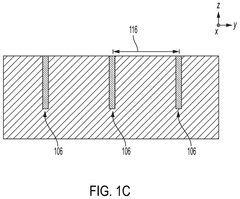

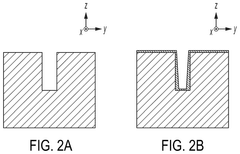

High-throughput microfluidic chip having parallelized constrictions for perturbing cell membranes

PatentPendingUS20240376415A1

Innovation

- The development of high-throughput microfluidic chips with parallelized constrictions, featuring deep, narrow, rectangular channels etched into a substrate, which increase the cross-sectional area while minimizing the perimeter, reducing clogging and enhancing throughput, and optimized geometries to ensure uniform flow velocities and patterns.

High throughput microfluidic systems and methods

PatentInactiveUS7316801B2

Innovation

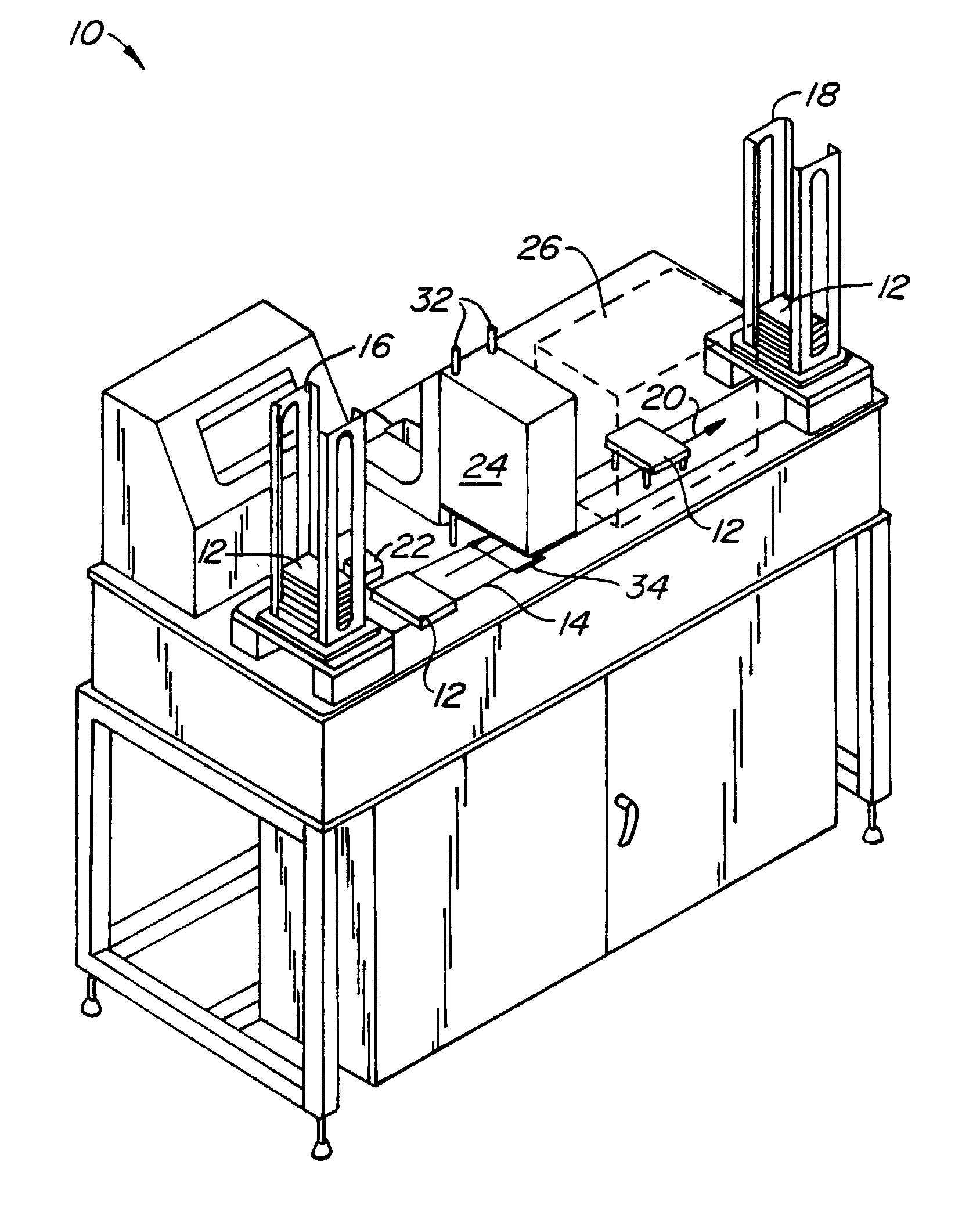

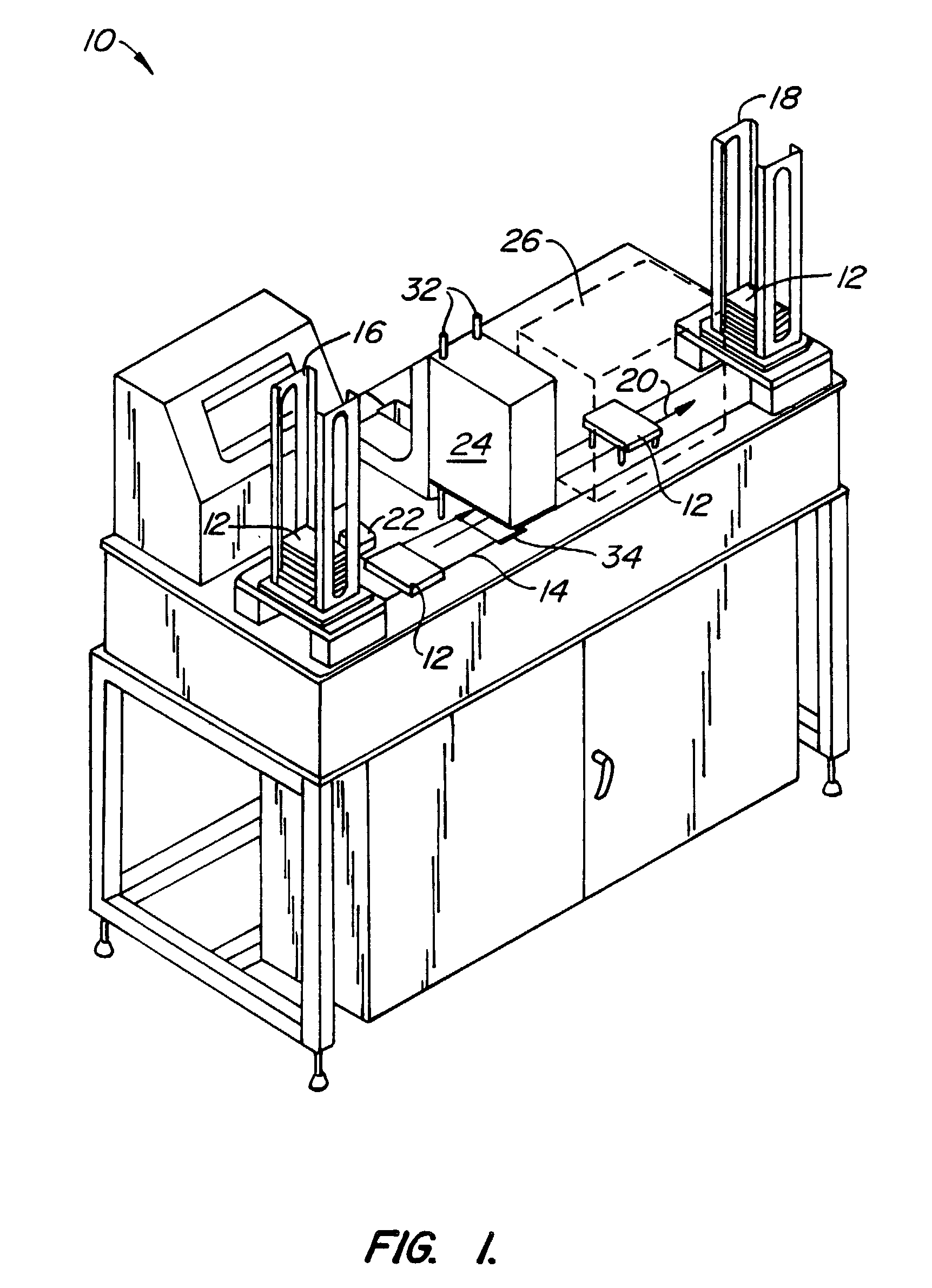

