How to Use Microfluidics for Real-Time Monitoring in Agriculture

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidics in Agriculture: Background and Objectives

Microfluidics technology has evolved significantly over the past three decades, transitioning from laboratory curiosities to practical applications across various industries. In agriculture, microfluidics represents a promising frontier for precision farming and sustainable resource management. The technology originated in the 1990s with simple channel designs and has progressively incorporated sophisticated features including valves, pumps, and sensors that enable complex fluid manipulation at the microscale level.

The agricultural sector faces unprecedented challenges including climate change, water scarcity, and the need to increase food production for a growing global population. Traditional monitoring methods in agriculture are often labor-intensive, time-consuming, and provide limited real-time data. This creates a technological gap that microfluidic systems are uniquely positioned to address through their capacity for rapid, sensitive, and in-situ analysis.

The integration of microfluidics into agricultural monitoring aims to revolutionize how farmers and agronomists collect and analyze critical data. By leveraging microscale fluid dynamics, these systems can detect plant pathogens, monitor soil nutrients, assess water quality, and measure plant stress hormones with remarkable precision and minimal resource consumption. The miniaturization inherent in microfluidic devices enables portable, field-deployable solutions that bring laboratory-grade analytical capabilities directly to farms.

Recent technological advancements have accelerated the development of microfluidic platforms specifically designed for agricultural applications. These include paper-based microfluidics for low-cost diagnostics, digital microfluidics for automated sample processing, and organ-on-a-chip systems that can model plant-pathogen interactions. The convergence of microfluidics with complementary technologies such as biosensors, nanomaterials, and wireless communication systems has further expanded their potential impact.

The primary objective of implementing microfluidics for real-time monitoring in agriculture is to enable data-driven decision making that optimizes resource utilization while maximizing crop yield and quality. Secondary goals include reducing chemical inputs through targeted application, minimizing environmental impact, detecting diseases before they spread, and providing early warning systems for stress conditions. These objectives align with the broader industry trend toward precision agriculture and sustainable farming practices.

Looking forward, the trajectory of microfluidic technology in agriculture points toward increasingly integrated systems that combine multiple analytical functions on single platforms. The evolution from single-parameter measurements to comprehensive environmental and biological monitoring represents a significant trend that promises to transform agricultural management practices. As fabrication costs decrease and device robustness increases, widespread adoption of microfluidic monitoring solutions becomes increasingly feasible for various scales of agricultural operations.

The agricultural sector faces unprecedented challenges including climate change, water scarcity, and the need to increase food production for a growing global population. Traditional monitoring methods in agriculture are often labor-intensive, time-consuming, and provide limited real-time data. This creates a technological gap that microfluidic systems are uniquely positioned to address through their capacity for rapid, sensitive, and in-situ analysis.

The integration of microfluidics into agricultural monitoring aims to revolutionize how farmers and agronomists collect and analyze critical data. By leveraging microscale fluid dynamics, these systems can detect plant pathogens, monitor soil nutrients, assess water quality, and measure plant stress hormones with remarkable precision and minimal resource consumption. The miniaturization inherent in microfluidic devices enables portable, field-deployable solutions that bring laboratory-grade analytical capabilities directly to farms.

Recent technological advancements have accelerated the development of microfluidic platforms specifically designed for agricultural applications. These include paper-based microfluidics for low-cost diagnostics, digital microfluidics for automated sample processing, and organ-on-a-chip systems that can model plant-pathogen interactions. The convergence of microfluidics with complementary technologies such as biosensors, nanomaterials, and wireless communication systems has further expanded their potential impact.

The primary objective of implementing microfluidics for real-time monitoring in agriculture is to enable data-driven decision making that optimizes resource utilization while maximizing crop yield and quality. Secondary goals include reducing chemical inputs through targeted application, minimizing environmental impact, detecting diseases before they spread, and providing early warning systems for stress conditions. These objectives align with the broader industry trend toward precision agriculture and sustainable farming practices.

