How to Resolve Scaling Issues in Microfluidic Equipment Design

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Scaling Background and Objectives

Microfluidic technology has evolved significantly since its inception in the early 1990s, transitioning from simple channel designs to complex integrated systems capable of performing multiple laboratory functions on a single chip. This evolution has been driven by the increasing demand for miniaturized analytical systems in various fields including healthcare, environmental monitoring, and chemical synthesis. The scaling issues in microfluidic equipment design represent a critical challenge that has persistently limited the technology's broader adoption and commercial viability.

The fundamental principle of microfluidics leverages the unique physical and chemical properties that emerge when fluids are manipulated at the microscale. At these dimensions, surface forces dominate over volume forces, laminar flow prevails over turbulent flow, and diffusion becomes a primary mechanism for mixing. While these properties enable precise control over fluid behavior, they also introduce significant challenges when attempting to scale microfluidic systems either up (for higher throughput) or down (for greater integration).

Historical attempts to address scaling issues have progressed through several distinct phases. Initial efforts focused on simple geometric scaling, which quickly revealed the non-linear relationships between channel dimensions and fluid behavior. This was followed by the development of parallelization strategies, which sought to maintain optimal channel dimensions while increasing throughput through multiple identical units. More recently, hierarchical design approaches have emerged, incorporating channels of varying dimensions within a single device to optimize different functions.

Current technical objectives in resolving microfluidic scaling issues center around several key areas. First is the development of design methodologies that can accurately predict fluid behavior across different scales, incorporating multiphysics modeling to account for the complex interactions between fluid dynamics, heat transfer, and chemical reactions. Second is the advancement of fabrication techniques capable of producing features across multiple scale ranges with high precision and reproducibility.

Additionally, there is a growing focus on creating standardized interfaces and modular components that can facilitate the integration of microfluidic systems with conventional laboratory equipment and analytical instruments. This standardization is essential for bridging the gap between microfluidic devices and macroscale environments, particularly for sample introduction and result extraction.

The ultimate goal of addressing scaling issues in microfluidic equipment design is to enable the technology to fulfill its promise of revolutionizing analytical and diagnostic processes across industries. This includes achieving higher throughput without sacrificing precision, enabling seamless integration with existing workflows, and reducing the cost and complexity of microfluidic systems to make them accessible to a broader range of users and applications.

The fundamental principle of microfluidics leverages the unique physical and chemical properties that emerge when fluids are manipulated at the microscale. At these dimensions, surface forces dominate over volume forces, laminar flow prevails over turbulent flow, and diffusion becomes a primary mechanism for mixing. While these properties enable precise control over fluid behavior, they also introduce significant challenges when attempting to scale microfluidic systems either up (for higher throughput) or down (for greater integration).

Historical attempts to address scaling issues have progressed through several distinct phases. Initial efforts focused on simple geometric scaling, which quickly revealed the non-linear relationships between channel dimensions and fluid behavior. This was followed by the development of parallelization strategies, which sought to maintain optimal channel dimensions while increasing throughput through multiple identical units. More recently, hierarchical design approaches have emerged, incorporating channels of varying dimensions within a single device to optimize different functions.

Current technical objectives in resolving microfluidic scaling issues center around several key areas. First is the development of design methodologies that can accurately predict fluid behavior across different scales, incorporating multiphysics modeling to account for the complex interactions between fluid dynamics, heat transfer, and chemical reactions. Second is the advancement of fabrication techniques capable of producing features across multiple scale ranges with high precision and reproducibility.

Additionally, there is a growing focus on creating standardized interfaces and modular components that can facilitate the integration of microfluidic systems with conventional laboratory equipment and analytical instruments. This standardization is essential for bridging the gap between microfluidic devices and macroscale environments, particularly for sample introduction and result extraction.

The ultimate goal of addressing scaling issues in microfluidic equipment design is to enable the technology to fulfill its promise of revolutionizing analytical and diagnostic processes across industries. This includes achieving higher throughput without sacrificing precision, enabling seamless integration with existing workflows, and reducing the cost and complexity of microfluidic systems to make them accessible to a broader range of users and applications.