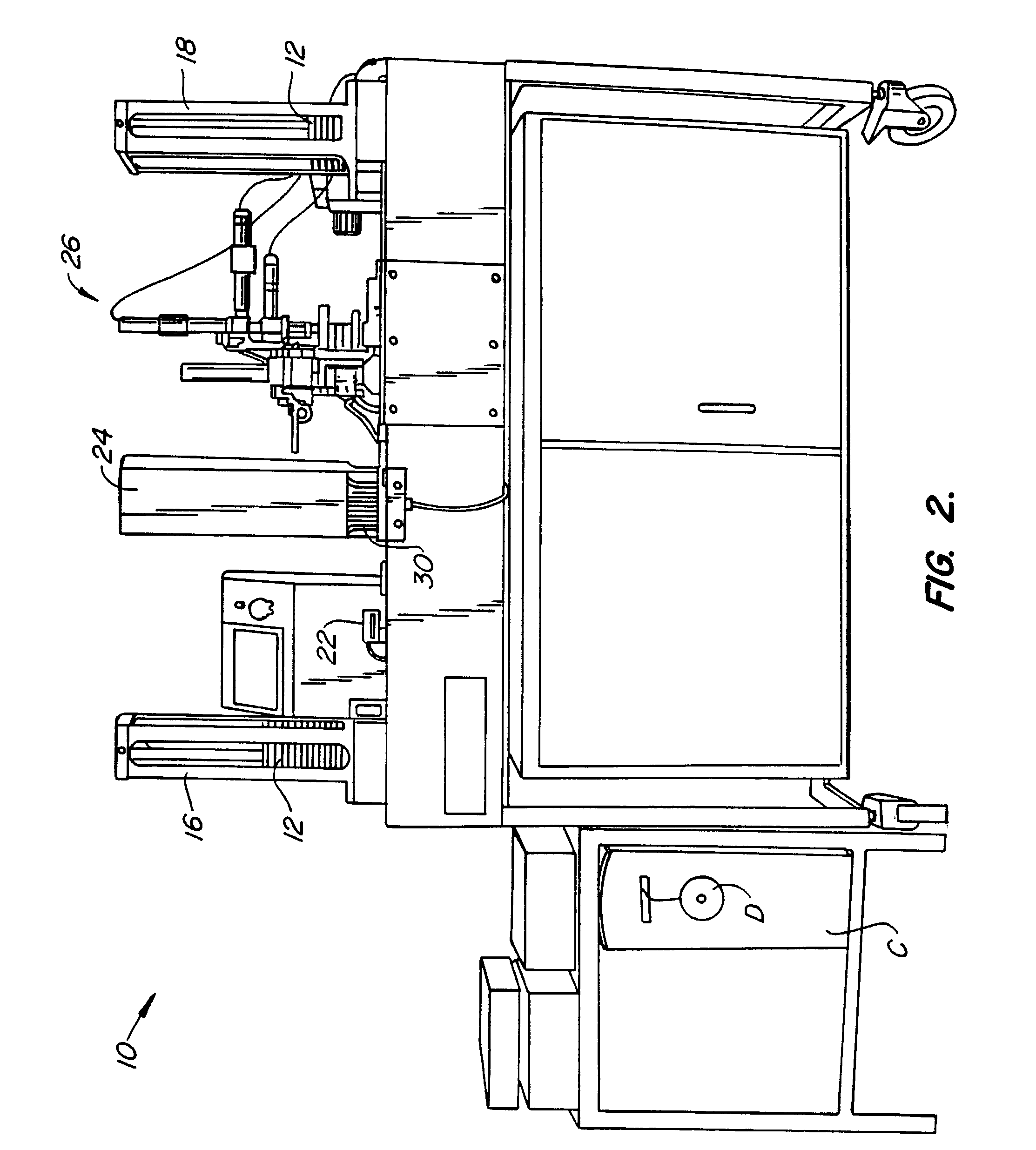

- A system comprising a conveyor belt with pre and post-processing stations, a clamshell interface structure, and an X-Y-Z robotic arm for precise alignment and introduction of samples into microfluidic devices, allowing for flexible testing sequences and minimizing the need for complex robotic grasping mechanisms.