Looking forward, the trajectory of microfluidic technology in agriculture points toward increasingly integrated systems that combine multiple analytical functions on single platforms. The evolution from single-parameter measurements to comprehensive environmental and biological monitoring represents a significant trend that promises to transform agricultural management practices. As fabrication costs decrease and device robustness increases, widespread adoption of microfluidic monitoring solutions becomes increasingly feasible for various scales of agricultural operations.

Market Analysis for Agricultural Monitoring Solutions

The agricultural monitoring solutions market is experiencing significant growth, driven by the increasing need for precision agriculture technologies that optimize resource utilization and crop yields. Currently valued at approximately $3.4 billion, this market is projected to reach $6.7 billion by 2026, with a compound annual growth rate of 14.2%. This growth trajectory is supported by the rising global food demand, shrinking arable land, and increasing focus on sustainable farming practices.

Real-time monitoring solutions represent the fastest-growing segment within this market, as they enable farmers to make immediate data-driven decisions. Microfluidic technologies for agricultural monitoring are emerging as a particularly promising niche, offering unprecedented capabilities for continuous analysis of soil nutrients, plant health indicators, and water quality parameters directly in the field.

The demand for these solutions varies significantly across different agricultural sectors. Large-scale commercial farming operations, particularly in high-value crops such as vineyards, specialty fruits, and greenhouse production, demonstrate the strongest initial adoption potential. These sectors can more readily justify the investment based on immediate returns through reduced input costs and improved yields.

Geographically, North America currently leads the market adoption of advanced agricultural monitoring technologies, accounting for 38% of global market share. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid modernization of agricultural practices in countries like China and India, coupled with government initiatives supporting precision agriculture adoption.

Key customer segments include commercial farms (62%), agricultural service providers (21%), research institutions (12%), and government agencies (5%). The willingness to pay varies significantly across these segments, with commercial farms demonstrating higher price sensitivity but larger volume potential, while research institutions accept premium pricing for advanced capabilities.

Market barriers include the relatively high initial investment costs, technical complexity requiring specialized knowledge, and integration challenges with existing farm management systems. Additionally, there remains a significant awareness gap among potential end-users about the benefits and return on investment potential of microfluidic monitoring solutions.

Customer pain points that microfluidic monitoring solutions could address include the labor-intensive nature of traditional sampling methods, delayed decision-making due to laboratory testing turnaround times, and the inability to capture temporal variations in critical agricultural parameters. Solutions that effectively address these challenges while demonstrating clear economic benefits will likely see accelerated market adoption.

Real-time monitoring solutions represent the fastest-growing segment within this market, as they enable farmers to make immediate data-driven decisions. Microfluidic technologies for agricultural monitoring are emerging as a particularly promising niche, offering unprecedented capabilities for continuous analysis of soil nutrients, plant health indicators, and water quality parameters directly in the field.

The demand for these solutions varies significantly across different agricultural sectors. Large-scale commercial farming operations, particularly in high-value crops such as vineyards, specialty fruits, and greenhouse production, demonstrate the strongest initial adoption potential. These sectors can more readily justify the investment based on immediate returns through reduced input costs and improved yields.

Geographically, North America currently leads the market adoption of advanced agricultural monitoring technologies, accounting for 38% of global market share. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid modernization of agricultural practices in countries like China and India, coupled with government initiatives supporting precision agriculture adoption.

Key customer segments include commercial farms (62%), agricultural service providers (21%), research institutions (12%), and government agencies (5%). The willingness to pay varies significantly across these segments, with commercial farms demonstrating higher price sensitivity but larger volume potential, while research institutions accept premium pricing for advanced capabilities.

Market barriers include the relatively high initial investment costs, technical complexity requiring specialized knowledge, and integration challenges with existing farm management systems. Additionally, there remains a significant awareness gap among potential end-users about the benefits and return on investment potential of microfluidic monitoring solutions.