Market Analysis for Scaled Microfluidic Systems

The global microfluidics market is experiencing robust growth, with a current valuation exceeding $20 billion and projected to reach $50 billion by 2027, growing at a CAGR of approximately 18%. This significant expansion is driven by increasing applications across healthcare, pharmaceuticals, and life sciences sectors, where scaled microfluidic systems offer substantial advantages in efficiency, cost reduction, and performance enhancement.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total microfluidics market. Point-of-care diagnostics, in particular, has emerged as a critical application area, with the COVID-19 pandemic accelerating adoption of microfluidic-based rapid testing solutions. The pharmaceutical industry follows closely, utilizing scaled microfluidic systems for drug discovery and development processes, reducing both time-to-market and development costs by up to 30%.

Regional analysis reveals North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by increasing healthcare infrastructure investments, rising R&D activities, and growing awareness of personalized medicine benefits in countries like China, Japan, and India.

Key market drivers include the rising demand for point-of-care testing, increasing focus on personalized medicine, technological advancements in microfluidic fabrication techniques, and growing investments in healthcare infrastructure globally. The miniaturization trend across industries further propels market expansion as companies seek more compact, efficient analytical systems.

Market challenges primarily revolve around scaling issues, with technical barriers including maintaining consistent fluid dynamics at different scales, ensuring manufacturing precision at higher volumes, and standardizing production processes. Commercial barriers include high initial investment costs, complex regulatory pathways for medical applications, and end-user resistance to adopting new technologies.

Customer segmentation reveals diverse needs across different sectors. Clinical laboratories require high-throughput systems with regulatory compliance, pharmaceutical companies prioritize reliability and integration with existing workflows, while academic research institutions focus on flexibility and customization capabilities. This diversity necessitates tailored scaling approaches for different market segments.

The competitive landscape features both established players and innovative startups. Major companies like Danaher, Thermo Fisher Scientific, and Bio-Rad Laboratories hold significant market share, while emerging players such as Fluidigm and uFluidix drive innovation through specialized solutions addressing specific scaling challenges. Strategic partnerships between technology developers and end-users are increasingly common, accelerating commercialization of scaled microfluidic solutions.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total microfluidics market. Point-of-care diagnostics, in particular, has emerged as a critical application area, with the COVID-19 pandemic accelerating adoption of microfluidic-based rapid testing solutions. The pharmaceutical industry follows closely, utilizing scaled microfluidic systems for drug discovery and development processes, reducing both time-to-market and development costs by up to 30%.

Regional analysis reveals North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by increasing healthcare infrastructure investments, rising R&D activities, and growing awareness of personalized medicine benefits in countries like China, Japan, and India.

Key market drivers include the rising demand for point-of-care testing, increasing focus on personalized medicine, technological advancements in microfluidic fabrication techniques, and growing investments in healthcare infrastructure globally. The miniaturization trend across industries further propels market expansion as companies seek more compact, efficient analytical systems.

Market challenges primarily revolve around scaling issues, with technical barriers including maintaining consistent fluid dynamics at different scales, ensuring manufacturing precision at higher volumes, and standardizing production processes. Commercial barriers include high initial investment costs, complex regulatory pathways for medical applications, and end-user resistance to adopting new technologies.

Customer segmentation reveals diverse needs across different sectors. Clinical laboratories require high-throughput systems with regulatory compliance, pharmaceutical companies prioritize reliability and integration with existing workflows, while academic research institutions focus on flexibility and customization capabilities. This diversity necessitates tailored scaling approaches for different market segments.

The competitive landscape features both established players and innovative startups. Major companies like Danaher, Thermo Fisher Scientific, and Bio-Rad Laboratories hold significant market share, while emerging players such as Fluidigm and uFluidix drive innovation through specialized solutions addressing specific scaling challenges. Strategic partnerships between technology developers and end-users are increasingly common, accelerating commercialization of scaled microfluidic solutions.

Current Scaling Challenges in Microfluidics

Microfluidic systems face significant scaling challenges that impede their widespread industrial adoption and commercial viability. The fundamental issue stems from the physics governing fluid behavior at microscale, where surface forces dominate over volume forces, creating phenomena not observed in macroscale systems. This scaling non-linearity presents unique engineering hurdles when attempting to increase throughput or production capacity.