Scaling Challenges and Manufacturing Considerations

As microfluidic array systems scale up to meet increasing throughput demands, several critical manufacturing challenges emerge that require innovative solutions. The transition from laboratory prototypes to industrial-scale production introduces significant complexities in maintaining consistent performance across larger arrays. Material selection becomes increasingly critical, as polymers that perform adequately in small-scale applications may exhibit unacceptable variability in mechanical properties, chemical resistance, or optical characteristics when manufactured at scale.

Manufacturing precision presents another substantial hurdle. While traditional microfabrication techniques like photolithography and soft lithography work well for research prototypes, they face limitations in mass production scenarios. The requirement for sub-micron precision across increasingly larger surface areas demands advanced manufacturing technologies such as roll-to-roll processing or injection molding with specialized tooling. These processes must maintain exceptional dimensional accuracy while simultaneously reducing per-unit costs.

Surface treatment uniformity represents a particular challenge in scaled microfluidic systems. As device footprints increase, ensuring consistent hydrophobic or hydrophilic properties across all channels becomes exponentially more difficult. Even minor variations in surface chemistry can lead to unpredictable fluid behavior, creating "dead zones" or irregular flow patterns that compromise throughput and reliability.

Integration complexity increases dramatically with scale. Larger arrays require more sophisticated interconnects, valves, and control systems. The density of these components often creates thermal management issues that can affect fluid properties and reaction kinetics. Additionally, the increased number of potential failure points necessitates robust quality control protocols that can identify defects without slowing production.

Economic considerations ultimately determine manufacturing viability. While microfluidic technology offers significant advantages in throughput and efficiency, production costs must be carefully balanced against performance benefits. Capital equipment investments for specialized manufacturing capabilities represent substantial barriers to entry. Companies must evaluate whether to develop proprietary manufacturing capabilities or partner with specialized fabrication facilities that can achieve the necessary precision at acceptable costs.

Standardization efforts are gradually emerging to address these scaling challenges. Industry consortia are working to establish common specifications for materials, connections, and testing protocols. These standards will be essential for enabling interoperability between components from different manufacturers and facilitating the development of modular systems that can be customized for specific applications while maintaining manufacturing efficiency.

Manufacturing precision presents another substantial hurdle. While traditional microfabrication techniques like photolithography and soft lithography work well for research prototypes, they face limitations in mass production scenarios. The requirement for sub-micron precision across increasingly larger surface areas demands advanced manufacturing technologies such as roll-to-roll processing or injection molding with specialized tooling. These processes must maintain exceptional dimensional accuracy while simultaneously reducing per-unit costs.

Surface treatment uniformity represents a particular challenge in scaled microfluidic systems. As device footprints increase, ensuring consistent hydrophobic or hydrophilic properties across all channels becomes exponentially more difficult. Even minor variations in surface chemistry can lead to unpredictable fluid behavior, creating "dead zones" or irregular flow patterns that compromise throughput and reliability.

Integration complexity increases dramatically with scale. Larger arrays require more sophisticated interconnects, valves, and control systems. The density of these components often creates thermal management issues that can affect fluid properties and reaction kinetics. Additionally, the increased number of potential failure points necessitates robust quality control protocols that can identify defects without slowing production.

Economic considerations ultimately determine manufacturing viability. While microfluidic technology offers significant advantages in throughput and efficiency, production costs must be carefully balanced against performance benefits. Capital equipment investments for specialized manufacturing capabilities represent substantial barriers to entry. Companies must evaluate whether to develop proprietary manufacturing capabilities or partner with specialized fabrication facilities that can achieve the necessary precision at acceptable costs.

Standardization efforts are gradually emerging to address these scaling challenges. Industry consortia are working to establish common specifications for materials, connections, and testing protocols. These standards will be essential for enabling interoperability between components from different manufacturers and facilitating the development of modular systems that can be customized for specific applications while maintaining manufacturing efficiency.