Customer pain points that microfluidic monitoring solutions could address include the labor-intensive nature of traditional sampling methods, delayed decision-making due to laboratory testing turnaround times, and the inability to capture temporal variations in critical agricultural parameters. Solutions that effectively address these challenges while demonstrating clear economic benefits will likely see accelerated market adoption.

Current Microfluidic Technologies and Implementation Challenges

Microfluidic technologies have evolved significantly over the past decade, offering promising applications for real-time monitoring in agriculture. Current microfluidic platforms primarily utilize several key technologies: lab-on-a-chip systems, paper-based microfluidics, digital microfluidics, and droplet-based microfluidics. Each technology presents unique capabilities for agricultural applications, particularly in soil nutrient analysis, plant pathogen detection, and water quality monitoring.

Lab-on-a-chip systems integrate multiple laboratory functions onto a single chip measuring only millimeters to a few square centimeters. These systems enable rapid, automated analysis of soil samples and plant tissues with minimal reagent consumption. Recent advancements have produced chips capable of simultaneous detection of multiple nutrients (N, P, K) and heavy metals in soil samples within minutes, compared to traditional laboratory methods requiring hours or days.

Paper-based microfluidics represent a cost-effective alternative, utilizing capillary action to move fluids through hydrophilic paper channels. These devices have gained traction for field applications due to their simplicity, disposability, and minimal power requirements. Current implementations include colorimetric assays for pesticide detection and paper-based lateral flow assays for plant disease identification.

Digital microfluidics employs electrowetting principles to manipulate discrete droplets on hydrophobic surfaces. This technology enables precise control over sample processing without requiring continuous fluid flow, making it suitable for complex agricultural assays requiring multiple reaction steps.

Despite these technological advances, significant implementation challenges persist. Robustness remains a primary concern, as agricultural environments expose devices to extreme temperatures, humidity, dust, and mechanical stress. Current microfluidic platforms often demonstrate reduced reliability under field conditions compared to laboratory settings.

Sample preparation presents another major hurdle. Agricultural samples (soil, plant tissue, water) contain complex matrices with particulates that can clog microchannels. While filtration systems have been integrated into some devices, they often increase complexity and cost while potentially removing analytes of interest.

Power requirements also limit widespread adoption. Although low-power microfluidic systems exist, continuous monitoring applications require sustainable power sources. Solar integration shows promise but faces challenges in maintaining consistent operation during adverse weather conditions.

Connectivity issues further complicate implementation in remote agricultural settings. Many current systems lack robust data transmission capabilities necessary for real-time monitoring applications. Emerging solutions combining microfluidics with IoT technologies address this gap but increase system complexity and cost.

Standardization remains underdeveloped, with various proprietary systems using different interfaces, detection methods, and data formats. This fragmentation impedes integration with existing agricultural management systems and slows broader adoption across the industry.

Lab-on-a-chip systems integrate multiple laboratory functions onto a single chip measuring only millimeters to a few square centimeters. These systems enable rapid, automated analysis of soil samples and plant tissues with minimal reagent consumption. Recent advancements have produced chips capable of simultaneous detection of multiple nutrients (N, P, K) and heavy metals in soil samples within minutes, compared to traditional laboratory methods requiring hours or days.

Paper-based microfluidics represent a cost-effective alternative, utilizing capillary action to move fluids through hydrophilic paper channels. These devices have gained traction for field applications due to their simplicity, disposability, and minimal power requirements. Current implementations include colorimetric assays for pesticide detection and paper-based lateral flow assays for plant disease identification.

Digital microfluidics employs electrowetting principles to manipulate discrete droplets on hydrophobic surfaces. This technology enables precise control over sample processing without requiring continuous fluid flow, making it suitable for complex agricultural assays requiring multiple reaction steps.