One primary challenge is maintaining consistent fluid dynamics during scale-up. As channel dimensions increase, Reynolds numbers shift, potentially disrupting laminar flow patterns that are essential for precise microfluidic operations. This transition can compromise mixing efficiency, separation performance, and reaction kinetics that were optimized at smaller scales.

Material considerations present another significant obstacle. Many microfluidic devices rely on specialized polymers, glass, or silicon substrates with specific surface properties. When scaling production, maintaining uniform surface characteristics across larger areas becomes increasingly difficult, leading to performance variability and reduced yield rates.

Thermal management emerges as a critical concern during scaling. Microfluidic systems often depend on precise temperature control for reactions or separations. As device dimensions increase, heat transfer characteristics change substantially, requiring redesigned thermal management strategies to maintain performance parity with smaller prototypes.

Manufacturing precision represents a persistent challenge. While photolithography and soft lithography techniques enable high-precision fabrication at laboratory scales, translating these approaches to mass production while maintaining nanometer-level feature accuracy remains problematic. Current industrial manufacturing processes struggle to deliver the required precision at economically viable costs.

Integration complexity increases exponentially with scale. Larger microfluidic systems require more sophisticated pumping mechanisms, more complex valve arrangements, and more extensive sensing networks. Each additional component introduces potential failure points and control challenges that compound as systems grow.

Parallelization, often proposed as a scaling solution, introduces its own complications. Ensuring uniform flow distribution across multiple parallel channels requires precise engineering to prevent preferential flow paths. Minor manufacturing variations can create significant performance discrepancies between theoretically identical parallel units.

Economic factors further constrain scaling efforts. The high-precision equipment required for microfluidic manufacturing represents substantial capital investment. Without economies of scale, the cost per device remains prohibitively high for many potential applications, creating a challenging market entry barrier for emerging microfluidic technologies.

One primary challenge is maintaining consistent fluid dynamics during scale-up. As channel dimensions increase, Reynolds numbers shift, potentially disrupting laminar flow patterns that are essential for precise microfluidic operations. This transition can compromise mixing efficiency, separation performance, and reaction kinetics that were optimized at smaller scales.

Material considerations present another significant obstacle. Many microfluidic devices rely on specialized polymers, glass, or silicon substrates with specific surface properties. When scaling production, maintaining uniform surface characteristics across larger areas becomes increasingly difficult, leading to performance variability and reduced yield rates.

Thermal management emerges as a critical concern during scaling. Microfluidic systems often depend on precise temperature control for reactions or separations. As device dimensions increase, heat transfer characteristics change substantially, requiring redesigned thermal management strategies to maintain performance parity with smaller prototypes.

Manufacturing precision represents a persistent challenge. While photolithography and soft lithography techniques enable high-precision fabrication at laboratory scales, translating these approaches to mass production while maintaining nanometer-level feature accuracy remains problematic. Current industrial manufacturing processes struggle to deliver the required precision at economically viable costs.

Integration complexity increases exponentially with scale. Larger microfluidic systems require more sophisticated pumping mechanisms, more complex valve arrangements, and more extensive sensing networks. Each additional component introduces potential failure points and control challenges that compound as systems grow.

Parallelization, often proposed as a scaling solution, introduces its own complications. Ensuring uniform flow distribution across multiple parallel channels requires precise engineering to prevent preferential flow paths. Minor manufacturing variations can create significant performance discrepancies between theoretically identical parallel units.

Economic factors further constrain scaling efforts. The high-precision equipment required for microfluidic manufacturing represents substantial capital investment. Without economies of scale, the cost per device remains prohibitively high for many potential applications, creating a challenging market entry barrier for emerging microfluidic technologies.