Integration Potential with Lab-on-a-Chip Technologies

The integration of microfluidic array systems with Lab-on-a-Chip (LOC) technologies represents a significant opportunity to enhance analytical capabilities across multiple scientific domains. Microfluidic array systems, when properly optimized for throughput, can serve as foundational components within more comprehensive LOC platforms, enabling complex sample processing, analysis, and detection within a single integrated device.

The compatibility between high-throughput microfluidic arrays and LOC technologies stems from their shared design principles focused on miniaturization, parallelization, and automation. By incorporating optimized microfluidic array systems into LOC platforms, researchers can achieve multiplexed analysis capabilities that significantly reduce sample volumes, reagent consumption, and processing times compared to conventional laboratory methods.

Several integration approaches have demonstrated promising results. Modular designs allow microfluidic array components to be incorporated as interchangeable units within larger LOC systems, facilitating customization for specific applications. Alternatively, monolithic integration approaches embed array functionality directly into comprehensive chip designs, potentially offering improved reliability through reduced interconnections.

The integration potential extends across diverse application domains. In clinical diagnostics, integrated systems combining high-throughput microfluidic arrays with detection modules enable simultaneous testing for multiple biomarkers from limited sample volumes. For drug discovery applications, integrated platforms support parallel screening of compound libraries against cellular arrays, accelerating lead identification processes.

Technical challenges remain in achieving seamless integration. Interface standardization between microfluidic array components and other LOC modules requires addressing compatibility issues in channel dimensions, flow rates, and connection protocols. Power management presents another challenge, particularly for portable or point-of-care applications where energy efficiency becomes critical.

Data integration represents a significant opportunity, with high-throughput microfluidic arrays generating substantial information that must be effectively processed and analyzed. Incorporating on-chip or closely coupled computational capabilities can enable real-time data processing, potentially unlocking new analytical capabilities through machine learning algorithms applied to complex microfluidic datasets.

Future integration directions point toward increased autonomy and intelligence in integrated systems. Self-calibrating microfluidic array systems that automatically adjust flow parameters based on feedback mechanisms could enhance reliability in field deployments. Additionally, the incorporation of wireless connectivity features would enable remote monitoring and control of integrated microfluidic array systems, expanding their utility in distributed sensing applications and telemedicine scenarios.

The compatibility between high-throughput microfluidic arrays and LOC technologies stems from their shared design principles focused on miniaturization, parallelization, and automation. By incorporating optimized microfluidic array systems into LOC platforms, researchers can achieve multiplexed analysis capabilities that significantly reduce sample volumes, reagent consumption, and processing times compared to conventional laboratory methods.

Several integration approaches have demonstrated promising results. Modular designs allow microfluidic array components to be incorporated as interchangeable units within larger LOC systems, facilitating customization for specific applications. Alternatively, monolithic integration approaches embed array functionality directly into comprehensive chip designs, potentially offering improved reliability through reduced interconnections.

The integration potential extends across diverse application domains. In clinical diagnostics, integrated systems combining high-throughput microfluidic arrays with detection modules enable simultaneous testing for multiple biomarkers from limited sample volumes. For drug discovery applications, integrated platforms support parallel screening of compound libraries against cellular arrays, accelerating lead identification processes.

Technical challenges remain in achieving seamless integration. Interface standardization between microfluidic array components and other LOC modules requires addressing compatibility issues in channel dimensions, flow rates, and connection protocols. Power management presents another challenge, particularly for portable or point-of-care applications where energy efficiency becomes critical.

Data integration represents a significant opportunity, with high-throughput microfluidic arrays generating substantial information that must be effectively processed and analyzed. Incorporating on-chip or closely coupled computational capabilities can enable real-time data processing, potentially unlocking new analytical capabilities through machine learning algorithms applied to complex microfluidic datasets.

Future integration directions point toward increased autonomy and intelligence in integrated systems. Self-calibrating microfluidic array systems that automatically adjust flow parameters based on feedback mechanisms could enhance reliability in field deployments. Additionally, the incorporation of wireless connectivity features would enable remote monitoring and control of integrated microfluidic array systems, expanding their utility in distributed sensing applications and telemedicine scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!