Despite these technological advances, significant implementation challenges persist. Robustness remains a primary concern, as agricultural environments expose devices to extreme temperatures, humidity, dust, and mechanical stress. Current microfluidic platforms often demonstrate reduced reliability under field conditions compared to laboratory settings.

Sample preparation presents another major hurdle. Agricultural samples (soil, plant tissue, water) contain complex matrices with particulates that can clog microchannels. While filtration systems have been integrated into some devices, they often increase complexity and cost while potentially removing analytes of interest.

Power requirements also limit widespread adoption. Although low-power microfluidic systems exist, continuous monitoring applications require sustainable power sources. Solar integration shows promise but faces challenges in maintaining consistent operation during adverse weather conditions.

Connectivity issues further complicate implementation in remote agricultural settings. Many current systems lack robust data transmission capabilities necessary for real-time monitoring applications. Emerging solutions combining microfluidics with IoT technologies address this gap but increase system complexity and cost.

Standardization remains underdeveloped, with various proprietary systems using different interfaces, detection methods, and data formats. This fragmentation impedes integration with existing agricultural management systems and slows broader adoption across the industry.

Existing Microfluidic Solutions for Real-Time Agricultural Monitoring

01 Microfluidic devices for real-time biological monitoring

Microfluidic systems designed for real-time monitoring of biological samples, including cells, tissues, and biomolecules. These devices integrate sensors and detection mechanisms to provide continuous data on biological processes, enabling applications in medical diagnostics, drug development, and personalized medicine. The systems often incorporate optical or electrochemical detection methods to track changes in biological parameters with high sensitivity and specificity.- Microfluidic devices for real-time biological monitoring: Microfluidic platforms designed for real-time monitoring of biological samples, including cells, tissues, and biomolecules. These systems integrate sensing elements that allow continuous observation of biological processes, metabolic activities, and cellular responses. The technology enables immediate detection of changes in biological parameters, providing valuable data for research, diagnostics, and therapeutic applications.

- Integrated sensor systems for microfluidic monitoring: Advanced sensor technologies integrated into microfluidic platforms for real-time data acquisition and analysis. These systems incorporate various sensing modalities such as optical, electrochemical, or mechanical sensors that can detect and measure parameters within microfluidic channels. The integration allows for continuous monitoring of flow conditions, chemical reactions, and physical properties of fluids in microfluidic devices.

- Automated microfluidic control and monitoring systems: Automated systems for controlling and monitoring microfluidic processes in real-time. These technologies incorporate feedback mechanisms that adjust flow rates, temperatures, and other parameters based on continuous monitoring data. The automation enables precise control of experimental conditions, improves reproducibility, and allows for complex protocols to be executed with minimal human intervention.

- Microfluidic platforms for environmental and industrial monitoring: Specialized microfluidic devices designed for real-time monitoring of environmental samples and industrial processes. These systems can continuously analyze water quality, air pollutants, or industrial fluids for contaminants and process parameters. The technology enables on-site, rapid detection of environmental hazards or process deviations, allowing for timely interventions and improved safety measures.

- Data management and visualization for microfluidic monitoring: Software and hardware solutions for processing, analyzing, and visualizing data from microfluidic monitoring systems in real-time. These technologies enable the transformation of complex sensor data into actionable information through advanced algorithms, machine learning, and intuitive user interfaces. The systems facilitate remote monitoring, alert generation, and comprehensive data analysis for improved decision-making based on microfluidic measurements.