Current Scaling Solutions for Microfluidic Devices

01 Scaling challenges in microfluidic device fabrication

Microfluidic device fabrication faces significant scaling challenges when transitioning from laboratory prototypes to mass production. These challenges include maintaining consistent channel dimensions, ensuring uniform flow characteristics, and preserving functionality across different production scales. Advanced manufacturing techniques and materials are required to address these issues while maintaining the precision and performance of microfluidic systems at larger production volumes.- Scaling challenges in microfluidic device fabrication: Microfluidic device fabrication faces significant scaling challenges when transitioning from laboratory prototypes to commercial production. These challenges include maintaining consistent channel dimensions, ensuring uniform flow characteristics, and preserving functionality across different scales. Advanced manufacturing techniques and materials are required to address these issues while maintaining precision and reproducibility in scaled production environments.

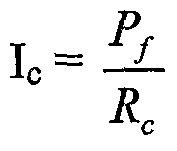

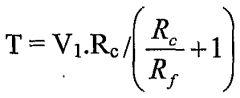

- Flow control and pressure management in scaled microfluidic systems: As microfluidic systems scale up or down, maintaining proper flow control and pressure management becomes increasingly complex. Scaling affects fluid dynamics, causing issues with laminar flow maintenance, pressure drops across channels, and flow rate consistency. Solutions include adaptive pressure control systems, specialized pumping mechanisms, and channel geometry optimizations to ensure consistent fluid behavior regardless of system scale.

- Computational approaches for microfluidic scaling optimization: Computational modeling and simulation play crucial roles in addressing microfluidic scaling issues. Advanced algorithms and computational fluid dynamics models help predict how scaling affects system performance. Machine learning approaches optimize design parameters across different scales, while parallel processing architectures enable real-time analysis of complex microfluidic behaviors, facilitating more efficient scaling solutions.

- Integration challenges for scaled microfluidic components: Scaling microfluidic systems presents significant integration challenges when combining multiple components. Issues include maintaining proper interfaces between components, ensuring compatibility of materials at different scales, and preserving signal integrity across integrated systems. Modular design approaches, standardized connection interfaces, and novel bonding techniques help address these integration challenges in scaled microfluidic equipment.

- Thermal management in scaled microfluidic systems: Thermal management becomes increasingly critical as microfluidic systems scale. Heat dissipation, temperature gradients, and thermal expansion can significantly impact system performance and reliability. Advanced cooling strategies, thermally-optimized materials, and temperature control systems are essential for maintaining consistent operation across different scales, particularly in applications requiring precise temperature control such as PCR or enzymatic reactions.

02 Flow control and pressure management in scaled microfluidic systems

As microfluidic systems scale up or down, maintaining proper flow control and pressure management becomes increasingly complex. Scaling affects fluid dynamics, causing issues with laminar flow maintenance, pressure drops across channels, and flow rate consistency. Solutions include adaptive pressure regulation systems, advanced flow sensors, and computational modeling to predict and compensate for scaling effects on fluid behavior within microchannels.Expand Specific Solutions03 Computational resources and processing challenges in microfluidic equipment

Scaling microfluidic systems often requires proportional scaling of computational resources for data processing, control systems, and real-time analysis. Challenges include managing increased data throughput, implementing efficient algorithms for larger datasets, and maintaining processing speed as system complexity grows. Solutions involve parallel processing architectures, optimized algorithms, and dedicated hardware accelerators specifically designed for microfluidic applications.Expand Specific Solutions04 Integration challenges with external systems during scaling

When scaling microfluidic equipment, integration with external systems presents significant challenges. These include maintaining compatible interfaces with detection systems, ensuring proper sample introduction mechanisms at different scales, and synchronizing operations with peripheral equipment. Standardized connection protocols, modular design approaches, and scalable interface technologies are being developed to address these integration issues across different operational scales.Expand Specific Solutions05 Material selection and compatibility issues in scaled microfluidic devices

Material properties and compatibility become critical factors when scaling microfluidic equipment. Different materials may exhibit varying performance characteristics at different scales, affecting channel wettability, chemical resistance, and mechanical stability. Scaling may also introduce new material interactions with reagents or samples. Advanced composite materials, surface treatments, and material testing protocols are being developed to ensure consistent performance across different production scales.Expand Specific Solutions

Leading Microfluidic Equipment Manufacturers

Microfluidic equipment design scaling issues are currently at a critical juncture in the industry's growth phase. The market is expanding rapidly, projected to reach $50 billion by 2026, driven by applications in healthcare diagnostics, pharmaceutical research, and chemical analysis. Technical maturity varies significantly across applications, with leading academic institutions (MIT, Caltech) establishing fundamental principles while commercial entities develop practical implementations. Companies like ibidi GmbH and OPKO Diagnostics are advancing point-of-care diagnostics, while larger corporations including Samsung Electronics and Robert Bosch are integrating microfluidic technologies into broader product ecosystems. Research institutions such as A*STAR and CNRS are bridging the gap between theoretical advances and commercial applications, focusing on overcoming key scaling challenges in manufacturing consistency, material compatibility, and system integration.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a comprehensive approach to microfluidic scaling challenges through their "Microfluidic Circuit Board" platform. This technology standardizes microfluidic components as modular units that can be assembled into complex systems, similar to electronic circuit boards[2]. The platform addresses scaling issues by implementing standardized interfaces between components, allowing researchers to design at a higher level of abstraction. MIT's approach includes advanced manufacturing techniques like 3D printing of microfluidic channels with feature sizes down to 20 microns, enabling rapid prototyping and scaling to production[4]. Their researchers have also pioneered parallelization strategies that maintain consistent fluid dynamics across multiple identical processing units, allowing throughput scaling without redesigning the core microfluidic architecture. MIT has further developed computational tools that predict scaling effects on fluid behavior, enabling designers to compensate for Reynolds number variations and surface tension effects that emerge at different production scales[6].

Strengths: Exceptional modular design approach enables rapid iteration and scaling; strong integration with computational modeling tools; advanced manufacturing capabilities support transition from prototype to production. Weaknesses: Higher initial development costs; requires specialized equipment for manufacturing; some designs may face challenges with biological sample compatibility.

Agency for Science, Technology & Research

Technical Solution: A*STAR has developed a comprehensive microfluidic scaling solution through their "Integrated Microfluidic Platform" (IMP). This platform addresses scaling challenges by implementing a hierarchical design methodology that separates microfluidic functions into standardized modules with well-defined interfaces[1]. Their approach incorporates advanced materials science, utilizing surface treatments that maintain consistent wetting properties across different manufacturing scales and production methods. A*STAR researchers have pioneered computational fluid dynamics models specifically calibrated for scale-up predictions, allowing designers to anticipate and compensate for changes in flow behavior when transitioning from prototype to production scales[3]. Their platform includes innovative pressure balancing systems that maintain consistent flow rates across parallel processing units, enabling linear throughput scaling without compromising process consistency. Additionally, A*STAR has developed specialized quality control methodologies for microfluidic manufacturing that ensure dimensional accuracy and surface properties remain consistent during mass production[5].

Strengths: Exceptional integration of materials science with microfluidic design; strong computational modeling capabilities; comprehensive quality control methodologies ensure manufacturing consistency. Weaknesses: Implementation requires significant interdisciplinary expertise; higher initial development costs; some proprietary technologies may limit accessibility for smaller organizations.

Key Patents in Microfluidic Scaling Technology

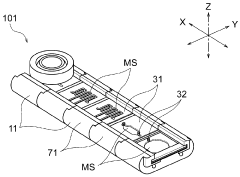

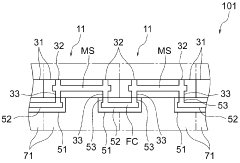

Microfluidic device

PatentWO2024004685A1

Innovation

- A microfluidic device design that allows for the connection of multiple microfluidic chips in a line using a main chip with communication holes and a joint chip, held by a guide, enabling two-dimensional expansion and easy assembly of customized flow paths without increasing the device's size, with the ability to visually access and process liquids within the microscopic spaces.

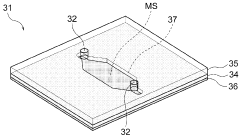

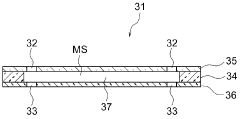

Microfluidic device

PatentWO2004103566A1

Innovation

- A microfluidic device design that includes input and output circuits connected to an enclosure, allowing for independent pressure modification at one end of the microchannel, enabling precise control of flow rates and eliminating the need for gas within the microchannel, thus reducing parasitic flows and improving dynamic control.