02 Integrated sensor systems for microfluidic monitoring

Advanced sensor technologies integrated into microfluidic platforms for continuous monitoring of chemical and physical parameters. These systems combine miniaturized sensors with microfluidic channels to enable real-time data collection on flow rates, pressure, temperature, pH, and analyte concentrations. The integration of multiple sensing modalities allows for comprehensive monitoring of complex processes within the microfluidic environment, enhancing control and analysis capabilities.Expand Specific Solutions03 Networked microfluidic monitoring systems

Microfluidic platforms connected to data networks for remote monitoring and control capabilities. These systems transmit real-time data from microfluidic devices to centralized monitoring stations or cloud-based platforms, enabling continuous surveillance without physical presence. The networked architecture supports applications in industrial process control, environmental monitoring, and distributed healthcare diagnostics, with features for automated alerts and response mechanisms based on predefined parameters.Expand Specific Solutions04 Microfluidic systems for environmental and industrial monitoring

Specialized microfluidic devices designed for real-time monitoring of environmental samples and industrial processes. These systems enable continuous analysis of water quality, air pollutants, or industrial fluids with high precision and minimal sample volume requirements. The integration of microfluidic technology with specific detection methods allows for on-site, real-time monitoring of critical parameters, reducing response times for environmental incidents or industrial process deviations.Expand Specific Solutions05 Advanced manufacturing and design of real-time microfluidic monitoring devices

Innovative manufacturing techniques and design principles for creating more effective real-time microfluidic monitoring systems. These approaches include novel fabrication methods, materials selection, and architectural designs that enhance the performance, reliability, and scalability of microfluidic monitoring devices. Advanced manufacturing processes enable the integration of complex functionalities into compact microfluidic platforms, supporting applications requiring continuous, high-precision monitoring in various fields.Expand Specific Solutions

Leading Companies and Research Institutions in Agricultural Microfluidics

The microfluidics market for real-time agricultural monitoring is in its early growth phase, with an expanding market projected to reach significant value as precision agriculture adoption increases. The technology maturity varies across applications, with companies demonstrating different specialization levels. Established technology corporations like HP Development, Xerox Holdings, and DuPont are leveraging their manufacturing expertise to develop robust microfluidic platforms. Research-focused entities including Zhejiang University, Tsinghua University, and Johns Hopkins University are advancing fundamental innovations. Agricultural-specific players such as HEMAV Technology and Novozymes are creating specialized solutions integrating microfluidics with field applications. The ecosystem shows a blend of academic research, established corporations, and specialized agricultural technology providers working to bridge laboratory precision with field deployment challenges.

Novozymes A/S

Technical Solution: Novozymes has developed an advanced microfluidic platform for real-time monitoring of soil enzyme activities in agricultural settings. Their system integrates miniaturized reaction chambers with enzyme-specific biosensors that can detect microbial activity and nutrient cycling processes directly in the field. The technology employs droplet-based microfluidics where soil samples are encapsulated in microscale droplets along with specific enzyme substrates that produce fluorescent signals when metabolized. These signals are detected in real-time using integrated optical sensors, providing immediate feedback on soil health parameters. Novozymes' approach includes wireless connectivity that allows farmers to access soil enzymatic activity data through mobile applications, enabling precision application of biological products. The company has demonstrated that their microfluidic sensors can detect changes in soil enzyme activities within hours rather than days or weeks required by traditional laboratory methods, allowing for rapid agricultural management decisions.

Strengths: Leverages Novozymes' extensive enzyme expertise to create highly specific biosensors for agricultural applications. The system provides rapid results compared to traditional soil testing methods, enabling timely interventions. Weaknesses: The technology requires careful calibration for different soil types and environmental conditions, which may limit broad applicability without significant customization.

HEMAV Technology SL

Technical Solution: HEMAV Technology has pioneered an integrated microfluidic-drone system for real-time agricultural monitoring. Their solution combines aerial drones equipped with sample collection mechanisms and onboard microfluidic labs-on-a-chip that can analyze plant sap, irrigation water, and environmental samples in flight. The microfluidic devices utilize capillary action and pressure-driven flow to move liquid samples through channels containing reagents that react with specific agricultural parameters such as nutrient levels, pathogen presence, and water quality indicators. Results are processed by onboard computing systems and transmitted in real-time to cloud platforms where AI algorithms generate actionable insights for farmers. HEMAV's technology incorporates electrochemical sensors within the microfluidic channels that can detect multiple analytes simultaneously, providing comprehensive field data. The company has successfully deployed these systems across various crop types, demonstrating the ability to map spatial variations in field conditions and detect early signs of plant stress or disease outbreaks before visible symptoms appear.