Materials Science Advancements for Microfluidics

Recent advancements in materials science have revolutionized the field of microfluidics, offering promising solutions to scaling issues that have traditionally plagued microfluidic equipment design. The emergence of novel polymers with enhanced chemical resistance and optical clarity has enabled the development of more robust microfluidic platforms capable of withstanding harsh operating conditions while maintaining precise fluid control at microscale dimensions.

Surface modification techniques have evolved significantly, allowing for tailored wettability and reduced biofouling in microchannels. Hydrophobic and hydrophilic surface treatments can now be applied with nanometer precision, enabling the creation of patterned surfaces that direct fluid flow without mechanical structures, thus simplifying fabrication and improving scalability of microfluidic devices.

Nanocomposite materials represent another breakthrough, combining the processability of polymers with the enhanced mechanical and thermal properties of nanoscale fillers. These materials exhibit reduced thermal expansion coefficients and improved dimensional stability, critical factors when scaling microfluidic systems for industrial applications where temperature fluctuations can compromise device performance.

Smart materials with stimuli-responsive properties offer dynamic control over fluid behavior within microchannels. Materials that change their properties in response to temperature, pH, or electrical stimuli can serve as integrated valves and pumps, eliminating the need for external mechanical components that often create scaling bottlenecks in traditional microfluidic systems.

3D-printable resins specifically formulated for microfluidics have transformed manufacturing approaches, enabling rapid prototyping and production of complex channel geometries previously unattainable through conventional fabrication methods. These materials feature reduced shrinkage and improved resolution, addressing key scaling challenges related to manufacturing precision and reproducibility.

Biomimetic materials inspired by natural systems have introduced self-healing capabilities to microfluidic devices, extending operational lifetimes and reliability. These materials can automatically repair microcracks and damage that typically occur during scaling up of operations, significantly reducing maintenance requirements and improving system robustness.

Paper-based and textile-based microfluidic substrates have emerged as cost-effective alternatives for large-scale applications, particularly in point-of-care diagnostics. These materials leverage capillary action for fluid transport, eliminating the need for external pumping systems and simplifying the scaling process while dramatically reducing production costs compared to traditional glass or silicon-based platforms.

Surface modification techniques have evolved significantly, allowing for tailored wettability and reduced biofouling in microchannels. Hydrophobic and hydrophilic surface treatments can now be applied with nanometer precision, enabling the creation of patterned surfaces that direct fluid flow without mechanical structures, thus simplifying fabrication and improving scalability of microfluidic devices.

Nanocomposite materials represent another breakthrough, combining the processability of polymers with the enhanced mechanical and thermal properties of nanoscale fillers. These materials exhibit reduced thermal expansion coefficients and improved dimensional stability, critical factors when scaling microfluidic systems for industrial applications where temperature fluctuations can compromise device performance.

Smart materials with stimuli-responsive properties offer dynamic control over fluid behavior within microchannels. Materials that change their properties in response to temperature, pH, or electrical stimuli can serve as integrated valves and pumps, eliminating the need for external mechanical components that often create scaling bottlenecks in traditional microfluidic systems.

3D-printable resins specifically formulated for microfluidics have transformed manufacturing approaches, enabling rapid prototyping and production of complex channel geometries previously unattainable through conventional fabrication methods. These materials feature reduced shrinkage and improved resolution, addressing key scaling challenges related to manufacturing precision and reproducibility.

Biomimetic materials inspired by natural systems have introduced self-healing capabilities to microfluidic devices, extending operational lifetimes and reliability. These materials can automatically repair microcracks and damage that typically occur during scaling up of operations, significantly reducing maintenance requirements and improving system robustness.

Paper-based and textile-based microfluidic substrates have emerged as cost-effective alternatives for large-scale applications, particularly in point-of-care diagnostics. These materials leverage capillary action for fluid transport, eliminating the need for external pumping systems and simplifying the scaling process while dramatically reducing production costs compared to traditional glass or silicon-based platforms.

Manufacturing Processes for Scaled Production

The transition from laboratory-scale microfluidic devices to commercial production presents significant manufacturing challenges. Traditional fabrication methods like soft lithography using polydimethylsiloxane (PDMS) are effective for prototyping but prove inadequate for mass production due to their labor-intensive nature and limited throughput. Addressing these limitations requires implementing scalable manufacturing processes specifically designed for high-volume production of microfluidic devices.

Injection molding represents one of the most promising approaches for scaled production, offering cycle times of 10-60 seconds per part compared to hours required for PDMS casting. This technique enables the production of thousands of identical devices with excellent dimensional accuracy. However, successful implementation requires careful mold design to accommodate microfeatures and prevent defects like incomplete filling or trapped air bubbles. The initial tooling costs are substantial but become economically advantageous at higher production volumes.

Hot embossing provides an alternative manufacturing route with lower initial investment costs. This process involves pressing a heated master mold into thermoplastic materials like PMMA or COC to transfer micropatterns. While slower than injection molding with cycle times of 5-15 minutes, it offers superior replication fidelity for extremely fine features below 10 micrometers. The process is particularly suitable for medium-scale production runs where the higher precision justifies the longer cycle times.

Roll-to-roll manufacturing represents the highest throughput option, enabling continuous production of microfluidic devices on flexible substrates. This approach adapts techniques from the printing industry to create microchannels and features at speeds of several meters per minute. While offering unprecedented production rates, roll-to-roll processes face challenges in achieving the same feature resolution as discrete manufacturing methods, typically limited to features above 20 micrometers.

Material selection becomes increasingly critical in scaled production scenarios. While PDMS dominates laboratory prototyping, thermoplastics like polycarbonate, PMMA, and cyclic olefin copolymers are preferred for mass production due to their compatibility with established manufacturing processes, consistent material properties, and lower per-unit costs. These materials also offer improved chemical resistance and optical properties necessary for commercial applications.

Bonding and assembly processes represent another crucial aspect of scaled production. Techniques such as ultrasonic welding, laser welding, and solvent bonding enable rapid and reliable sealing of microfluidic layers without adhesives that might contaminate channels. Automated assembly systems incorporating machine vision for quality control ensure consistent device performance while minimizing labor costs and human error during production.

Injection molding represents one of the most promising approaches for scaled production, offering cycle times of 10-60 seconds per part compared to hours required for PDMS casting. This technique enables the production of thousands of identical devices with excellent dimensional accuracy. However, successful implementation requires careful mold design to accommodate microfeatures and prevent defects like incomplete filling or trapped air bubbles. The initial tooling costs are substantial but become economically advantageous at higher production volumes.

Hot embossing provides an alternative manufacturing route with lower initial investment costs. This process involves pressing a heated master mold into thermoplastic materials like PMMA or COC to transfer micropatterns. While slower than injection molding with cycle times of 5-15 minutes, it offers superior replication fidelity for extremely fine features below 10 micrometers. The process is particularly suitable for medium-scale production runs where the higher precision justifies the longer cycle times.

Roll-to-roll manufacturing represents the highest throughput option, enabling continuous production of microfluidic devices on flexible substrates. This approach adapts techniques from the printing industry to create microchannels and features at speeds of several meters per minute. While offering unprecedented production rates, roll-to-roll processes face challenges in achieving the same feature resolution as discrete manufacturing methods, typically limited to features above 20 micrometers.

Material selection becomes increasingly critical in scaled production scenarios. While PDMS dominates laboratory prototyping, thermoplastics like polycarbonate, PMMA, and cyclic olefin copolymers are preferred for mass production due to their compatibility with established manufacturing processes, consistent material properties, and lower per-unit costs. These materials also offer improved chemical resistance and optical properties necessary for commercial applications.

Bonding and assembly processes represent another crucial aspect of scaled production. Techniques such as ultrasonic welding, laser welding, and solvent bonding enable rapid and reliable sealing of microfluidic layers without adhesives that might contaminate channels. Automated assembly systems incorporating machine vision for quality control ensure consistent device performance while minimizing labor costs and human error during production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!