Strengths: The integration with drone technology allows for wide-area coverage and spatial mapping of agricultural parameters without manual sampling. The system provides multi-parameter analysis in a single flight, increasing efficiency. Weaknesses: Flight time limitations restrict the duration of analysis, and the technology faces challenges in adverse weather conditions which can affect sample collection reliability.

Key Technical Innovations in Agricultural Sensing Microfluidics

Microfluidic apparatus with integrated porous-substrate/sensor for real-time (BIO) chemical molecule detection

PatentInactiveUS20120141329A1

Innovation

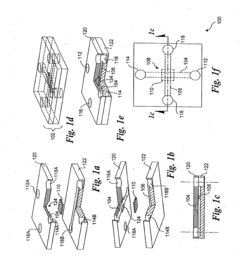

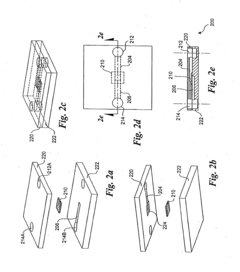

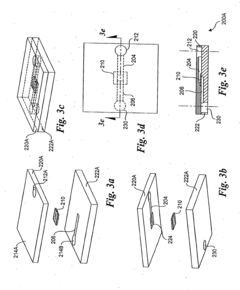

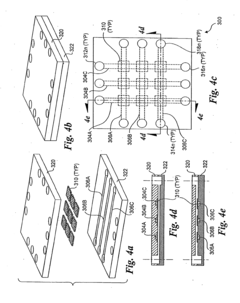

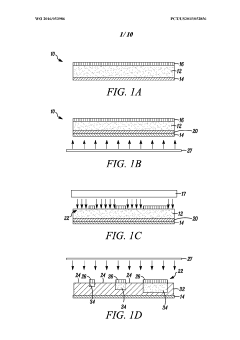

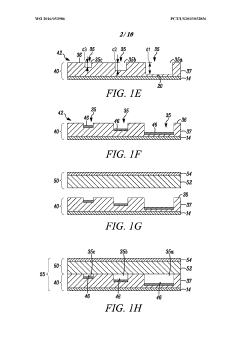

- A microfluidic device with an integrated porous-silicon membrane for molecular sieving, metering, and separation, which includes a porous substrate sandwiched between upper and lower microfluidic channels, allowing for the filtration and detection of biological and chemical molecules, and featuring a sensor that changes optical or electrical characteristics in response to chemical reactions.

A microfluidic device and a method for preparing the microfluidic device from a photosensitive element

PatentWO2016053986A1

Innovation

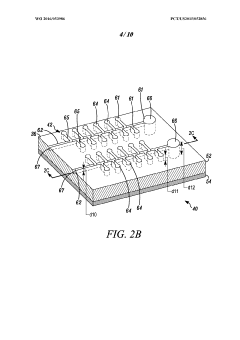

- A method using a photosensitive element with a photopolymerizable composition that is imagewise exposed to actinic radiation to form microfluidic devices without the need for a mold, allowing for direct imaging and creation of microstructures with varying depths and widths, enabling high-volume production and degas-driven flow.

Environmental Impact and Sustainability Considerations

The integration of microfluidic technologies in agricultural monitoring systems presents significant environmental benefits while also raising important sustainability considerations. Microfluidic devices require substantially less reagent volume compared to conventional analytical methods, reducing chemical waste generation by up to 95% in some applications. This minimization of chemical inputs directly translates to decreased environmental contamination risks and lower ecological footprints for agricultural monitoring operations.

Water conservation represents another critical environmental advantage of microfluidic systems. Traditional agricultural monitoring often requires substantial water volumes for sample preparation and analysis, whereas microfluidic platforms can achieve comparable analytical results using microliters or even nanoliters of water. In water-stressed agricultural regions, this efficiency could conserve millions of gallons annually if implemented at scale.

From a lifecycle perspective, microfluidic devices present mixed sustainability implications. While their miniaturized nature reduces material requirements during manufacturing, many current designs incorporate non-biodegradable polymers like polydimethylsiloxane (PDMS) or acrylic materials. Recent research has begun exploring biodegradable alternatives, including cellulose-based substrates and other bio-derived polymers that could significantly improve end-of-life environmental profiles.

Energy efficiency constitutes another important sustainability dimension. Microfluidic monitoring systems typically consume 60-80% less energy than conventional laboratory equipment, particularly when deployed with solar-powered field units. This reduced energy demand makes these systems particularly suitable for remote agricultural monitoring applications where grid connectivity is limited or unreliable.

The potential for microfluidic technologies to enable precision agriculture practices offers perhaps the most substantial environmental benefit. By providing real-time, spatially-resolved data on soil nutrients, water quality, and plant health indicators, these systems can optimize fertilizer and pesticide application. Studies suggest precision agriculture enabled by advanced monitoring can reduce fertilizer use by 15-30% and pesticide application by 10-20%, dramatically decreasing agricultural runoff and associated water pollution.

However, challenges remain regarding the scalability of environmentally-friendly microfluidic solutions. Mass production techniques must evolve to maintain sustainability advantages at commercial scales. Additionally, establishing effective collection and recycling systems for spent microfluidic devices will be essential to prevent these monitoring tools from creating new waste streams in agricultural environments.

Water conservation represents another critical environmental advantage of microfluidic systems. Traditional agricultural monitoring often requires substantial water volumes for sample preparation and analysis, whereas microfluidic platforms can achieve comparable analytical results using microliters or even nanoliters of water. In water-stressed agricultural regions, this efficiency could conserve millions of gallons annually if implemented at scale.

From a lifecycle perspective, microfluidic devices present mixed sustainability implications. While their miniaturized nature reduces material requirements during manufacturing, many current designs incorporate non-biodegradable polymers like polydimethylsiloxane (PDMS) or acrylic materials. Recent research has begun exploring biodegradable alternatives, including cellulose-based substrates and other bio-derived polymers that could significantly improve end-of-life environmental profiles.

Energy efficiency constitutes another important sustainability dimension. Microfluidic monitoring systems typically consume 60-80% less energy than conventional laboratory equipment, particularly when deployed with solar-powered field units. This reduced energy demand makes these systems particularly suitable for remote agricultural monitoring applications where grid connectivity is limited or unreliable.

The potential for microfluidic technologies to enable precision agriculture practices offers perhaps the most substantial environmental benefit. By providing real-time, spatially-resolved data on soil nutrients, water quality, and plant health indicators, these systems can optimize fertilizer and pesticide application. Studies suggest precision agriculture enabled by advanced monitoring can reduce fertilizer use by 15-30% and pesticide application by 10-20%, dramatically decreasing agricultural runoff and associated water pollution.

However, challenges remain regarding the scalability of environmentally-friendly microfluidic solutions. Mass production techniques must evolve to maintain sustainability advantages at commercial scales. Additionally, establishing effective collection and recycling systems for spent microfluidic devices will be essential to prevent these monitoring tools from creating new waste streams in agricultural environments.

Integration with IoT and Data Analytics Platforms

The integration of microfluidic systems with IoT (Internet of Things) and data analytics platforms represents a critical advancement in agricultural monitoring technologies. These integrated systems enable seamless data collection, transmission, and analysis from microfluidic sensors deployed across agricultural environments. Modern IoT frameworks provide the connectivity infrastructure necessary for microfluidic devices to transmit real-time data to cloud-based analytics platforms, creating a comprehensive monitoring ecosystem.

Microfluidic sensors in agricultural settings can be equipped with low-power wireless communication modules (LoRaWAN, NB-IoT, or Zigbee) that enable long-range data transmission while maintaining battery efficiency. These communication protocols are specifically designed for applications requiring minimal power consumption and can operate effectively in rural agricultural environments where traditional connectivity infrastructure may be limited.

Cloud-based data analytics platforms serve as the central nervous system for microfluidic monitoring networks, processing incoming sensor data through sophisticated algorithms that can detect patterns, anomalies, and trends. Machine learning models deployed on these platforms can be trained to recognize early indicators of plant stress, nutrient deficiencies, or pathogen presence based on subtle changes in fluid composition detected by microfluidic sensors.

Edge computing architectures further enhance these integrated systems by enabling preliminary data processing directly on or near the microfluidic devices. This approach reduces bandwidth requirements and latency while allowing for immediate response to critical conditions. For instance, edge processors can trigger automated irrigation systems when soil moisture levels fall below predetermined thresholds, without waiting for cloud-based analysis.

Visualization dashboards and mobile applications provide farmers and agronomists with intuitive interfaces to access and interpret the complex data generated by microfluidic monitoring systems. These user-facing tools typically offer customizable alerts, historical trend analysis, and predictive insights that transform raw sensor data into actionable agricultural intelligence.

Standardized API (Application Programming Interface) frameworks are emerging to facilitate interoperability between microfluidic monitoring systems and existing farm management software. These APIs enable bidirectional data flow, allowing microfluidic systems to both contribute to and benefit from broader agricultural datasets, including weather forecasts, satellite imagery, and historical yield data.

The integration challenges primarily revolve around power management, data standardization, and system reliability. Ongoing research focuses on developing energy harvesting technologies specifically designed for powering microfluidic-IoT nodes in agricultural settings, as well as creating robust data models that can accommodate the diverse parameters measured by different microfluidic sensor types.

Microfluidic sensors in agricultural settings can be equipped with low-power wireless communication modules (LoRaWAN, NB-IoT, or Zigbee) that enable long-range data transmission while maintaining battery efficiency. These communication protocols are specifically designed for applications requiring minimal power consumption and can operate effectively in rural agricultural environments where traditional connectivity infrastructure may be limited.

Cloud-based data analytics platforms serve as the central nervous system for microfluidic monitoring networks, processing incoming sensor data through sophisticated algorithms that can detect patterns, anomalies, and trends. Machine learning models deployed on these platforms can be trained to recognize early indicators of plant stress, nutrient deficiencies, or pathogen presence based on subtle changes in fluid composition detected by microfluidic sensors.

Edge computing architectures further enhance these integrated systems by enabling preliminary data processing directly on or near the microfluidic devices. This approach reduces bandwidth requirements and latency while allowing for immediate response to critical conditions. For instance, edge processors can trigger automated irrigation systems when soil moisture levels fall below predetermined thresholds, without waiting for cloud-based analysis.

Visualization dashboards and mobile applications provide farmers and agronomists with intuitive interfaces to access and interpret the complex data generated by microfluidic monitoring systems. These user-facing tools typically offer customizable alerts, historical trend analysis, and predictive insights that transform raw sensor data into actionable agricultural intelligence.

Standardized API (Application Programming Interface) frameworks are emerging to facilitate interoperability between microfluidic monitoring systems and existing farm management software. These APIs enable bidirectional data flow, allowing microfluidic systems to both contribute to and benefit from broader agricultural datasets, including weather forecasts, satellite imagery, and historical yield data.

The integration challenges primarily revolve around power management, data standardization, and system reliability. Ongoing research focuses on developing energy harvesting technologies specifically designed for powering microfluidic-IoT nodes in agricultural settings, as well as creating robust data models that can accommodate the diverse parameters measured by different microfluidic sensor types.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!